The effective functioning of flow control systems relies on a variety of interconnected elements, each serving a specific purpose. Grasping how these components work together is essential for achieving optimal performance and reliability in various applications. This section delves into the fundamental aspects of these essential building blocks, providing insights into their roles and significance.

From the foundational structures that ensure stability to the intricate mechanisms that regulate operations, the complexity of these systems is often overlooked. By exploring the various functions and interactions of each element, one can appreciate the sophistication involved in their design. Understanding this interconnectedness is key to mastering the nuances of flow control.

As we navigate through the essential components, we will uncover the practical applications and benefits they bring to both simple and complex systems. This exploration not only enhances comprehension but also aids in identifying potential areas for improvement and innovation within existing frameworks.

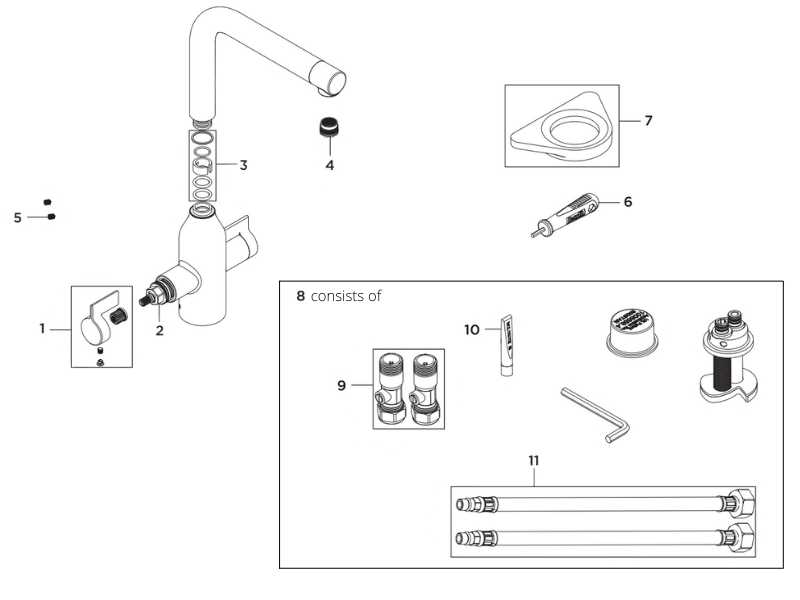

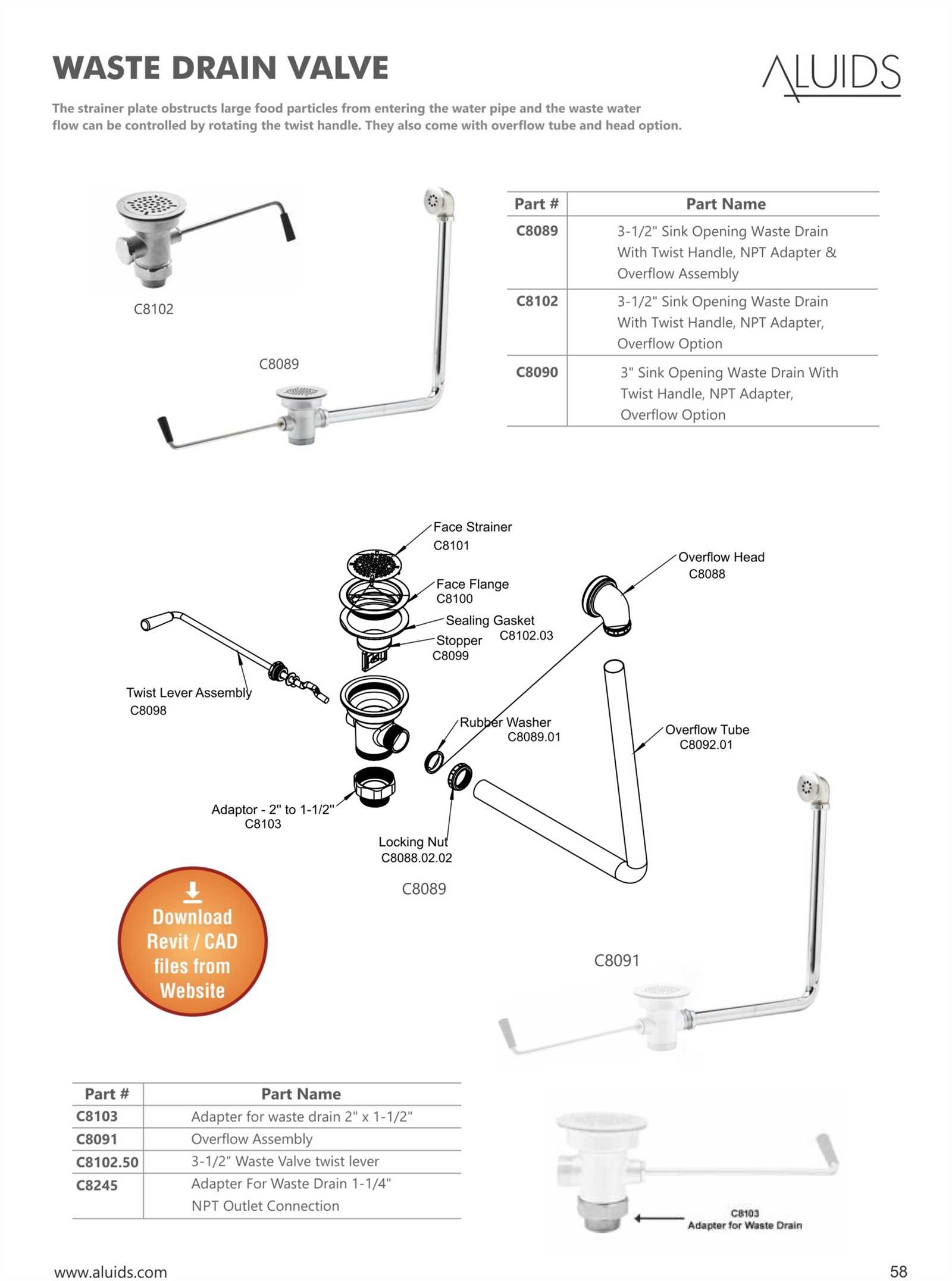

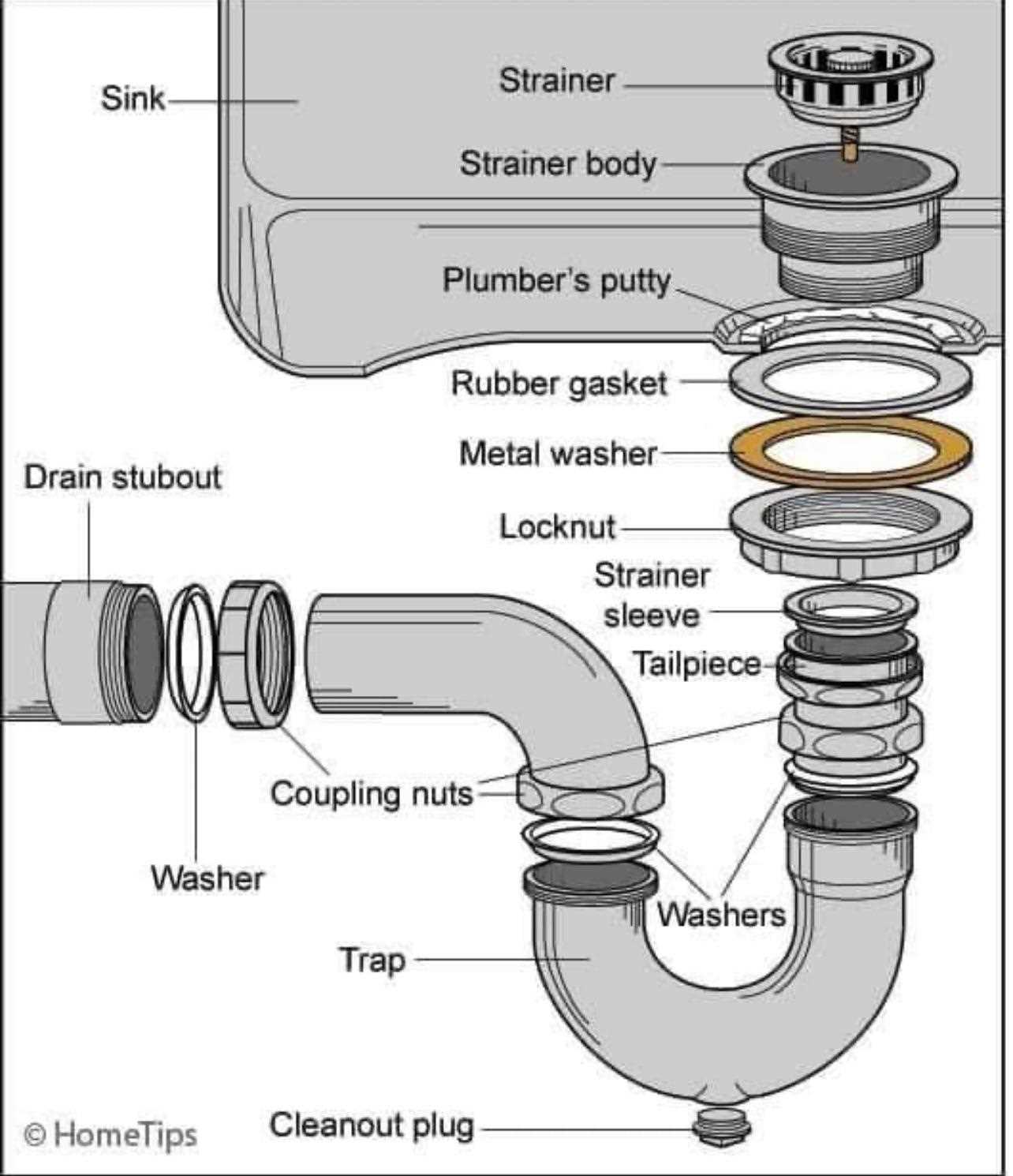

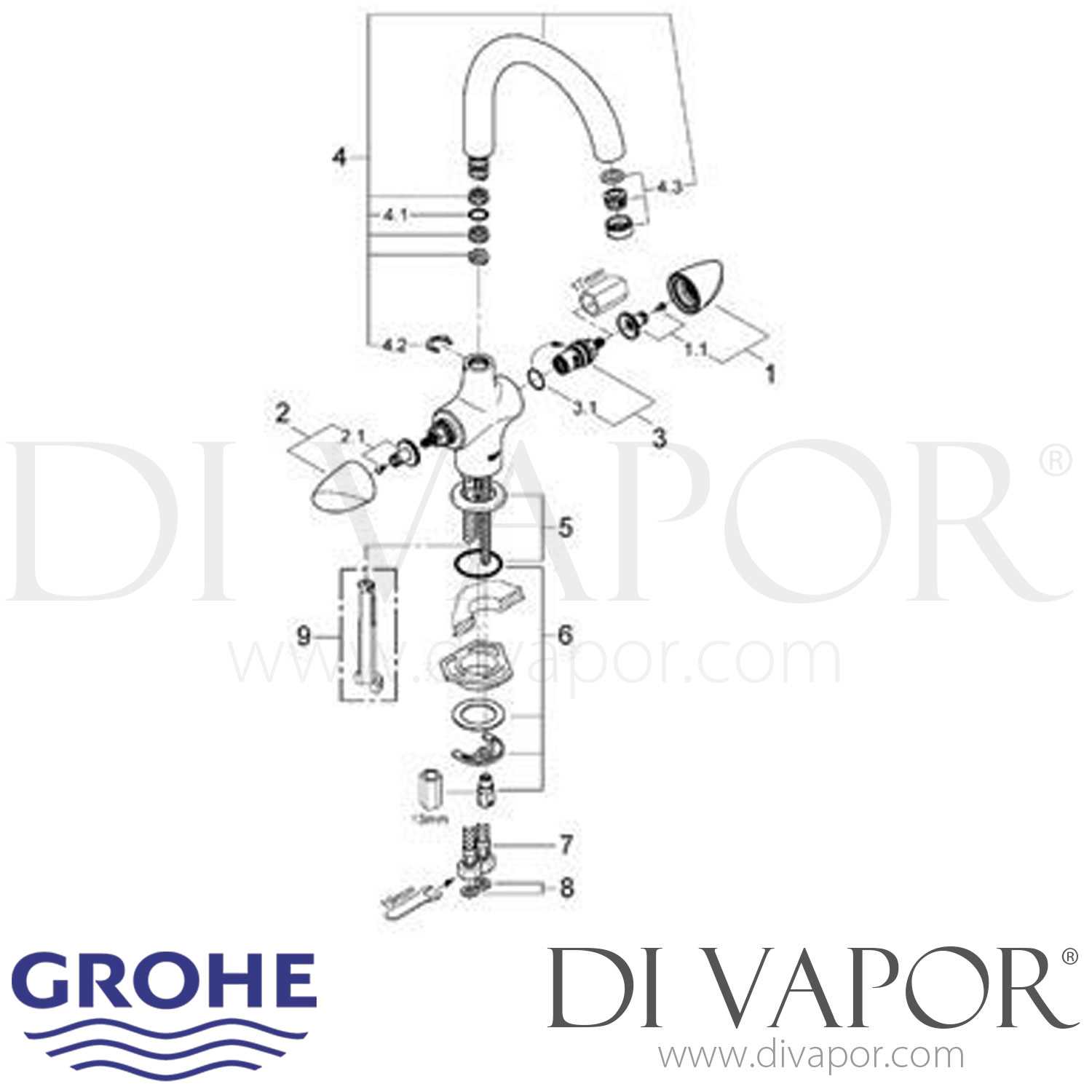

Essential Elements of a Sink Diagram

Understanding the fundamental components of a fluid management representation is crucial for effective design and functionality. These elements work together to ensure proper operation and efficiency in various systems. By examining each key aspect, one can gain insights into how they contribute to the overall process.

One of the primary components is the flow representation, which illustrates the movement of liquids within the system. This feature is vital for assessing how resources are directed and utilized. Another important element is the connection points, which indicate where various segments interface with each other, facilitating seamless integration.

Additionally, control mechanisms play a significant role in regulating flow and ensuring safety measures are in place. These mechanisms can vary, ranging from manual valves to automated systems, all designed to enhance operational reliability. Lastly, measurement indicators provide essential data on performance, enabling adjustments to be made as needed for optimal function.

Materials Used in Sink Construction

When it comes to the creation of basin fixtures, the selection of materials plays a crucial role in determining their durability, aesthetics, and functionality. Various substances are utilized to ensure that these essential components meet the demands of everyday use while also enhancing the overall design of a kitchen or bathroom environment.

Common Materials

Among the most prevalent materials for these fixtures are stainless steel, porcelain, and composite options. Stainless steel is favored for its resistance to rust and corrosion, making it ideal for high-moisture areas. Porcelain, known for its sleek and glossy finish, offers a classic appeal, while composite materials provide versatility and can mimic the look of natural stone without the associated weight.

Innovative Alternatives

In recent years, innovative materials such as solid surface and granite have gained popularity. Solid surface materials offer seamless designs and are easily repairable, while granite provides a luxurious and robust option that adds a touch of elegance. These alternatives not only contribute to the aesthetic appeal but also enhance the longevity and performance of the fixtures.

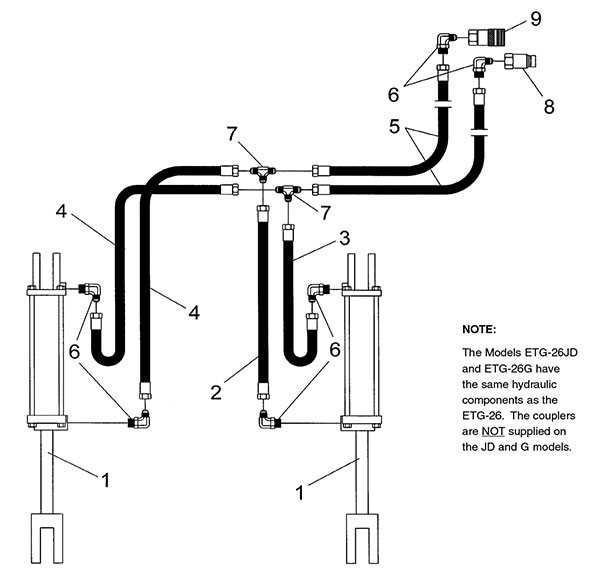

Common Configurations and Designs

In the realm of hydraulic systems, various arrangements and structures play a vital role in ensuring efficient performance. Understanding these configurations allows for optimal functionality and adaptability in diverse applications. Each setup serves unique purposes, influenced by the specific requirements of the system.

Several prevalent arrangements are commonly utilized in these systems:

- Parallel Configuration: This design allows multiple units to operate simultaneously, distributing the workload evenly.

- Series Arrangement: In this setup, components are connected sequentially, enabling a step-by-step flow of fluids.

- Modular Design: This approach utilizes interchangeable modules, facilitating easy upgrades and repairs.

- Custom Layouts: Tailored configurations that meet specific operational demands and spatial constraints.

Each of these designs presents its own advantages and challenges, making it essential to select the appropriate configuration based on the intended application. By analyzing the specific needs and constraints, one can effectively implement the most suitable design for any hydraulic system.

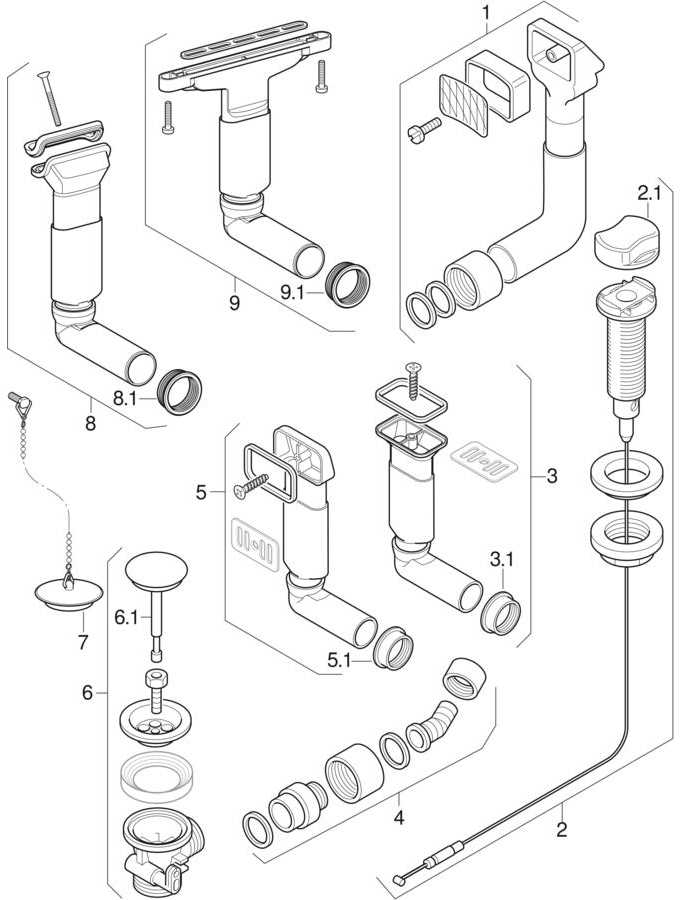

Connecting Pipes and Fixtures

Establishing a reliable connection between various conduits and components is crucial for ensuring the smooth flow of water and the efficient operation of household systems. Properly integrating these elements contributes to both functionality and durability, allowing for seamless usage over time.

Types of Connections

Several connection methods are commonly used to link conduits and fixtures. Each method has its advantages and disadvantages, depending on factors such as space availability, accessibility, and the specific requirements of the installation. Here are some popular techniques:

- Soldering: A robust option that uses heat to bond metal pipes, creating a strong and lasting joint.

- Threaded Connections: Ideal for disassembly, these joints utilize threads to secure pipes together, making maintenance easier.

- Compression Fittings: Often employed in tight spaces, these fittings enable quick and easy assembly without the need for special tools.

Sealing and Insulation

Ensuring that connections are both sealed and insulated is essential for preventing leaks and maintaining temperature. Utilizing appropriate sealing materials, such as plumber’s tape or thread sealant, can provide an effective barrier against leaks. Additionally, insulating exposed sections can help in minimizing heat loss, enhancing overall efficiency.

Maintenance Tips for Sink Parts

Regular upkeep is essential for ensuring the longevity and proper functioning of your plumbing fixtures. By following a few simple guidelines, you can prevent common issues and maintain optimal performance over time.

Routine Cleaning

Keeping the components clean is fundamental to avoiding blockages and corrosion. Here are some effective practices:

- Wipe surfaces with a soft cloth to remove residue and prevent buildup.

- Use mild detergents or vinegar solutions for deeper cleaning, ensuring all areas are reached.

- Avoid abrasive cleaners that may scratch or damage finishes.

Periodic Inspections

Regular inspections can help identify potential problems before they escalate. Consider the following:

- Check for leaks around joints and connections.

- Inspect seals and gaskets for wear and tear.

- Examine fixtures for any signs of rust or corrosion.

By implementing these maintenance strategies, you can enhance the performance and durability of your plumbing fixtures, ultimately leading to a more efficient and enjoyable experience.

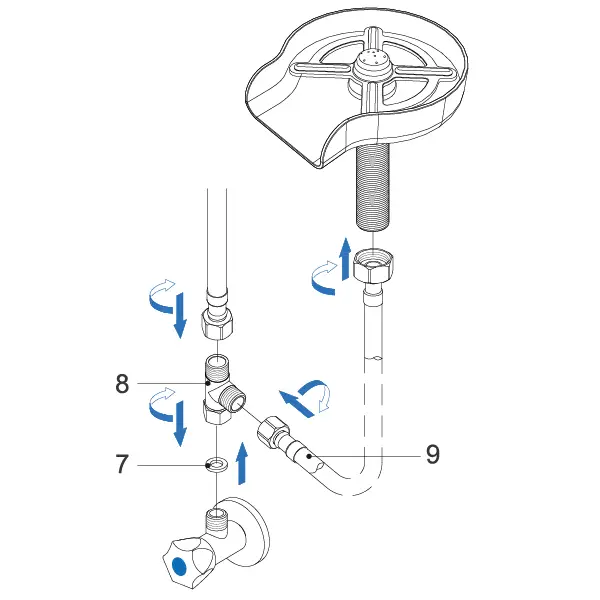

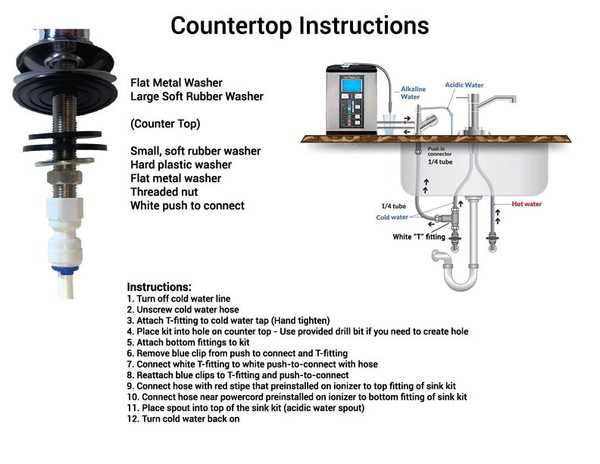

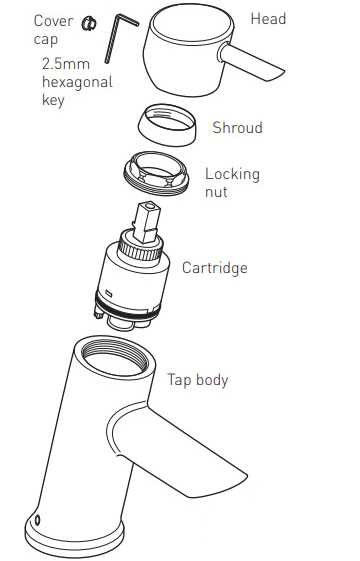

Installation Procedures for New Sinks

Proper installation of a new basin is crucial for ensuring functionality and longevity. This process involves careful planning, precise execution, and the right tools to create a seamless fit. Below are the steps to guide you through the installation, ensuring a successful outcome.

Preparation and Tools

Before beginning, gather all necessary tools and materials. Preparation is key, and ensuring you have everything on hand will streamline the process. The following table lists the essential tools required for this installation:

| Tool | Purpose |

|---|---|

| Adjustable Wrench | To tighten or loosen nuts and bolts |

| Screwdriver | For securing fixtures and fittings |

| Plumber’s Putty | To create watertight seals |

| Level | To ensure even placement |

| Measuring Tape | For accurate measurements |

Step-by-Step Installation

Once preparations are complete, follow these steps for a successful setup:

- Measure the area where the new basin will be installed to ensure a proper fit.

- Prepare the installation site by cleaning the surface and removing any old fittings.

- Apply plumber’s putty around the edges of the new unit to create a seal.

- Carefully position the basin and press it down into place, ensuring it is level.

- Connect the plumbing and secure all fixtures, double-checking for leaks.

- Test the installation by running water to confirm everything functions correctly.

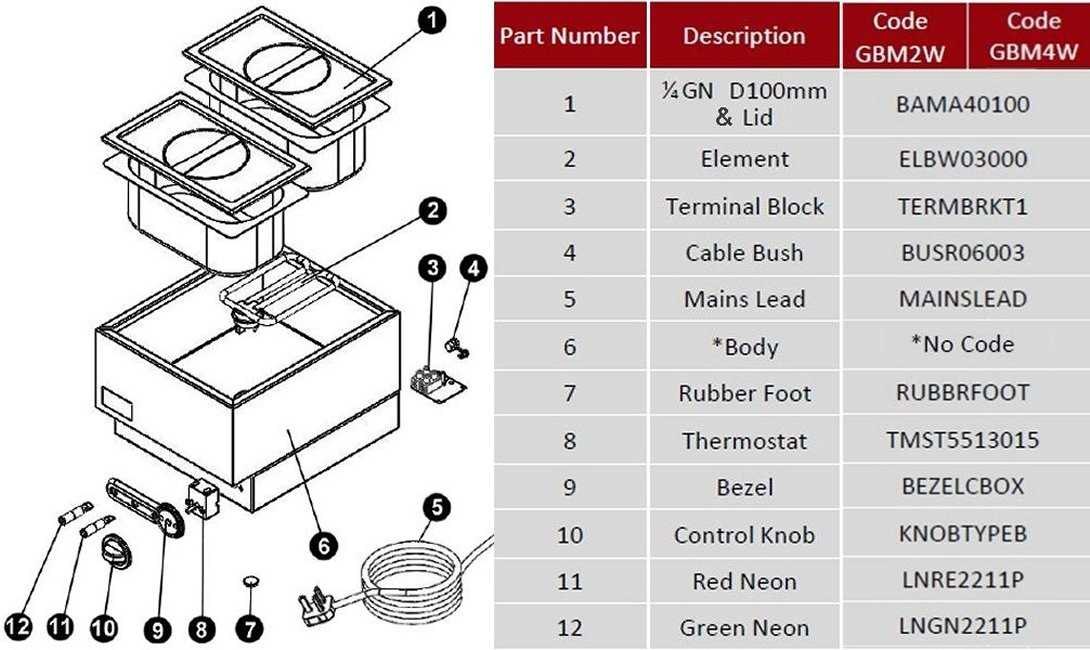

Identifying Potential Issues

Recognizing possible challenges in the functioning of a drainage system is crucial for maintaining efficiency and preventing damage. Early detection of these concerns can save time and resources, ensuring the longevity of the system.

Common Challenges to Look For

- Clogs: Blockages in the flow can lead to backups and inefficient drainage.

- Leaks: Undetected leaks may cause water loss and structural damage over time.

- Corrosion: Deterioration of components can compromise the integrity of the entire system.

- Improper Slope: Incorrect angling can hinder flow, causing pooling and stagnant water.

Signs of Malfunction

- Unusual noises during operation, indicating potential mechanical issues.

- Visible water damage around connection points or structures.

- Slow drainage or pooling of water in areas where it should not accumulate.

- Frequent need for repairs or maintenance beyond routine checks.

Upgrading Sink Features Effectively

Enhancing the functionality and aesthetics of your fixtures can significantly improve the overall appeal and usability of your space. This section focuses on practical strategies for refining existing elements, ensuring they meet contemporary standards while offering improved performance and convenience.

Assessing Current Functionality

Before initiating any upgrades, it is essential to evaluate the current capabilities of your fixtures. Identify areas where performance may be lacking, such as inadequate flow rates or outdated designs. Conducting a thorough assessment helps prioritize upgrades based on necessity and potential impact, leading to more effective enhancements.

Incorporating Innovative Technologies

Integrating modern technologies can elevate the efficiency and user experience of your fixtures. Consider features like touchless operation, smart controls, or energy-efficient systems. These advancements not only enhance convenience but also contribute to sustainability efforts by reducing water consumption and energy usage.