Maintaining and repairing your snow-clearing machinery is essential for ensuring optimal performance during the harsh winter months. Having a comprehensive understanding of the various components and their configurations can significantly enhance your efficiency when addressing issues that arise. This section aims to provide valuable insights into the specific elements that make up these powerful machines.

Whether you are a seasoned operator or a novice, recognizing the layout of the key mechanisms is crucial. Familiarity with the intricate design allows for quicker identification of malfunctions and facilitates smoother repair processes. By delving into the details of the assembly, users can better appreciate how each segment contributes to the overall functionality of the equipment.

Furthermore, this exploration not only aids in maintenance but also empowers you to make informed decisions when sourcing replacements. Understanding the relationships between different parts enables operators to enhance their troubleshooting skills, ultimately leading to improved longevity and reliability of their snow removal tools.

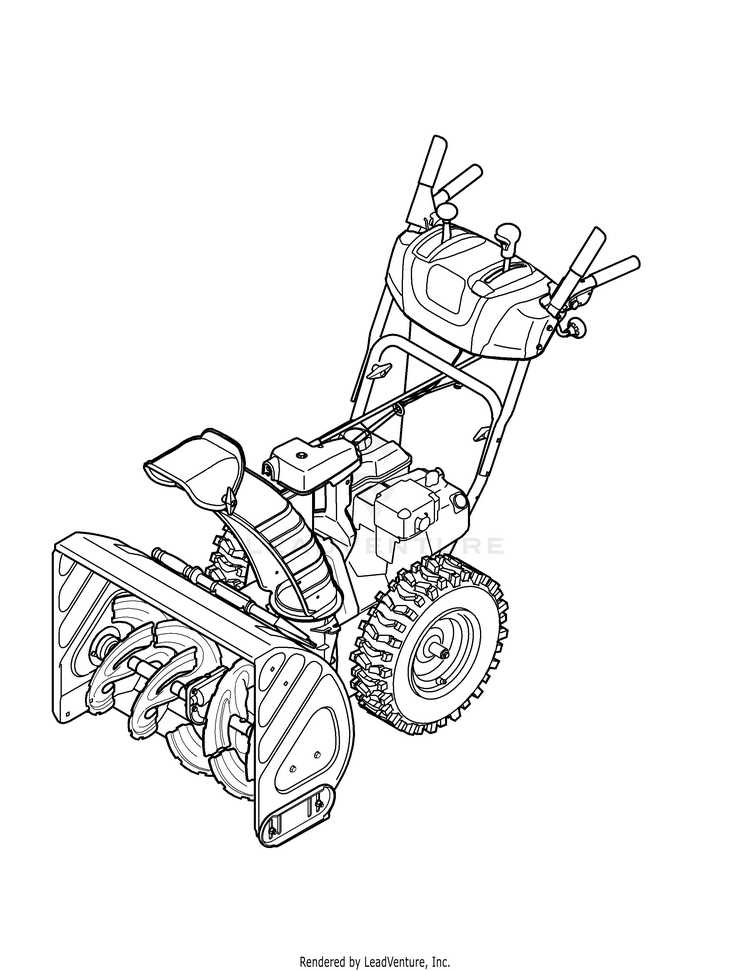

Understanding the John Deere 726 Snowblower

This section aims to provide insights into the operation and components of a specific winter clearing equipment. By exploring its design and functionality, users can gain a better appreciation of its capabilities and maintenance needs.

Key features of this equipment include:

- Robust construction for durability

- Efficient snow removal technology

- Adjustable settings for various snow conditions

Proper understanding of the individual components can greatly enhance performance. Here are some critical elements to consider:

- Auger System: Responsible for collecting snow and directing it towards the impeller.

- Impeller: Facilitates the expulsion of collected snow through the discharge chute.

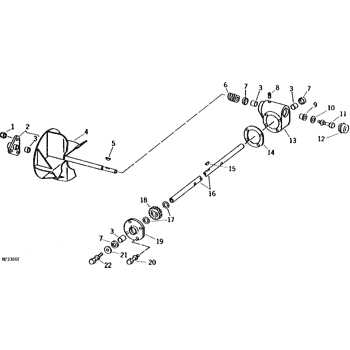

- Drive Mechanism: Ensures the smooth operation of the entire assembly.

Regular maintenance is essential for optimal performance. Key maintenance tasks include:

- Inspecting and replacing worn components

- Clearing debris from the auger and impeller

- Checking fluid levels and lubrication

By familiarizing oneself with these aspects, operators can ensure efficient operation and longevity of the equipment, ultimately making winter tasks more manageable.

Key Components of the Snowblower

The effective operation of a snow-clearing machine relies on several essential elements that work in harmony. Understanding these critical components not only aids in maintenance but also enhances the overall performance during winter challenges.

Major Functional Parts

Each piece plays a pivotal role in ensuring the machinery functions smoothly and efficiently. Below are some of the core components that contribute to its success:

| Component | Function |

|---|---|

| Auger | Collects and chops snow for effective removal. |

| Impeller | Propels the snow away from the machine after collection. |

| Chassis | Houses all parts and provides structural support. |

| Drive System | Facilitates movement and control over the unit. |

Additional Support Elements

In addition to the primary components, there are various auxiliary elements that enhance the functionality and usability of the equipment:

| Component | Function |

|---|---|

| Skid Shoes | Adjusts the height and protects the scraper blade. |

| Scraper Blade | Removes the last layer of snow for a clean surface. |

| Control Panel | Allows the operator to adjust settings and speed. |

| Fuel System | Supplies power for the engine to operate. |

Importance of Maintenance for Longevity

Regular upkeep is crucial for extending the lifespan of any mechanical equipment. By implementing a consistent maintenance routine, owners can ensure optimal performance and prevent unforeseen breakdowns. Neglecting this essential practice can lead to costly repairs and decreased efficiency over time.

Timely inspections allow for the early detection of potential issues. Addressing these problems promptly can save time and money in the long run. Furthermore, keeping components clean and well-lubricated enhances functionality, reducing wear and tear on critical parts.

In addition to mechanical benefits, proper maintenance fosters user safety. Well-maintained machinery operates more reliably, minimizing the risk of accidents caused by equipment failure. Adopting a proactive approach not only enhances performance but also contributes to the overall safety of users.

Ultimately, committing to a maintenance schedule reflects a dedication to quality and reliability. This practice not only maximizes the lifespan of equipment but also ensures that it operates efficiently, providing peace of mind for operators.

Identifying Common Replacement Parts

When maintaining outdoor equipment, recognizing frequently needed components is essential for ensuring optimal performance. Understanding these elements can significantly enhance the efficiency and lifespan of your machine. This guide aims to provide insights into the most common items that may require replacement, helping you keep your machinery in top condition.

Auger Blades: These are crucial for cutting through snow and ice. Over time, they can wear down, necessitating timely replacement to maintain effective operation.

Belts: Often subject to stress and strain, belts play a vital role in transmitting power. Regular inspection can help you identify signs of wear, preventing unexpected breakdowns.

Scraper Bars: Located at the bottom of the unit, scraper bars help to clear surfaces effectively. Deterioration of these bars can lead to poor performance, making it important to check them regularly.

Drive Wheels: These components enable mobility and maneuverability. Inspecting for damage or wear is crucial to ensure smooth operation across different terrains.

Gearbox Components: Essential for power transfer, any issues here can lead to operational difficulties. Keep an eye on these parts for any signs of malfunction.

By familiarizing yourself with these critical components, you can make informed decisions about maintenance and repairs, ultimately enhancing the reliability of your outdoor machinery.

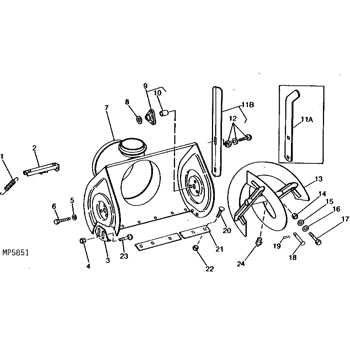

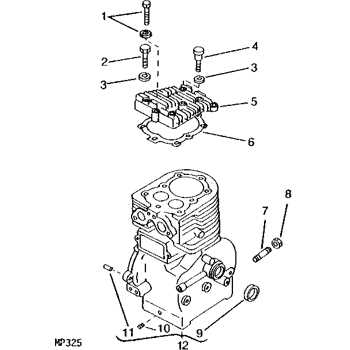

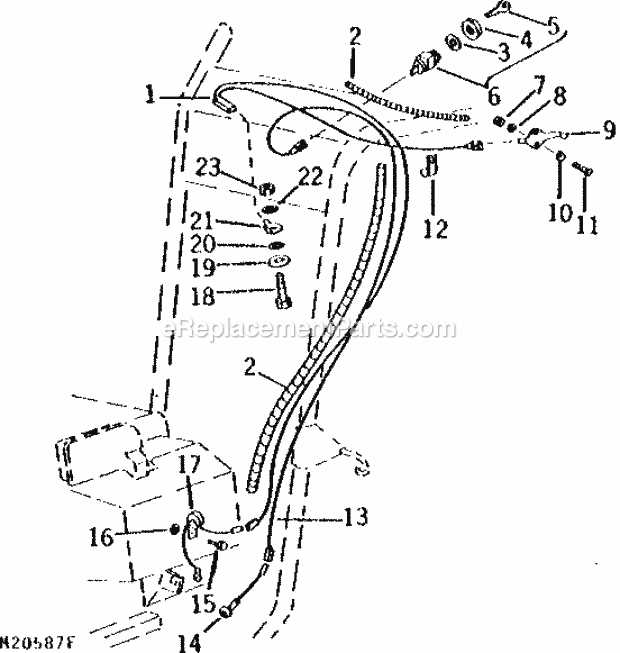

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair tasks. These visual guides provide valuable information, showing the relationship and arrangement of individual elements, helping users identify what is needed for assembly or troubleshooting.

Identifying Components

Start by familiarizing yourself with the various symbols and labels used in the visual representation. Each element typically corresponds to a specific item, which is often numbered or marked for easy reference. Cross-referencing these identifiers with the accompanying list can streamline the process of locating the required components.

Understanding Assembly Instructions

Pay attention to the layout and sequence indicated in the illustration. It usually conveys the order in which components should be assembled or disassembled, which is crucial for avoiding mistakes. Note any directional arrows or annotations that provide additional guidance, ensuring a smoother workflow during your project.

Where to Find OEM Parts

Locating original equipment manufacturer components is essential for maintaining the optimal performance of your machinery. Ensuring that you use genuine items can enhance reliability and prolong the lifespan of your equipment.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealerships. These locations often have a comprehensive selection of items tailored for specific models. Additionally, their staff can provide expert advice and assistance in identifying the right components for your needs.

Online Retailers

Numerous online platforms specialize in offering OEM components. Websites dedicated to machinery supplies frequently stock a wide array of items. When shopping online, it’s vital to verify that the retailer is reputable and offers genuine components. Reading customer reviews and checking return policies can provide extra assurance.

Installation Tips for New Parts

Installing new components can greatly enhance the efficiency and longevity of your equipment. Proper techniques and attention to detail are essential for ensuring optimal performance. Below are some key recommendations to facilitate a smooth installation process.

Preparation and Safety

Before beginning the installation, make sure to gather all necessary tools and components. Ensure your workspace is clean and organized to avoid losing any small items. Always prioritize safety: wear appropriate gear such as gloves and goggles to protect yourself from potential hazards.

Step-by-Step Installation

Follow a systematic approach when installing the new components. Start by consulting the manufacturer’s guidelines for specific instructions. Carefully remove the old parts, taking note of how they are assembled. This will serve as a reference when positioning the new items. Align each component precisely before tightening any bolts or screws to avoid misalignment. Once everything is in place, conduct a final check to ensure that all fasteners are secure and that the installation meets the required specifications.

Benefits of Using Genuine Parts

Utilizing authentic components in machinery maintenance offers numerous advantages that significantly enhance performance and longevity. Genuine parts are designed specifically for each model, ensuring optimal compatibility and functionality. This attention to detail results in a seamless operation that is crucial for reliable performance.

One of the primary benefits is improved reliability. Authentic components undergo rigorous testing and meet strict quality standards, reducing the likelihood of failures or malfunctions. This not only ensures smoother operation but also minimizes the risk of costly repairs down the line.

Moreover, using original components can lead to better efficiency. These parts are engineered to work together, enhancing the overall performance of the equipment. With improved efficiency, users can expect a more effective and powerful experience, whether it’s tackling heavy tasks or managing routine maintenance.

Another important aspect is warranty protection. Many manufacturers require the use of genuine components to maintain warranty coverage. Utilizing non-authentic alternatives may void the warranty, exposing users to potential financial risks if issues arise.

Lastly, opting for authentic components contributes to safety. Components designed by the manufacturer incorporate necessary safety features that are often overlooked in generic alternatives. Prioritizing safety ensures peace of mind while operating machinery.

Frequently Asked Questions about Parts

This section addresses common inquiries related to components and accessories used in outdoor equipment. Understanding the nuances of these elements can enhance performance and ensure longevity. Here, we clarify frequent concerns and provide useful insights for users.

What should I consider when replacing a component?

When looking to replace a component, it’s crucial to check compatibility with your specific model. Always refer to the manufacturer’s specifications to ensure a perfect fit.

How do I find the right component for my machine?

To locate the appropriate component, consult your user manual or visit the official website. Many manufacturers offer online catalogs that allow for easy searching by model number.

Are aftermarket components reliable?

Aftermarket components can vary in quality. While some may offer cost savings, it’s important to research the manufacturer’s reputation and read reviews before purchasing.

What maintenance should I perform on components?

Regular maintenance includes cleaning, lubrication, and checking for wear and tear. Following the maintenance schedule outlined in the manual can extend the life of your equipment.

Where can I find repair guides?

Repair guides can often be found in the user manual or on the manufacturer’s website. Additionally, many online forums and communities share valuable tips and resources for DIY repairs.