When it comes to maintaining outdoor power equipment, having a clear understanding of its internal structure is essential. This knowledge not only aids in effective repairs but also enhances overall performance. A detailed visual representation can serve as a valuable guide, helping users identify and locate various elements of their tool efficiently.

Within this context, exploring the layout of the components becomes crucial. Each section plays a specific role, contributing to the seamless operation of the machine. By examining the arrangement and function of these parts, users can better appreciate how they interact to achieve optimal results.

Moreover, familiarity with the configuration can empower operators to undertake maintenance tasks confidently. Whether it’s replacing worn-out pieces or troubleshooting issues, a comprehensive understanding of the setup lays the groundwork for successful interventions. This article aims to provide insights into the intricate workings of this widely used trimming device.

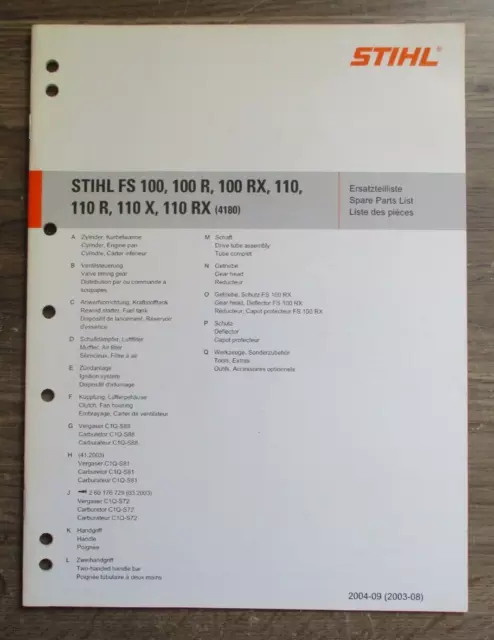

Understanding Stihl FS 110 Components

In order to maintain optimal performance and longevity of your outdoor power equipment, it is essential to familiarize yourself with its various elements. Each component plays a crucial role in the overall functionality, influencing efficiency, durability, and ease of use. A comprehensive understanding of these parts will empower you to make informed decisions regarding maintenance, repairs, and upgrades.

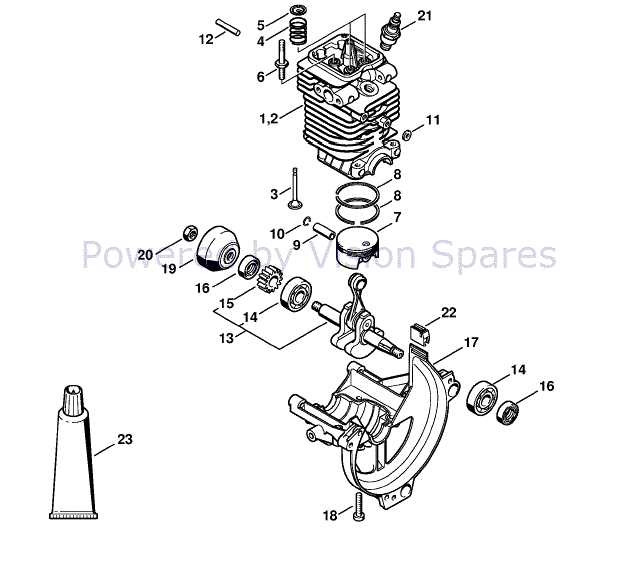

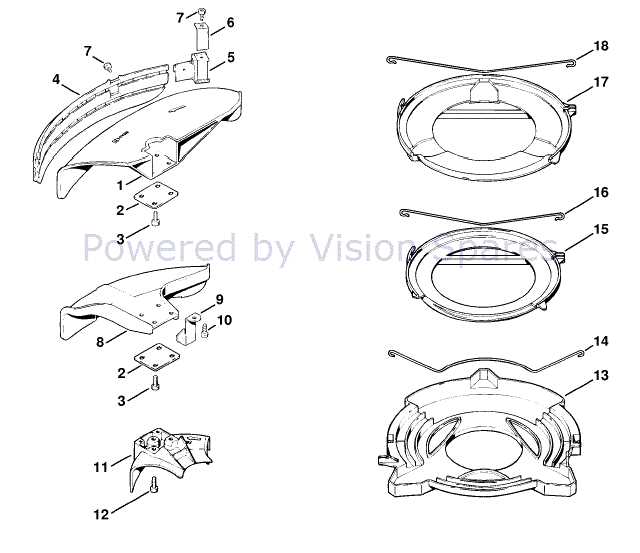

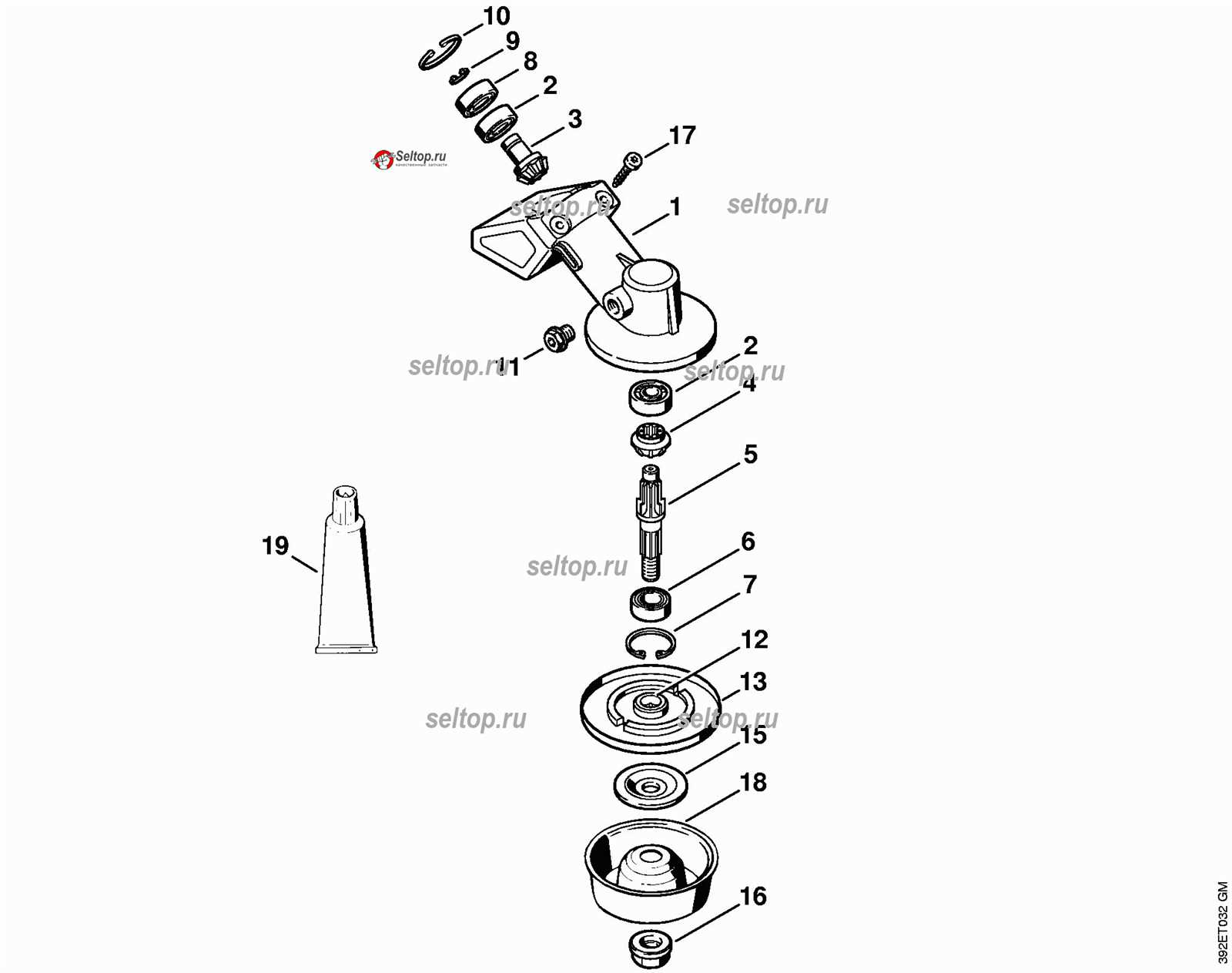

Main Assembly Overview

The primary structure consists of several key assemblies, each designed to work harmoniously. The engine, fuel system, and drive shaft are vital for powering the machine and facilitating movement. Recognizing how these assemblies interact can enhance your troubleshooting skills and aid in timely repairs.

Additionally, accessories and attachments expand the versatility of the equipment. Trimmer heads, blades, and protective gear not only enhance performance but also ensure safety during operation. Being aware of the available options allows for tailored usage, catering to specific tasks and user preferences.

Key Features of FS 110 Model

The FS 110 model stands out in its category due to a combination of innovative design, robust performance, and user-friendly characteristics. This equipment is crafted to meet the demands of both professional landscapers and avid gardeners, making it a versatile tool for various tasks.

Powerful Engine

The heart of this machine is its high-performance engine, which delivers exceptional power and efficiency. This ensures that even the toughest vegetation can be managed with ease.

- Engine displacement designed for optimal torque

- Low emissions technology for environmentally friendly operation

- Easy-start feature for quick and convenient usage

User-Centric Design

Ergonomics play a vital role in the design of this equipment, allowing users to operate it comfortably for extended periods. The features include:

- Adjustable handles to suit various user heights

- Lightweight construction for improved maneuverability

- Anti-vibration system to minimize operator fatigue

These key attributes make this model not only powerful but also accessible for all users, ensuring effective performance in any gardening or landscaping project.

Importance of Maintenance for Equipment

Proper upkeep of machinery is crucial for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected failures that can lead to costly repairs or downtime.

Timely servicing allows for the identification of potential issues before they escalate, ensuring that equipment operates smoothly. By keeping components clean and well-lubricated, users can improve functionality and extend the lifespan of their tools.

Neglecting maintenance can result in decreased productivity and increased operational costs. It is essential to establish a routine maintenance schedule, which can greatly enhance reliability and effectiveness in the long run.

Common Issues with Stihl Trimmers

String trimmers are essential tools for maintaining a well-groomed garden or lawn, but they can experience various issues over time. Understanding these common problems can help users troubleshoot effectively and keep their equipment running smoothly.

Fuel Problems: One of the most frequent issues arises from improper fuel mixtures. Using stale or incorrect fuel can lead to poor performance or even engine failure. Regularly checking and replacing the fuel is crucial for optimal functionality.

Starting Difficulties: Many users report challenges when trying to start their devices. This can be due to a variety of factors, including a clogged air filter, a faulty spark plug, or issues with the ignition system. Regular maintenance can prevent these frustrating situations.

Line Feed Issues: Another common problem is with the trimmer line itself. Users often find that the line does not feed correctly, which can be caused by tangled line, a worn spool, or incorrect loading. Proper handling and regular checks can mitigate these concerns.

Overheating: Overheating can occur if the equipment is used for extended periods without breaks. This can lead to decreased performance and potential damage. It’s important to allow the machine to cool down between uses to extend its lifespan.

Mechanical Failures: Wear and tear can cause mechanical failures in various components. Regular inspections can help identify worn parts, ensuring timely replacements and avoiding more serious repairs.

Where to Find Replacement Parts

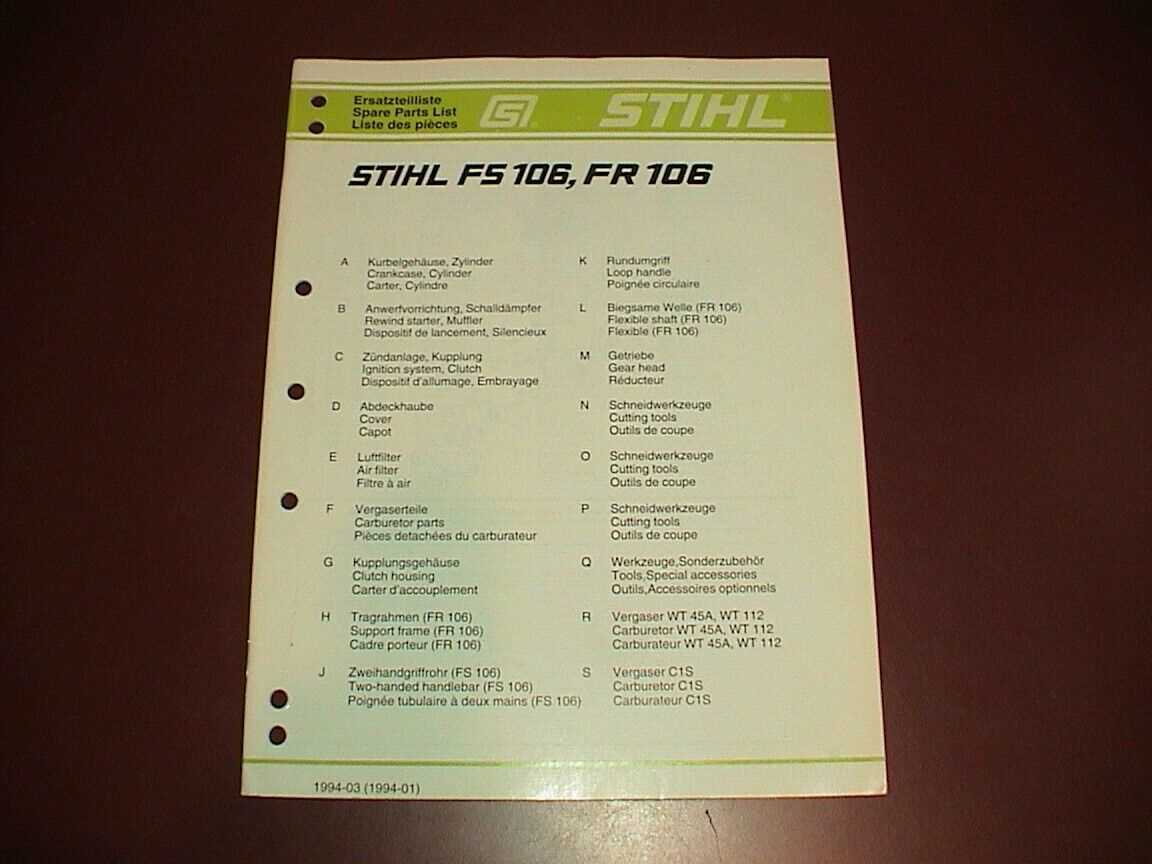

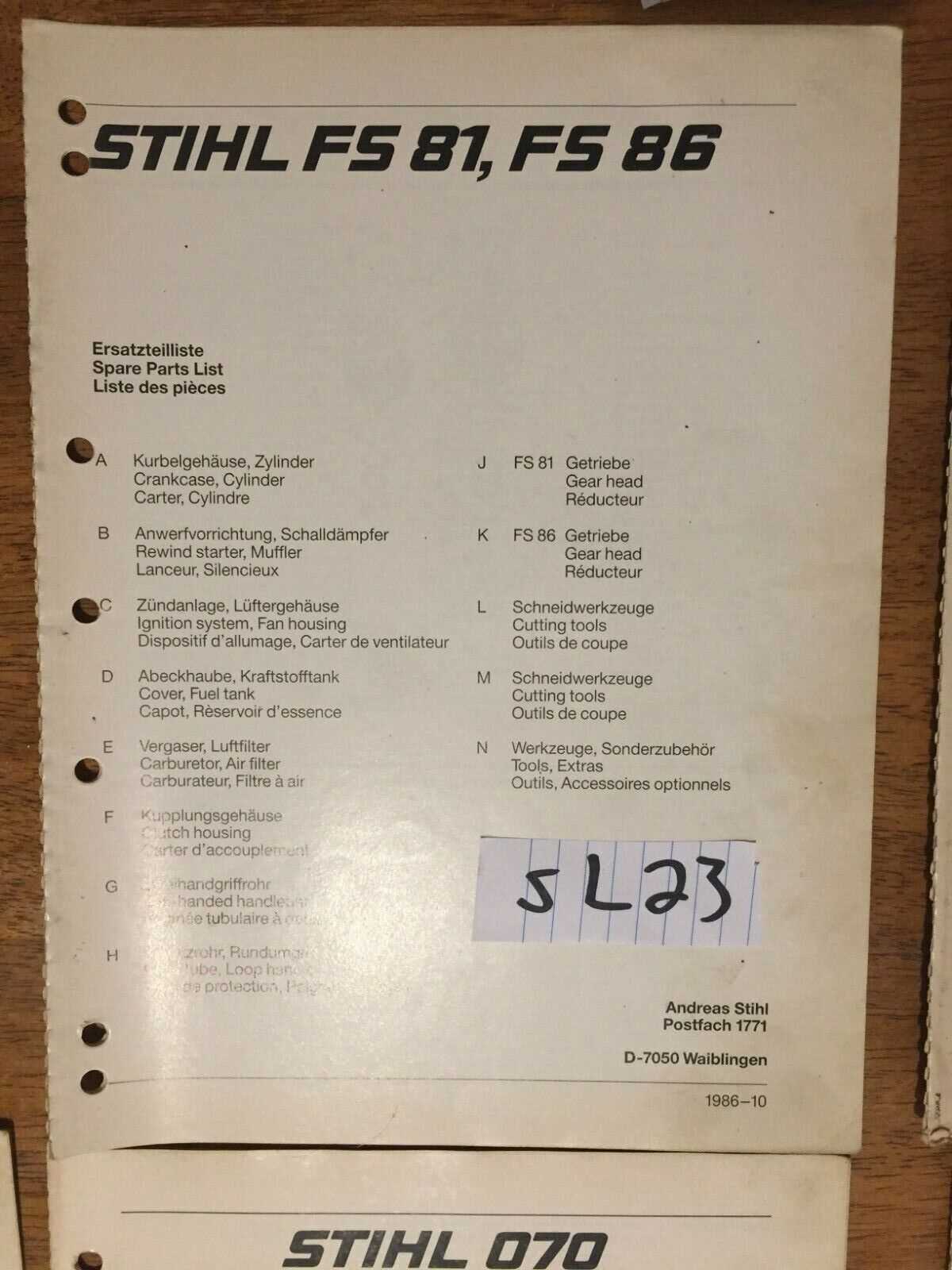

Finding components for maintenance and repair is essential for ensuring the longevity of your equipment. Several reliable sources can help you locate the necessary items to keep your machine running smoothly.

- Official Dealers: Authorized retailers often provide genuine components, ensuring quality and compatibility.

- Online Marketplaces: Websites such as eBay and Amazon feature a wide variety of options from different sellers.

- Specialty Shops: Local stores that focus on outdoor equipment may stock a selection of relevant items.

- Manufacturer Websites: Directly visiting the brand’s site can lead you to an online catalog and purchasing options.

By exploring these avenues, you can effectively secure the right components to enhance your equipment’s performance.

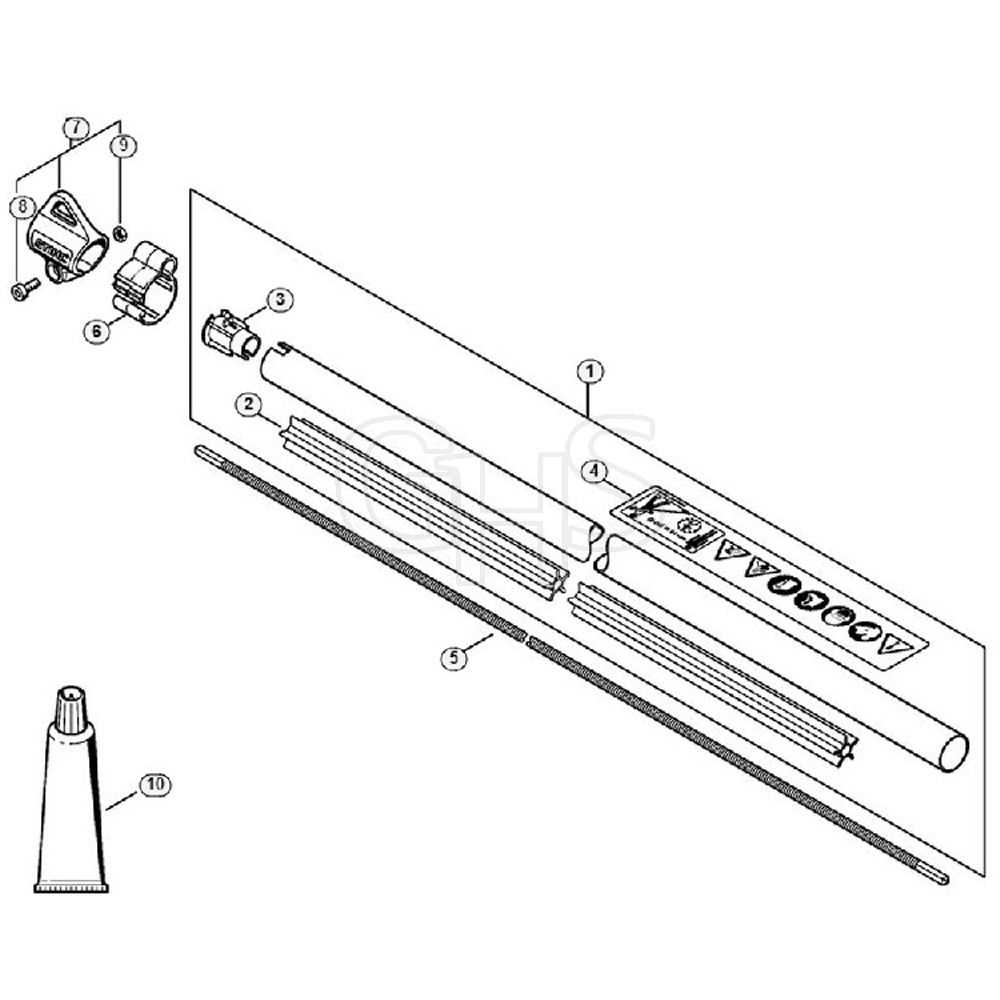

How to Read Parts Diagrams

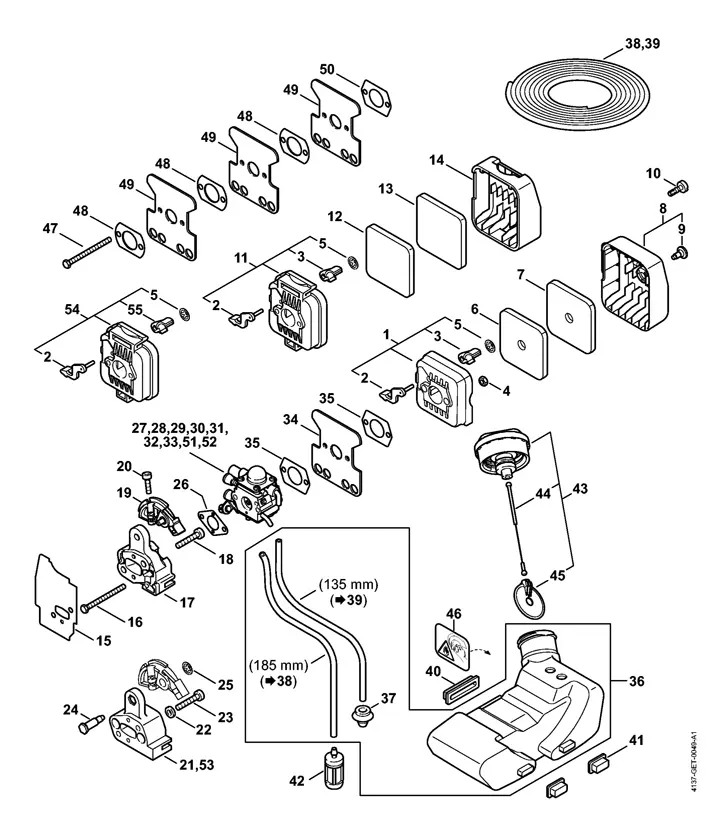

Understanding technical illustrations can significantly enhance your ability to maintain and repair equipment. These visual guides provide a detailed representation of various components and their relationships, making it easier to identify necessary items for service or replacement. By familiarizing yourself with the structure and symbols used in these illustrations, you can navigate them with confidence.

Interpreting Symbols and Labels

Each component is typically marked with specific identifiers. These may include alphanumeric codes that correspond to a list of items, allowing you to pinpoint what you need. Familiarize yourself with common symbols and their meanings, as this knowledge is crucial for efficient interpretation.

Understanding Assembly Order

Another essential aspect is recognizing the sequence in which parts are assembled. This is vital for both disassembly and reassembly processes. Pay attention to the layout; parts that are positioned higher or in the foreground usually indicate they should be attached first, while those in the background are often added later. This approach helps ensure that you do not miss any critical steps.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to effectively troubleshoot and repair your gardening equipment. By following these detailed instructions, you will gain confidence in identifying common issues and restoring functionality to your machine.

1. Gather Your Tools: Before starting, ensure you have all necessary tools at hand. Common items include screwdrivers, wrenches, and safety gloves.

2. Disconnect Power: For safety, always disconnect the power source. This prevents accidental starts while you work on the equipment.

3. Inspect Components: Begin by examining each part for wear and damage. Look for cracks, frays, or any irregularities that may affect performance.

4. Consult the Manual: Refer to the user manual for specific information about your model. It will provide valuable insights into assembly and disassembly.

5. Remove the Cover: Carefully detach the outer cover to access the internal components. Keep track of screws and small parts to avoid losing them.

6. Replace Faulty Parts: Identify any defective components and replace them as needed. Use genuine replacements to ensure compatibility and longevity.

7. Reassemble the Unit: Once repairs are complete, reattach the cover and ensure all screws are securely fastened. Double-check that everything is in its proper place.

8. Test the Equipment: Reconnect the power and perform a test run. Monitor for any unusual noises or malfunctions, and address any remaining issues.

9. Regular Maintenance: To prevent future problems, establish a routine maintenance schedule. This includes cleaning, lubricating, and inspecting parts regularly.

Upgrading Your Trimmer’s Performance

Enhancing the efficiency of your grass cutting tool can lead to remarkable improvements in its overall functionality. By focusing on key components and adjustments, you can elevate its power and precision, allowing for a smoother and more effective trimming experience.

Choosing High-Quality Accessories

Investing in premium attachments can significantly impact performance. Look for durable lines, blades, and cutting heads designed for your specific needs. High-quality accessories can reduce wear and tear, ensuring longevity and effectiveness during use.

Tuning and Maintenance Tips

Regular maintenance is essential for optimal performance. Cleaning air filters, checking spark plugs, and ensuring proper fuel mixtures can make a substantial difference. Delve into the specifics of your model to identify any necessary adjustments that could enhance functionality.