Understanding the internal mechanisms of fishing gear can significantly enhance both its use and maintenance. By familiarizing yourself with the key elements of the system, you can ensure optimal performance, avoid common malfunctions, and improve your overall fishing experience.

This article provides a detailed look at the essential elements found in typical fishing tools, breaking down their structure and function. Whether you are a beginner or a seasoned angler, a deeper understanding of these components can lead to more efficient equipment handling and longer-lasting durability.

In the following sections, we will delve into the specific features of these mechanisms, helping you to identify and properly care for each part. By doing so, you will be able to maintain your fishing equipment with greater ease and confidence.

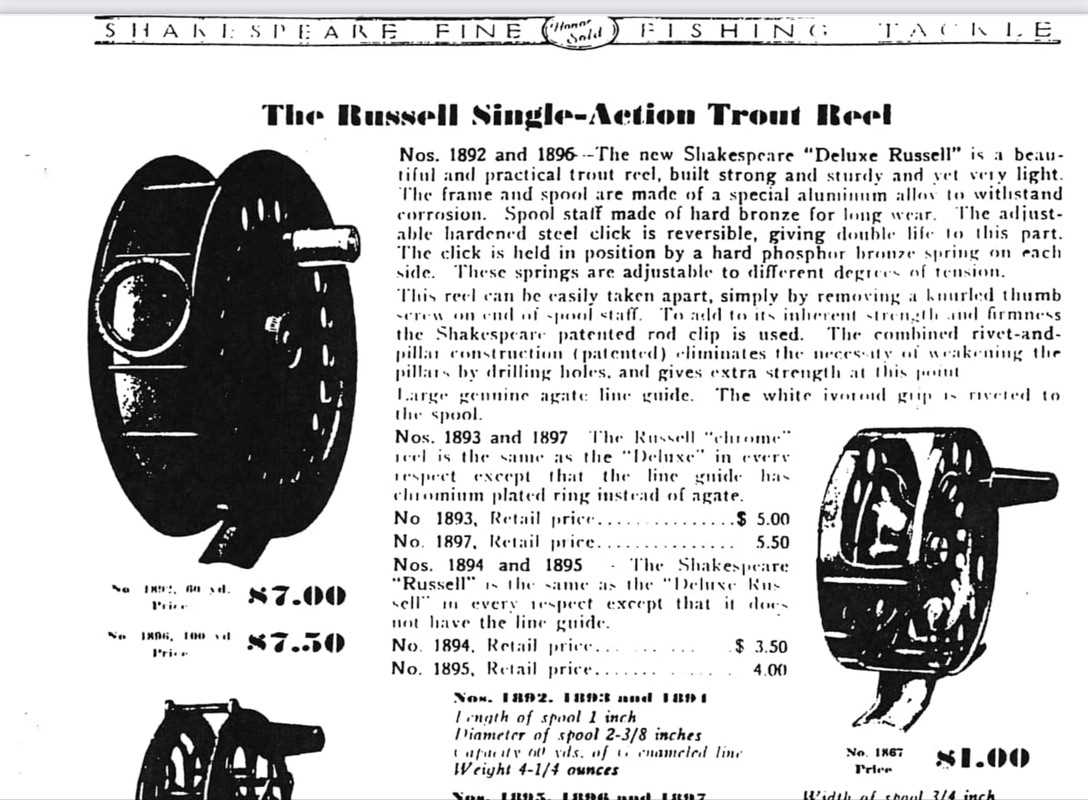

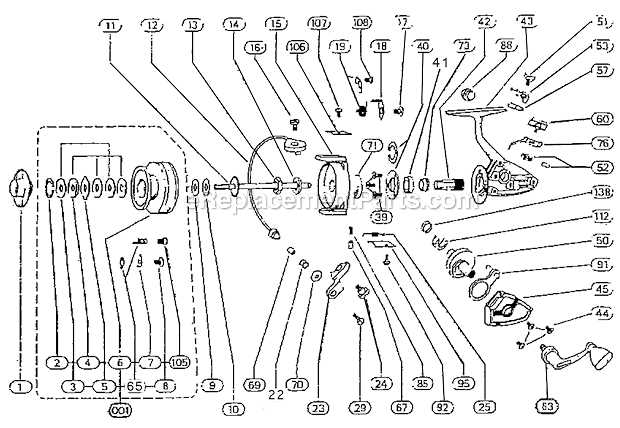

Shakespeare Reel Parts Diagram Overview

Understanding the intricate mechanisms of angling equipment can enhance performance and maintenance. By exploring the individual elements that make up the entire assembly, one gains insight into the structure and function of these essential components. This knowledge proves invaluable for enthusiasts aiming to optimize their fishing experience.

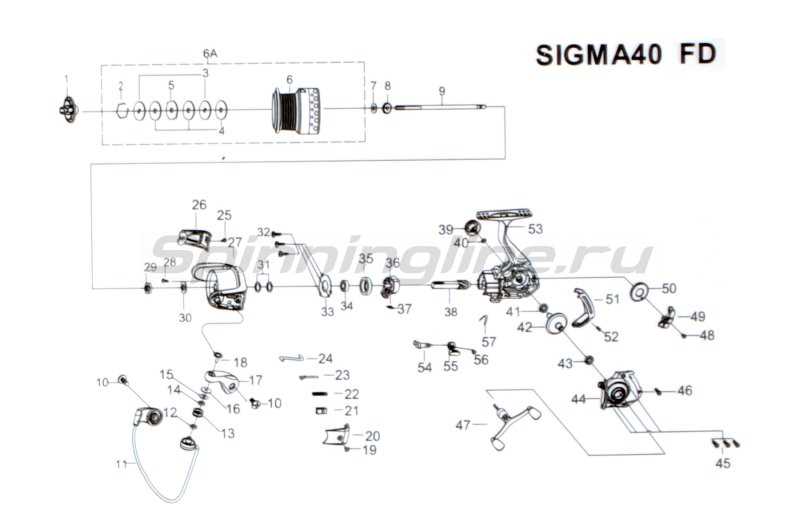

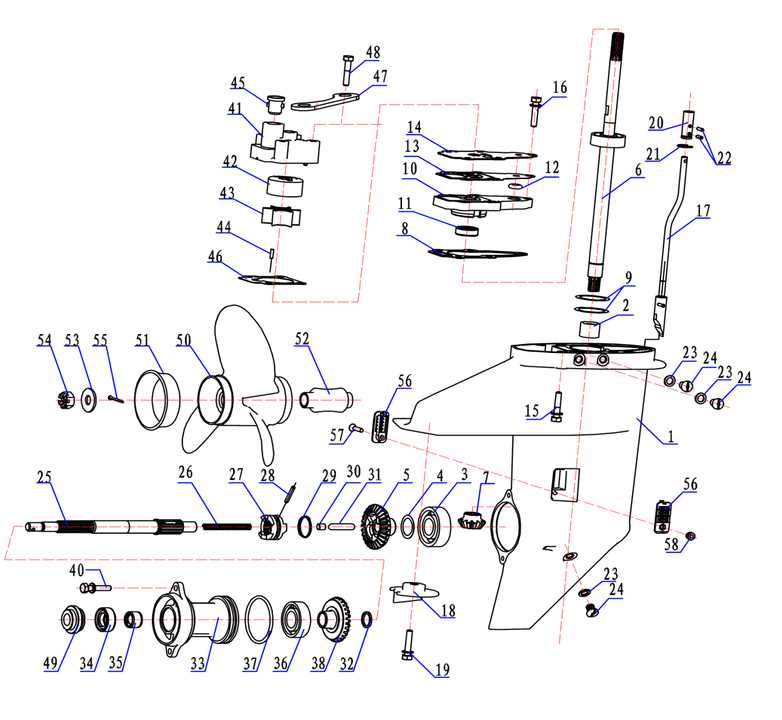

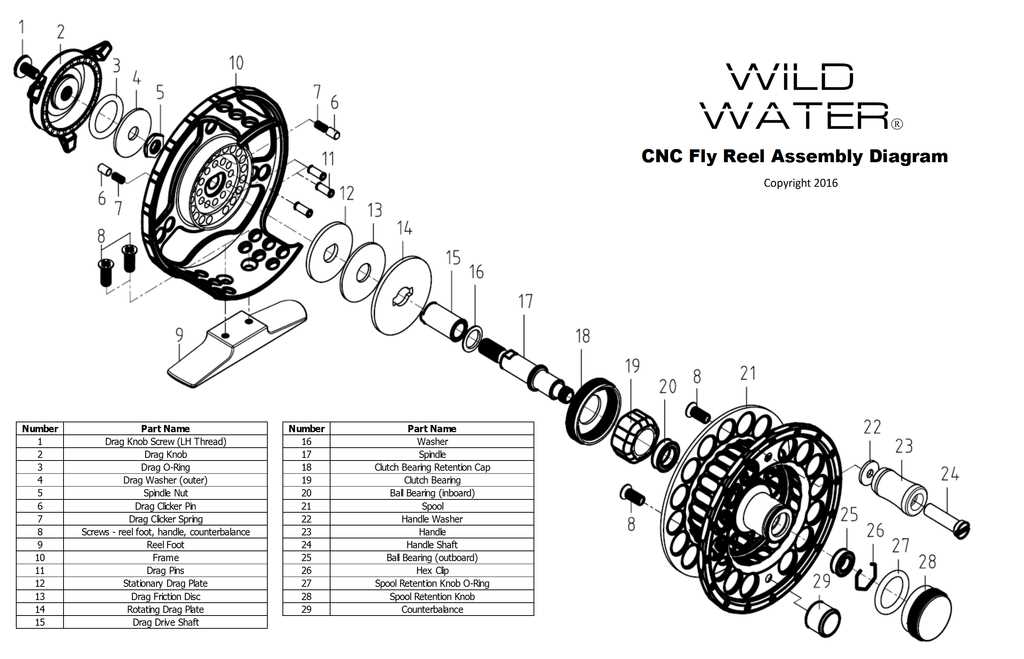

Core Components Breakdown

The mechanical system consists of various interconnected elements, each playing a vital role in the overall operation. From the rotating mechanism to the drag system, every piece is designed to ensure smooth and efficient functionality. These parts work in harmony to provide the necessary tension, stability, and control during use.

Detailed Element Chart

| Component | Function | ||||

|---|---|---|---|---|---|

| Handle | Allows for manual control and rotation | ||||

| Spool | Holds the line and enables it to unwind smoothly | ||||

| Component | Function |

|---|---|

| Handle | Provides grip and leverage for rotation |

| Crank | Converts rotational force into motion |

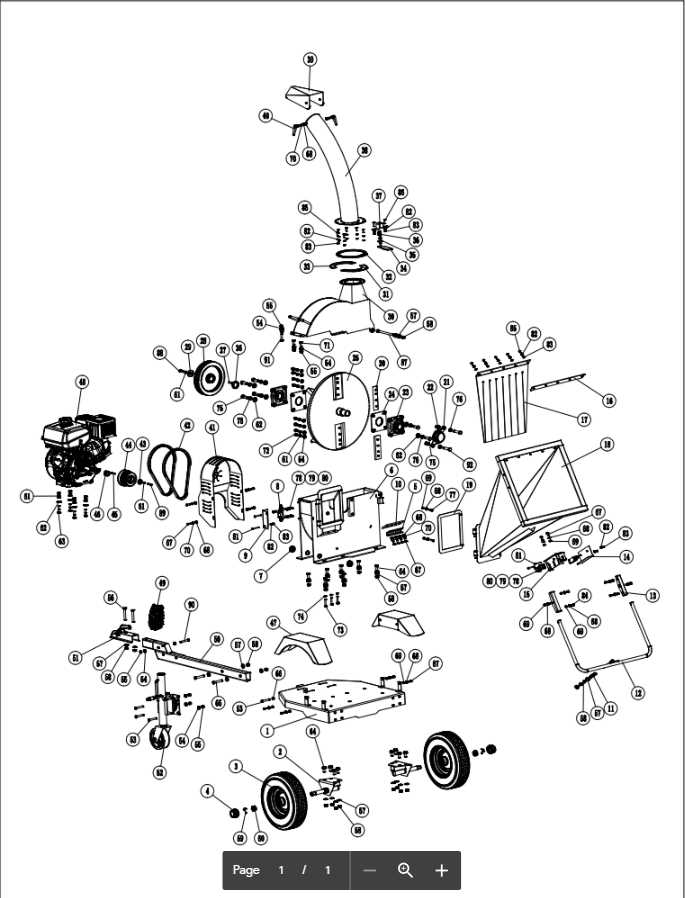

Detailed Breakdown of Spool Parts

This section offers a comprehensive examination of the individual components involved in the functionality of a fishing mechanism. Understanding the configuration and role of each element is essential for enhancing performance and ensuring smooth operation during use.

Key Components and Their Functions

Each element within this assembly plays a vital role in the overall effectiveness of the device. The primary components typically include the housing, which provides structural integrity; the spool, which holds the line; and the drag system, which manages the resistance during a catch. Additionally, the handle and gear system facilitate easy retrieval and control.

Maintenance and Care Tips

Proper maintenance of these elements is crucial for longevity. Regular cleaning of the housing and spool prevents debris buildup, while lubricating the gear system ensures smooth functionality. Periodically checking the drag mechanism for wear will also help maintain optimal performance during fishing activities.

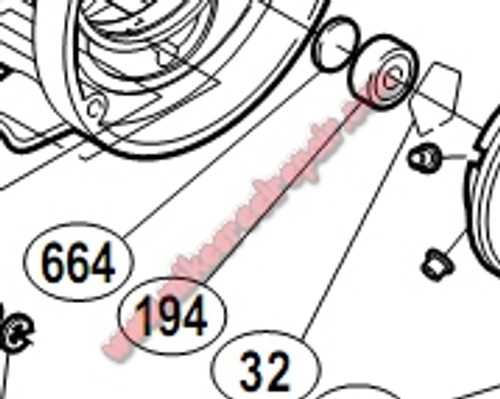

The Role of Bearings in Smooth Operation

In the realm of mechanical devices, components that facilitate rotation play a crucial role in ensuring seamless functionality. These elements are designed to minimize friction and wear, thereby enhancing overall efficiency and longevity. Their importance cannot be overstated, as they serve as the backbone of smooth operation in various machinery.

Bearings provide essential support for moving parts, allowing them to rotate freely without excessive resistance. This functionality not only improves performance but also contributes to the reliability of the system. Effective design and placement of these components are vital for optimal operation, as they help maintain alignment and reduce the risk of failure during use.

Additionally, the choice of materials used in these supporting structures can significantly impact durability and performance. High-quality options are often selected to withstand the pressures and stresses encountered during operation. Understanding the mechanics behind these components leads to better maintenance practices, ultimately prolonging the life of the entire system.

Line Guide Assembly and Its Importance

The line guide assembly plays a crucial role in the functionality of fishing equipment, serving as a pivotal component that influences performance and user experience. This assembly ensures that the fishing line is properly aligned and evenly distributed during casting and retrieval, which significantly impacts the overall efficiency of the gear.

Proper alignment of the line is essential for preventing tangles and ensuring smooth operation. When the line guide assembly is designed effectively, it minimizes friction and wear, extending the lifespan of the line and enhancing the angler’s ability to manage their tackle with precision. Moreover, a well-functioning assembly contributes to greater casting distance and accuracy, allowing enthusiasts to reach their desired fishing spots more effortlessly.

In summary, understanding the significance of the line guide assembly is vital for both novice and experienced anglers. By recognizing its importance, users can make informed choices when selecting and maintaining their fishing equipment, ultimately leading to more successful outings on the water.

Troubleshooting Common Issues with Reel Parts

When engaging with fishing gear, it’s not uncommon to encounter various challenges that can impact performance. Understanding how to identify and address these concerns is essential for maintaining the functionality of your equipment. By being proactive and knowledgeable, you can enhance your fishing experience and ensure that your gear operates smoothly.

One frequent issue is the occurrence of unusual noises during operation. These sounds can indicate internal wear or misalignment. If you hear grinding or clicking noises, it’s advisable to inspect the internal components carefully. Ensure that everything is properly lubricated and that there are no foreign objects obstructing movement.

Another common problem involves difficulty in retrieving line. This may stem from a malfunctioning mechanism or entanglements in the line itself. Check for any tangles or knots that might be causing resistance. Additionally, assess the winding system to ensure it is functioning as intended. If the winding is uneven or inconsistent, it may require adjustment or replacement.

Lastly, maintaining the integrity of seals and gaskets is crucial. Deterioration in these components can lead to water ingress, which may damage internal mechanisms. Regularly inspect seals for cracks or wear, and replace them as necessary to prevent potential issues.