In the realm of winter maintenance, ensuring the efficiency of your machinery is paramount. Familiarizing yourself with the intricate assembly of each unit can significantly enhance its performance and longevity. This knowledge empowers users to troubleshoot effectively and perform necessary upkeep with confidence.

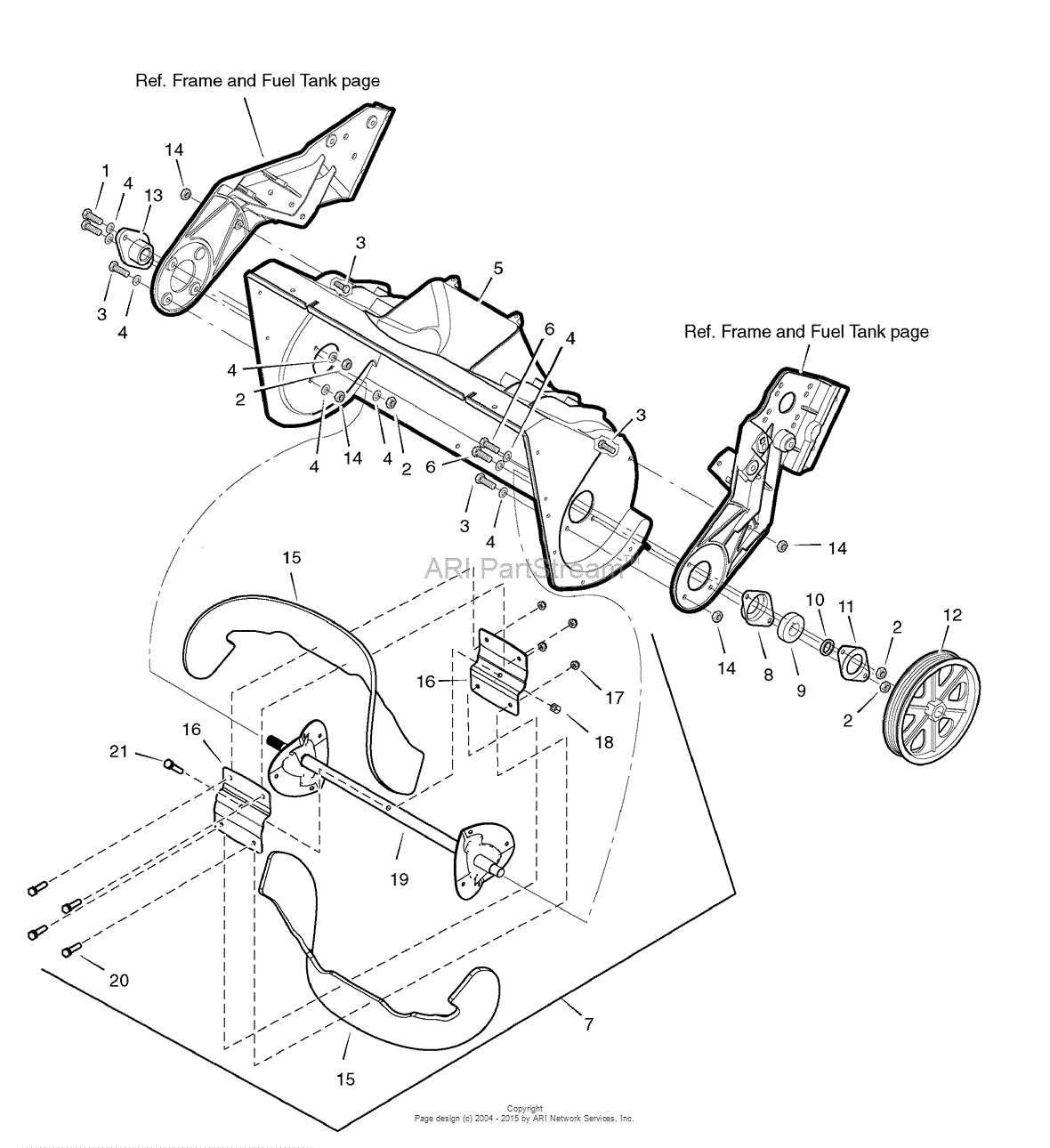

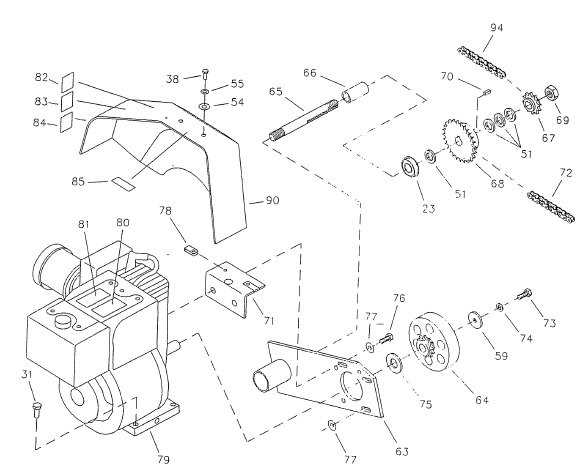

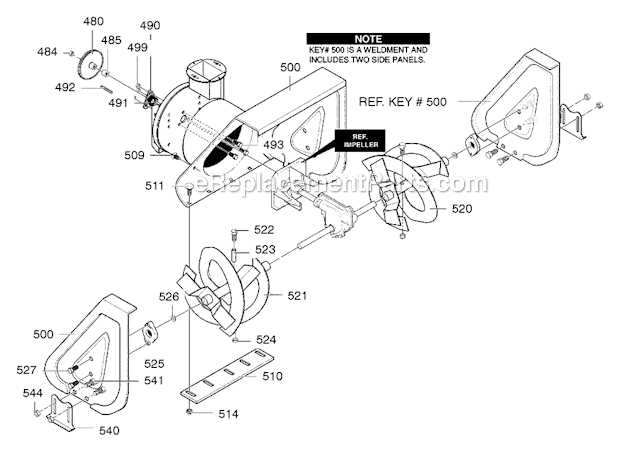

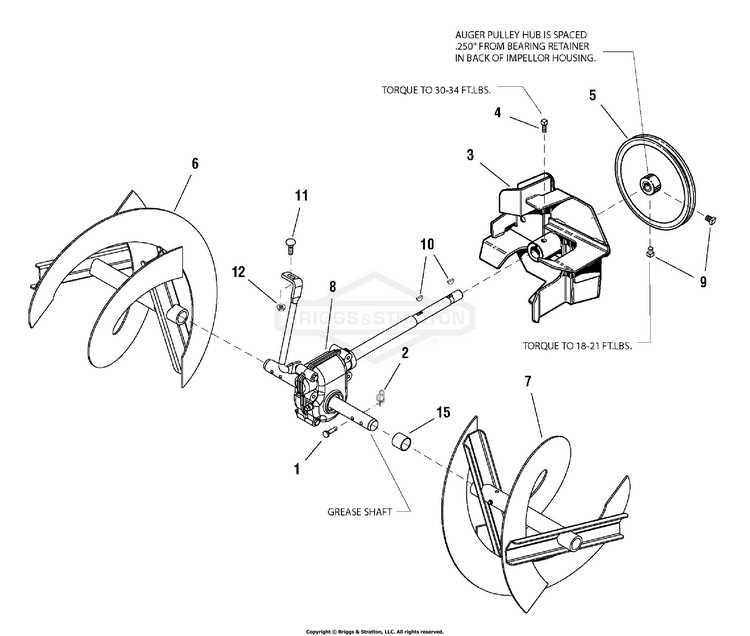

Visual representations of these components serve as essential guides for both novice and experienced operators. By breaking down the intricate relationships between various elements, you can identify potential issues before they escalate. Furthermore, such illustrations can assist in the procurement of the correct replacements, ensuring that your equipment remains in top condition.

As we delve into the specifics of these illustrations, we’ll explore how a comprehensive understanding of each component can lead to better care practices. Whether you’re looking to maintain your current machinery or enhance your skills in repair and maintenance, grasping the layout of these systems is an invaluable asset.

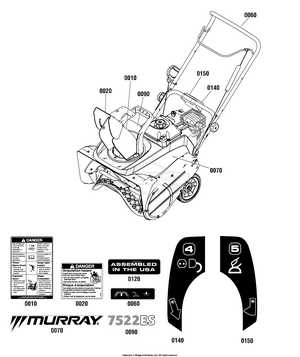

Murray Snow Thrower Overview

This section provides an insightful look into a powerful outdoor equipment designed for managing winter conditions. Its efficient design enables users to tackle challenging weather by clearing pathways and driveways effectively. Understanding its components and functionality can greatly enhance the experience of operating this machinery.

Key Features

The equipment is equipped with several notable attributes that improve performance and usability. These features are engineered to ensure reliability and ease of operation, making winter maintenance less of a chore.

| Feature | Description |

|---|---|

| Engine Power | Robust engine designed for high efficiency and durability. |

| Auger System | Advanced auger mechanism for effective snow removal. |

| Adjustable Chute | Flexible chute design for directing snow to desired locations. |

| Ergonomic Handle | Comfortable grip to reduce fatigue during extended use. |

Maintenance Tips

Importance of Replacement Parts

Ensuring the longevity and efficiency of equipment relies significantly on the availability and quality of its components. Regular maintenance and timely substitution of worn-out elements are crucial for optimal performance and safety. Neglecting these aspects can lead to decreased functionality and potentially costly repairs.

Enhancing Performance

Upgrading or replacing specific components can dramatically improve the overall efficiency of machinery. When parts wear down, they may hinder operation, leading to subpar results. By investing in quality replacements, users can restore and even enhance functionality, ensuring that the equipment operates at its best.

Cost-Effectiveness and Longevity

While some may view replacement as an unnecessary expense, it often proves to be a cost-effective strategy in the long run. Addressing issues promptly can prevent more significant damage, which would require more extensive repairs or even full replacement of the unit. Maintaining high-quality components not only extends the life of the machinery but also saves money by avoiding major malfunctions.

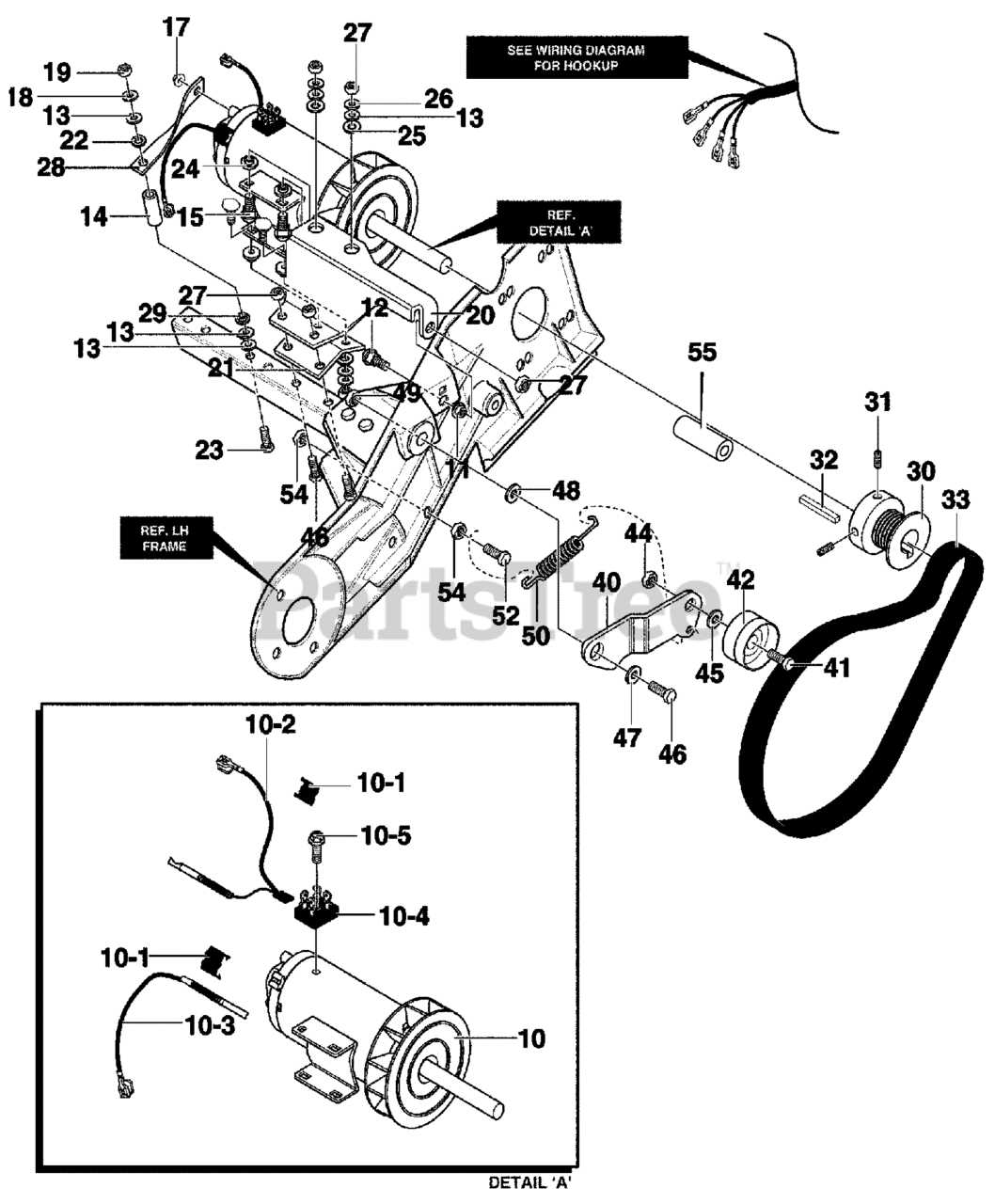

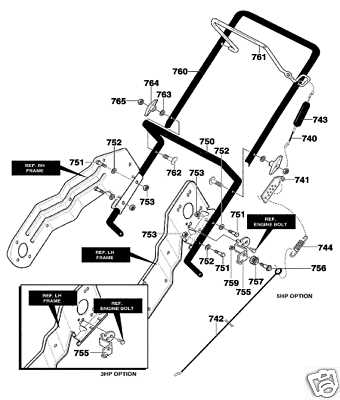

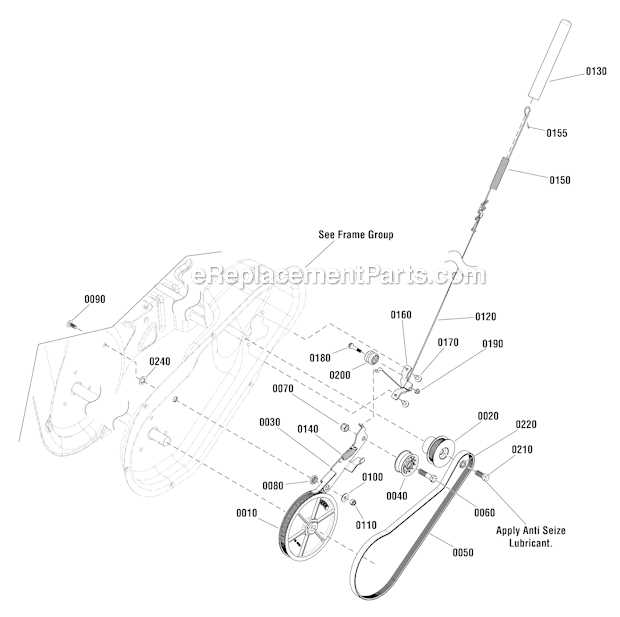

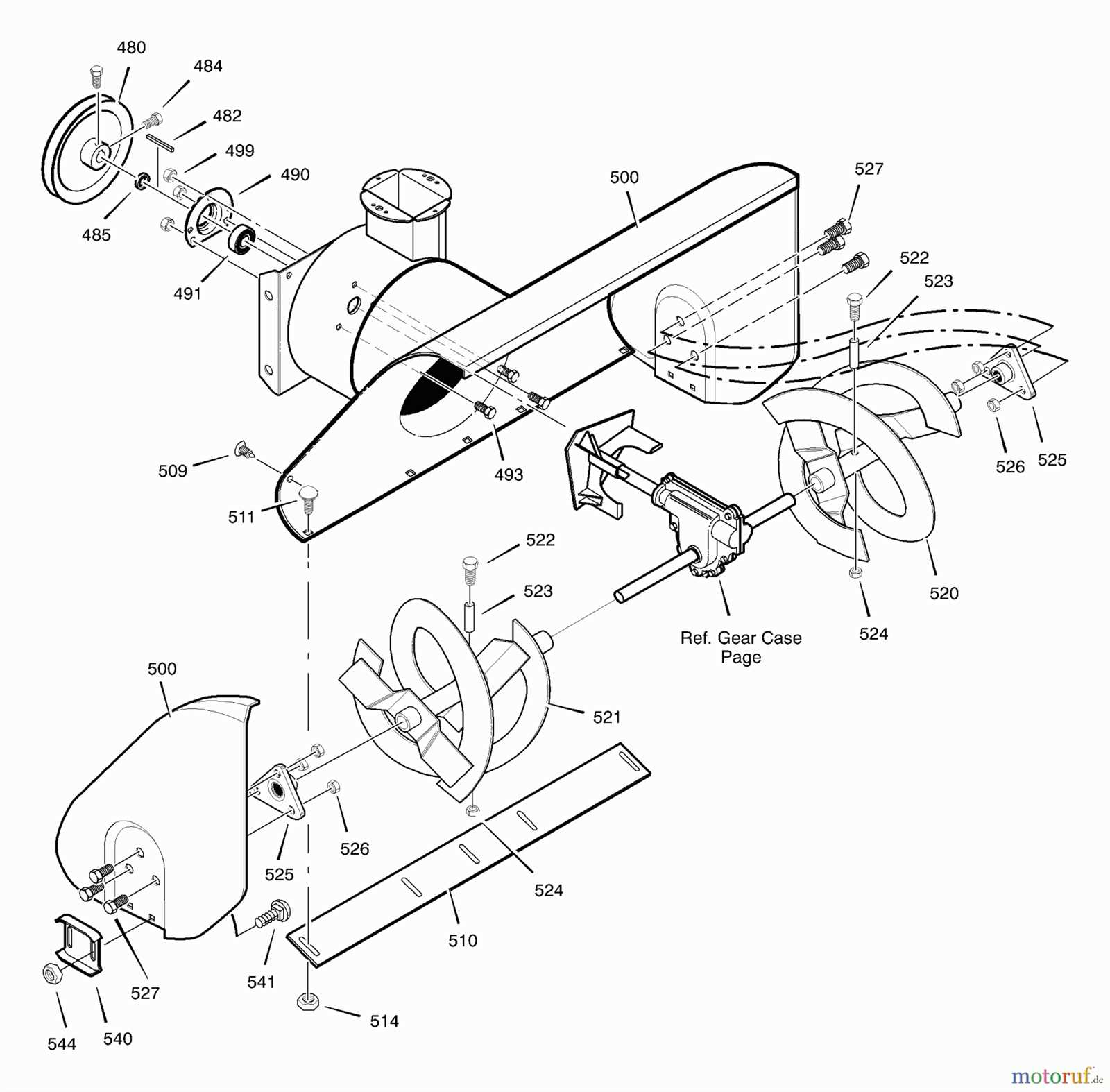

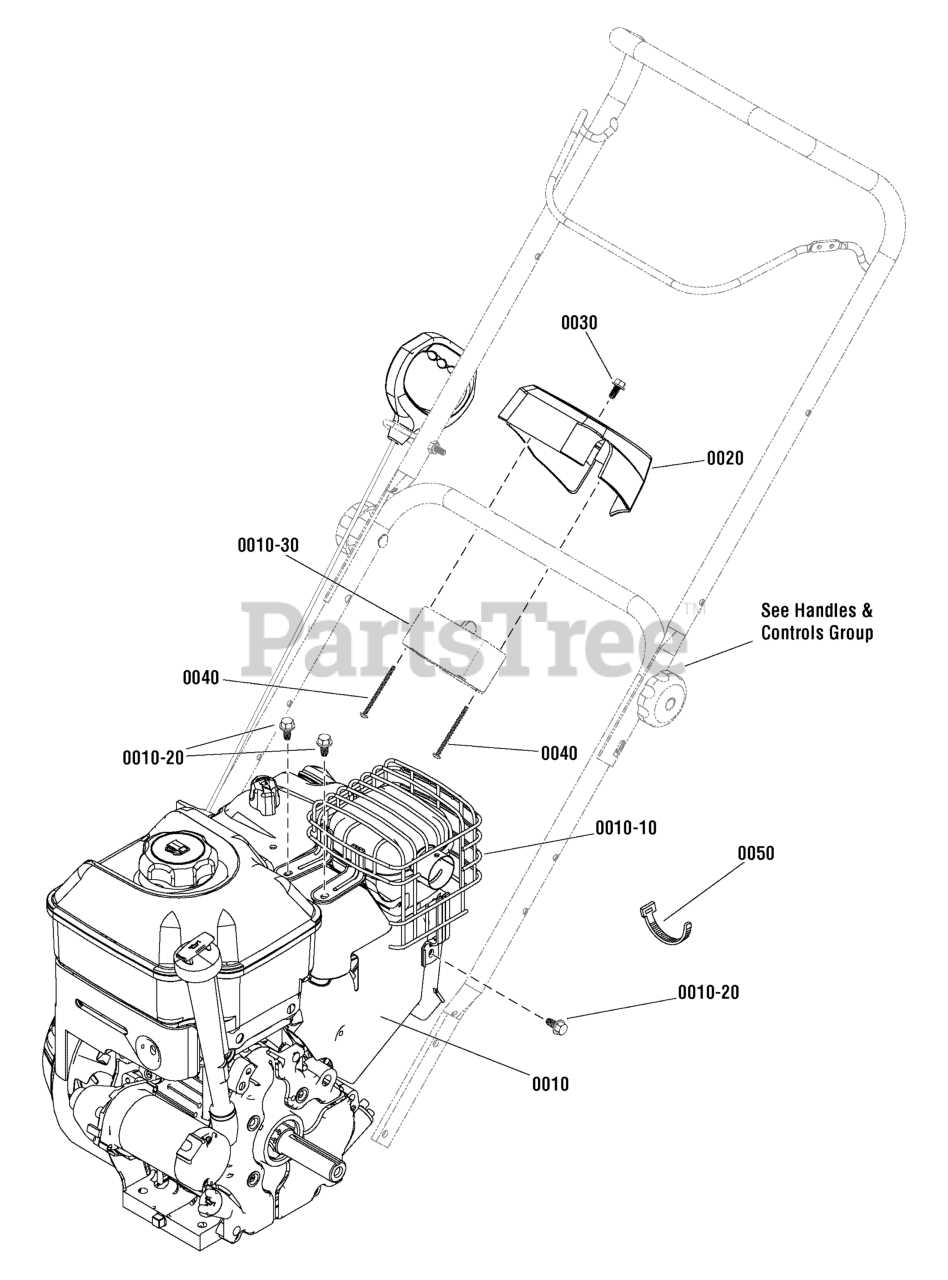

Understanding Parts Diagrams

Visual representations of components play a crucial role in comprehending the structure and functionality of machinery. These illustrations serve as a roadmap, allowing users to identify various elements and their relationships within a device. By breaking down complex systems into simpler visuals, individuals can enhance their understanding and streamline maintenance or repairs.

Each illustration typically includes labels and references that guide users through the assembly and disassembly processes. Familiarity with these visuals can significantly reduce confusion when troubleshooting issues or sourcing replacements. Moreover, these representations often provide insights into the overall design, highlighting areas that require special attention or care during servicing.

Utilizing these visual guides not only aids in efficient repairs but also fosters a deeper appreciation for the engineering behind the equipment. A clear grasp of component layout can empower users to tackle challenges with confidence, ensuring optimal performance and longevity of their machinery.

Common Components of Snow Throwers

Understanding the essential elements of a snow-clearing machine is crucial for effective maintenance and operation. Each component plays a vital role in ensuring the equipment functions smoothly during winter conditions. Below are the main parts typically found in these devices.

Main Elements

- Engine: The power source that drives the entire system.

- Auger: A rotating blade that collects and moves the snow towards the chute.

- Chute: The structure that directs the snow once it has been gathered.

- Transmission: The mechanism that transfers power from the engine to the wheels and auger.

- Skids: Adjustable supports that control the height of the device above the ground.

Additional Features

- Control Panel: The interface for operating various functions, including speed and chute direction.

- Headlight: Provides visibility during low-light conditions, ensuring safe operation.

- Wheels or Tracks: Facilitate mobility, allowing the machine to traverse different terrains.

- Deflector: A component that helps in adjusting the distance the snow is thrown.

How to Read Diagrams Effectively

Understanding visual representations can greatly enhance your ability to interpret information quickly and accurately. These illustrations serve as guides, providing essential details about components and their relationships. To maximize comprehension, it’s important to adopt a systematic approach when analyzing these visuals.

Identify Key Elements

Start by familiarizing yourself with the primary features of the illustration. Look for labels, symbols, and any color coding that may indicate different functions or types. Recognizing these elements allows you to grasp the overall structure and flow of the information presented.

Follow the Flow of Information

Next, trace the connections between different components. Understanding how each element interacts with others will help you piece together the bigger picture. Pay attention to directional arrows and lines, as they often signify the order of operations or the sequence of assembly.

Finding Original Murray Parts

Locating authentic components for outdoor equipment is crucial for maintaining optimal performance and longevity. Using original items ensures compatibility and reliability, which can significantly affect the efficiency of your machine.

Benefits of Using Authentic Components

- Guaranteed compatibility with existing equipment

- Improved durability and performance

- Access to manufacturer warranties and support

- Enhanced safety features and compliance with standards

Where to Search for Original Components

- Official manufacturer websites

- Authorized dealers and retailers

- Specialty shops focusing on outdoor machinery

- Online marketplaces with verified sellers

Utilizing these resources will help ensure you acquire the correct items, facilitating effective repairs and maintenance for your equipment.

Maintenance Tips for Snow Throwers

Regular upkeep is essential for ensuring optimal performance and longevity of your outdoor clearing equipment. By following a structured maintenance routine, you can avoid common issues and keep your machine in excellent working condition throughout the cold season.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Oil Level | Before Each Use | Ensure that the oil level is adequate to prevent engine damage and promote efficiency. |

| Inspect Belts | Monthly | Look for signs of wear or fraying to avoid potential malfunctions during operation. |

| Clear Debris | After Each Use | Remove any accumulated snow, ice, or debris to maintain functionality and prevent rust. |

| Sharpen Blades | Seasonally | Ensure cutting edges are sharp for efficient operation and better snow displacement. |

| Check Fuel System | Before Each Use | Inspect fuel lines and filters for leaks and ensure the fuel is fresh to avoid starting issues. |

Implementing these simple yet effective maintenance tasks will not only enhance performance but also prolong the lifespan of your equipment, ensuring reliable operation when you need it most.

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and functionality of outdoor equipment. Here, users can find answers to their most pressing concerns, ensuring they have the information needed for efficient operation and care.

General Inquiries

Understanding the essential components and their functions can greatly enhance your experience. Below are some frequently asked questions that provide clarity on various aspects.

| Question | Answer |

|---|---|

| What are the main components of the equipment? | The primary elements include the motor, blades, and drive system, each playing a crucial role in its performance. |

| How often should maintenance be performed? | Regular checks should be conducted before each season, with detailed inspections at least once a year. |

| Where can I find replacement components? | Replacement items can be sourced from authorized dealers, online retailers, or through specialized service centers. |

Troubleshooting Tips

Issues may arise during usage, and having a troubleshooting guide can be immensely helpful. Here are some common problems and their solutions.

| Issue | Solution |

|---|---|

| Machine won’t start | Check the power supply and ensure all connections are secure. Inspect the fuel if applicable. |

| Poor performance | Examine the blades for wear and tear and consider sharpening or replacing them as needed. |

| Unusual noises | Stop the equipment immediately and inspect for foreign objects lodged in the mechanism. |