The intricate setup of mechanical systems plays a crucial role in ensuring seamless functionality and performance. Understanding the arrangement and connection points of various elements can significantly aid in both maintenance and repairs, leading to a more efficient operation of the equipment.

Identifying specific elements within the framework requires a detailed examination of each piece’s role within the overall structure. By analyzing the connections and positions, users can effectively diagnose issues and streamline the replacement process. This organized approach not only simplifies troubleshooting but also enhances the durability of the machinery.

Gaining insights into the layout of individual components can also empower users to perform preventive measures, ultimately extending the life span of their equipment. The detailed outline of each mechanical segment allows for a more targeted approach to both care and upgrades, making sure every element is in optimal condition.

This section provides an overview of the various components, emphasizing their roles and interactions. Understanding these elements is crucial for efficient maintenance and troubleshooting.

- Main Structure: Analyzing the framework that supports all interconnected elements.

- Engine Unit: Exploring the power source and how its various segments collaborate for optimal performance.

- Air Filtration System: Understanding the function of filters in maintaining clean airflow and protecting the core mechanisms.

- Fuel Mechanism: Overview of the components that regulate fuel flow and ensure stable operation.

- Ignition Assembly: Examining the components responsible for initiating the power cycle.

- Exhaust Design: Discussing the setup that manages waste gases and minimizes emissions.

- Control Elements: Detailing the levers and switches that allow for precise ha

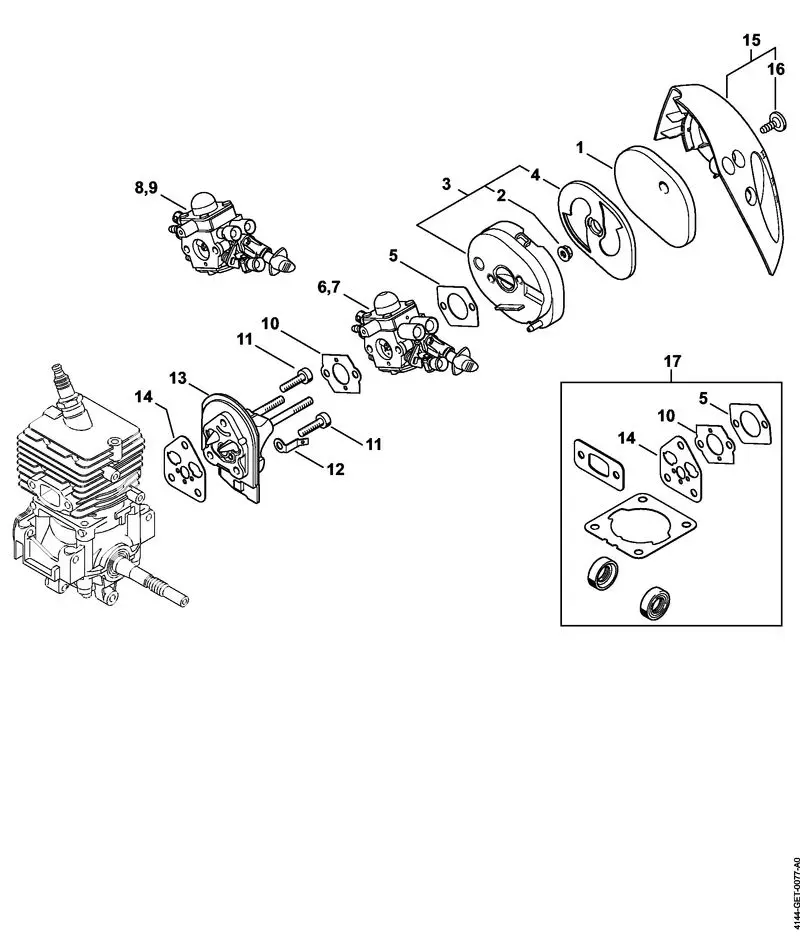

Engine Assembly Breakdown

The dissection of the motor setup involves understanding the individual components and how they integrate to form a functional unit. Each element within the mechanism plays a vital role, working together to convert energy into motion effectively.

In this breakdown, we’ll delve into the key sections of the assembly, exploring the intricate linkages between the internal parts. Recognizing these connections is essential for ensuring proper maintenance and enhancing overall performance. Whether focusing on the ignition area or examining the fuel supply pathways, every detail counts when it comes to optimal operation.

By comprehensively analyzing each section, you gain deeper insights into how to address common issues and perform efficient repairs. This systematic approach to the mechanical structure allows for better handling of troubleshooting tasks, leading to more precise adjustments and long-term reliability.

Air Filter and Housing Details

The air intake system plays a critical role in maintaining engine performance by ensuring a clean flow of air. Understanding its structure and components is essential for proper maintenance and optimal functionality.

Component Description Filter Element A replaceable layer designed to trap dust, debris, and other contaminants, preventing them from reaching the engine. Housing Unit The protective casing that encases the filter, securing it in place and guiding the airflow efficiently into the engine. Cover Fasteners These connectors hold the housing cover firmly in position, allowing for quick access during filter replacements or inspections. Ignition System Parts Overview

The ignition system plays a crucial role in ensuring smooth engine startup and efficient performance. Understanding its individual elements can help in diagnosing issues and maintaining optimal functionality. This overview highlights the key components that work together to ignite the engine and sustain its operation.

Key Components Explained

The ignition system includes several essential elements that interact seamlessly to create a spark for combustion. One of the primary units is the ignition coil, responsible for converting low voltage into a higher one to generate the spark. Paired with this, the spark plug transfers that spark to the engine’s combustion chamber, igniting the air-fuel mixture.

Supporting Elements

Additional components such as the flywheel and magneto assembly play a pivotal role in timing the ignition process. The flywheel’s rotation generates magnetic energy, which the magneto then converts into electrical power. These elements ensure that the ign

Fuel System Components Guide

The operation of any fuel-powered equipment relies on a series of interconnected elements that work together to ensure efficient combustion. Understanding these components and their functions is key to maintaining the performance and longevity of the device.

- Fuel Tank: This reservoir stores the energy source, keeping it ready for the delivery process. Proper sealing and positioning are crucial to prevent leaks and ensure consistent flow.

- Fuel Lines: These tubes act as the delivery path, transporting the liquid from the storage area to the mixing chamber. It’s essential to check them regularly for any cracks or obstructions that could impede movement.

- Carburetor: A vital part that blends the liquid energy source with air in precise ratios. This combination is critical for generating the proper mixture needed for ignition.

- Fuel Filter: Po

Exhaust and Muffler Assembly

The exhaust and muffler assembly is a crucial component of any outdoor power equipment, playing a vital role in managing emissions and minimizing noise levels. Understanding its structure and function can enhance maintenance practices and improve the overall performance of the machine.

This assembly typically consists of several key elements:

- Exhaust Pipe: Directs exhaust gases away from the engine.

- Muffler: Reduces engine noise and filters exhaust emissions.

- Gaskets: Ensure a tight seal between the components, preventing leaks.

- Clamps: Secure the exhaust components together, maintaining stability.

Proper care and timely replacement of worn parts are essential for optimal functioning. Neglecting this assembly may lead to increased noise, reduced efficiency, and potential damage to the engine.

To maintain the exhaust and muffler assembly effectively, consider the following tips:

- Regularly inspect for any signs of wear or damage.

- Ensure that all connections are tight and free of leaks.

- Replace gaskets and clamps as needed to maintain optimal performance.

- Clean the muffler periodically to prevent buildup that can hinder exhaust flow.

By understanding the components and their functions, users can ensure their equipment operates efficiently and effectively, prolonging its lifespan.

Throttle and Control Mechanism

The throttle and control mechanism is a vital component in managing the performance and efficiency of outdoor power equipment. This system regulates the engine’s speed and power output, ensuring optimal functionality during operation. Understanding how these elements work together can enhance both the user experience and the longevity of the equipment.

Functionality Overview

The primary role of the throttle system is to control airflow to the engine. By adjusting the amount of air entering the combustion chamber, the user can influence the engine’s RPM and overall performance. Key aspects include:

- Regulation of engine speed

- Response to operator input

- Impact on fuel efficiency

Components of the Throttle System

Several components work in tandem to create a functional throttle and control mechanism:

- Throttle Lever: The user interface for adjusting engine speed.

- Throttle Cable: Connects the throttle lever to the carburetor, transmitting user commands.

- Carburetor: Regulates the fuel-air mixture based on throttle position.

- Governor System: Automatically adjusts engine speed under varying load conditions.

Understanding these components is essential for effective maintenance and troubleshooting.

Blower Fan and Housing Layout

The arrangement of the fan and its enclosure plays a crucial role in the efficient operation of any air-moving device. This section explores the structural design and functional aspects of the components involved, ensuring optimal airflow and performance.

Understanding the Housing Configuration is essential for maintaining the effectiveness of the blower. The outer casing is engineered to protect internal mechanisms while facilitating airflow. Proper sealing and material choice are critical to prevent air leaks and enhance durability.

Fan Placement and Design significantly influence the performance of the device. The fan must be correctly positioned within the housing to maximize air intake and exhaust efficiency. Additionally, blade design impacts the velocity and volume of air moved, contributing to the overall effectiveness of the unit.

Maintenance Tips for Optimal Performance

Regular upkeep is crucial for ensuring your equipment operates at its best. By following a consistent maintenance routine, you can enhance efficiency, prolong the lifespan of components, and reduce the risk of unexpected failures.

Here are essential practices to consider:

Maintenance Task Frequency Description Inspect Air Filter Every 10 hours Check for dirt and debris; clean or replace as necessary to ensure optimal airflow. Sharpen Cutting Blades Every 25 hours Keep blades sharp to improve cutting performance and reduce strain on the engine. Check Fuel System Before each use Ensure fuel is fresh and free of contaminants; clean fuel lines if necessary. Inspect Spark Plug Every 50 hours Examine for wear and replace if damaged; this promotes better ignition and engine efficiency. Clean Exterior After each use Remove dirt and debris from the exterior to prevent corrosion and ensure safe operation. Implementing these practices will not only optimize performance but also enhance safety and reliability during operation.