In the realm of advanced remote-controlled vehicles, comprehending the intricate layout of various elements is essential for enthusiasts and operators alike. A thorough exploration of these components not only enhances the performance of the machine but also aids in efficient maintenance and repairs. Knowing how each section contributes to the overall functionality empowers users to optimize their driving experience.

The assembly of these specialized machines involves numerous intricate parts, each playing a crucial role in delivering speed and agility. Familiarity with the configuration of these elements allows for better troubleshooting and upgrades. This understanding ultimately leads to improved handling and extended lifespan of the vehicle.

Whether you are an avid hobbyist or a casual user, gaining insight into the configuration of your machine fosters a deeper connection with your equipment. By diving into the specifics, one can appreciate the engineering marvel that these vehicles represent, unlocking new possibilities for exploration and enjoyment.

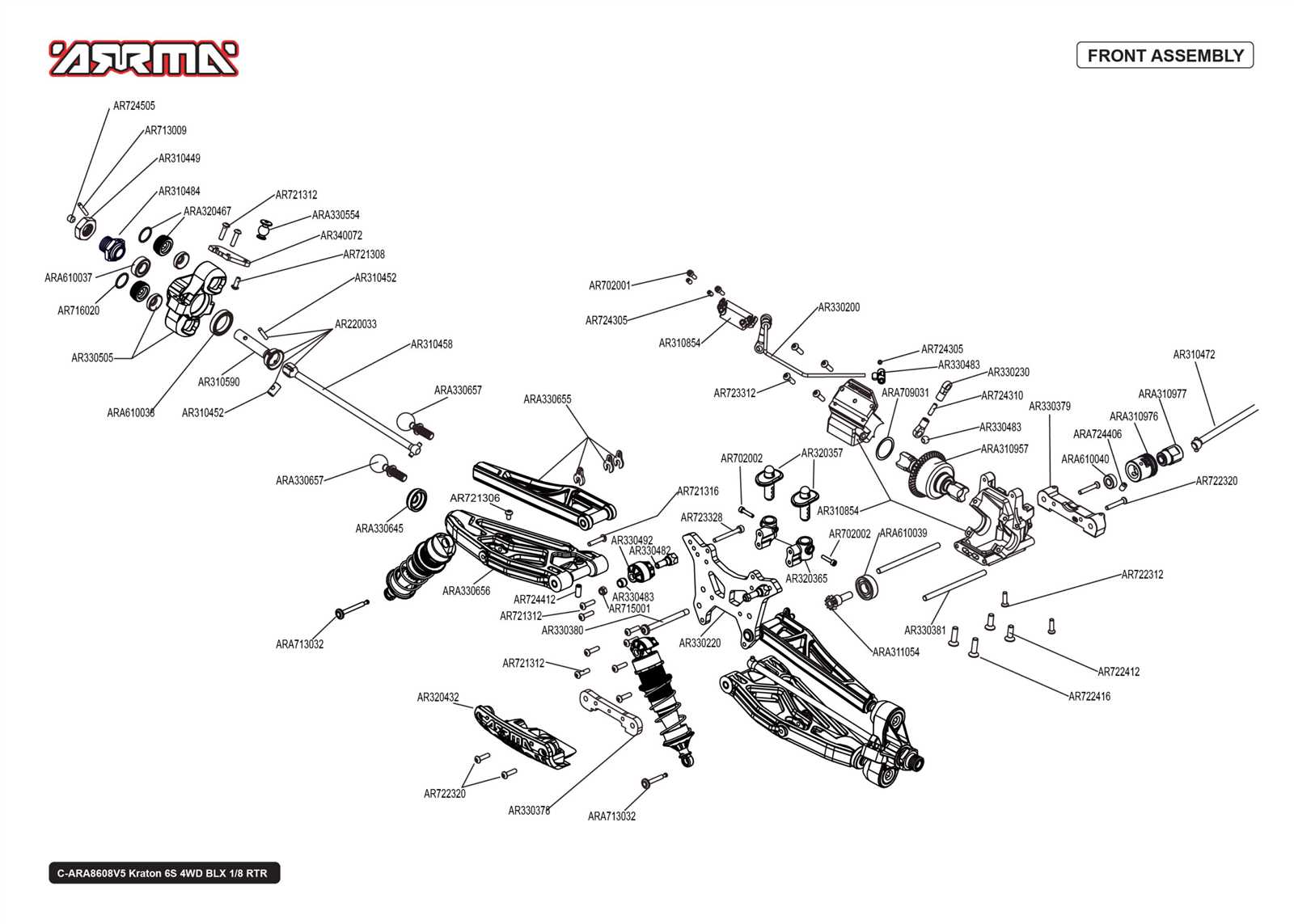

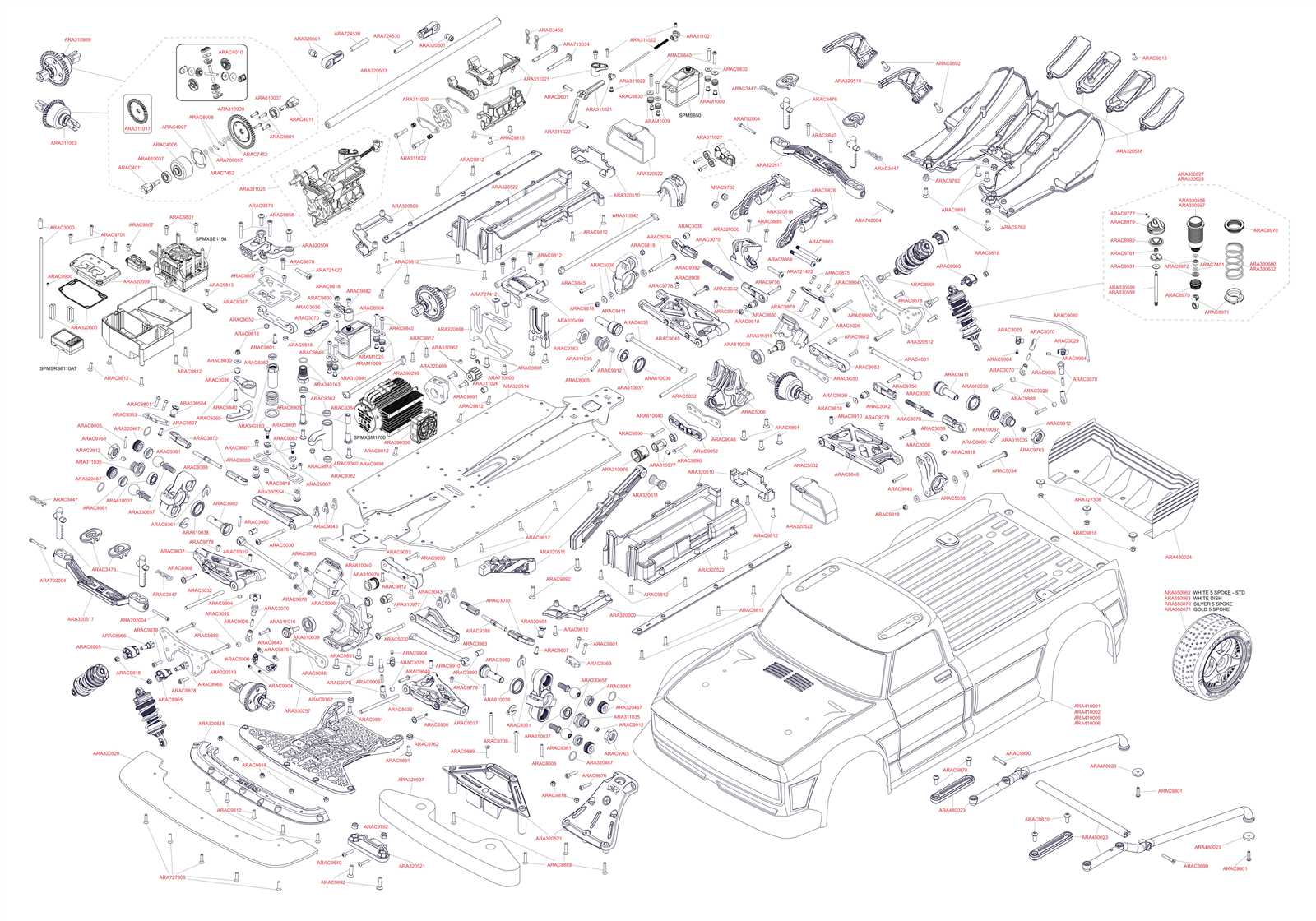

Essential Components of Kraton 6s

This section highlights the fundamental elements that contribute to the functionality and performance of the model. Understanding these vital components is crucial for anyone looking to enhance their experience and ensure optimal operation. Each part plays a specific role in the overall efficiency and reliability of the vehicle, making it essential to be familiar with them.

The first significant element is the power unit, which provides the necessary energy for propulsion. Additionally, the suspension system is critical for maintaining stability and handling during operation. Another important aspect is the steering mechanism, which allows for precise navigation and control. Finally, the chassis serves as the foundation, supporting all other components and ensuring structural integrity.

Understanding the Parts Diagram

Grasping the layout of components within a system is essential for effective maintenance and repair. A visual representation of these elements offers a clear overview, enabling users to identify and understand the relationships and functions of various pieces. This knowledge is crucial for troubleshooting and enhancing performance.

Each section of the illustration serves as a guide, highlighting the specific functionalities of individual components. Familiarity with this arrangement allows users to recognize potential issues and makes it easier to execute modifications or upgrades. Furthermore, an organized view assists in the assembly process, ensuring that every part is correctly positioned.

Utilizing this comprehensive representation can significantly improve the efficiency of any maintenance work. By referencing the organized layout, users can efficiently pinpoint areas that may require attention, leading to informed decisions and timely interventions.

Assembly Instructions for Kraton 6s

This section provides a comprehensive guide to assembling your vehicle, ensuring all components fit together seamlessly. Proper assembly is crucial for optimal performance and longevity, allowing you to enjoy your machine to the fullest.

Follow the steps outlined below to ensure a smooth assembly process:

| Step | Description |

|---|---|

| 1 | Gather all necessary components and tools required for the assembly. |

| 2 | Begin by securing the chassis and preparing it for component installation. |

| 3 | Carefully attach the suspension elements, ensuring they are properly aligned. |

| 4 | Install the drivetrain components, following the recommended sequence for optimal performance. |

| 5 | Finally, verify all connections and perform a thorough check to ensure everything is secure. |

Troubleshooting Common Issues

Addressing frequent challenges can significantly enhance the performance and longevity of your equipment. Understanding these common complications is essential for effective resolution and maintenance.

Power Issues: If the device fails to power on, check the battery connections and ensure that the batteries are charged. Inspect the power switch for any malfunction.

Connectivity Problems: Loss of connection may arise from improper setup or interference. Verify all connections and ensure that the components are correctly aligned.

Performance Fluctuations: Inconsistent operation can indicate wear or misalignment of internal parts. Regular inspection and timely replacement of worn components are crucial.

Unusual Noises: Unexpected sounds can signal a need for maintenance. Examine moving parts for debris or damage that could lead to malfunction.

By systematically addressing these issues, users can maintain optimal functionality and extend the lifespan of their equipment.

Upgrading Parts for Better Performance

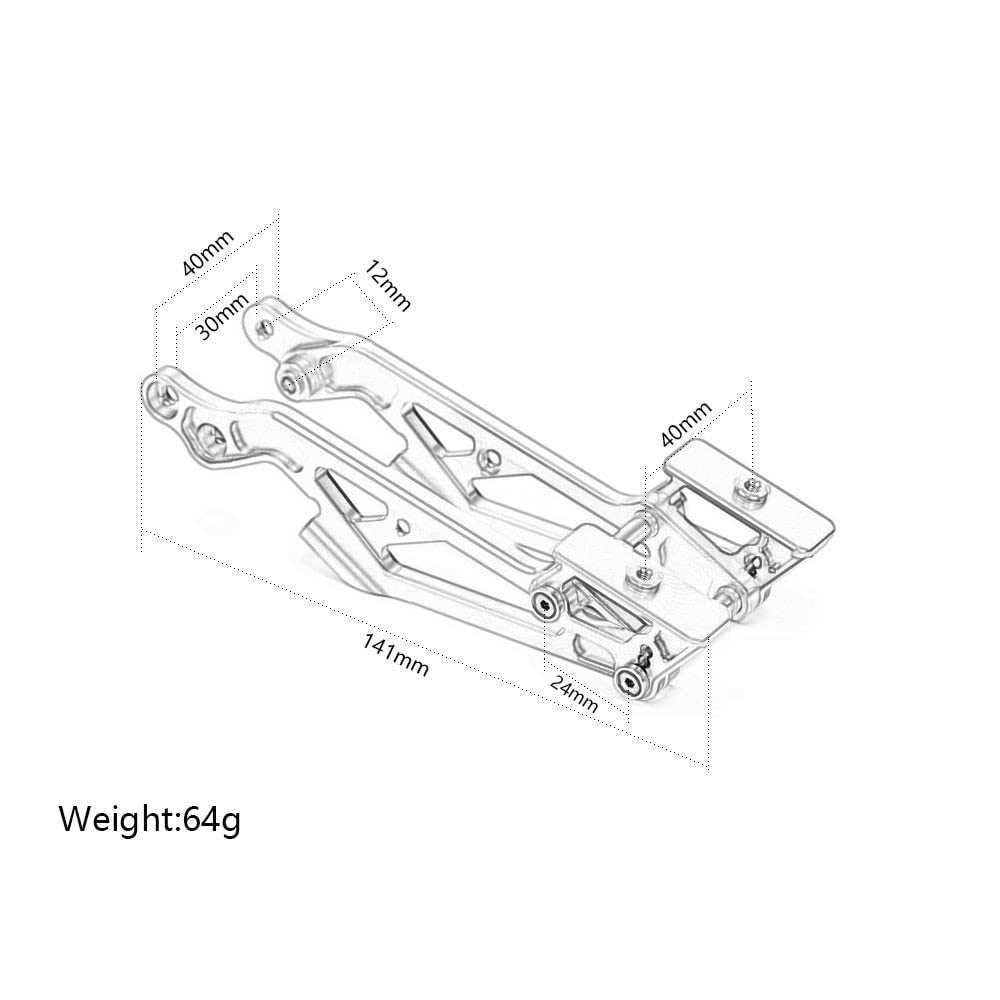

Enhancing the functionality of your vehicle can significantly improve its overall efficiency and responsiveness. By selecting high-quality components designed for durability and superior performance, you can achieve a smoother ride and better handling. This section will explore various enhancements that can elevate your vehicle’s capabilities.

Choosing High-Quality Components

Investing in premium materials is crucial for achieving optimal performance. Upgrading to advanced alternatives can reduce wear and tear, ensuring longevity and reliability. For instance, consider stronger materials for structural elements, which can enhance stability during operation.

Performance Tuning and Adjustments

Adjustments to various systems can lead to notable improvements in handling and speed. Fine-tuning aspects such as suspension settings, gear ratios, and electronic controls can create a more responsive driving experience. Implementing these modifications allows for personalized performance tailored to specific driving conditions.

Maintenance Tips for Longevity

Ensuring the durability and extended use of your equipment depends largely on consistent care and preventive upkeep. Regular attention to various components will not only prevent unexpected malfunctions but also improve performance and reliability over time.

Regular Cleaning

One of the simplest yet most effective ways to maintain your gear is through regular cleaning. Dirt, dust, and debris can accumulate over time, leading to friction and unnecessary wear. A soft brush or cloth can be used to clear away any buildup, while more delicate areas may require a gentle touch or compressed air for thorough cleaning.

Lubrication and Tightening

Maintaining proper lubrication of moving parts is crucial for smooth operation. Periodically check for any signs of dryness or stiffness and apply a suitable lubricant to keep everything running smoothly. Additionally, regularly inspect screws and fasteners, tightening them as needed to ensure that all components remain securely in place.

Inspect for Wear: It’s important to routinely check for signs of wear or damage. Identifying issues early allows you to address them before they lead to more significant problems, ensuring that your equipment remains in optima

Where to Find Replacement Parts

When maintaining or upgrading your equipment, it’s important to know where to source the right components to keep everything functioning properly. Whether you’re looking for standard replacements or specialized upgrades, several options are available to ensure you get the necessary items quickly and efficiently.

- Online Retailers: Many e-commerce platforms specialize in offering a wide variety of mechanical components and accessories. These platforms often provide detailed descriptions, customer reviews, and shipping options.

- Manufacturer’s Website: Visiting the official website of the brand can give you access to a dedicated catalog of components specifically designed for your device. This ensures compatibility and reliability.

- Local Hobby Shops: Physical stores focusing on technical or hobby-related gear can often stock a range of useful components. Staff expertise can also be beneficial in guiding you to the right choice.

- Second-Hand Marketplaces: For those looking for more affordable solutions, second-hand online markets can be a good source for gently used or

FAQs about Kraton 6s Components

This section addresses the most common inquiries about maintaining and optimizing the performance of your vehicle. Here, you’ll find concise answers to frequent questions regarding the individual elements that make up your machine, ensuring smooth functionality and prolonged use.

What are the key elements to inspect regularly?

For optimal performance, it’s essential to regularly check certain critical components. These include suspension systems, motor bearings, and transmission gears, as they experience the most wear and tear during operation. Routine inspections and timely replacements ensure long-lasting durability.

Can these elements be upgraded for better performance?

Yes, many of these components can be swapped out for higher-grade versions. Upgrading materials like shock absorbers or driveshafts can enhance your machine’s handling and endurance, providing a more responsive and robust experience during usage.

Component Inspection Frequency Upgrade Options Suspension System Every 3 months Heavy-duty shocks