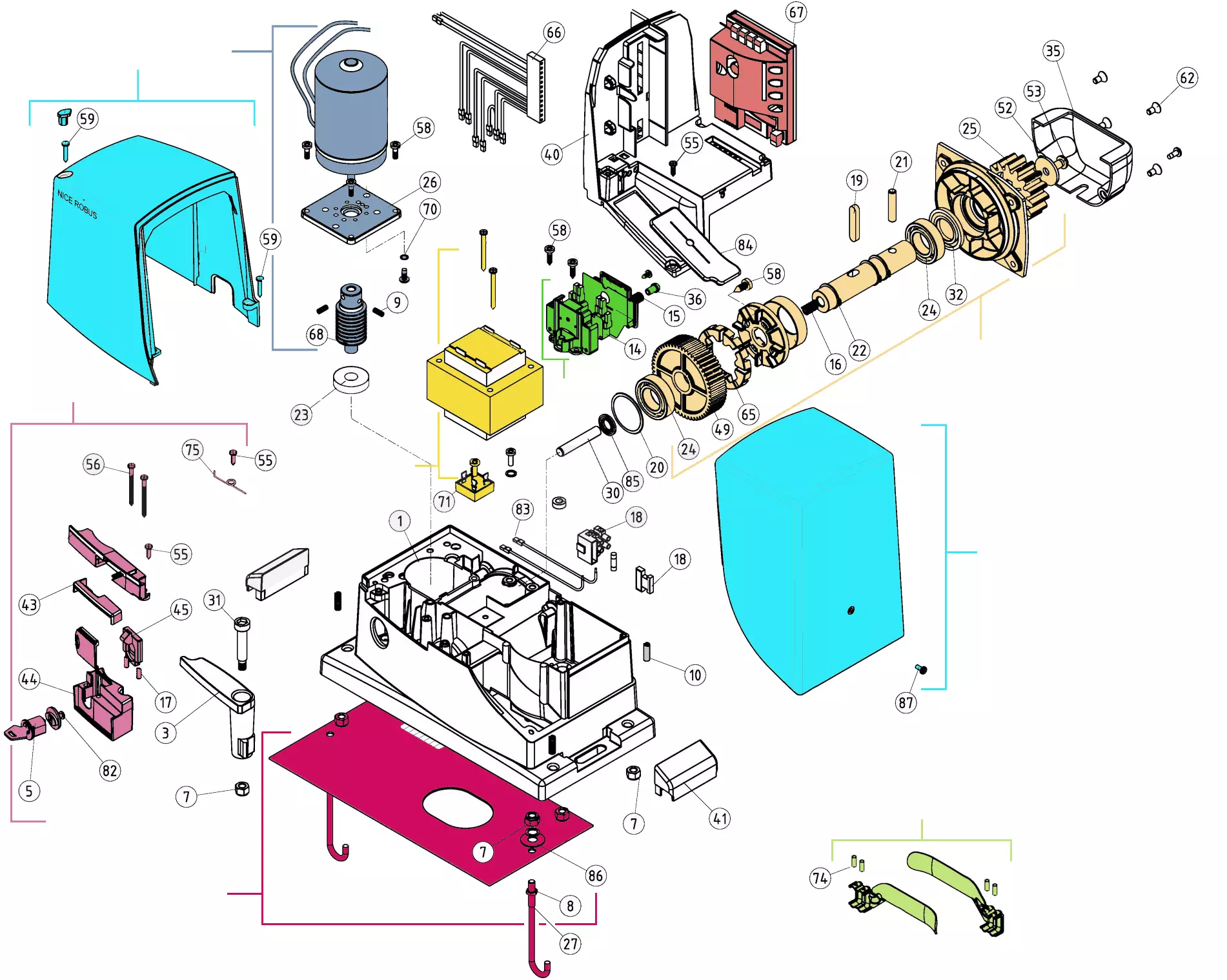

The intricate design of outdoor equipment plays a crucial role in its performance and maintenance. Familiarizing oneself with the components and their layout can significantly enhance the user experience and prolong the lifespan of the machine. By examining a comprehensive visual representation of the unit, operators can gain insights into its functionality and care.

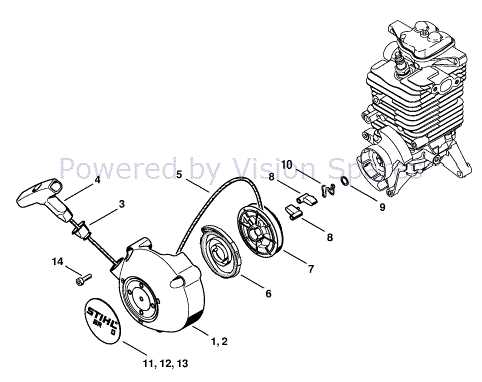

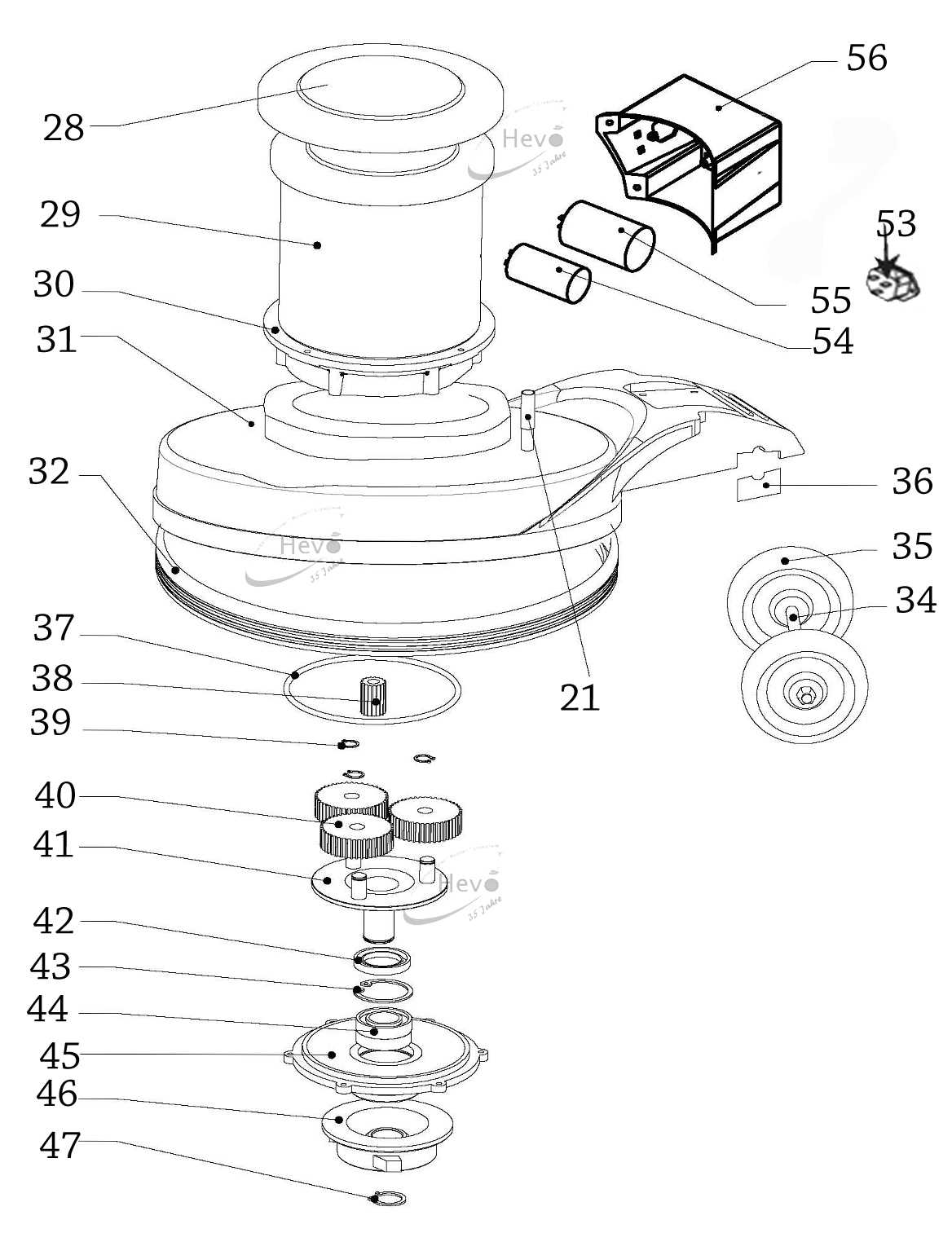

In this section, we will explore the essential elements that contribute to the overall operation of a well-known power tool. By delving into the various sections, users will uncover the ultimate arrangement of the components, facilitating easier repairs and upgrades. Understanding this structure is invaluable for both novice and experienced users alike.

Additionally, having access to a clear outline of the mechanism allows for efficient troubleshooting. When any part malfunctions, recognizing its position and relation to other elements is key. This knowledge empowers users to address issues proactively, ensuring the equipment remains in optimal working condition.

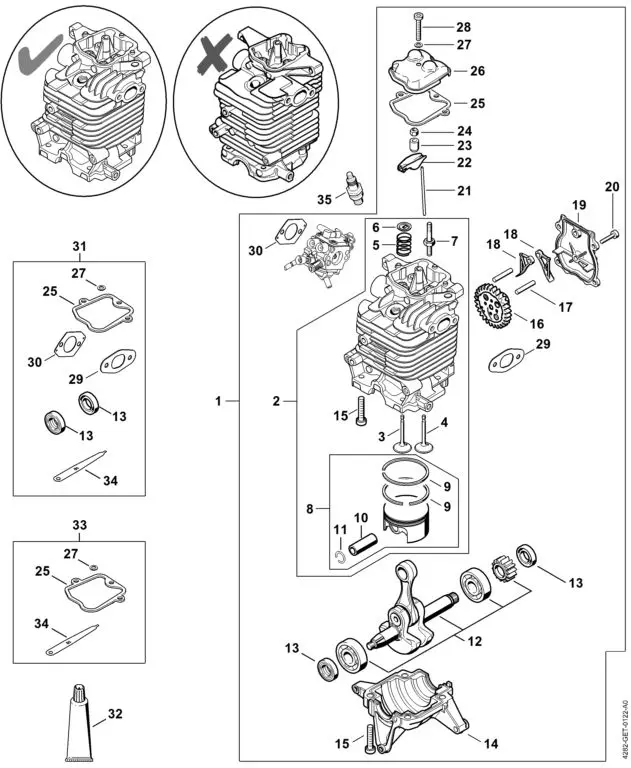

Understanding Stihl RB 600 Components

Grasping the various elements of a specific garden tool is essential for optimal performance and maintenance. Each component plays a crucial role in ensuring that the device operates smoothly and efficiently. Familiarity with these elements not only aids in troubleshooting but also enhances the overall user experience.

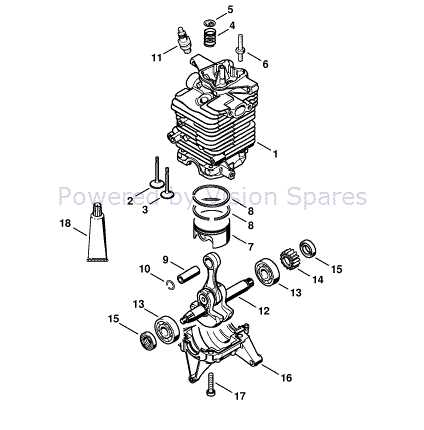

Core Mechanism: The heart of any garden tool is its engine, which drives the entire system. Understanding how this engine functions, including its fuel intake and power output, is vital for effective use.

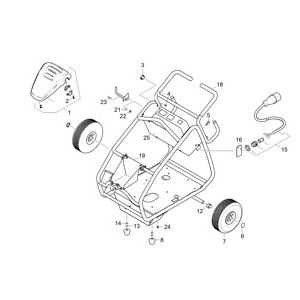

Chassis and Frame: The structure provides stability and support to all other parts. A robust frame is necessary for durability, especially in demanding environments. Knowing how to inspect and maintain this component is key to prolonging the lifespan of the equipment.

Operational Features: Various features enhance usability, such as adjustable settings for different tasks. Recognizing how to adjust these features can improve efficiency and yield better results.

Maintenance Parts: Regular upkeep is essential for peak performance. Being aware of replaceable items, such as filters and spark plugs, ensures the tool remains in top condition. Understanding the location and function of these components can simplify the maintenance process.

Safety Mechanisms: Many tools are equipped with safety features designed to protect users during operation. Familiarizing oneself with these safety components is crucial to preventing accidents and injuries.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements facilitate easier identification and organization, ultimately enhancing the efficiency of service tasks.

| Benefit | Description |

|---|---|

| Improved Clarity | Illustrations help users quickly locate specific pieces, reducing confusion. |

| Enhanced Communication | Diagrams provide a universal language for technicians, ensuring everyone is on the same page. |

| Time Efficiency | With clear visuals, troubleshooting and repairs can be performed more swiftly. |

| Accurate Ordering | Reference materials ensure the correct components are procured, minimizing errors. |

Key Features of RB 600 Model

The RB 600 model is designed to offer exceptional performance and reliability for various outdoor tasks. Its innovative features ensure efficiency and ease of use, making it a preferred choice for many users.

- Powerful Engine: Equipped with a robust engine that delivers superior power and performance.

- Ergonomic Design: The user-friendly design promotes comfort during extended use, reducing fatigue.

- Durable Construction: Built with high-quality materials to withstand harsh conditions and ensure longevity.

- Efficient Fuel Consumption: Engineered for optimal fuel efficiency, minimizing operational costs.

- Versatile Applications: Suitable for a wide range of tasks, from heavy-duty work to light maintenance.

Overall, the RB 600 model stands out with its combination of power, durability, and ease of use, making it an ultimate tool for outdoor enthusiasts and professionals alike.

Common Replacement Parts Overview

When maintaining outdoor power equipment, understanding the frequently replaced components is essential for ensuring optimal performance and longevity. Regular wear and tear can lead to the need for replacements, which can enhance functionality and prevent further damage. This overview highlights some of the most commonly exchanged items that users should be aware of for effective upkeep.

| Component | Description | Typical Issues |

|---|---|---|

| Air Filter | Prevents dirt and debris from entering the engine. | Reduced airflow, decreased efficiency. |

| Fuel Filter | Filters impurities from the fuel supply. | Clogging, fuel starvation. |

| Spark Plug | Ignites the fuel-air mixture for combustion. | Hard starting, engine misfires. |

| Blades | Cutting elements that maintain sharpness for optimal performance. | Dullness, nicks, or breaks. |

| Battery | Provides electrical power to start the equipment. | Failure to start, slow cranking. |

Recognizing these vital components and their roles can facilitate timely replacements, ultimately enhancing the reliability and efficiency of the equipment.

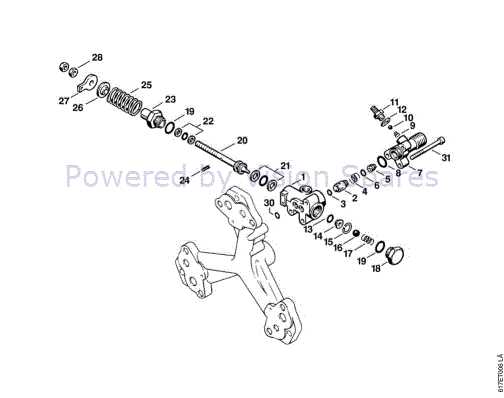

How to Interpret Diagrams Effectively

Understanding visual representations can greatly enhance your ability to assemble, maintain, or repair machinery. These illustrations serve as essential guides, providing a clear view of components and their relationships. Mastering the skill of reading these visuals will lead to more efficient work and improved outcomes.

Key Strategies for Effective Interpretation

- Familiarize Yourself with Symbols: Different diagrams use unique icons to represent various elements. Spend time learning these symbols to avoid confusion.

- Follow the Flow: Many visuals are designed to be read in a specific order. Start from one end and move systematically to the other, paying attention to connections.

- Take Notes: As you examine the illustration, jot down important points or unclear areas that may need further research.

Common Mistakes to Avoid

- Ignoring the Legend: Always check the legend or key if available, as it provides crucial information about the symbols used.

- Rushing Through: Take your time. Skimming can lead to misunderstandings and mistakes.

- Neglecting Context: Consider the overall context of the illustration. Understanding how each part fits into the larger assembly is vital for proper interpretation.

By implementing these strategies and avoiding common pitfalls, you can enhance your ability to decode complex visual guides effectively.

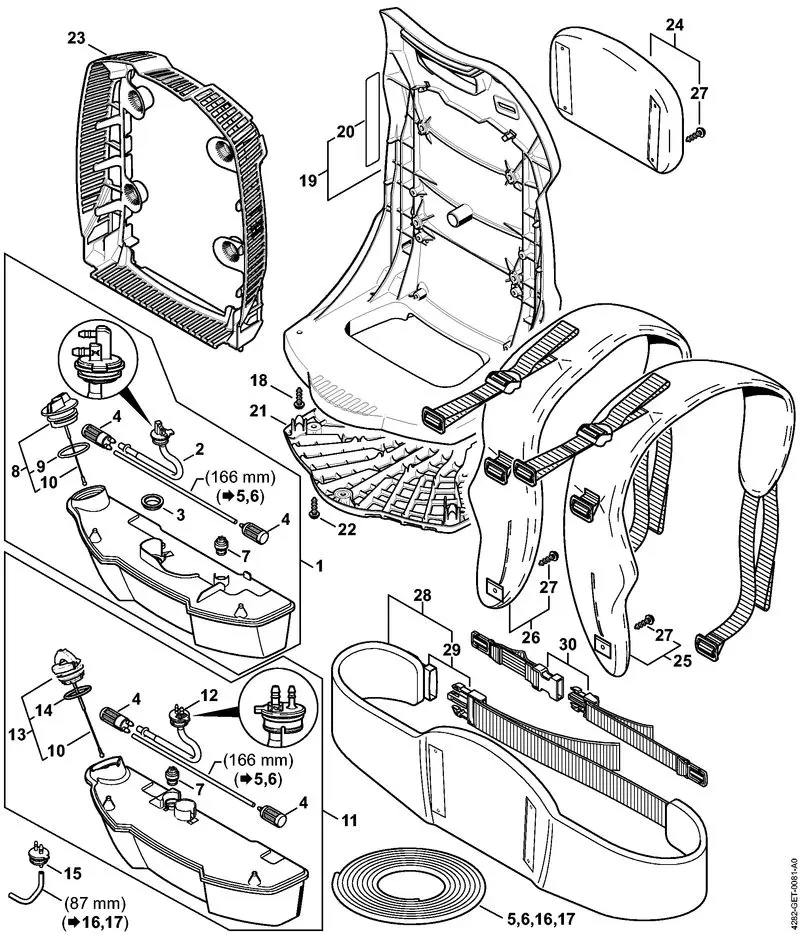

Maintenance Tips for RB 600

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Implementing a consistent maintenance routine can prevent unexpected issues and enhance efficiency. Here are some effective strategies to keep your machine in top shape.

1. Routine Cleaning: After each use, take the time to remove debris and dirt from the exterior. This prevents buildup that can affect performance. Pay special attention to air filters and cooling fins, as these areas can easily become clogged.

2. Inspecting Components: Regularly check critical components for wear and tear. Look for signs of damage on belts, hoses, and electrical connections. Early detection of issues can save time and costly repairs down the line.

3. Lubrication: Ensure that all moving parts are properly lubricated according to the manufacturer’s guidelines. This helps reduce friction and wear, ensuring smoother operation.

4. Fuel Maintenance: Use high-quality fuel and consider adding a fuel stabilizer if the equipment will sit unused for extended periods. This helps prevent fuel degradation and ensures reliable starts.

5. Storage Tips: When not in use, store your machine in a dry, sheltered location. If possible, cover it to protect it from dust and moisture, which can lead to corrosion and other issues.

6. Follow Manufacturer’s Recommendations: Always adhere to the specific maintenance schedule and guidelines provided in the user manual. This ensures that you are taking the right steps for your specific model.

By implementing these maintenance practices, you can ensure your equipment remains efficient and reliable for years to come.

Finding Genuine Stihl Parts

When it comes to maintaining outdoor power equipment, sourcing authentic components is crucial for optimal performance and longevity. Using high-quality replacements ensures your machine operates efficiently and minimizes the risk of breakdowns.

Here are some key tips for locating genuine components:

- Authorized Dealers: Purchase from certified retailers to guarantee the authenticity of the items.

- Manufacturer Websites: Visit official platforms to explore available components and verify their legitimacy.

- Customer Reviews: Check feedback from previous buyers to gauge the reliability of the seller.

It’s essential to be cautious when considering aftermarket options, as they may not meet the same standards as original products. Always ensure you are buying from reputable sources to maintain the integrity of your machinery.

In summary, taking the time to find genuine components will not only enhance your equipment’s efficiency but also extend its lifespan, providing you with better value over time.

Troubleshooting Common Issues

When operating outdoor power equipment, users may encounter various challenges that can hinder performance. Understanding how to diagnose and resolve these problems can significantly enhance efficiency and prolong the lifespan of the machinery. This section outlines frequent issues and their potential solutions.

- Engine Won’t Start

- Check the fuel level and ensure it is fresh.

- Inspect the ignition system for any faults.

- Examine the air filter for clogs.

- Uneven Performance

- Verify that the cutting blade is sharp and properly installed.

- Look for blockages in the discharge area.

- Check the settings for proper adjustment.

- Excessive Vibration

- Ensure all bolts and screws are tightened correctly.

- Inspect for any worn or damaged components.

- Balance the cutting attachment if needed.

- Fuel Leaks

- Examine fuel lines and connections for wear.

- Inspect the tank for cracks or damage.

- Replace any faulty seals or gaskets.

By systematically addressing these common problems, users can maintain their equipment effectively, ensuring optimal operation and longevity.

Comparative Analysis with Similar Models

This section explores the similarities and differences between various machines designed for outdoor maintenance. By examining key features, performance metrics, and user feedback, we aim to provide insights into which models may best suit specific needs.

When comparing these devices, several factors are crucial:

- Engine Power: Assessing the horsepower and torque to determine efficiency.

- Fuel Efficiency: Evaluating how much fuel each model consumes under comparable conditions.

- Weight and Portability: Considering ease of transport and maneuverability.

- Durability: Reviewing materials used and the longevity of each model.

- User-Friendly Features: Looking at controls, adjustments, and overall ease of operation.

In addition, customer reviews can provide practical insights into real-world performance:

- Model A: Known for its robust engine but heavier weight.

- Model B: Offers excellent fuel efficiency, though it lacks some advanced features.

- Model C: Lightweight and easy to handle, yet has less power compared to others.

Ultimately, this analysis will assist potential buyers in making informed decisions based on their specific requirements and preferences.