In the realm of restroom fixtures, efficient operation hinges on a well-designed assembly of elements that facilitate the essential task of waste management. Each component plays a pivotal role, ensuring that the entire system functions seamlessly. A thorough comprehension of these individual pieces not only aids in maintenance but also enhances the overall user experience.

As we delve into the intricacies of these essential elements, it becomes clear that familiarity with their arrangement and functionality is crucial for both troubleshooting and repair. Recognizing how each segment interacts within the system can lead to quicker resolutions of common issues, ultimately saving time and resources.

In this exploration, we will examine the various components, detailing their specific functions and relationships within the mechanism. With a focus on clarity and accessibility, this guide aims to equip readers with the knowledge necessary to navigate the complexities of restroom assembly effectively.

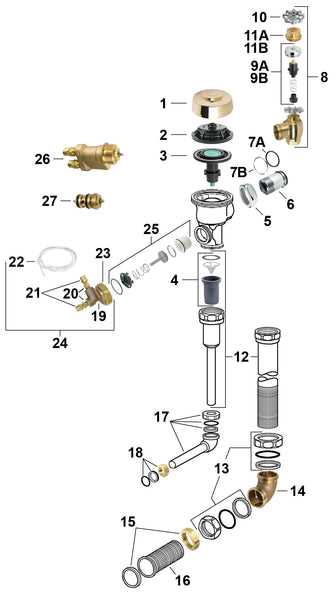

Understanding Sloan Flush Valve Components

In modern sanitation systems, specific components play a crucial role in ensuring efficient operation. These elements work together to manage water flow and maintain functionality in restroom facilities. A comprehensive understanding of these components is essential for effective maintenance and troubleshooting.

Main Elements of the System

- Body: The central structure that houses various mechanisms.

- Seal: A crucial element that prevents leaks and maintains pressure.

- Actuator: The part that initiates the flushing process, often triggered by a manual or sensor-based input.

- Adjustable Mechanism: Allows for fine-tuning of water flow and flushing strength.

Common Issues and Solutions

- Leakage: Often caused by worn seals; regular inspection and replacement can resolve this.

- Inconsistent Flushing: This may indicate a problem with the actuator or adjustable mechanism; adjustments or part replacements may be necessary.

- No Response: If the system fails to engage, check the power supply or manual trigger for issues.

Familiarity with these components and potential issues will empower users to maintain and troubleshoot effectively, ensuring reliable operation in any facility.

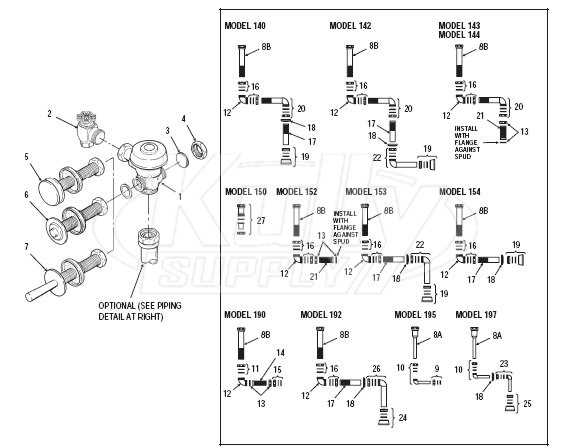

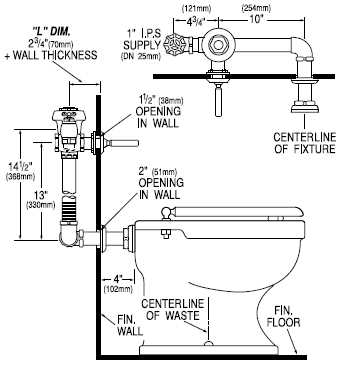

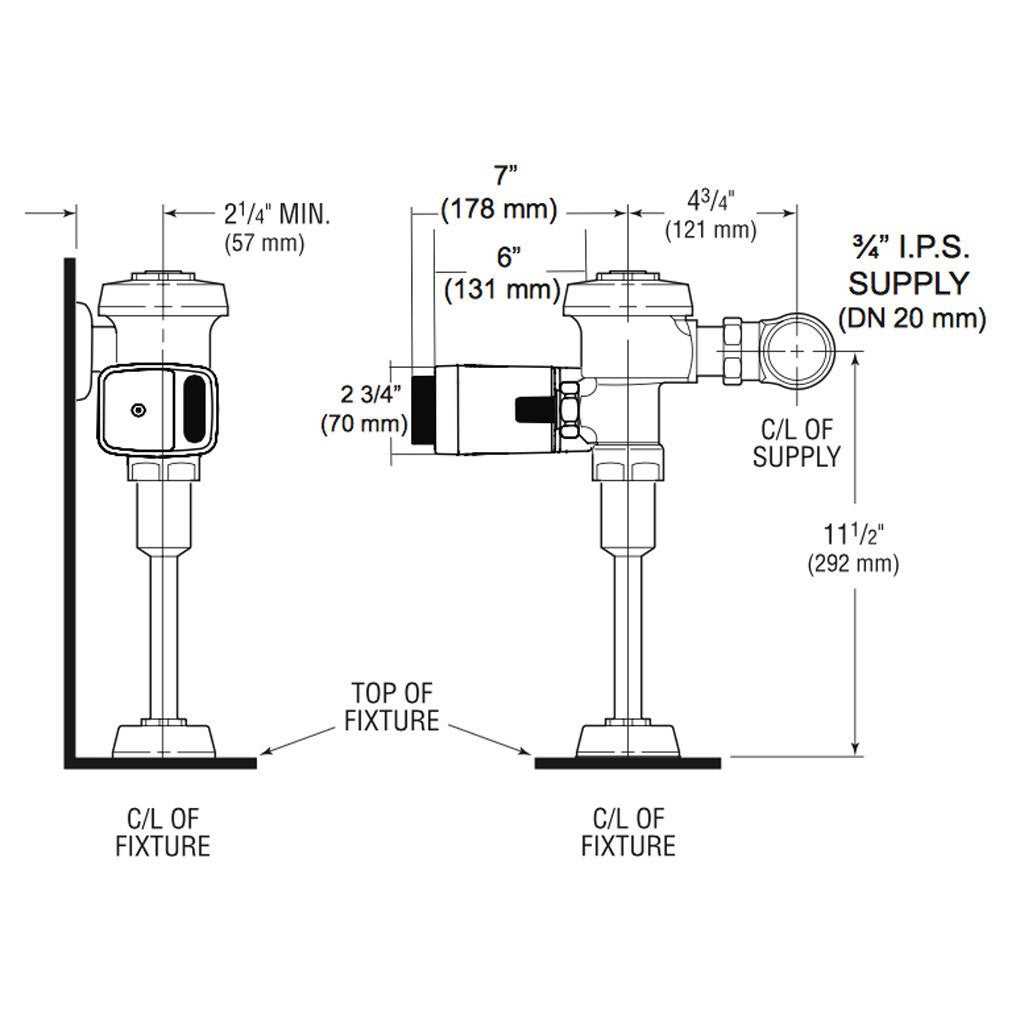

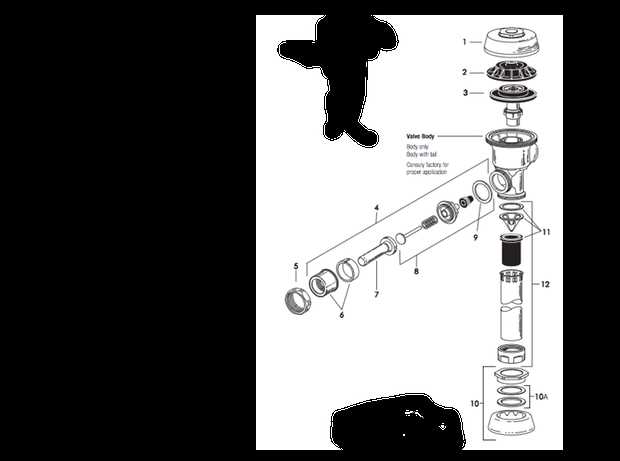

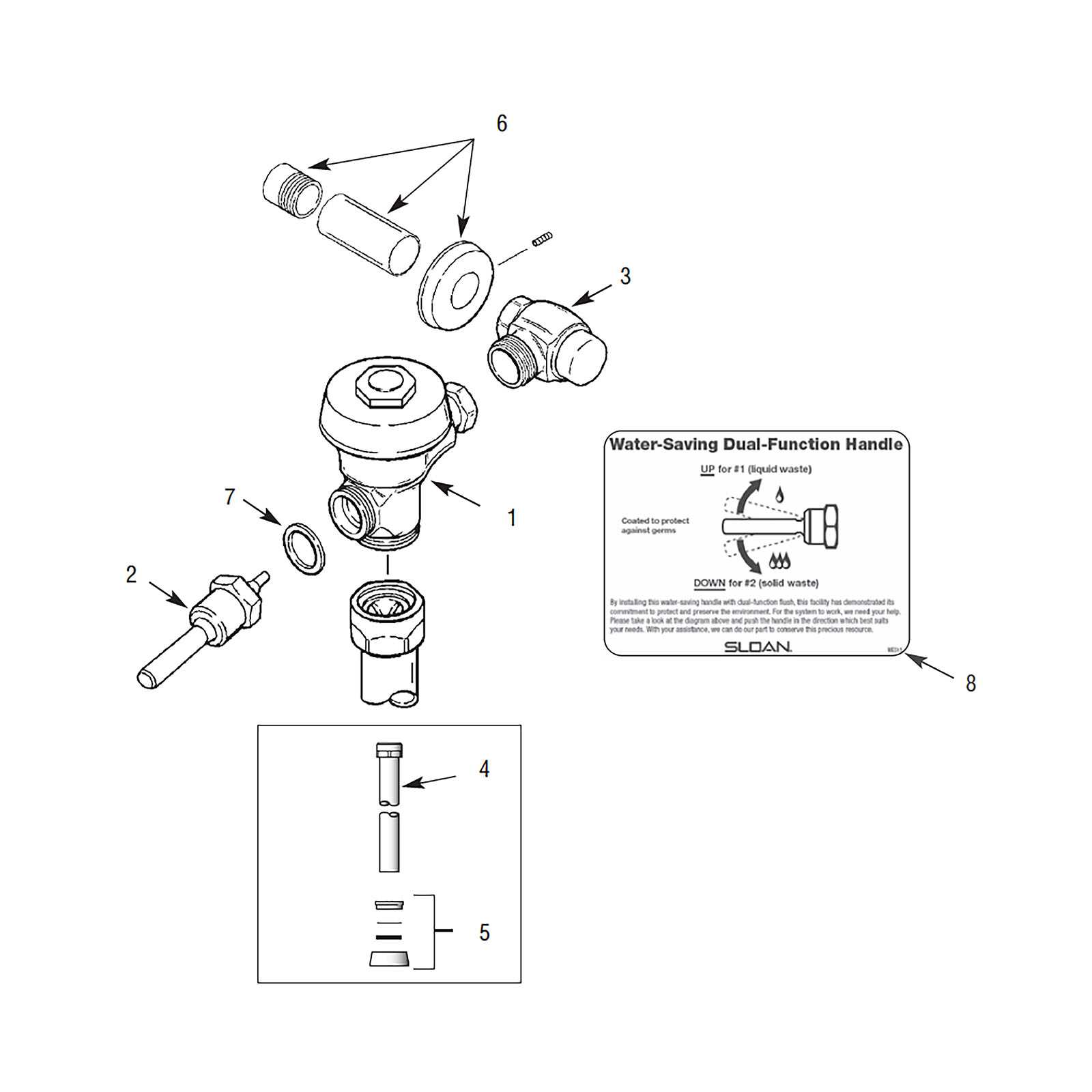

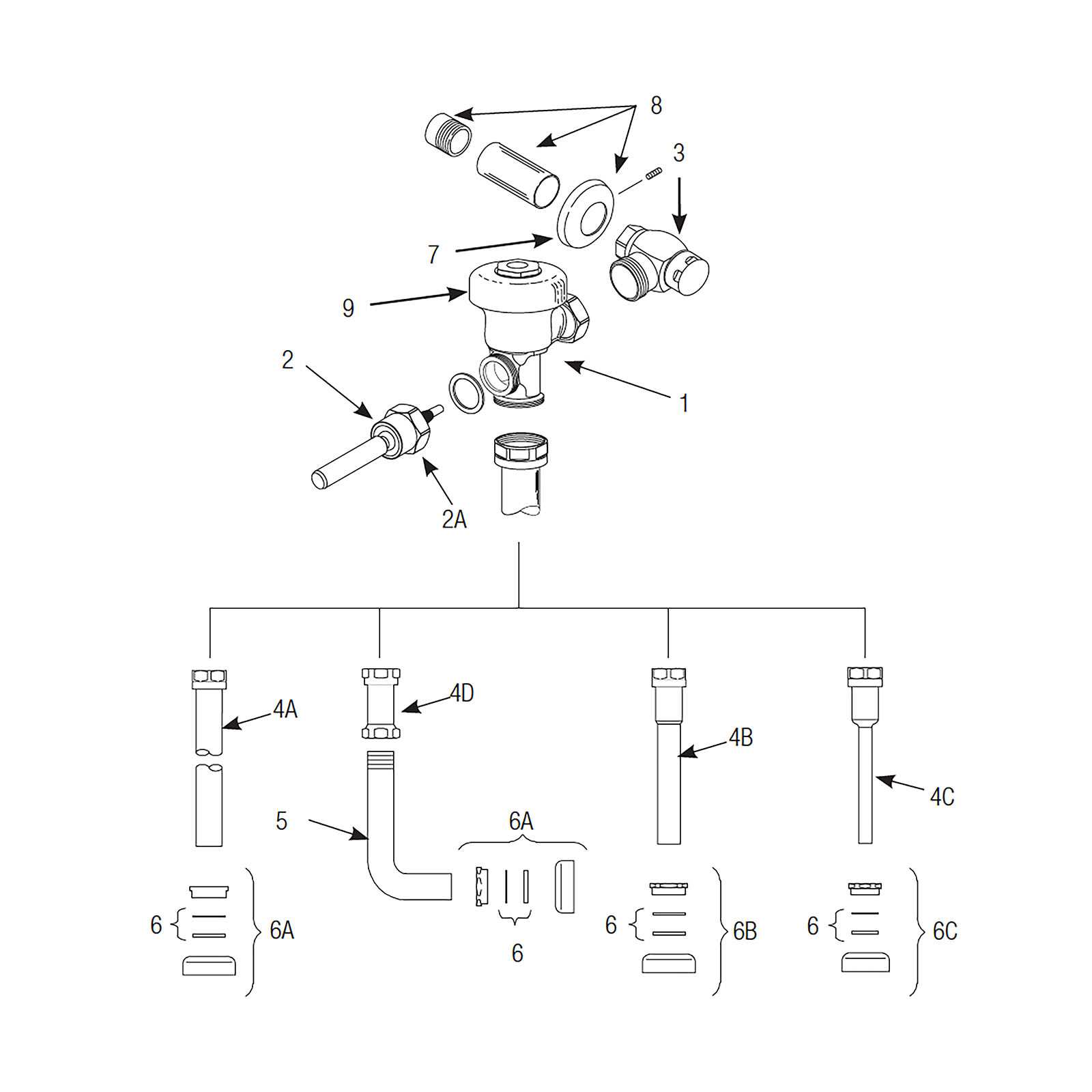

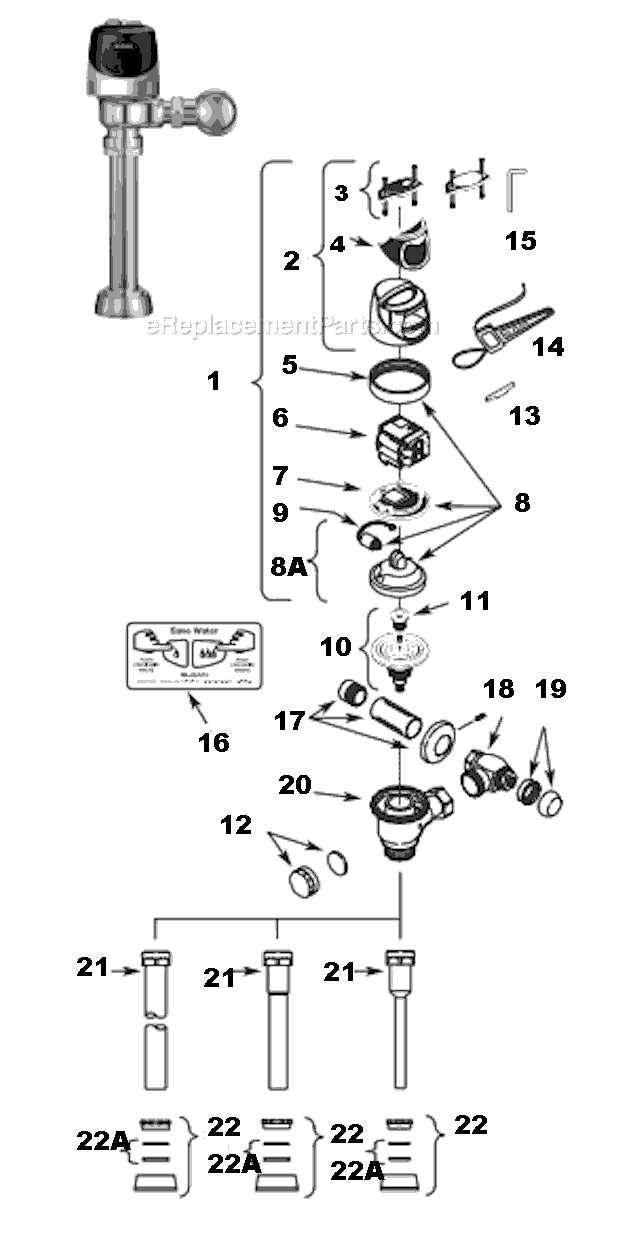

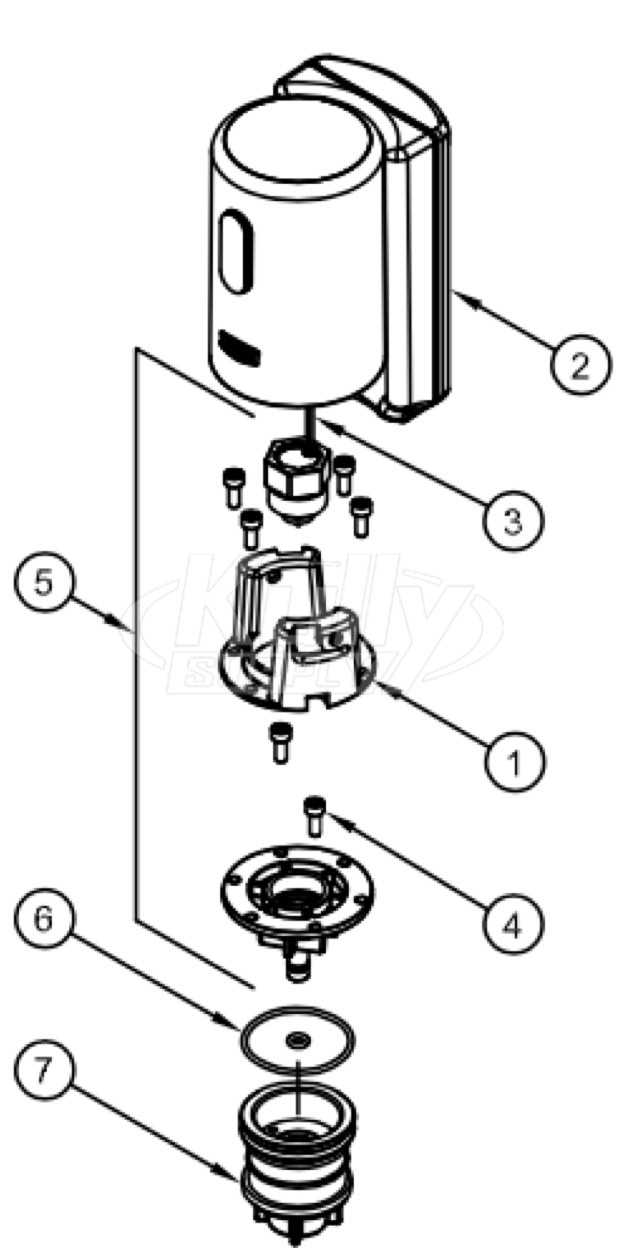

Diagram Overview of Sloan Systems

This section presents a comprehensive overview of the various components and their interrelations within the mechanisms designed for efficient water management. Understanding the configuration and functionality of these elements is crucial for maintaining optimal performance in restroom facilities.

Key Components and Their Functions

The system comprises several essential elements, each playing a pivotal role in regulating water flow and pressure. Control units ensure precise operation, while actuators facilitate the response to user interaction. Additionally, water supply fittings maintain the necessary pressure levels, ensuring effective operation.

Interaction and Maintenance

Proper interaction among these components is vital for efficiency and longevity. Regular maintenance checks are recommended to identify any potential issues early on. Identifying wear and tear on components can prevent more significant malfunctions and ensure smooth operation throughout the system’s lifespan.

Common Issues with Flush Valve Parts

Understanding the frequent problems that can arise with toilet mechanisms is essential for effective maintenance and repair. These components often face wear and tear, leading to inefficiencies and malfunctions.

Frequent Problems

- Leaking components can cause water waste and increased bills.

- Clogged mechanisms may prevent proper operation, leading to inconsistent flushing.

- Worn seals can result in persistent dripping noises.

Identifying Symptoms

- Check for water pooling around the base.

- Listen for unusual sounds during operation.

- Observe the performance for any irregular flushing patterns.

Maintenance Tips for Sloan Valves

Regular upkeep of your toilet mechanisms is essential for ensuring optimal performance and longevity. By following a few simple maintenance practices, you can prevent common issues and enhance the efficiency of your restroom fixtures.

Routine Inspections

Conduct periodic checks on your systems to identify any signs of wear or malfunction. Look for leaks, unusual noises, or irregular flushing behavior. Early detection can save time and resources by addressing minor problems before they escalate.

Cleaning Procedures

Keep the components clean by regularly removing debris and mineral buildup. Use a soft cloth and a mild cleaner to wipe down surfaces, ensuring that moving parts can operate freely. For deeper cleaning, consider using vinegar to dissolve any hard water deposits.

Remember: Regular maintenance not only improves performance but also extends the lifespan of your restroom systems, promoting a better experience for all users.

How to Identify Parts in Diagrams

Understanding how to recognize components in technical illustrations is essential for effective maintenance and repair. These visual representations often contain various symbols and notations that signify different elements. Familiarizing yourself with these aspects can significantly enhance your troubleshooting skills and facilitate efficient repairs.

To begin, it’s crucial to grasp the basic layout and organization of the illustration. Most schematics will have a key or legend that provides explanations for the symbols used. This reference is invaluable for identifying each component accurately. Additionally, the arrangement of the elements can indicate how they interact with one another, giving insight into their functions.

| Symbol | Description |

|---|---|

| ⬤ | Connection Point |

| – | Piping or Tubing |

| ▲ | Flow Direction |

| □ | Control Mechanism |

Furthermore, paying attention to the scaling in the image can help you understand the relative sizes and positions of each element. This aspect can aid in visualizing the assembly and the spatial relationship between various components, which is crucial for proper installation or replacement.

Finally, consulting additional resources such as manufacturer manuals or online guides can provide further clarity and context. Combining these approaches will equip you with the knowledge needed to effectively interpret and utilize technical illustrations in practical applications.

Replacement Parts: A Buying Guide

Understanding the essentials of acquiring replacement components is crucial for maintaining functionality and efficiency. This guide aims to assist you in navigating the options available, ensuring you select the most suitable items for your specific requirements.

Identifying the Right Components

Before making a purchase, it’s important to identify the correct components that match your system. Consider the following:

- Compatibility: Ensure the selected components are designed for your specific model.

- Quality: Opt for high-quality items that offer durability and reliable performance.

- Manufacturer: Stick with reputable brands known for their expertise and reliability.

Where to Purchase

There are several avenues to explore when looking for replacement components:

- Online Retailers: Websites specializing in plumbing supplies often have a wide range of options.

- Local Hardware Stores: Visiting a nearby store can provide immediate access to items and the chance to seek advice from staff.

- Specialty Suppliers: Certain suppliers focus on specific systems, offering expert knowledge and tailored solutions.

By following these guidelines, you can ensure that you make informed decisions when selecting components, ultimately enhancing the performance of your system.

Installation Steps for Flush Valves

Proper installation of the components responsible for water release is crucial for ensuring efficient operation and longevity. This process involves several essential stages that guide users in setting up the mechanism accurately, leading to optimal performance and minimal leaks.

Preparation and Tools Required

Before commencing the installation, gather the necessary tools and materials. Commonly required items include a wrench, screwdriver, and Teflon tape for sealing connections. It’s advisable to have a clean working space and to review the manufacturer’s instructions to familiarize yourself with the specific components.

Step-by-Step Installation Process

Follow these steps to successfully install the mechanism:

| Step | Description |

|---|---|

| 1 | Turn off the water supply to the toilet to prevent leaks during installation. |

| 2 | Remove the existing assembly by unscrewing any fasteners and disconnecting water lines. |

| 3 | Install the new components in accordance with the provided guidelines, ensuring all parts are oriented correctly. |

| 4 | Secure the assembly using appropriate fasteners, making sure they are tightened to avoid any movement. |

| 5 | Reconnect the water supply and check for any leaks by observing the connections. |

| 6 | Test the setup by flushing the toilet to ensure everything is functioning as intended. |

Following these steps will help ensure that the installation is successful, leading to reliable performance and minimizing future issues.

Comparing Sloan Models and Parts

Understanding the various models and components of restroom fixtures is essential for selecting the right system for specific needs. Each design variant offers unique features, ensuring optimal performance and efficiency. By examining the differences and similarities among different series, users can make informed decisions regarding replacements and upgrades.

Key Features of Different Series

- Water Efficiency: Various models prioritize water conservation, featuring advanced mechanisms that minimize usage without compromising functionality.

- Installation Flexibility: Certain designs allow for easier installation in a variety of settings, making them suitable for both new constructions and renovations.

- Durability: Different configurations utilize materials that enhance longevity, reducing the frequency of replacements and repairs.

- Maintenance Requirements: Some models are engineered for straightforward upkeep, while others may require specialized tools or expertise.

Common Components Across Series

- Seal assemblies play a critical role in maintaining a watertight seal and preventing leaks.

- Actuators vary in design but serve the same purpose of initiating the flow of water.

- Mounting brackets are essential for securing the fixtures in place, with variations to accommodate different installation scenarios.

- Replacement kits are often available, offering all necessary elements for a complete overhaul.

By comparing these features and components, users can better assess which model aligns with their requirements, ensuring a functional and efficient restroom experience.

FAQs about Sloan Flush Valves

This section addresses common inquiries regarding a specific type of water-saving mechanism commonly found in restrooms. Understanding the functionality, maintenance, and troubleshooting of these devices can enhance user experience and efficiency.

Common Questions

- What is the purpose of this water-saving mechanism?

- How can I identify if my device is functioning properly?

- What maintenance tasks are recommended to ensure longevity?

- Are there any common issues that can arise with this type of device?

Maintenance and Troubleshooting

- Regularly inspect for leaks or irregular sounds.

- Check the water supply connection for any blockages.

- Replace worn-out components to prevent failures.

- If problems persist, consult a professional for assistance.