In the realm of modern automotive engineering, the intricacies of advanced injection mechanisms play a crucial role in enhancing performance and efficiency. The various elements within these systems work in harmony to deliver optimal power and reduce emissions. A comprehensive grasp of how these components interact is essential for anyone involved in maintenance or repair.

Delving into the specifics of these assemblies reveals a complex network of interconnected units. Each element serves a distinct purpose, contributing to the overall functionality and reliability of the system. Understanding the arrangement and operation of these components not only aids in troubleshooting but also ensures that technicians can perform their tasks with confidence.

Through an exploration of the structural design and operational principles, one can gain insights into the effectiveness of these critical mechanisms. This knowledge empowers professionals to maintain peak performance levels while adhering to industry standards, ultimately leading to enhanced vehicle longevity and user satisfaction.

Cummins PT Fuel Pump Overview

This section provides a comprehensive examination of a critical component designed for optimal performance in diesel engines. The mechanism plays a vital role in delivering precise quantities of liquid to the combustion chamber, ensuring efficiency and power output.

Functionality and Importance

The device operates through a series of intricate actions that facilitate the transfer of liquid from the tank to the engine. Its engineering allows for adjustments in flow, accommodating varying demands based on engine speed and load. Reliability and efficiency are paramount, as any malfunction can significantly impact engine performance and longevity.

Components and Maintenance

Understanding the various components is essential for effective maintenance and troubleshooting. Each element contributes to the overall functionality, and regular inspections can prevent costly repairs. Attention to detail and adherence to maintenance schedules are critical for sustaining optimal operation over time.

Key Components of the Fuel Pump

Understanding the essential elements of an injection system is crucial for maintaining optimal performance. Each component plays a vital role in ensuring efficient operation, contributing to the overall functionality and reliability of the system.

| Component | Description |

|---|---|

| Housing | Provides structure and support, housing various internal elements. |

| Plunger | Drives the fluid through the system, enabling precise control of delivery. |

| Spring | Assists in the return motion of the plunger, ensuring it resets after operation. |

| Check Valve | Prevents backflow, maintaining pressure and flow direction. |

| Drive Mechanism | Connects to the engine, providing the necessary power for operation. |

Each of these elements interacts closely to deliver the required performance, underscoring the importance of regular inspection and maintenance to prevent failures and prolong service life.

Understanding Fuel Pump Functionality

The operation of a vital component in combustion engines plays a crucial role in ensuring optimal performance. This mechanism is responsible for delivering a precise amount of liquid to the engine’s injection system, thereby influencing efficiency and power output. Understanding how this system works is essential for maintenance and troubleshooting.

At its core, the device utilizes mechanical and hydraulic principles to create pressure. When activated, it draws the liquid from a reservoir and pushes it through a series of channels toward the combustion chamber. This process involves several key elements that work in harmony to maintain consistent flow and pressure levels.

Components within this system include regulators, filters, and sensors, each serving a specific function to ensure reliability. Regulators control the pressure, while filters remove impurities to prevent damage to sensitive components. Sensors monitor performance metrics, allowing for adjustments as needed.

Overall, grasping the intricacies of this mechanism enhances understanding of engine dynamics and contributes to improved vehicle operation.

Common Issues and Solutions

In any mechanical system, certain challenges can arise that may hinder performance and efficiency. Understanding these common problems and their respective solutions is essential for maintaining optimal functionality. By identifying symptoms early, users can implement corrective measures to avoid further complications.

One frequent issue is irregular operation, often characterized by fluctuations in performance. This can stem from wear and tear of internal components or contamination within the system. To address this, regular inspections and cleaning protocols should be established to ensure that all elements remain in good working condition.

Another common concern involves leaks, which can lead to decreased efficiency and potential damage to surrounding parts. Identifying the source of a leak is crucial; replacing seals or tightening connections often resolves the problem effectively.

Additionally, unexpected noise can indicate underlying issues, such as misalignment or component degradation. Conducting thorough checks and, if necessary, replacing affected parts can help restore quiet operation.

Lastly, performance loss may be attributed to improper calibration or settings. Regularly reviewing and adjusting configurations according to manufacturer specifications can enhance overall performance and longevity.

Importance of Regular Maintenance

Consistent upkeep is vital for ensuring the longevity and efficiency of any mechanical system. Neglecting this aspect can lead to diminished performance, increased wear, and ultimately, costly repairs. Regular inspections and timely interventions help identify potential issues before they escalate, maintaining optimal functionality.

Benefits of Routine Care

Engaging in systematic maintenance provides several advantages. First, it enhances reliability, allowing the machinery to perform at peak levels without unexpected interruptions. Additionally, it promotes safety by reducing the risk of malfunctions that could lead to hazardous situations. Furthermore, maintaining equipment can lead to significant cost savings over time, as it mitigates the likelihood of extensive damage and the need for replacement.

Conclusion

In summary, regular maintenance is not just a recommendation; it is a necessity for anyone seeking to preserve the integrity and efficiency of their machinery. By prioritizing this practice, one can ensure a smoother operation and extend the lifespan of their investments.

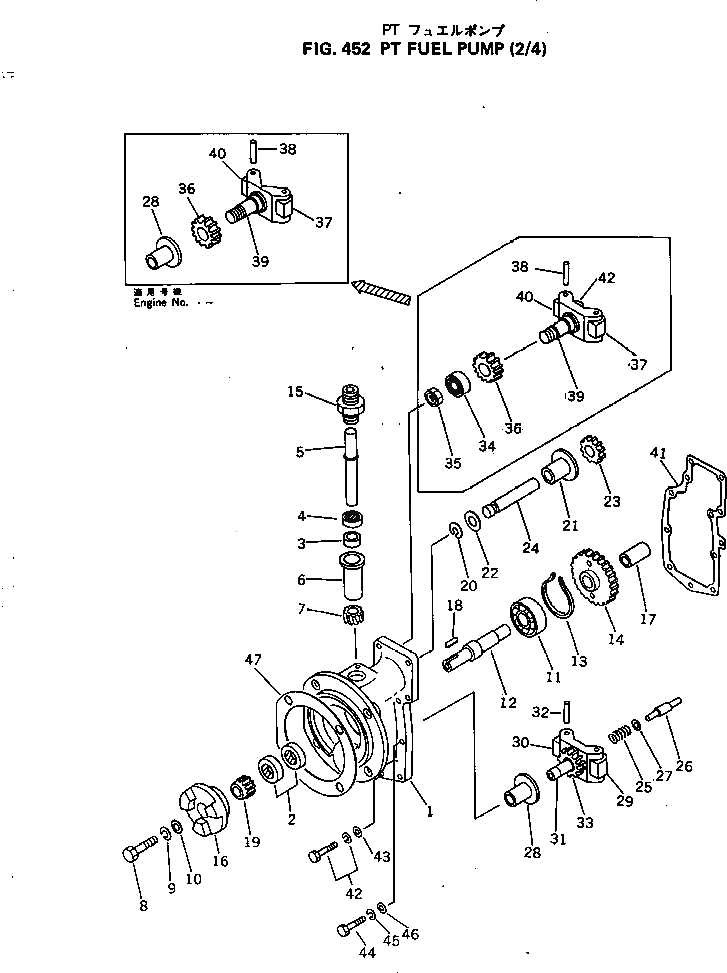

How to Read the Diagram

Understanding a technical illustration requires familiarity with its components and the relationships between them. This visual representation serves as a guide, outlining various elements and their functions within a specific system. By grasping the conventions used, you can effectively interpret the information conveyed.

Begin with the legend: Most illustrations include a key that explains the symbols and notations used. Familiarizing yourself with this section will clarify what each symbol represents, making it easier to follow the overall layout.

Next, examine the flow: Trace the direction indicated by arrows or lines, which typically represent movement or connectivity. Recognizing how parts interact will enhance your understanding of the operational principles.

Identify major components: Look for the primary elements highlighted in the illustration. These often play critical roles in the system’s functionality and provide insight into how everything works together.

Pay attention to annotations: Notes or labels accompanying the illustration often provide additional context, explaining specific features or important details. These annotations are invaluable for grasping more complex aspects of the layout.

With practice, interpreting such illustrations becomes second nature, allowing you to quickly glean essential information and troubleshoot effectively.

Replacement Parts and Upgrades

When it comes to maintaining optimal performance in machinery, the choice of components plays a crucial role. Upgrading or replacing certain elements can enhance efficiency, reliability, and longevity. Understanding the options available can lead to informed decisions that positively impact overall functionality.

Essential Components for Improvement

Identifying critical elements that may require replacement is the first step towards enhancement. Common options include seals, gaskets, and various internal mechanisms that may wear over time. Selecting high-quality alternatives can significantly boost performance metrics, reduce operational disruptions, and ensure smoother functionality.

Considerations for Upgrading

Upgrades often involve the integration of advanced technologies that offer improved efficiency or capabilities. Evaluating compatibility with existing systems is essential. Moreover, consulting with experts or referring to user feedback can provide insights into the best practices for implementing such enhancements, ultimately leading to more robust and effective machinery.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks on specialized machinery, having the right instruments is crucial for ensuring efficiency and precision. The selection of tools can significantly impact the ease of the process and the quality of the results achieved.

Essential Hand Tools: A reliable set of wrenches, screwdrivers, and pliers forms the foundation of any repair kit. These tools are indispensable for loosening and tightening components securely.

Measuring Instruments: Accurate measurements are vital. A caliper and torque wrench are essential for achieving the correct specifications during assembly, preventing potential issues from incorrect fitting.

Specialized Equipment: Depending on the complexity of the task, you may need specific tools designed for particular functions, such as extraction tools or alignment jigs. These can facilitate a smoother workflow and enhance safety.

Protective Gear: Always prioritize safety by wearing appropriate protective equipment, including gloves and goggles. This helps to minimize the risk of injury during the repair process.

By assembling the right toolkit, you can enhance your efficiency and ensure that each project is completed to the highest standard.

Expert Tips for Installation

When undertaking a complex assembly task, having a strategic approach can significantly enhance the efficiency and effectiveness of the process. Proper preparation, understanding the components involved, and following systematic steps are crucial for achieving optimal results. Here are some valuable insights to ensure a successful installation.

Preparation is Key

Before beginning, gather all necessary tools and components. Review the manual thoroughly to familiarize yourself with the specifications and procedures. This initial step not only saves time but also reduces the likelihood of errors. Make sure to work in a clean, organized space to keep track of smaller elements.

Follow the Right Sequence

Adhering to the prescribed order of assembly can prevent complications. Take your time with each phase and double-check your work as you progress. If issues arise, consult the guidelines to troubleshoot effectively. Ensuring that every element is securely fastened before moving on will lead to a more reliable outcome.