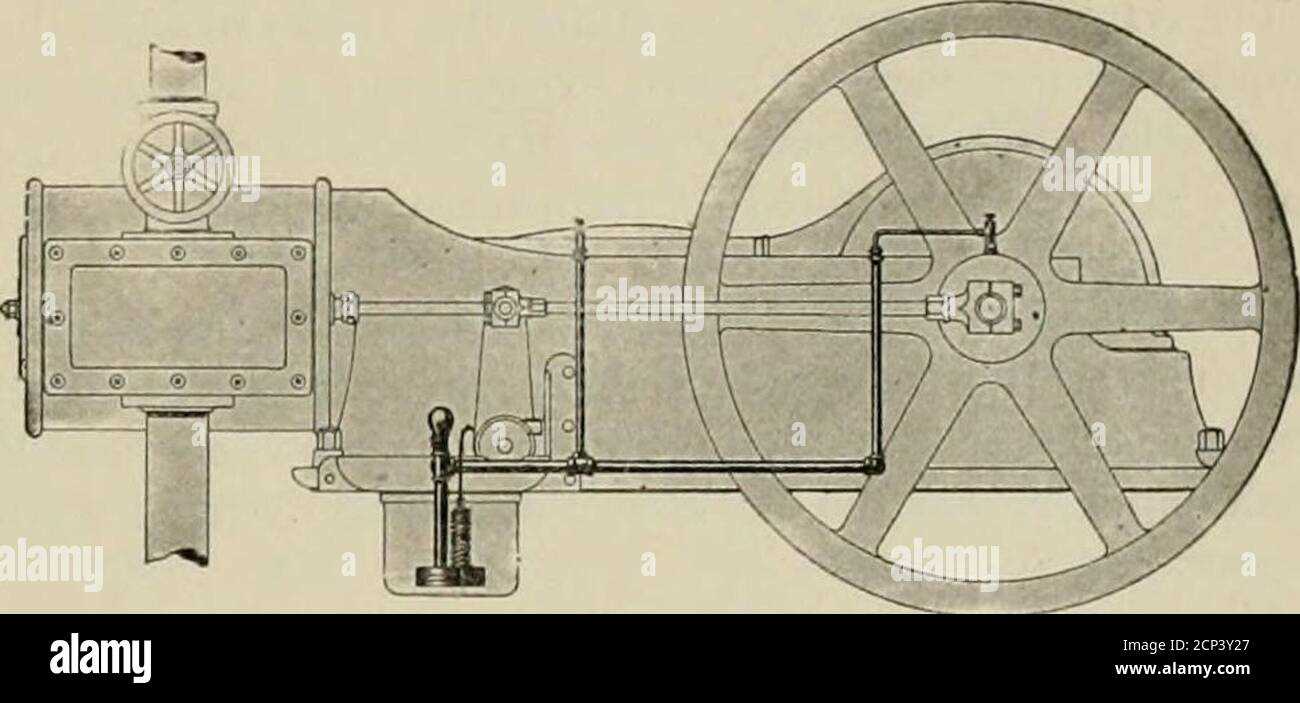

In the realm of power generation, comprehending the intricate assembly of machinery is crucial for efficiency and maintenance. Analyzing the individual elements that contribute to the overall functionality allows users to troubleshoot effectively and enhance performance. This exploration serves as a guide to familiarize oneself with the essential components that play a vital role in the operation of these systems.

Each segment of the machinery has a specific purpose, and recognizing these roles can significantly impact the longevity and reliability of the equipment. From the mechanisms that convert energy to those ensuring smooth operation, a detailed understanding promotes better management and care. Whether you are a technician, an engineer, or an enthusiast, knowing the layout and function of these components is invaluable.

This section delves into the various sections of the equipment, offering insights into their configuration and interrelations. By grasping how each part connects and interacts, individuals can optimize their approach to maintenance and repairs, ensuring peak performance over time.

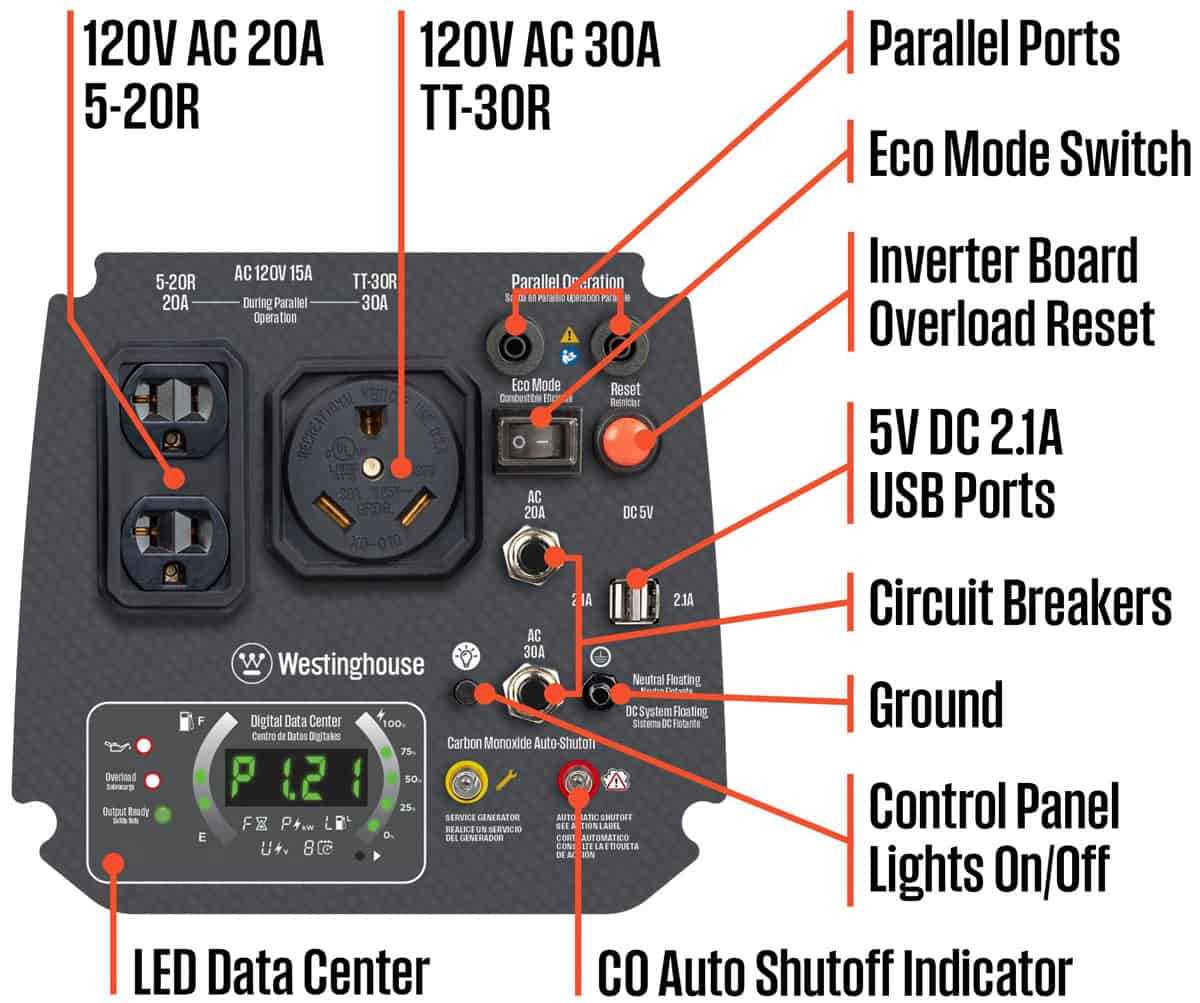

Understanding Westinghouse Generators

This section explores the intricacies of power production equipment designed for efficiency and reliability. By delving into their mechanisms and components, we can appreciate how these machines convert energy into usable electricity.

Key Components

At the core of these devices are essential elements that work harmoniously. Each component, from the engine to the electrical output system, plays a vital role in the overall functionality. Understanding the role of each part enhances operational knowledge and maintenance practices.

Maintenance and Performance

Regular upkeep is crucial for optimal performance. Implementing routine checks and addressing wear can lead to longevity and efficiency. Awareness of how each element contributes to the whole can ultimately improve reliability and reduce downtime.

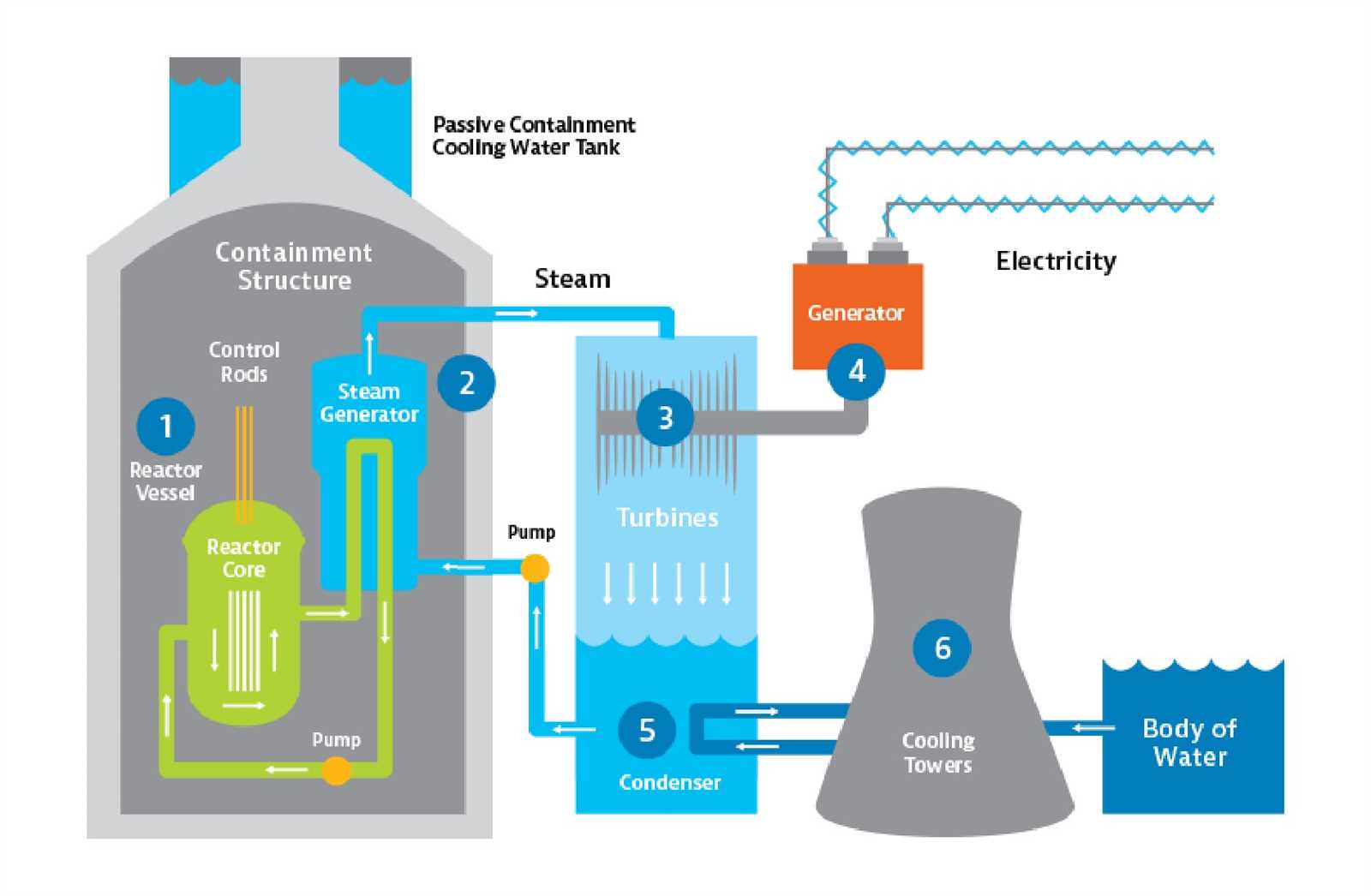

Key Components of Generator Systems

Understanding the essential elements of power-producing systems is crucial for effective operation and maintenance. Each component plays a vital role in ensuring efficiency and reliability. Below, we explore the fundamental parts that contribute to the functionality of these systems.

Core Elements

- Engine: The heart of the system, converting fuel into mechanical energy.

- Alternator: This component transforms mechanical energy into electrical energy.

- Fuel System: Responsible for delivering the necessary fuel to the engine.

- Cooling System: Maintains optimal operating temperatures to prevent overheating.

- Exhaust System: Safely expels gases produced during combustion.

Supportive Mechanisms

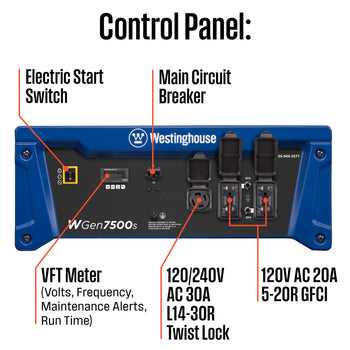

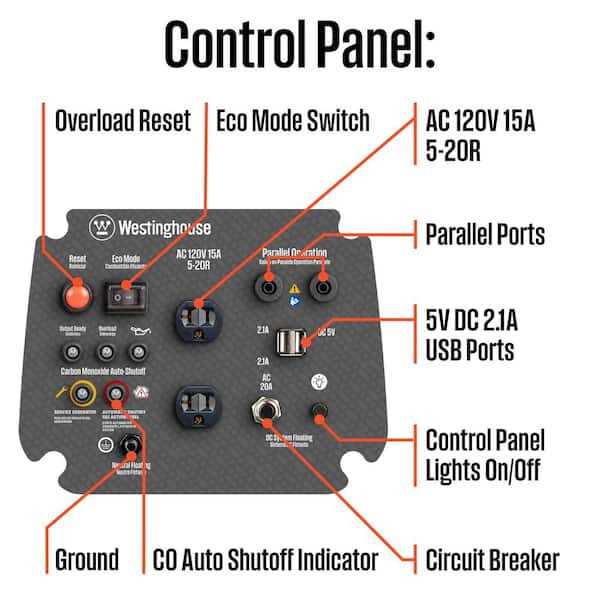

- Control Panel: Manages the operation and provides monitoring functions.

- Starting System: Initiates the engine’s operation, often using batteries.

- Frame: Provides structural support and protects internal components.

- Wiring: Facilitates electrical connections between components.

- Mounting Feet: Stabilizes the unit and minimizes vibrations during operation.

Each of these components plays a significant role in the overall system, ensuring it operates smoothly and effectively for a variety of applications.

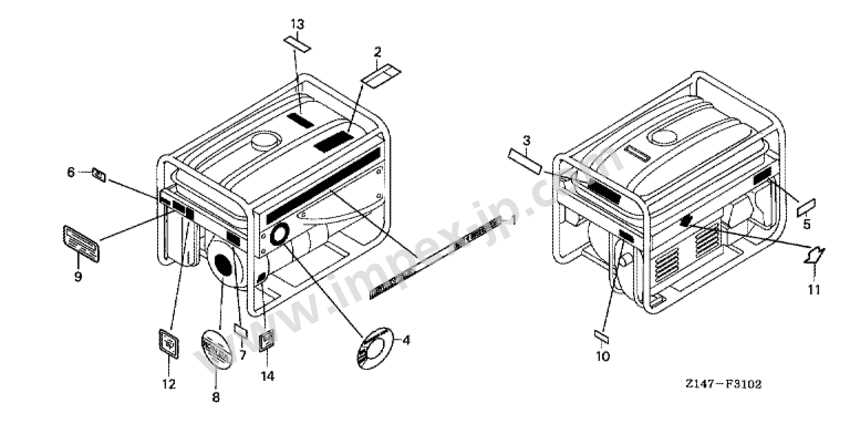

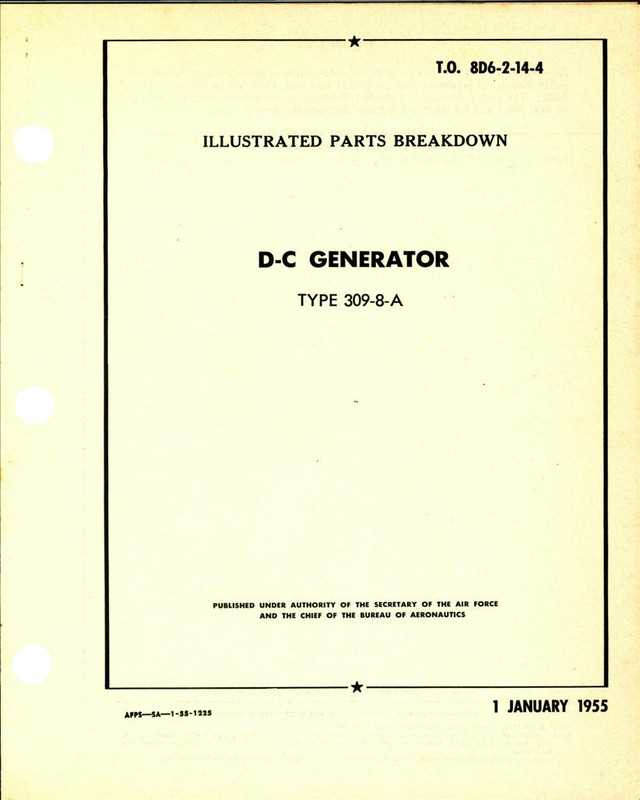

Importance of Parts Diagrams

Understanding the components of complex machinery is crucial for effective maintenance and troubleshooting. Visual representations of these elements provide a clear overview, enabling technicians to identify, locate, and assess the functionality of each part efficiently.

Facilitating Repairs

Having access to accurate schematics can significantly speed up repair processes. It allows technicians to quickly reference the arrangement and connection of various elements, reducing downtime and enhancing productivity.

Enhancing Communication

Clear illustrations improve communication among team members. When everyone can refer to the same visual guide, it minimizes misunderstandings and ensures that tasks are executed accurately.

| Benefits | Description |

|---|---|

| Time Efficiency | Speeds up maintenance and repairs. |

| Accuracy | Reduces the risk of errors during assembly. |

| Training Aid | Assists in educating new technicians. |

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair tasks. These illustrations serve as a roadmap, guiding users through the various elements and their interconnections. Familiarity with this kind of schematic enables efficient troubleshooting and identification of individual pieces.

To start, pay attention to the labeling of each section. Labels often indicate specific functions or categories, making it easier to locate the items you need. Additionally, observe the symbols and lines that connect different components; these typically signify relationships or assembly instructions, helping to clarify how parts work together.

Next, take note of any legends or keys provided alongside the visual. These references can offer critical insights into colors, shapes, or other identifiers used throughout the representation. They are invaluable for interpreting the information accurately.

Finally, practice is key. Familiarizing yourself with the layout and common conventions will enhance your ability to quickly glean necessary details. Over time, you’ll become more adept at navigating these representations, leading to greater efficiency in your repair and maintenance activities.

Common Issues in Generator Parts

Understanding the frequent complications that arise in mechanical systems can significantly enhance performance and longevity. Identifying these challenges early can prevent costly repairs and ensure efficient operation.

Electrical Malfunctions

One prevalent issue involves electrical components failing due to wear or environmental factors. Loose connections can disrupt power flow, leading to reduced efficiency. Corrosion on terminals also poses a significant threat, often resulting in overheating.

Mechanical Wear and Tear

Another common concern is the deterioration of moving elements over time. Insufficient lubrication can lead to increased friction, causing parts to wear out faster than expected. Additionally, vibration damage can create misalignments, further complicating functionality.

Finding Replacement Parts Easily

Locating suitable components for your machinery can often feel daunting. However, with the right approach, you can streamline the process and ensure you get what you need without hassle.

Start by identifying the exact specifications of the components required. Understanding the model and features of your equipment will help narrow down options significantly.

Online marketplaces and specialty suppliers offer a vast selection, often with detailed descriptions and compatibility information. Use filters to refine your search based on your specific requirements.

Additionally, consider joining relevant community forums or groups. Engaging with experienced users can provide insights and recommendations on where to find reliable replacements.

Lastly, don’t overlook local retailers. Many brick-and-mortar stores have knowledgeable staff who can assist in sourcing the necessary components quickly.

Maintenance Tips for Longevity

Ensuring the extended life of your machinery involves regular upkeep and careful attention to detail. By following a consistent maintenance routine, you can significantly reduce wear and tear, enhance performance, and avoid costly repairs. This section outlines essential practices to help you achieve optimal efficiency and durability.

Regular Inspections

Conduct frequent checks on all critical components. Look for signs of wear, leaks, or loose connections. Identifying potential issues early allows for timely intervention, preventing more severe problems down the line. Make it a habit to examine fluid levels and filters, as these are vital for smooth operation.

Cleanliness and Lubrication

Keep the equipment clean to avoid debris buildup that can hinder performance. Regularly clean exterior surfaces and ensure that vents are free from obstructions. Additionally, applying the appropriate lubricants to moving parts will minimize friction and prolong the lifespan of essential components.

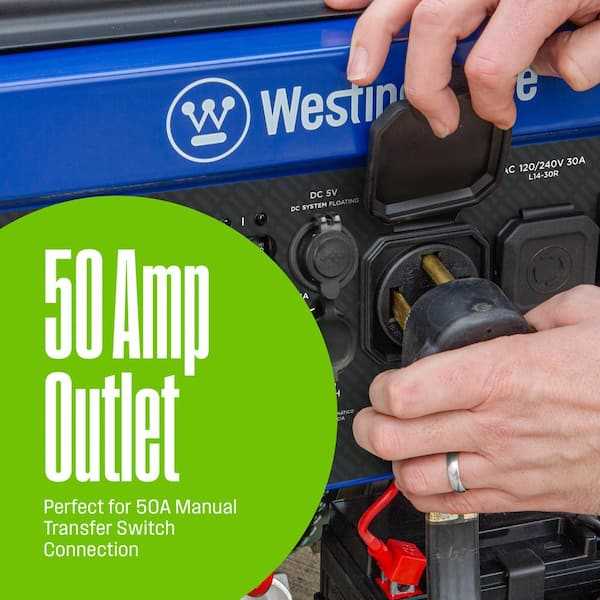

Comparing Different Westinghouse Models

This section delves into the diverse range of models offered by a renowned manufacturer, focusing on their unique features, capabilities, and intended applications. Understanding these differences is crucial for users to select the most suitable option for their specific needs.

When evaluating various units, several key aspects can be considered:

- Power Output: Different models provide varying wattage levels, catering to both small-scale and larger power demands.

- Fuel Type: Some units operate on gasoline, while others may use propane or diesel, affecting efficiency and availability.

- Portability: The weight and design impact how easily the devices can be transported and set up in different locations.

- Noise Levels: Certain options are designed to operate quietly, making them ideal for residential use or sensitive environments.

- Durability: Construction materials and design influence the longevity and resilience of each model in various conditions.

By carefully considering these factors, users can make informed decisions tailored to their requirements. Each option offers distinct advantages, ensuring a suitable choice for every application.

In conclusion, comparing the various offerings allows users to leverage the best features and capabilities suited to their specific tasks, enhancing overall satisfaction and performance.

Resources for Further Learning

Expanding your knowledge on machinery and its components can greatly enhance your understanding of complex systems. This section provides various avenues for acquiring deeper insights, from online tutorials to specialized publications. Engaging with these resources will help you develop a well-rounded perspective and improve your practical skills.

For those interested in comprehensive guides, many online platforms offer detailed articles and video tutorials. Websites dedicated to engineering and technical education often include interactive modules that can reinforce your learning experience. Additionally, forums and community groups provide spaces for discussions, where you can ask questions and share knowledge with peers.

Books and manuals authored by industry experts are invaluable for in-depth study. These resources typically cover a wide range of topics, including troubleshooting, maintenance, and best practices. Local libraries or online bookstores can be excellent places to find these references.

Attending workshops or seminars can also significantly enhance your expertise. These events allow for hands-on experience and direct interaction with professionals, making them ideal for practical learning. Networking with others in the field can lead to additional resources and opportunities for collaboration.

Finally, many manufacturers and suppliers provide technical documentation and support. Accessing these materials can offer specific insights tailored to particular models or systems, ensuring you have the most relevant information at your fingertips.