In the world of sports, particularly baseball and softball, having the right tools can make a significant difference in training and performance. This section explores the intricate elements that contribute to the functionality of a specific type of throwing apparatus. By gaining insight into these components, enthusiasts can enhance their knowledge and improve their practice sessions.

Every element plays a crucial role in the overall efficiency of the device, ensuring that players receive optimal training experiences. From the mechanism that generates speed to the adjustments that allow for varied trajectories, understanding these features is essential. Delving into each aspect not only reveals how they interact but also highlights the importance of maintenance and care for prolonged usability.

By examining the individual segments, users can appreciate how design and engineering merge to create a reliable tool for skill development. This exploration aims to provide clarity and foster a deeper appreciation for the technology behind effective training aids.

Understanding Jugs Pitching Machines

This section delves into the essential aspects of a specific type of equipment designed for enhancing throwing accuracy and speed training. By exploring its components and functionalities, users can better appreciate how this device supports skill development in various sports.

Core Features

- Durable construction for longevity.

- Adjustable speed settings for different skill levels.

- Versatile design suitable for various ball types.

Key Components

-

Motor: Powers the device, allowing for consistent delivery.

-

Feeder: Holds and releases balls at predetermined intervals.

-

Adjustment Mechanism: Enables users to modify angles and speeds easily.

Understanding these elements helps users maximize their training sessions and tailor the experience to meet specific needs.

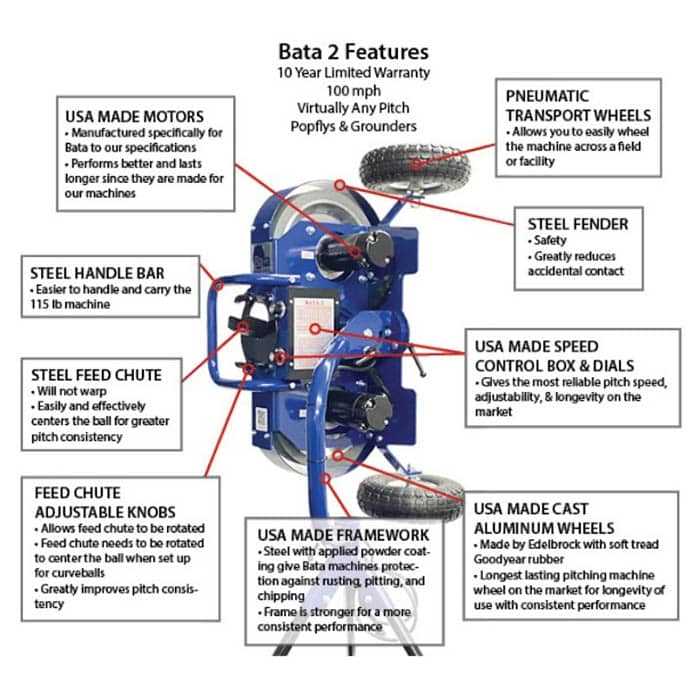

Essential Components of Jugs Machines

Understanding the critical elements that make up these devices is key to maximizing their performance and ensuring longevity. Each component plays a significant role in delivering consistent and reliable results, contributing to the overall functionality of the system.

At the heart of these systems is the propulsion mechanism, designed to accurately launch the ball at various speeds. This is complemented by an adjustable angle feature, allowing users to simulate different pitching styles. The control unit serves as the brain, enabling precise adjustments and settings for tailored practice sessions.

Durable housing is essential, providing protection against wear and tear while ensuring stability during operation. Additionally, safety features, including automatic shut-off and protective shields, enhance user security. Regular maintenance of these key components is vital for optimal performance and reliability over time.

How the Pitching Mechanism Works

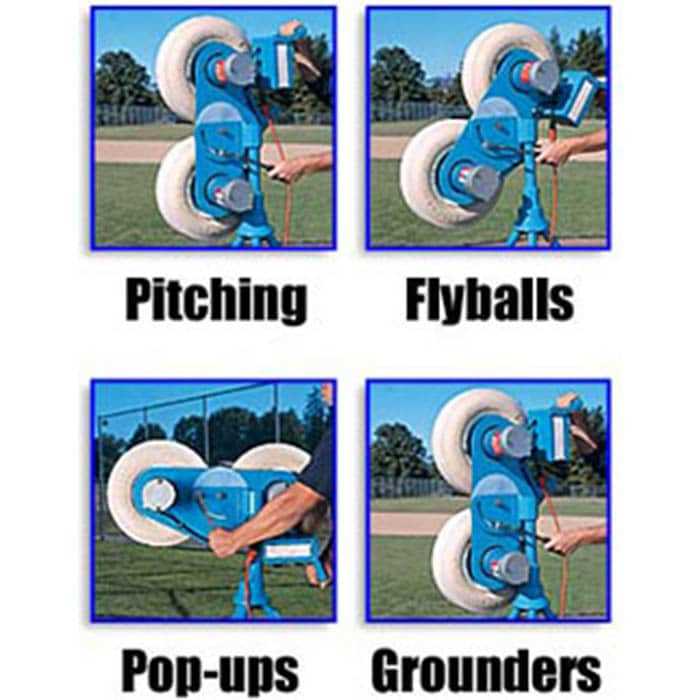

The mechanism responsible for delivering balls operates through a carefully engineered system designed to replicate human-like throws. This intricate setup relies on the interplay of various components that work together to achieve consistent and accurate releases.

Key Components

At the heart of this system are the motors that control speed and trajectory. These motors are synchronized to ensure that each ball is propelled with precision, allowing for various angles and velocities. Additionally, the feeding system plays a crucial role by seamlessly loading each ball into the path of release.

Operational Dynamics

The process begins when a ball is positioned, triggering the motor to activate. As the mechanism engages, it generates the force needed to launch the ball forward. The design allows for adjustments, enabling users to modify parameters for different training scenarios, ultimately enhancing skill development.

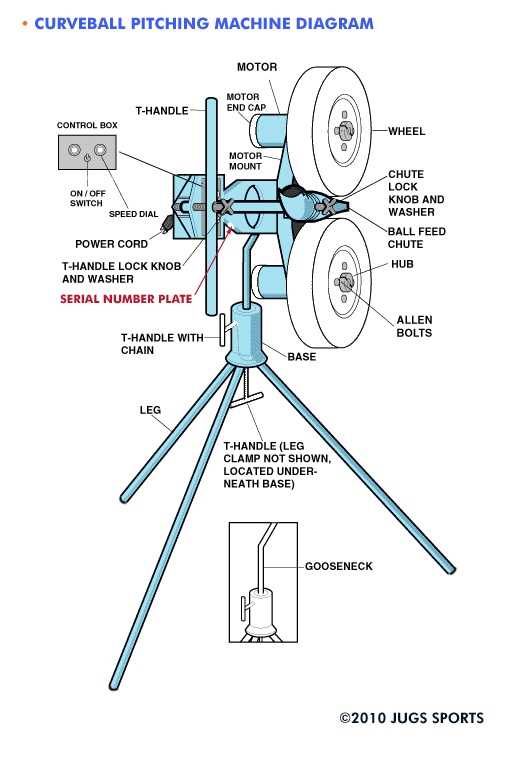

Identifying Parts in the Diagram

Understanding the various components represented in the illustration is crucial for effective maintenance and operation. Each section plays a vital role in the overall functionality, and recognizing them will enhance your ability to troubleshoot and repair the equipment.

To assist in this process, here are key components you might encounter:

- Frame: The structural backbone that supports all other elements.

- Motor: The powerhouse responsible for driving the system.

- Feeder: The element that ensures a steady supply of projectiles.

- Wheel: A critical component that propels the items at desired velocities.

- Adjustable Angles: Mechanisms that allow for trajectory modifications.

When reviewing the illustration, it’s helpful to approach it systematically:

- Start with the main structure to understand its stability.

- Identify the energy source and its connection to the motion components.

- Locate the delivery system for the projectiles.

- Examine any adjustable features that influence performance.

By familiarizing yourself with these elements, you’ll be better equipped to manage and optimize the equipment effectively.

Common Issues with Pitching Machines

When utilizing automated throwing devices, users may encounter a variety of challenges that can affect performance and reliability. Understanding these common difficulties can help in troubleshooting and maintenance, ensuring optimal functioning for training purposes.

Frequent Problems

| Issue | Description |

|---|---|

| Misalignment | The device may not throw balls accurately due to improper setup or wear over time. |

| Power Issues | Electrical failures or inadequate power supply can lead to inconsistent operation. |

| Ball Jamming | Obstructions in the feeding mechanism can cause interruptions in ball delivery. |

Maintenance Tips

Regular checks and maintenance can prevent many of these issues. Ensuring proper alignment, maintaining power connections, and keeping the feeding mechanism clear will enhance performance and longevity.

Maintenance Tips for Longevity

Ensuring the durability of your equipment is essential for optimal performance and longevity. Regular upkeep can prevent issues and enhance functionality, making it crucial to adopt a proactive approach. Below are some practical strategies to keep your device in excellent condition over time.

Regular Inspections

Perform consistent evaluations to identify wear and tear. Look for any signs of damage or misalignment that could affect performance. Early detection of potential problems allows for timely repairs, reducing the risk of significant breakdowns.

Proper Cleaning Techniques

Maintaining cleanliness is vital for efficient operation. Use appropriate cleaning solutions to remove dirt and debris without causing harm. Regularly wipe down surfaces and check for any accumulation of residue that could hinder performance. A clean environment promotes better functionality and extends the lifespan of your equipment.

Emphasizing care in these areas will not only enhance performance but also contribute to the overall efficiency and reliability of your setup. Investing time in maintenance ensures that your equipment serves you well for years to come.

Upgrading Jugs Machine Parts

Enhancing the functionality of your throwing apparatus can significantly improve performance and longevity. Whether you’re seeking better accuracy, increased speed, or more durability, selecting the right components for your system is essential. Upgrading various elements can lead to an overall boost in effectiveness, allowing for a more enjoyable experience during practice sessions.

Choosing Quality Components

When considering upgrades, prioritize high-quality materials and reputable brands. Components made from advanced materials can withstand wear and tear, providing consistent performance over time. Researching user reviews and expert recommendations can guide you in making informed choices that align with your specific needs.

Installation and Maintenance Tips

Proper installation of upgraded components is crucial for optimal performance. Follow the manufacturer’s instructions closely to ensure compatibility and functionality. Additionally, regular maintenance checks can help identify any potential issues early, ensuring that your apparatus remains in top condition. Simple tasks, such as lubrication and alignment adjustments, can greatly enhance operational efficiency.

Comparing Different Jugs Models

This section aims to explore the various designs and features of different models available in the market. Each variant comes with its unique set of specifications, catering to diverse needs and preferences.

| Model | Speed Range | Weight | Power Source | Price |

|---|---|---|---|---|

| Model A | 30-60 mph | 40 lbs | Electric | $300 |

| Model B | 20-50 mph | 35 lbs | Battery | $250 |

| Model C | 25-70 mph | 45 lbs | Electric | $400 |

By examining these options, users can identify which model aligns best with their requirements and preferences.

Finding Replacement Parts Online

In today’s digital age, locating components for your equipment has become more accessible than ever. Whether you need to repair a unit or enhance its functionality, the internet offers a plethora of resources to assist you in your search. From specialized retailers to online marketplaces, options abound to help you procure what you need efficiently.

Start your journey by identifying the specific element you require. Accurate descriptions and model numbers can significantly streamline the process. Utilize search engines effectively; entering precise terms will yield targeted results.

Additionally, consider visiting forums or communities dedicated to your equipment type. Fellow enthusiasts often share valuable insights and recommendations on where to find quality replacements. Reviews and ratings can guide you towards reputable sources, ensuring you make informed purchases.

Finally, don’t overlook the potential for discounts and promotions. Many online vendors offer sales, especially during seasonal events, making it an ideal time to acquire necessary components at reduced prices.