When working with outdoor equipment, it is essential to know how each component contributes to the overall function. Every tool consists of multiple interconnected elements, each playing a crucial role in ensuring smooth operation. A thorough understanding of these individual elements can greatly enhance maintenance and repair efforts.

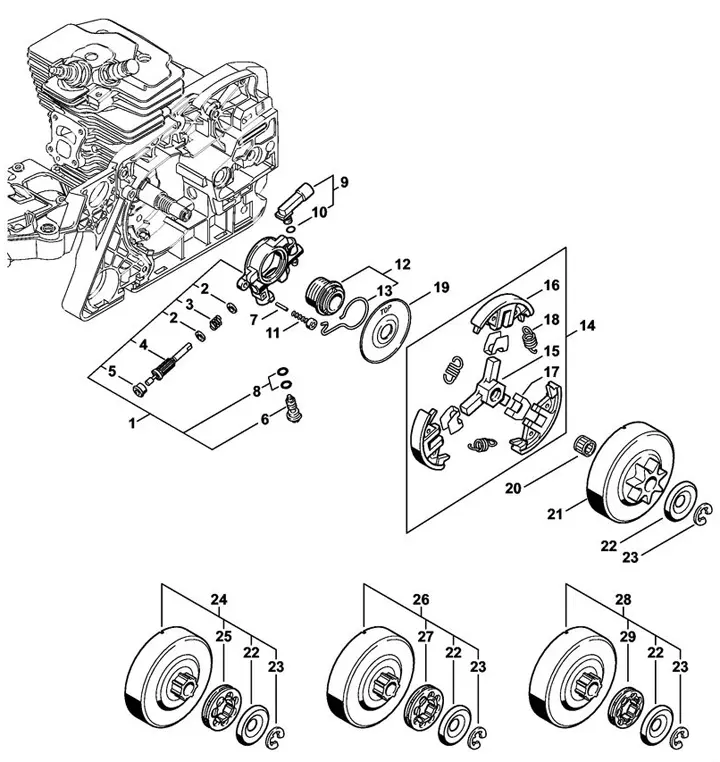

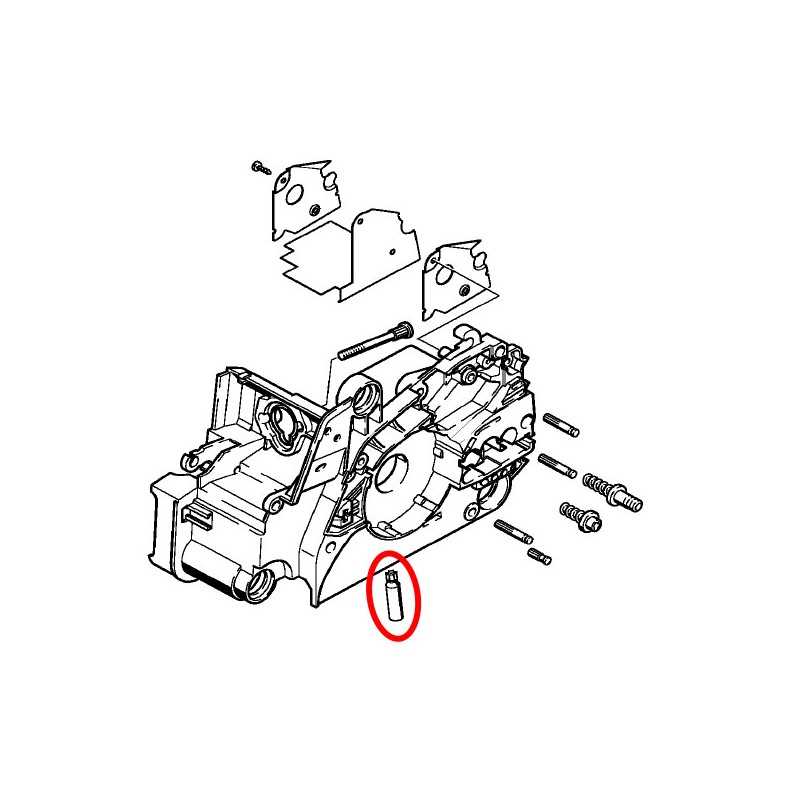

Having access to detailed illustrations of these components allows for easier identification and replacement when necessary. It provides an insightful overview of how everything fits together, helping users keep their tools in top condition.

Whether you are a seasoned professional or a DIY enthusiast, knowing how to maintain and repair your equipment is key to prolonging its life. A well-maintained tool not only performs better but also lasts longer, saving you time and money in the long run.

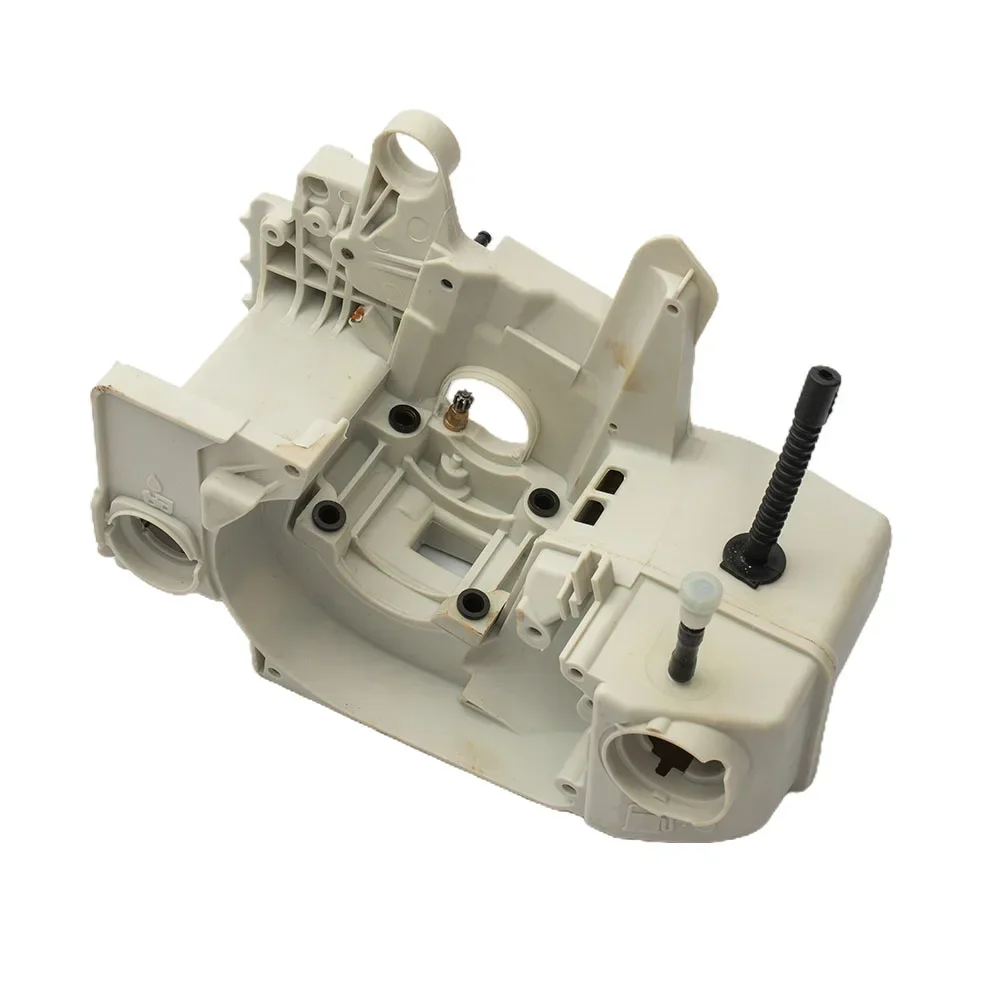

Stihl 025 Parts Overview

This model’s components are designed to work together efficiently, providing durability and high performance. Each element plays a critical role in ensuring the tool operates smoothly and reliably, making it a preferred choice for a wide range of tasks. Understanding the layout of the different elements can help maintain and extend the life of the machine.

Key Components

- Engine assembly: Powers the device and drives other mechanisms.

- Ignition system: Ensures a consistent start and maintains operation under different conditions.

- Fuel system: Manages the flow of fuel to the motor for optimal performance.

- Chain mechanism: Responsible for cutting and requires regular maintenance.

Maintenance and Care

- Regularly clean the air filter to prevent debris from entering the engine.

- Lubricate the chain to ensure smooth operation and prevent wear.

- Inspect the ignition system for consistent performance.

- Check the fuel system for any leaks or blockages.

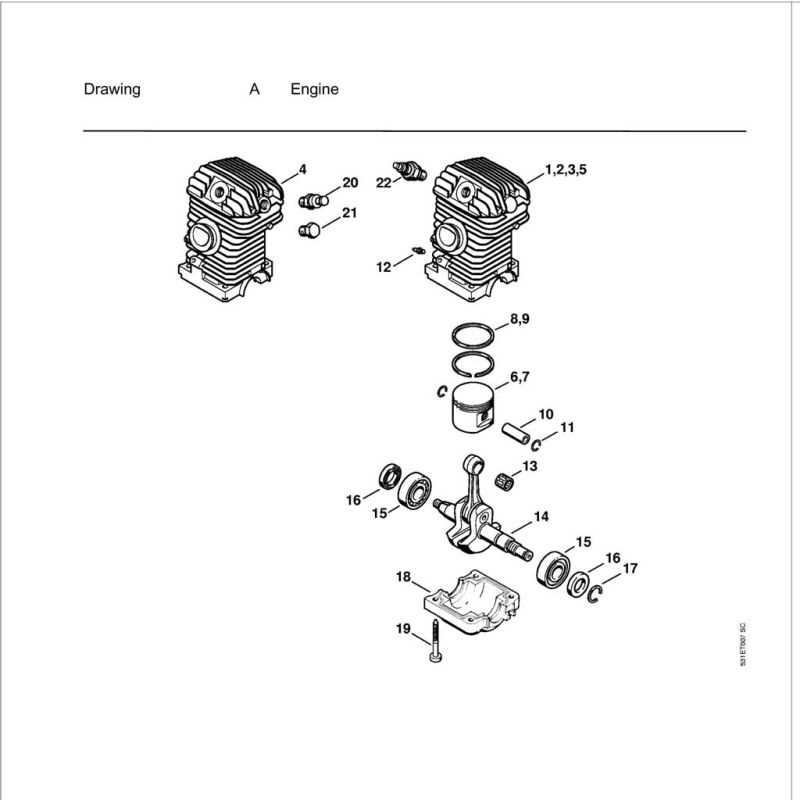

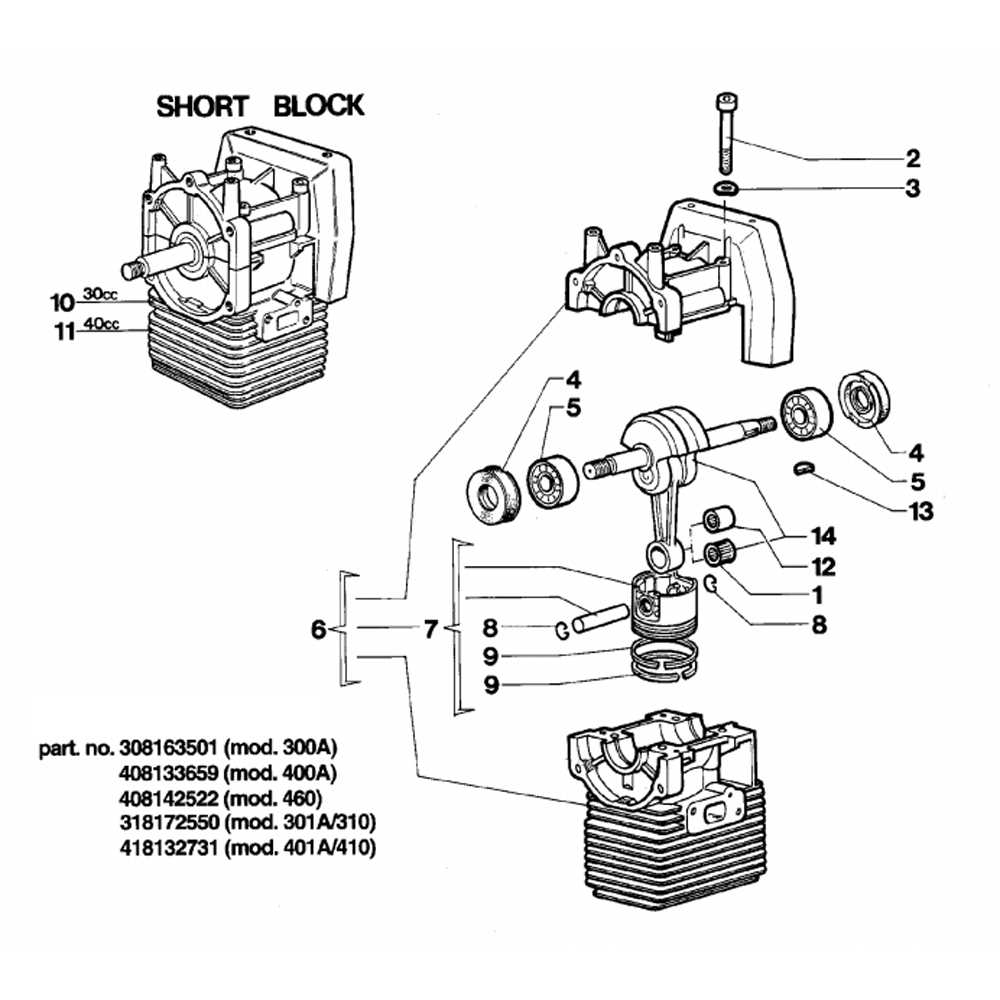

Engine Components in Stihl 025

The internal mechanism of this chainsaw is driven by several key components that work together to generate power. Understanding how these elements interact can help maintain the tool’s functionality and extend its lifespan. The core of the engine involves various parts responsible for ignition, fuel combustion, and the overall movement of the cutting chain.

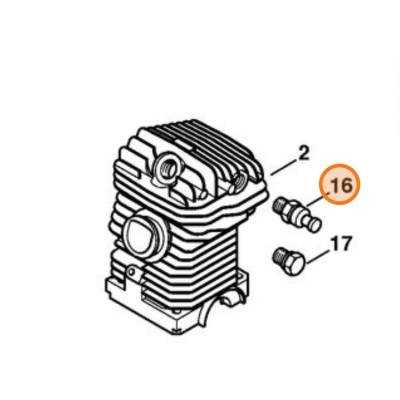

Cylinder and Piston

At the heart of the motor, the cylinder and piston play a crucial role in converting fuel into mechanical energy. The piston moves within the cylinder, creating pressure that ignites the fuel mixture, leading to combustion. This process is essential for generating the power needed to operate the saw effectively.

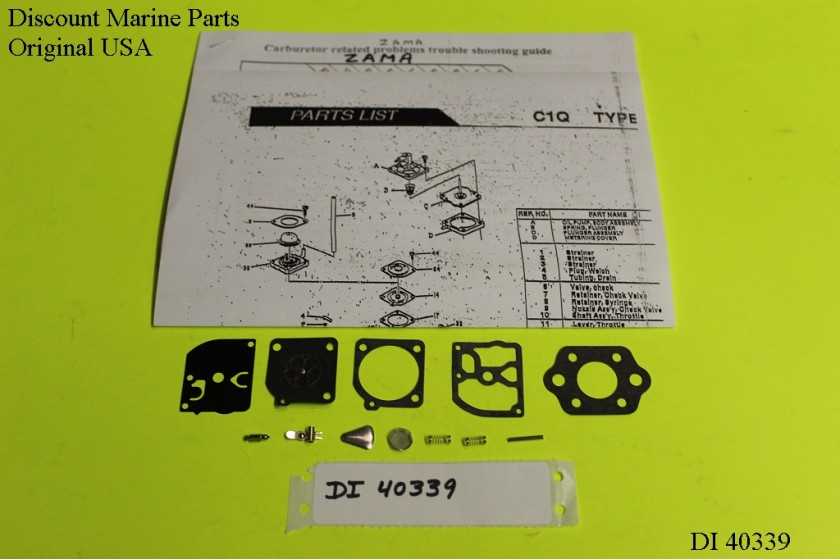

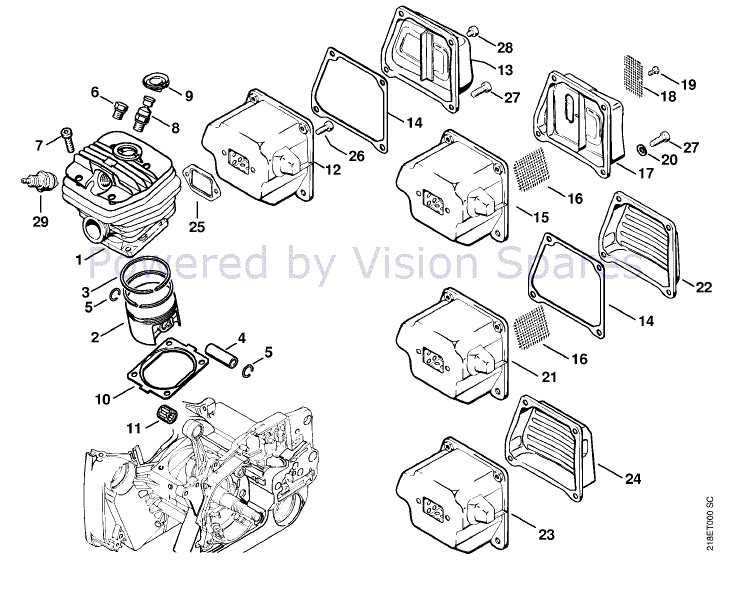

Carburetor and Air Filter

The carburetor ensures that the right mix of air and fuel enters the combustion chamber, which is vital for smooth engine performance. Alongside this, the air filter protects the system by preventing dirt and debris from entering the engine, keeping it clean and efficient during operation.

Guide Bar and Chain Parts

The guide bar and chain are crucial components that ensure smooth operation and precise cuts. They require proper maintenance and occasional replacement to guarantee efficiency and safety during use. Understanding the various elements that make up these two components is essential for optimal performance.

- Guide Bar: This serves as the path for the chain, maintaining alignment and providing stability during operation.

- Chain: The cutting tool itself, which rotates around the bar, designed to slice through wood and other materials efficiently.

- Drive Links: These connect the chain to the drive system, ensuring smooth movement along the guide bar.

- Tensioning System: Adjusts the chain’s tightness, ensuring it stays in place while in use.

- Nose Sprocket: Located at the tip of the guide bar, it helps to reduce friction and wear on the chain.

Regular checks and adjustments to these components can prevent wear and tear, enhancing both the lifespan and performance of the equipment.

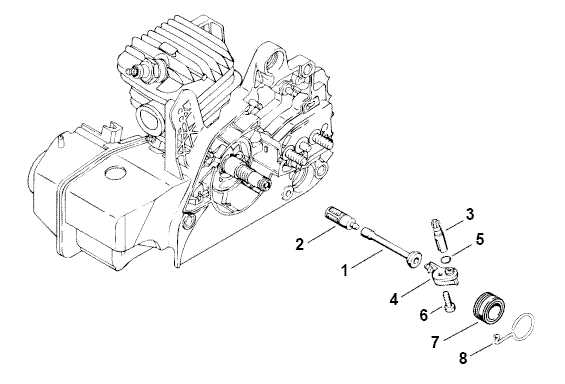

Fuel System Breakdown

The fuel system plays a crucial role in ensuring that the engine receives the correct mixture of air and fuel for efficient operation. A well-maintained system allows the equipment to run smoothly and reliably, reducing the risk of malfunctions and ensuring optimal performance.

At the core of the fuel system are several key components that work together to regulate the flow and quality of the fuel being delivered to the engine. These components include elements responsible for filtration, pressure regulation, and precise fuel delivery. Each part must function properly to prevent issues such as blockages, leaks, or irregular fuel flow, all of which can severely impact engine efficiency.

Fuel Filter: The fuel filter ensures that any impurities or debris are removed from the fuel before it reaches the engine. This prevents clogging and wear on the more sensitive components.

Carburetor: The carburetor is responsible for mixing air and fuel in the correct proportions before the mixture enters the combustion chamber. A clean and well-adjusted carburetor is essential for smooth engine performance.

Fuel Lines:

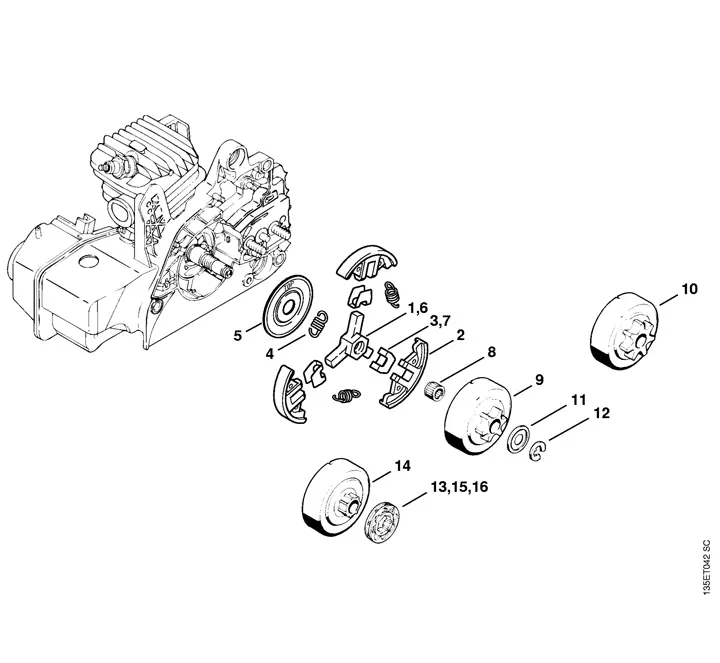

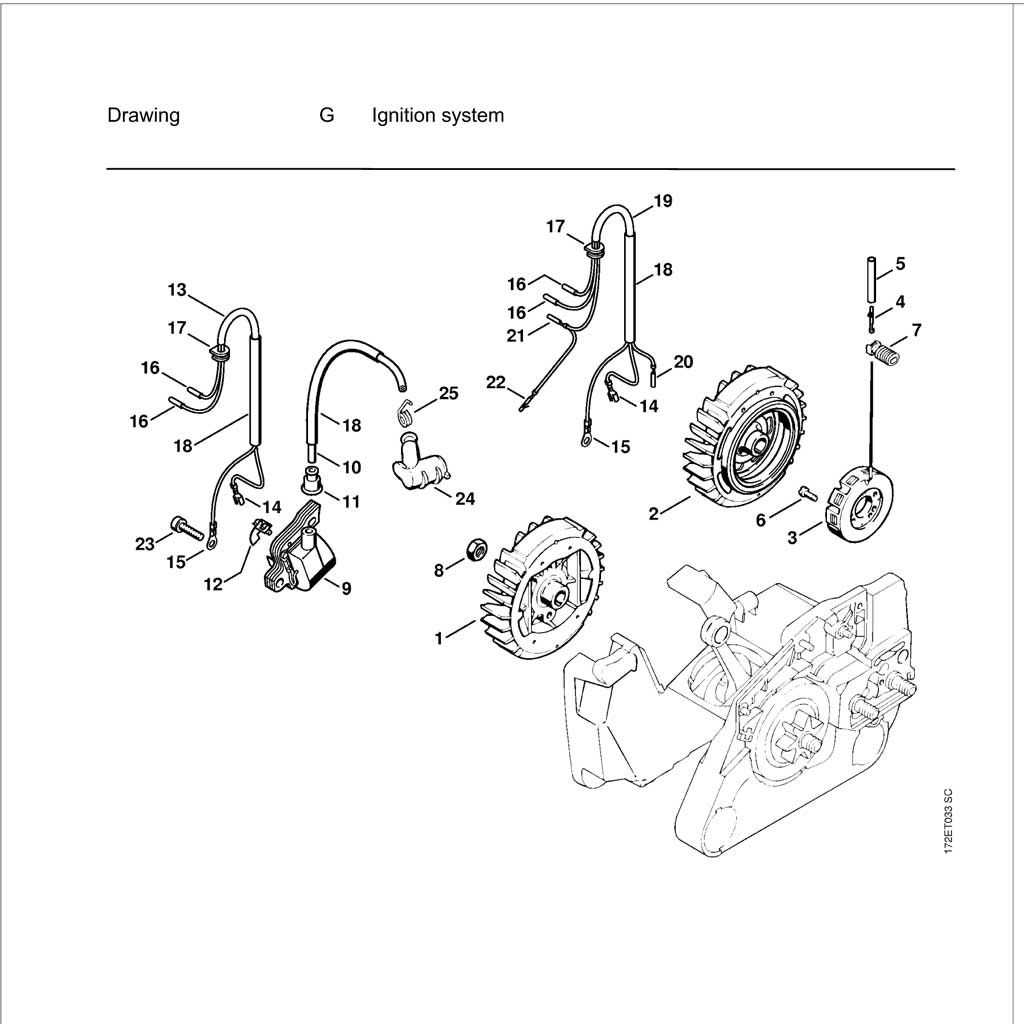

Understanding the Ignition System

The ignition system is a critical component in the operation of small engines, playing a vital role in initiating combustion. It is responsible for generating the necessary spark to ignite the air-fuel mixture within the combustion chamber, ensuring the engine runs smoothly and efficiently. A well-functioning ignition system is essential for optimal performance, reliability, and longevity of the engine.

Components of the Ignition System

The ignition system typically consists of several key elements, including the ignition coil, spark plug, and flywheel magnet. The ignition coil transforms low voltage from the battery into a high-voltage spark, which is then transmitted to the spark plug. The spark plug creates a spark at the right moment, igniting the air-fuel mixture and allowing the engine to produce power. The flywheel magnet assists in generating the electrical current needed for the ignition process.

Troubleshooting Common Issues

Common problems with the ignition system can lead to poor engine performance, misfires, or failure to start. Issues may arise from a faulty spark plug, a malfunctioning ignition coil, or wiring problems. Regular maintenance and timely replacement of worn components are crucial for maintaining an efficient ignition system. Ensuring that all connections are secure and that components are in good condition will help prevent unexpected breakdowns.

Air Filter and Carburetor Details

The air filtration and fuel delivery system play a crucial role in the overall performance and efficiency of any power tool. Proper maintenance and understanding of these components ensure optimal operation and longevity. This section explores the essential elements of these systems, highlighting their functions and importance.

Functionality of the Air Filter

The air filter serves to prevent dirt, debris, and contaminants from entering the engine. A clean filter is vital for maintaining airflow, which directly impacts combustion efficiency. Regular inspection and replacement of the air filter can significantly enhance the performance of the machinery and extend its lifespan.

Understanding the Carburetor

The carburetor is responsible for mixing air and fuel in the correct proportions for combustion. It regulates the flow of fuel based on the engine’s needs, ensuring smooth operation under various conditions. Proper tuning and cleaning of the carburetor are essential for achieving optimal fuel efficiency and engine responsiveness.

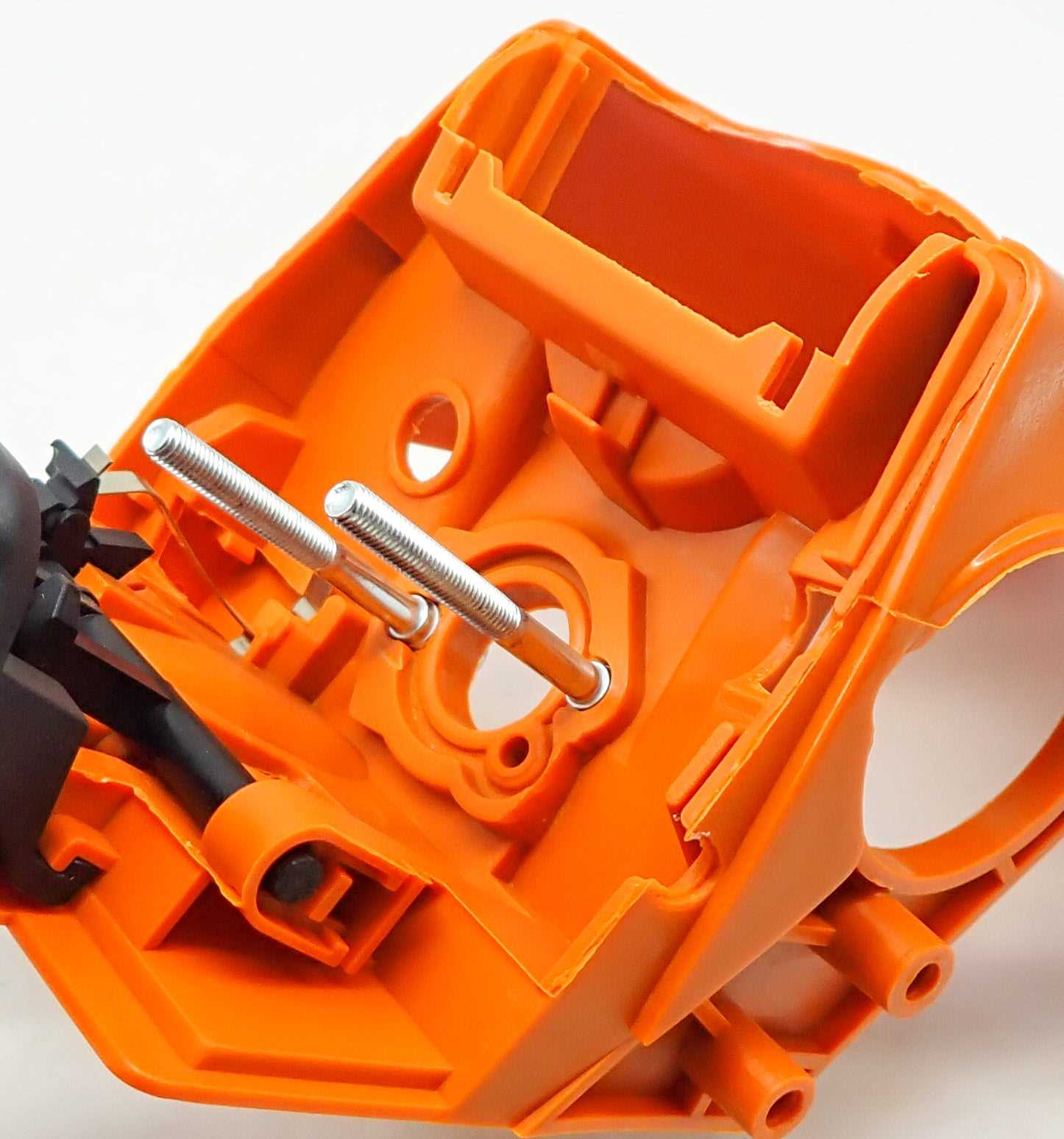

Handle and Control Elements

The handle and control components of a chainsaw are crucial for ensuring safe and efficient operation. These elements are designed to provide the user with a comfortable grip while allowing for precise manipulation of the machine’s functions. Understanding their arrangement and functionality is essential for effective use and maintenance.

Typically, the handle is ergonomically shaped to fit comfortably in the user’s hand, promoting a secure hold during operation. Various controls, such as throttle and brake levers, are strategically positioned to enable quick access and response. This layout enhances the overall user experience, making it easier to control the device even in challenging conditions.

Regular inspection of these components is important for maintaining optimal performance. Any wear or damage to the handle or controls can compromise safety and effectiveness. Therefore, ensuring these parts are in good condition and properly adjusted is vital for reliable operation.

Chain Tensioning and Adjustment

Proper tensioning and adjustment of the cutting chain is essential for optimal performance and safety during operation. Maintaining the correct tightness ensures that the chain runs smoothly along the guide bar, reducing wear and tear while enhancing cutting efficiency. Regular checks and adjustments can prevent potential accidents and prolong the lifespan of the equipment.

To achieve the right chain tension, follow these simple steps:

| Step | Action |

|---|---|

| 1 | Turn off the engine and ensure the equipment is on a stable surface. |

| 2 | Loosen the bar nuts to allow movement of the guide bar. |

| 3 | Adjust the tensioning screw until the chain fits snugly against the bar but can still be turned by hand. |

| 4 | Tighten the bar nuts securely to lock the adjustment in place. |

| 5 | Perform a final check to ensure the chain is properly tensioned before starting the engine. |

Regular inspection of the chain tension is recommended after every use to ensure safety and efficiency. Proper care will not only improve performance but also enhance the overall user experience.

Common Maintenance and Replacement Parts

Regular upkeep is essential for optimal performance and longevity of outdoor power equipment. Understanding the frequently needed components for maintenance and replacement can significantly enhance the efficiency and reliability of your machinery. This section explores the typical items that require attention over time to ensure seamless operation.

Essential Components for Upkeep

Maintaining your equipment involves routine checks and replacements of several key elements. Filters play a crucial role in keeping the engine clean and functioning properly. Air filters should be inspected regularly and replaced when necessary to prevent dirt and debris from affecting performance. Additionally, spark plugs are vital for engine ignition, and timely replacement ensures reliable starts and smooth running.

Common Replacement Items

Over time, wear and tear can necessitate the replacement of various components. Chains and bars are frequently replaced due to extensive use, especially in demanding conditions. It’s important to monitor these items closely to avoid operational issues. Furthermore, maintaining the fuel lines and ensuring they are free of leaks can prevent larger, more costly repairs in the future.