When the colder months arrive, ensuring that your outdoor machinery operates at peak performance becomes essential. Familiarity with the various components of your winter tools not only enhances efficiency but also simplifies maintenance and repairs. This guide aims to illuminate the intricate workings of your essential winter helper.

By breaking down the essential elements, users can gain insight into how each piece contributes to overall functionality. Whether it’s the drive mechanism or the clearing system, comprehending these components allows for better decision-making when it comes to upkeep or replacements.

In this exploration, we will provide a comprehensive overview of the specific elements involved, offering clarity on their arrangement and interrelationships. With this knowledge, users can approach troubleshooting and enhancements with confidence, ensuring that their equipment is ready to tackle the challenges of winter weather.

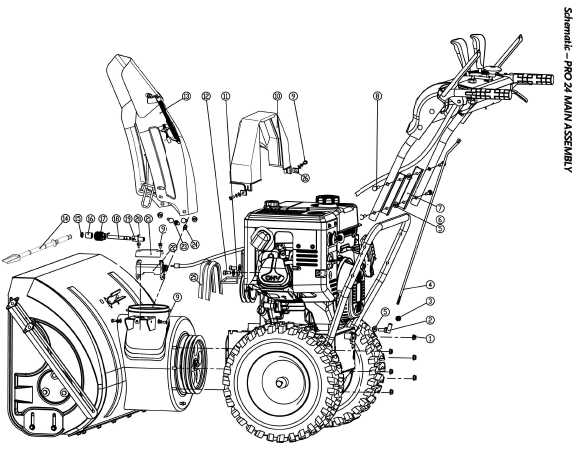

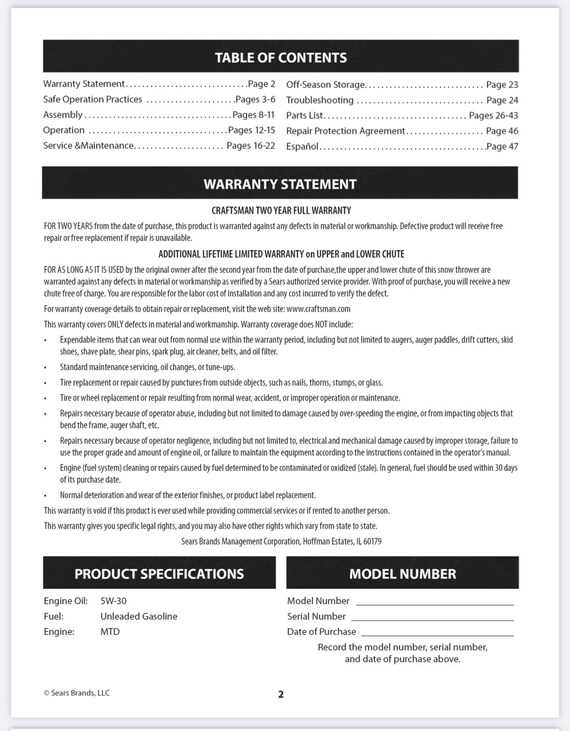

Understanding Craftsman Snowblower Components

Exploring the essential elements of winter machinery can enhance both performance and maintenance. Each component plays a crucial role in ensuring efficiency and reliability during snow removal tasks. Familiarity with these elements helps users identify issues quickly and make informed decisions about repairs or upgrades.

Key Components Overview

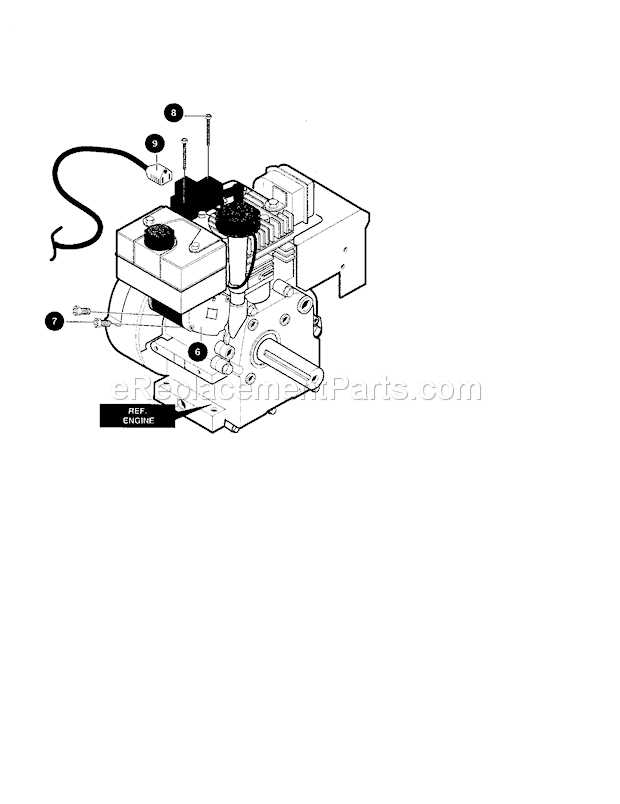

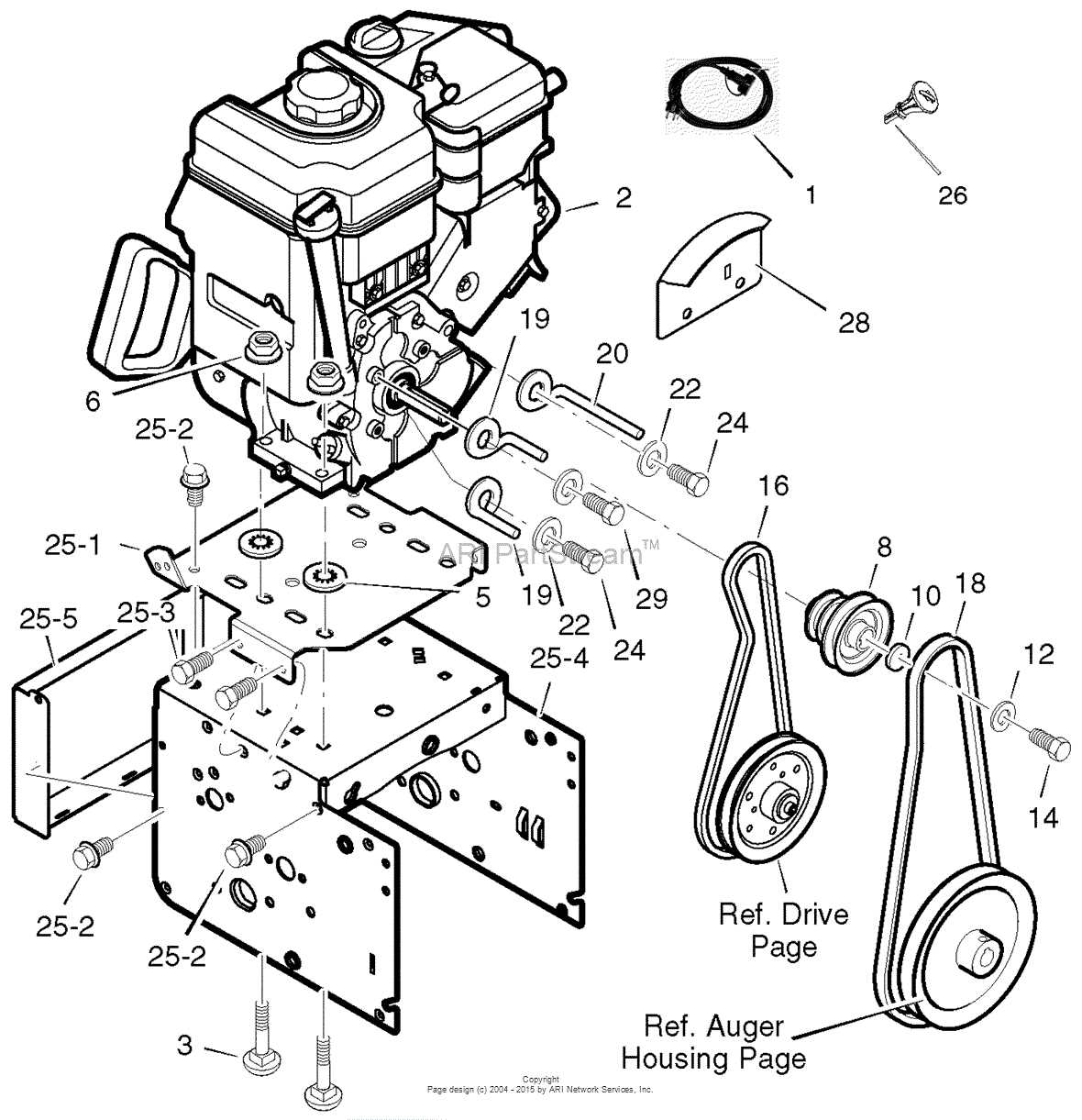

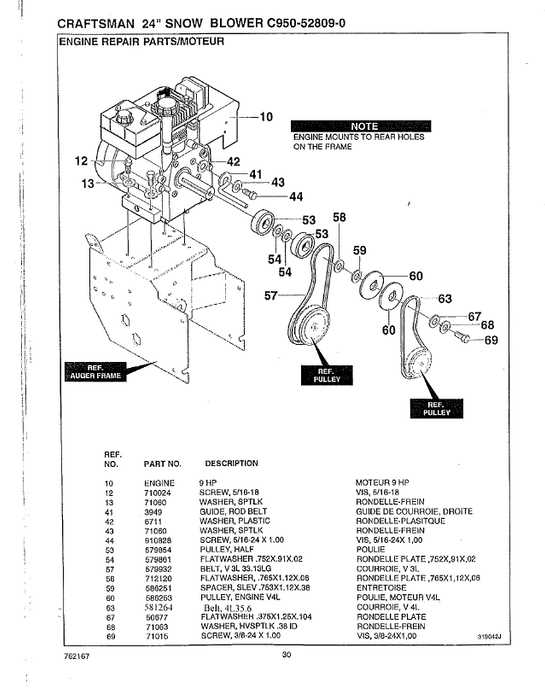

- Engine: The powerhouse responsible for driving the entire unit.

- Auger: The mechanism that collects and moves the snow into the discharge chute.

- Chassis: The frame that supports all other components and provides stability.

- Discharge Chute: Directs the expelled snow away from the working area.

- Control Panel: Allows the operator to manage settings and functions easily.

Maintenance Tips

- Regularly check the engine oil and replace it as needed.

- Inspect the auger for any signs of wear or damage.

- Ensure that the discharge chute is clear of obstructions.

- Lubricate moving parts to prevent rust and ensure smooth operation.

- Store the unit in a dry place to prolong its lifespan.

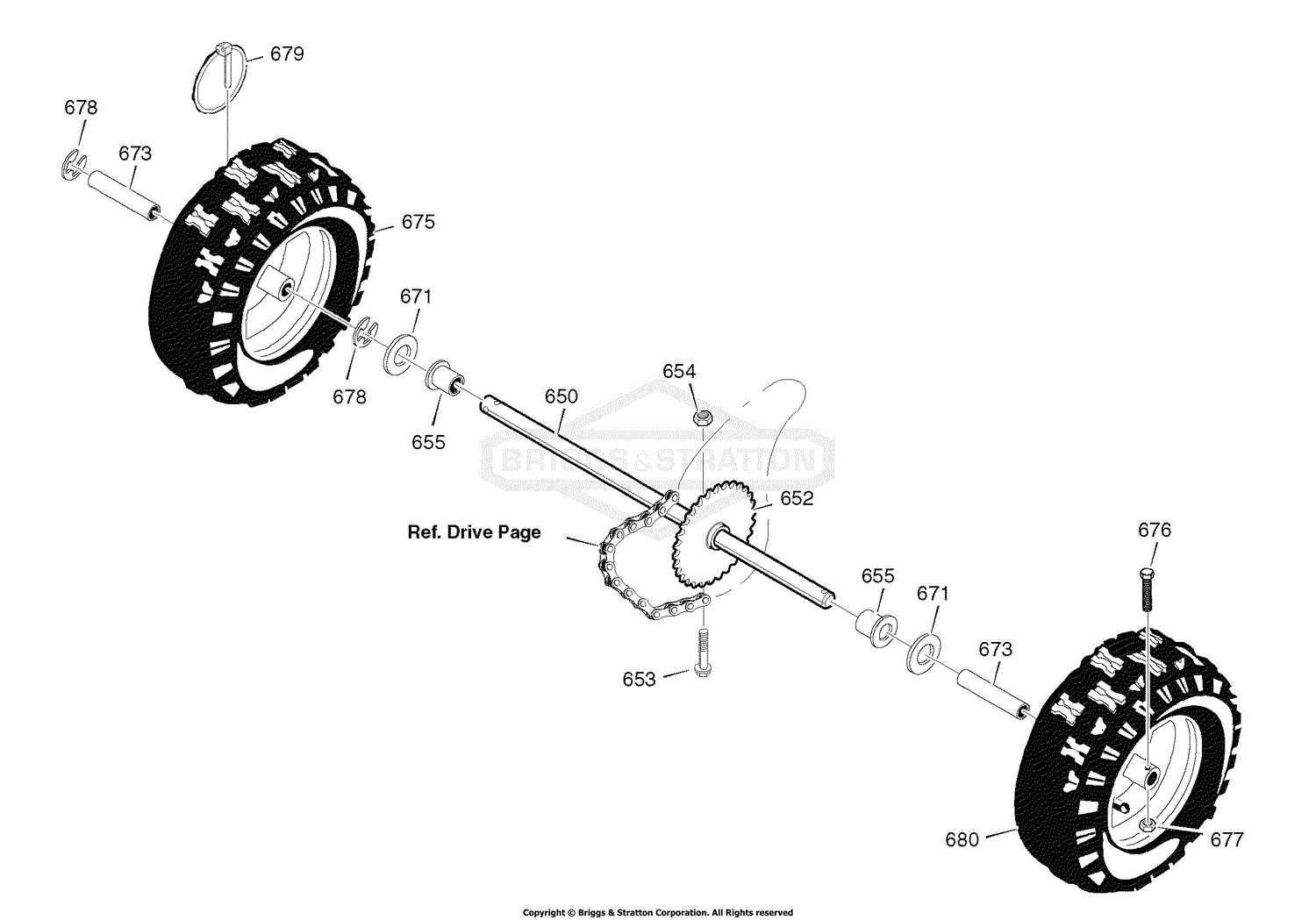

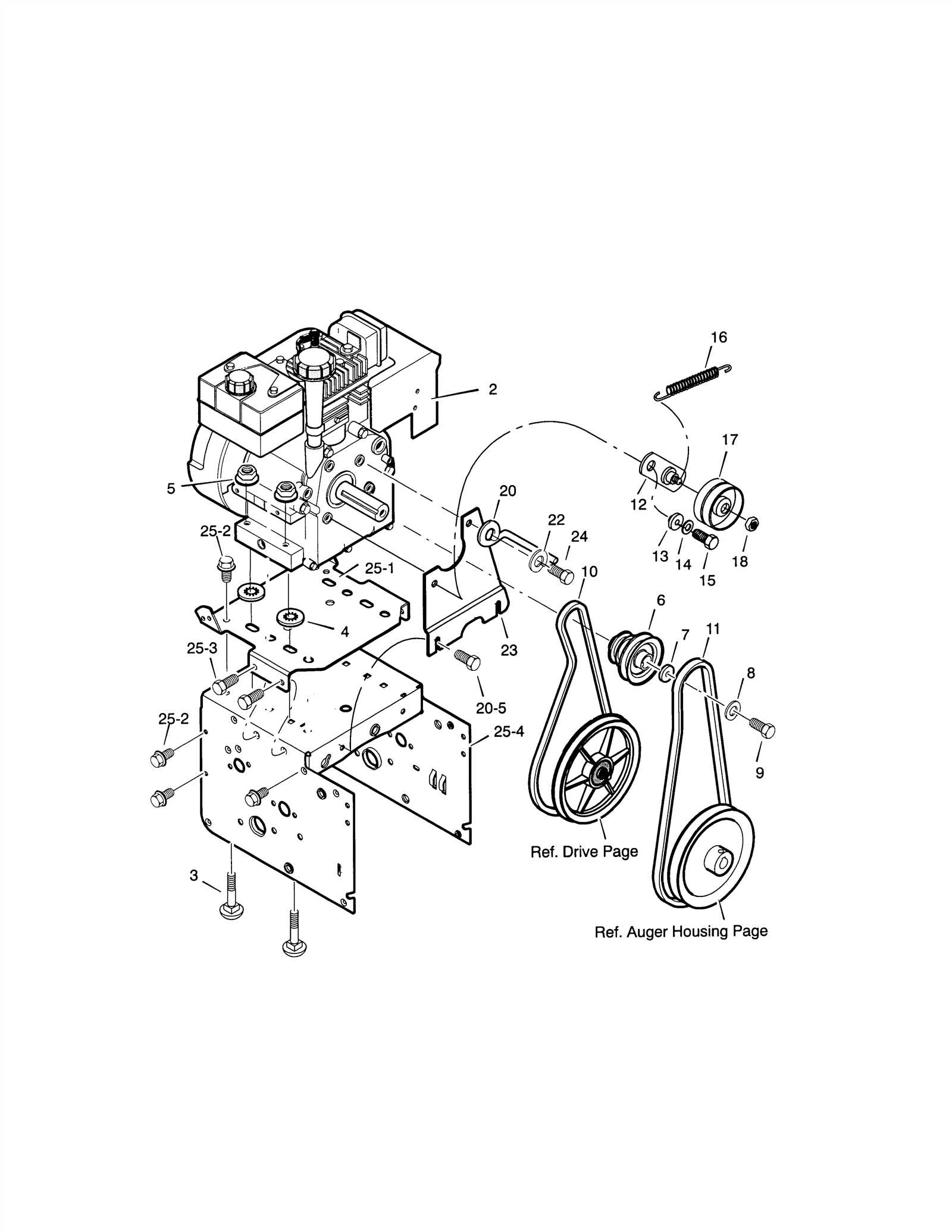

Key Parts of a 24 Inch Model

Understanding the essential components of this 24-inch machine is crucial for effective operation and maintenance. Each element plays a significant role in ensuring optimal performance during winter conditions.

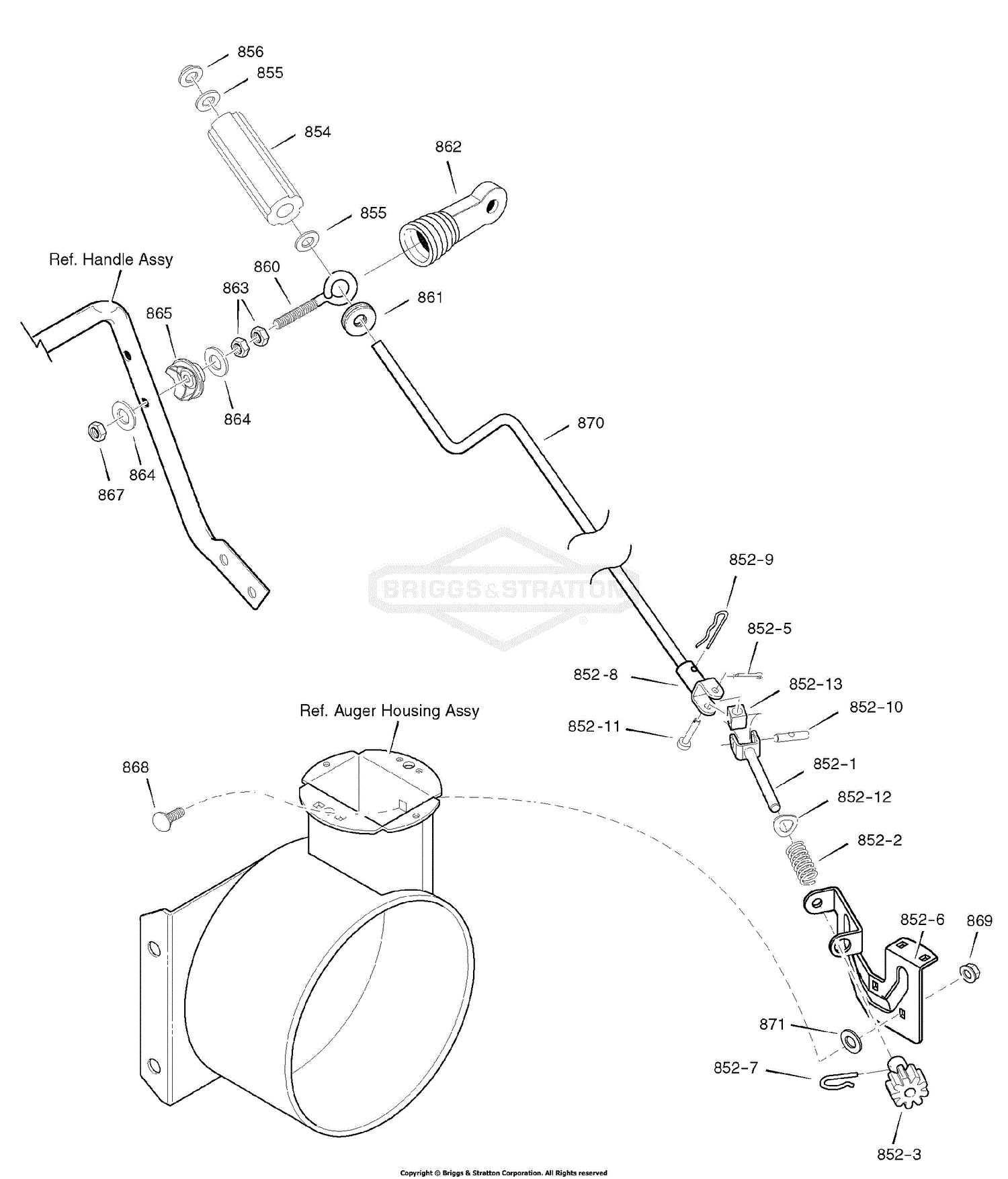

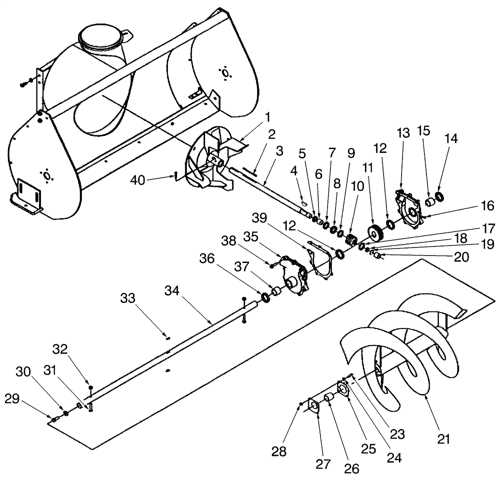

The primary component is the auger, which is responsible for gathering and breaking up snow. This feature is vital for efficient clearing, as it determines the machine’s ability to handle different snow types. Another important aspect is the impeller, which propels the snow away from the unit, affecting the distance and direction of discharge.

The engine serves as the powerhouse, driving all functions and impacting overall efficiency. A robust engine ensures reliable operation, even in challenging weather. The chute is also noteworthy, allowing for adjustable snow discharge, enabling the operator to direct snow where needed.

Finally, the handles and controls are essential for user interaction, providing ease of maneuverability and comfort during use. Understanding these key elements will enhance the user experience and ensure proper maintenance of the machine.

Common Issues and Replacement Parts

When operating outdoor machinery designed for winter conditions, users often encounter various challenges that can impact performance and efficiency. Understanding these issues is crucial for maintaining optimal functionality and ensuring a smooth experience during snowy weather. This section explores typical problems faced by users and highlights the essential components that may require replacement over time.

Frequent Problems

One of the most common difficulties involves engine starting issues, which can stem from a variety of factors such as fuel quality or ignition system malfunctions. Additionally, users might experience reduced throwing distance, often attributed to wear in the impeller or clogging in the chute. Another prevalent concern is inconsistent performance, which can signal the need for maintenance or replacement of specific internal components.

Essential Components for Replacement

Identifying and replacing worn or damaged components is vital for restoring optimal performance. Below is a table outlining key elements that may need attention:

| Component | Common Issue | Replacement Recommendation |

|---|---|---|

| Ignition System | Difficulty starting | Check and replace spark plug |

| Impeller | Reduced throwing distance | Inspect for wear and replace if necessary |

| Fuel Lines | Fuel leaks | Replace damaged or cracked lines |

| Chute | Clogging issues | Clear blockages and check for cracks |

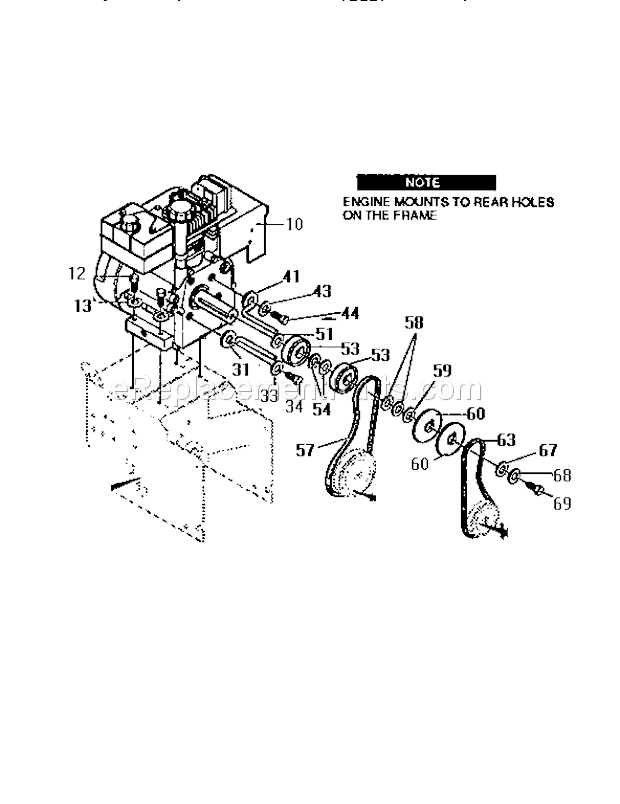

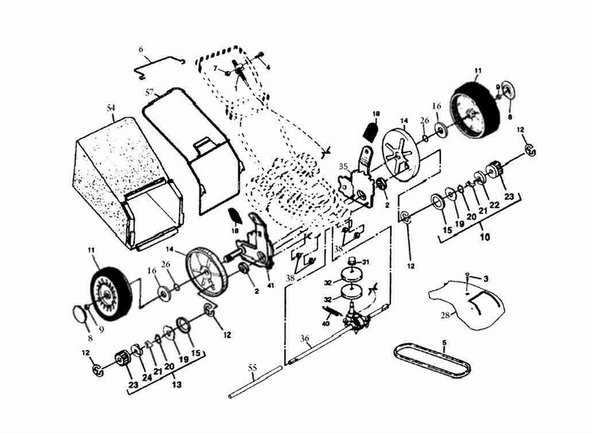

How to Read a Parts Diagram

Understanding the layout of a mechanical illustration is crucial for effective maintenance and repair. Such visuals provide an organized representation of components, allowing users to identify each piece’s role and how they interconnect. By familiarizing yourself with these illustrations, you can streamline the process of troubleshooting and replacing elements.

To successfully interpret a mechanical illustration, follow these key steps:

| Step | Description |

|---|---|

| 1 | Examine the overall layout to get a sense of how the elements are arranged. |

| 2 | Identify the labeled components; each will typically correspond to specific functions. |

| 3 | Note any accompanying numbers or letters that may refer to a list of parts. |

| 4 | Look for arrows or lines that illustrate connections and relationships between parts. |

| 5 | Refer to the accompanying list for detailed information about each component’s specifications. |

By following these guidelines, you can gain a clearer understanding of how to navigate complex mechanical illustrations, leading to more effective repairs and maintenance tasks.

Maintenance Tips for Snowblower Longevity

Proper upkeep is essential for ensuring the durability and efficient operation of your winter equipment. Regular attention to maintenance tasks can significantly extend its lifespan and improve performance during the cold months. Here are some valuable practices to consider.

Regular Inspections

Conducting frequent checks is vital to identify any potential issues early on. Look for signs of wear and tear, and address them promptly.

- Check the belts and cables for fraying or damage.

- Inspect the scraper blade and auger for wear.

- Examine the fuel system for leaks or blockages.

Seasonal Preparations

Before the snow season begins, ensure that your equipment is ready for use. Follow these steps for optimal preparation.

- Change the oil to ensure smooth operation.

- Replace the spark plug for reliable starting.

- Clean or replace the air filter to improve airflow.

By adhering to these maintenance tips, you can enhance the performance and longevity of your winter machinery, ensuring it remains reliable during challenging weather conditions.

Where to Find Replacement Parts

Locating the right components for your outdoor equipment can significantly enhance its performance and longevity. Various sources provide essential items to keep your machine running smoothly. Understanding where to search can streamline the process and save time.

Online Retailers: Many websites specialize in selling equipment essentials. These platforms often offer extensive catalogs, detailed specifications, and customer reviews to assist in your selection.

Local Stores: Hardware shops and specialty stores frequently stock a variety of items. Engaging with knowledgeable staff can help identify the right solutions tailored to your needs.

Manufacturer Websites: Directly visiting the official site of the equipment maker can yield original components and specific recommendations. This option often ensures compatibility and quality.

Forums and Community Groups: Joining online communities dedicated to outdoor machinery can provide insights from experienced users. These platforms often share valuable tips on where to find specific items and might offer second-hand options.

By exploring these avenues, you can enhance your equipment’s functionality and enjoy a more efficient experience.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing common issues associated with your outdoor clearing machine. Following this structured guide will help you understand the necessary steps and ensure a successful repair process.

Identification of the Problem

Start by assessing the symptoms your equipment is exhibiting. Common issues include reduced performance, unusual noises, or failure to start. Carefully examine the components to determine what may be malfunctioning. Take notes on any irregularities to assist in the repair process.

Gathering Tools and Components

Before proceeding with repairs, ensure you have the necessary tools and replacement components on hand. A basic toolkit including wrenches, screwdrivers, and pliers is essential. Additionally, consult the manual to identify specific items that may need replacement, such as belts or filters, ensuring you have the correct specifications for your model.

Safety Precautions When Handling Equipment

Ensuring safety while operating machinery is essential for preventing accidents and injuries. Proper precautions can significantly reduce risks associated with equipment handling and maintenance. Awareness of potential hazards and adherence to safety guidelines is crucial for a safe working environment.

Here are some important safety measures to consider:

- Always read the manufacturer’s manual before use.

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Inspect the equipment before operation to ensure it is in good working condition.

- Keep the work area clear of obstacles and debris.

- Ensure that all safety features are functioning properly before starting the machine.

- Never operate machinery under the influence of drugs or alcohol.

- Maintain a safe distance from others while operating the equipment.

By following these guidelines, users can enhance their safety and reduce the likelihood of accidents during equipment handling. Regular training and refreshers on safety practices are also recommended.

Enhancing Performance with Upgrades

Improving the functionality of outdoor equipment can significantly enhance its efficiency and longevity. By implementing specific enhancements, users can experience better performance, reliability, and even increased safety. Upgrades can range from simple modifications to more advanced installations, each contributing to a superior operational experience.

One effective way to boost efficiency is by upgrading the power source. A more robust engine can lead to improved torque and speed, making the machinery more capable in challenging conditions. Additionally, enhanced cutting or clearing tools can streamline tasks, allowing for quicker and more effective results.

Maintenance plays a crucial role in performance as well. Regularly replacing worn components with higher-quality alternatives can prevent breakdowns and maintain optimal function. Moreover, incorporating advanced features such as improved controls or ergonomic designs can enhance user comfort and control during operation.

Ultimately, investing in upgrades not only maximizes productivity but also ensures that the equipment remains in peak condition for years to come. Taking these steps is essential for anyone looking to elevate their outdoor tasks to a new level of excellence.