In the realm of machinery, particularly in the field of compressed air systems, comprehending the intricate arrangements of individual elements is vital for both maintenance and efficient operation. A thorough exploration of these configurations enables users to identify components easily and troubleshoot potential issues effectively.

Every assembly consists of various sections, each playing a crucial role in the overall functionality of the unit. By familiarizing oneself with the layout, operators can enhance their understanding of how these segments interact, thus optimizing performance and ensuring longevity.

Additionally, a clear representation of these components aids in the procurement of replacements and upgrades, facilitating smoother repairs. This knowledge empowers technicians and enthusiasts alike to delve deeper into the mechanics of their devices, ensuring that each part functions harmoniously within the system.

Understanding Ingersoll Rand SS3

The equipment in question is renowned for its reliability and efficiency in various applications. Its design is aimed at providing robust performance, making it a preferred choice for many professionals in the industry. This section will delve into the essential components and their functions, ensuring users can maximize the utility of this machinery.

Key Features: The primary characteristics of this equipment include its durable construction and user-friendly operation. Each element plays a crucial role in the overall performance, contributing to seamless functionality. Understanding these attributes allows users to appreciate the engineering excellence behind the machinery.

Maintenance and Care: Regular upkeep is vital for ensuring longevity and optimal performance. Familiarity with the various components and their maintenance needs can prevent common issues and extend the lifespan of the unit. Emphasizing proper care practices will enhance user experience and operational efficiency.

In summary, a comprehensive understanding of this machinery not only aids in its effective use but also enhances the overall productivity of the tasks at hand. Familiarity with its core components and maintenance practices is essential for anyone looking to leverage its full potential.

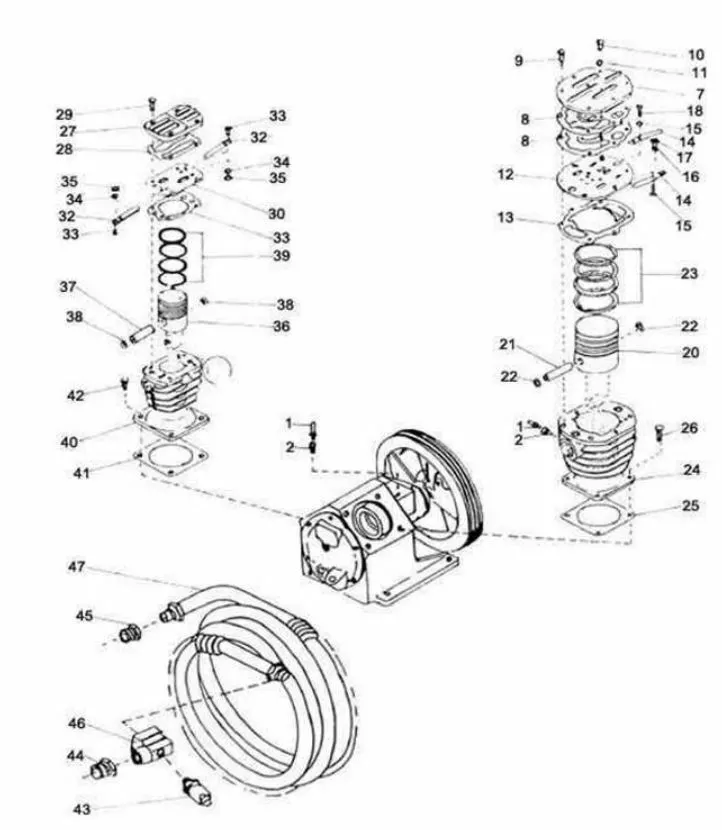

Components of SS3 Air Compressor

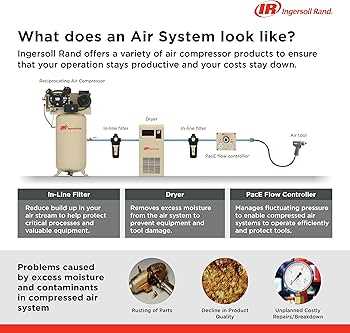

The effective operation of an air compression system relies on various integral elements that work in harmony. Understanding these components is crucial for maintenance, troubleshooting, and optimizing performance. Each part contributes to the overall efficiency and reliability of the machine.

Main Components

The primary elements of an air compressor include the motor, pump, and storage tank. The motor powers the pump, which compresses air and delivers it to the tank for storage. This fundamental interaction enables the system to generate compressed air as needed for various applications.

Additional components enhance the functionality and safety of the compressor. These features include pressure switches, regulators, and filters, which ensure stable pressure levels and clean air output. Regular maintenance of these parts is essential for optimal performance.

| Component | Function |

|---|---|

| Motor | Powers the pump for air compression |

| Pump | Compresses air and delivers it to the tank |

| Storage Tank | Holds compressed air for use |

| Pressure Switch | Controls the compressor’s operation based on pressure levels |

| Regulator | Maintains desired air pressure output |

| Filter | Removes contaminants from the air supply |

Common Issues and Solutions

Maintaining equipment can often lead to various challenges that may affect performance and longevity. Understanding the typical problems and their remedies is essential for ensuring smooth operation. Below are some frequently encountered issues along with practical solutions that can help restore efficiency.

Pressure Fluctuations

One common problem is the inconsistency in pressure levels. This can be caused by leaks in the system or worn components. To address this, inspect all connections and seals for any signs of wear or damage. Replacing faulty parts and ensuring all fittings are tight can significantly improve pressure stability.

Noisy Operation

Unusual sounds during operation can indicate underlying issues, such as misaligned parts or insufficient lubrication. To resolve this, check for any misalignments in the motor and housing. Additionally, ensure that all moving parts are adequately lubricated according to the manufacturer’s specifications. If the noise persists, further investigation into bearings and internal components may be necessary.

Importance of Regular Maintenance

Consistent upkeep of machinery is crucial for ensuring optimal performance and longevity. By prioritizing maintenance, operators can prevent potential issues that may arise from neglect.

- Enhances Efficiency: Regular checks help in identifying inefficiencies and correcting them.

- Extends Lifespan: Routine care can significantly prolong the life of equipment.

- Reduces Downtime: Preventive maintenance minimizes unexpected breakdowns.

- Ensures Safety: Well-maintained machines are less likely to pose safety risks.

- Improves Reliability: Consistent service builds trust in machinery performance.

Incorporating a maintenance schedule not only boosts productivity but also leads to cost savings in the long run.

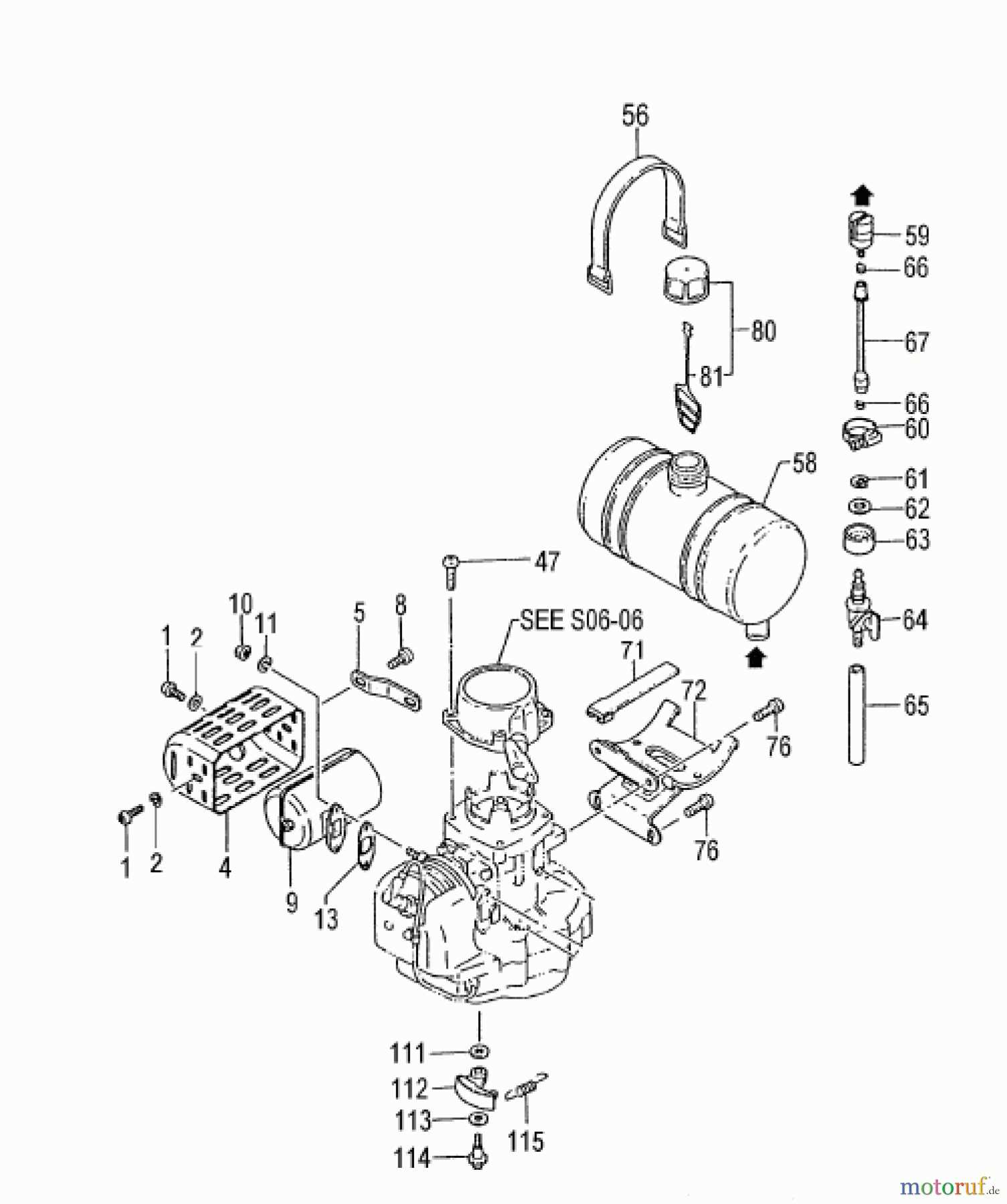

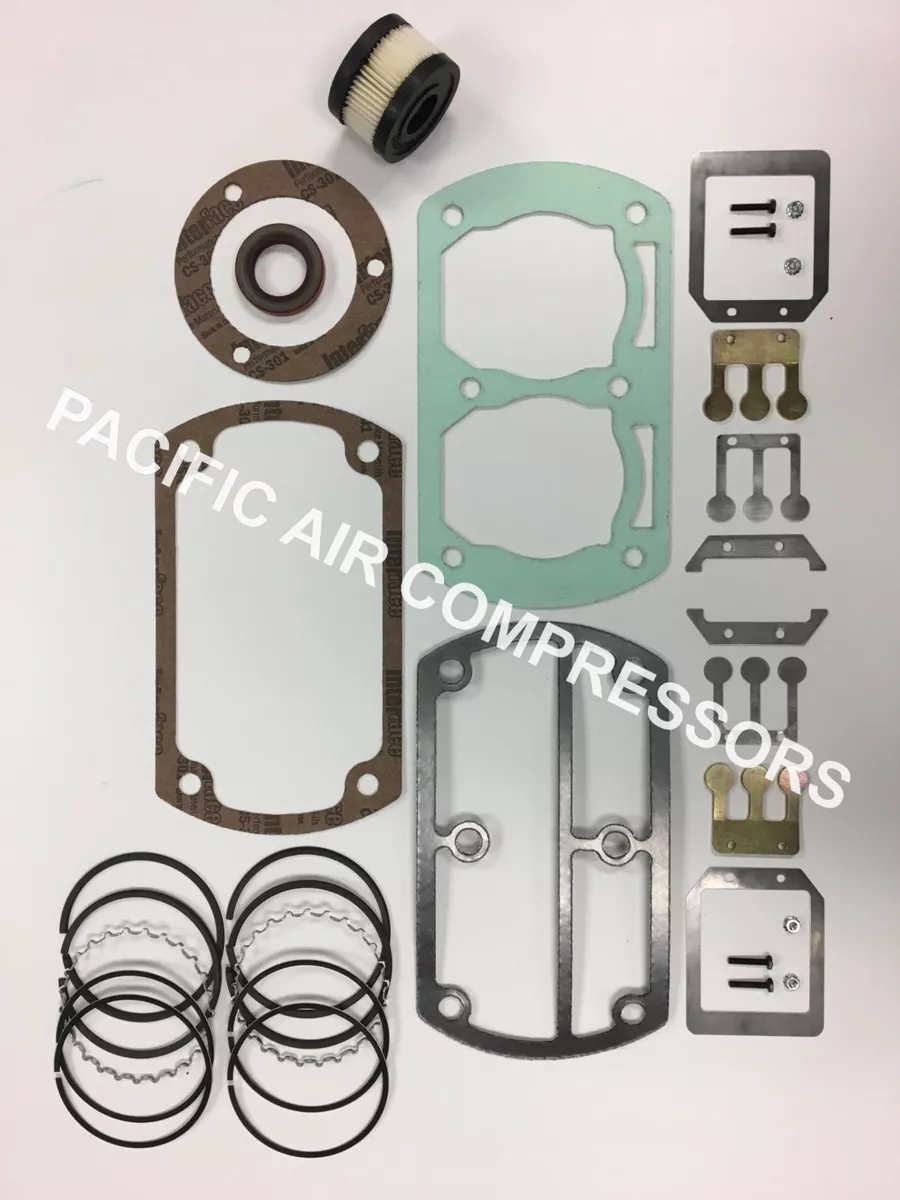

Identifying Replacement Parts

When maintaining complex machinery, recognizing the components that require substitution is crucial for optimal performance. Understanding the specific elements of your equipment helps ensure that you can effectively source replacements when necessary, minimizing downtime and maintaining efficiency.

Common Components and Their Functions

Every mechanical system comprises various elements, each serving a distinct purpose. Familiarity with these components allows for quick identification of any that may need replacement. Essential parts often include seals, valves, and filters, which play vital roles in the overall functionality. Knowing the specific type of each element is important for ensuring compatibility with your system.

Using Reference Materials for Assistance

Utilizing manuals and visual references can greatly aid in pinpointing the necessary replacements. These resources typically include detailed descriptions and illustrations, which can enhance your understanding of each component’s placement and function. Additionally, consulting with suppliers or experts can provide further insights, ensuring that you select the right replacements that meet your equipment’s requirements.

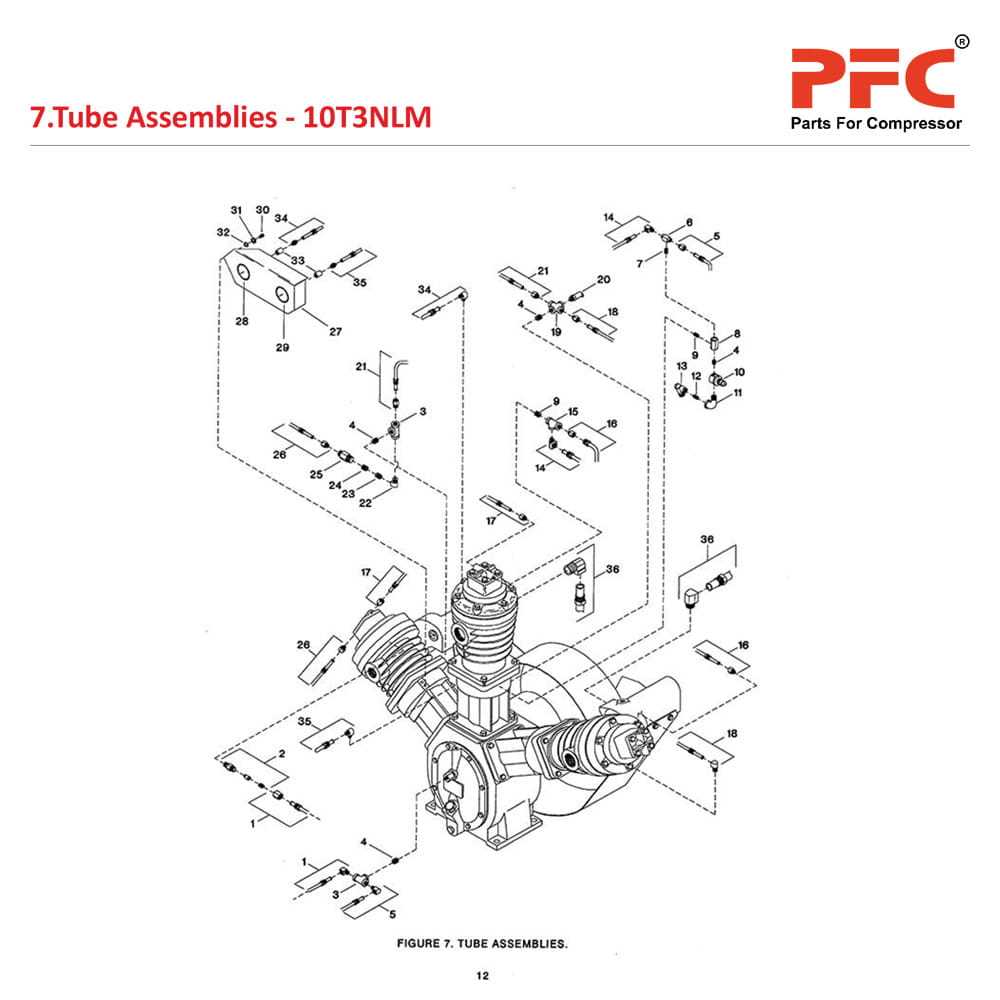

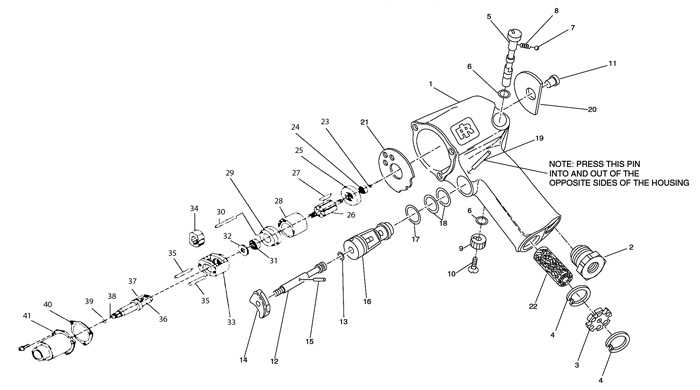

How to Read Parts Diagrams

Understanding a visual representation of components is crucial for effective maintenance and repair. It helps users identify specific elements, their arrangements, and relationships within a system.

To effectively interpret these illustrations, follow these key steps:

- Familiarize with Symbols: Learn common icons and notations used to represent different elements.

- Identify Key Sections: Focus on major components and their connections within the layout.

- Reference the Legend: Use the accompanying key to understand specific markings and designations.

- Follow the Flow: Analyze the directional arrows and lines to comprehend the movement and functionality of each part.

By applying these strategies, you can effectively navigate through technical visuals and enhance your understanding of mechanical systems.

Benefits of Using Genuine Parts

Opting for authentic components in your machinery not only enhances performance but also ensures longevity and reliability. These elements are meticulously designed to meet stringent quality standards, contributing to optimal functionality and minimizing the risk of malfunctions.

| Benefit | Description |

|---|---|

| Quality Assurance | Authentic components undergo rigorous testing, ensuring they meet high-quality benchmarks. |

| Compatibility | Designed specifically for your equipment, genuine parts guarantee perfect fit and operation. |

| Longevity | Using original components reduces wear and tear, leading to longer equipment lifespan. |

| Warranty Protection | Many manufacturers offer warranties when using their certified components, providing peace of mind. |

| Performance Optimization | Authentic parts are engineered for maximum efficiency, ensuring your machinery runs at its best. |

Comparing SS3 to Other Models

When evaluating various models within the same category, it’s essential to understand their distinct features and performance capabilities. This comparison allows potential users to make informed decisions based on their specific needs and preferences.

Several key factors can be assessed when juxtaposing these models:

- Power Output: Different units offer varying horsepower ratings, affecting their efficiency and suitability for specific tasks.

- Size and Portability: Some models are designed for easy transportation, while others prioritize durability and stability.

- Noise Levels: Sound output can be a critical consideration, particularly in residential or noise-sensitive environments.

- Maintenance Requirements: The frequency and complexity of maintenance tasks can vary significantly among different models.

- Cost Efficiency: Evaluating the initial purchase price alongside long-term operational costs can guide budget-conscious consumers.

By analyzing these aspects, users can determine which model aligns best with their operational demands, ensuring optimal performance and satisfaction.

Resources for Further Learning

Expanding your knowledge on specific equipment and its components can significantly enhance your understanding and skills in maintenance and repair. There are various avenues to explore that provide valuable insights, from manuals to online forums. Below is a curated list of resources that can help you deepen your expertise.

| Resource Type | Description | Link |

|---|---|---|

| User Manuals | Official documentation detailing specifications, maintenance procedures, and troubleshooting tips. | Visit Manuals |

| Online Forums | Communities where users share experiences, advice, and solutions related to equipment and repairs. | Join Forums |

| Video Tutorials | Step-by-step guides demonstrating repair techniques and maintenance practices. | Watch Tutorials |

| Workshops | Hands-on training sessions that provide practical experience and expert insights. | Find Workshops |

| Books | Comprehensive literature covering a wide range of topics related to machinery and maintenance. | Explore Books |