Understanding the intricate layout and various mechanical elements is crucial for maintaining performance and extending the life of outdoor equipment. Each component plays a specific role, contributing to the overall functionality and efficiency of the machine. By familiarizing oneself with these elements, it becomes easier to perform routine checks, adjustments, and replacements, ensuring smooth operation.

Delving into the arrangement of individual elements allows for a better grasp of how each piece fits within the overall system. This knowledge is invaluable when conducting repairs or performing preventive maintenance, as it aids in identifying which element may require attention. Moreover, a clear understanding of the structural organization simplifies the troubleshooting process, making it easier to address potential issues promptly.

The organized visual representation of these elements serves as a helpful reference, especially for those looking to keep their equipment in prime condition. With a well-structured guide, users can confidently identify the necessary components, learn about their functions,

Overview of Components in the HRC216

This section explores the main elements that come together to ensure the effective operation of the model. Each part is specifically designed to work in harmony, contributing to the durability and precision that this machine is known for. Understanding these elements can help users with maintenance and troubleshooting, ensuring optimal performance.

Engine Assembly

The power unit serves as the core of the entire system. It is responsible for generating the necessary force to drive the blades and move the equipment forward. Featuring a robust design, this assembly ensures smooth operation even under tough conditions. Regular upkeep of this component can significantly extend the overall lifespan of the machine.

Cutting Mechanism

The cutting mechanism is essential for achieving a clean and precise trim. It includes multiple parts that work together to ensure an even cut, providing a professional-grade f

Understanding the Mowing Mechanism Structure

The cutting system is a vital component, designed to ensure efficient grass trimming. It combines various interconnected elements that work together to deliver precise and uniform results on different terrains. This section delves into how these components function and interact to achieve optimal performance.

- Blade Assembly: The primary cutting tool, spinning at high speeds to slice through grass evenly. Its design varies to adapt to different grass types and thicknesses, ensuring smooth operation.

- Drive System: Responsible for transferring power from the engine to the rotating parts, this setup ensures consistent motion, allowing for a balanced cutting pace. This element includes pulleys, belts, and shafts, each contributing to maintaining consistent power flow.

- Height Adjustment Mechanism: T

Identifying Key Engine Elements

The arrangement of crucial components in a small engine is essential for ensuring smooth operation and reliable performance. Understanding the placement and role of each part helps in maintaining and troubleshooting the system effectively. By examining these elements, users can gain insight into the functioning and maintenance requirements of such machinery.

The power unit typically includes a cylinder, fuel delivery system, and an ignition mechanism, each working in tandem to ensure efficient power generation. The cylinder is where the conversion of fuel into energy occurs, while the fuel system ensures a precise mixture of air and fuel reaches the combustion chamber. The ignition setup, in turn, sparks the mixture to drive the engine cycle.

Another vital aspect is the cooling system, which prevents overheating and maintains optimal temperature levels. It usually incorporates a set of fins or a fan to dissipate heat generated during operation. This not only enhances the efficiency but also prolongs the lifespan of the engine. The lubrication system also plays a critical role by reducing friction between moving parts, ensuring smooth and seamless operation.

Guide to the Cutting Blades Assembly

The proper arrangement and installation of the trimming components ensure effective performance and a clean, precise trim. Understanding the placement and structure of these elements is crucial for maintaining optimal functionality and extending the longevity of the equipment.

Components of the Cutting Mechanism

- Main Blades: These are the primary elements responsible for achieving a uniform cut, crafted from durable materials for extended use.

- Support Plate: Positioned directly under the cutting edges, this component provides stability, reducing vibrations during operation.

- Fastening Bolts: These secure the blades in place, ensuring they remain tightly fitted and balanced during rotation.

Step-by-Step Assembly Process

- Preparation: Begin by carefully placing the main cutting components onto the support plate, aligning the holes for precise fitting.

- Secure the Blades: Insert the fastening bolts through the designated points and tighten evenly to

Exploring the Handle Controls Layout

The arrangement of the controls on the handlebar plays a crucial role in the overall user experience, allowing for smooth operation and quick access to key functions. Understanding how each element is positioned and interacts can help in maintaining or adjusting for improved handling and ease of use.

Overview of Control Elements

The handle area includes various components designed to facilitate precise control. Each component has a specific function, contributing to a seamless and efficient operation. Knowing where these elements are positioned aids in quick adjustments and ensures safety during use.

Control Placement Details

To better illustrate the arrangement, the table below outlines the key controls and their respective locations on the handle section. This layout ensures optimal reach and accessibility, enhancing the overall functionality during operation.

Control Element Position Primary Function Fuel System Parts Breakdown

This section provides a comprehensive overview of the components involved in the fuel delivery mechanism, essential for optimal engine performance. Understanding each element can enhance maintenance and troubleshooting efforts, ensuring smooth operation.

Component Description Fuel Tank Stores fuel and provides a consistent supply to the engine. Fuel Pump Moves fuel from the tank to the carburetor or injector. Carburetor/Injector Mixes air and fuel in the correct proportions for combustion. Fuel Filter Cleans the fuel by removing impurities before it reaches the engine. Fuel Lines Transport fuel between the tank, pump, and engine. Inspecting the Wheel and Drive System

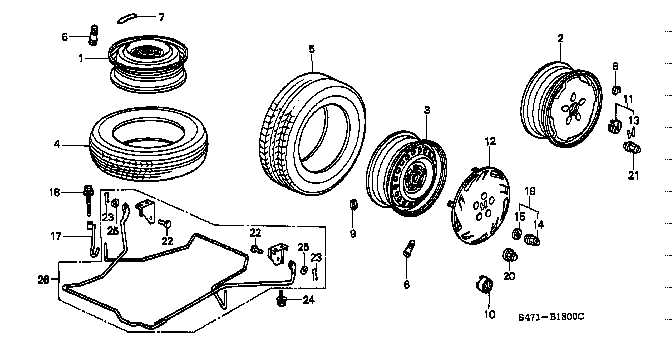

Regular examination of the rolling components and propulsion mechanism is crucial for optimal performance and longevity. This process ensures that all elements function harmoniously, minimizing wear and enhancing efficiency.

Checking the Wheels

Begin by inspecting the wheels for signs of damage or wear. Look for cracks, dents, or excessive wear on the tread. Ensure that the wheels are properly aligned and that the bearings rotate smoothly. Regular lubrication is essential to prevent friction and prolong the lifespan of the wheels.

Evaluating the Drive Mechanism

The drive system should be thoroughly assessed for any signs of wear or misalignment. Examine belts and gears for fraying or excessive play. Proper tension in the drive belts is vital for efficient power transfer. Addressing any issues promptly will ensure that the entire system operates at its ultimate efficiency.

Maintaining the Air Filter Section

Regular upkeep of the air filtration component is essential for optimal engine performance and longevity. A clean filter ensures efficient airflow, preventing debris from entering the engine and causing potential damage.

To effectively maintain this vital section, follow these key steps:

- Inspection: Check the filter regularly for dirt buildup and damage.

- Cleaning: If reusable, clean the filter according to manufacturer recommendations, using appropriate tools and cleaning solutions.

- Replacement: If the filter is disposable or too worn, replace it with a new unit to maintain performance.

- Sealing: Ensure the filter is properly sealed to prevent unfiltered air from entering the engine.

By adhering to these maintenance practices, you can enhance the efficiency and reliability of your equipment, ensuring it runs smoothly and effectively for years to come.

Common Replacement Parts for HRC216

Maintaining a high-performance lawn mower involves knowing which components may need to be replaced over time. Regular usage can lead to wear and tear, making it essential to identify the most frequently needed items for optimal functionality. Here are some of the common components that often require attention:

- Blades: Sharp, well-maintained blades ensure a clean cut. Regular replacement prevents grass damage.

- Filters: Air and fuel filters need to be changed periodically to maintain engine efficiency and longevity.

- Spark Plugs: These components play a crucial role in starting and engine performance. Regular checks are advised.

- Belts: Drive and mower belts can wear out, affecting movement and cutting ability. Inspecting and replacing them can enhance performance.

- Wheels: Tires may suffer from wear, affecting traction and maneuverability. Replacing them ensures smoother operation.

Understanding which components may need replacement allows for better preparation and maintenance, ultimately extending the lifespan of the mower.