The efficiency and performance of any agricultural implement largely depend on its intricate design and the quality of its components. For operators and maintenance personnel, having a clear understanding of these elements is essential for optimal functionality and longevity of the equipment. This section delves into the various segments of a specific rotary cutting apparatus, offering insights into their arrangement and significance.

By familiarizing oneself with the layout and interconnections of the machine’s components, users can better diagnose issues and perform necessary maintenance tasks. Each part plays a crucial role, contributing to the overall effectiveness of the machinery in the field. Through detailed visual representation and descriptive analysis, this resource aims to enhance your knowledge and ensure that your equipment operates at peak performance.

Whether you are a seasoned operator or new to agricultural machinery, understanding the structure and design of these implements can lead to improved productivity and reduced downtime. This guide serves as a comprehensive resource to empower users with the information needed to keep their equipment in top condition.

Kuhn GMD 600 Overview

This section provides a comprehensive look at a specific type of agricultural equipment designed for efficient forage management. With advanced engineering and innovative features, this machinery is tailored for optimal performance in various farming conditions.

Key Features

Equipped with robust cutting systems, this implement ensures clean and precise operation. Its user-friendly design enhances productivity while minimizing maintenance needs. The integration of modern technology further boosts its efficiency, making it an essential tool for modern agricultural practices.

Benefits of Use

Utilizing this equipment leads to significant improvements in operational efficiency and crop quality. Farmers can expect higher yields and reduced labor costs, resulting in enhanced overall profitability. The durability and reliability of the machine also contribute to its long-term value in any farming operation.

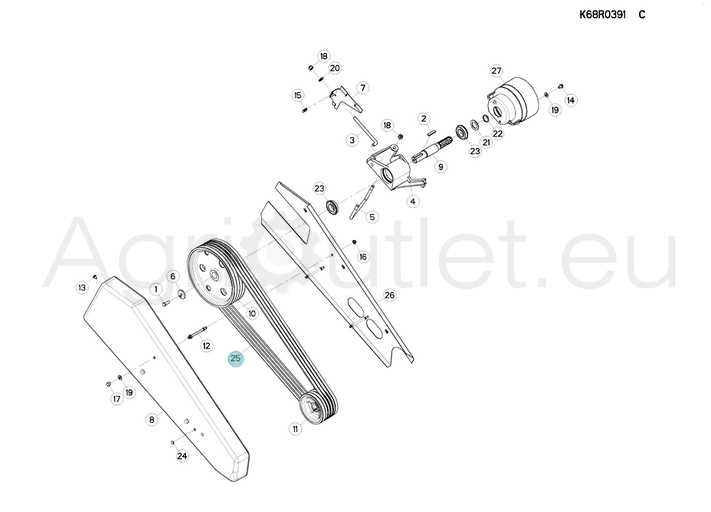

Understanding Disc Mower Components

To optimize the performance of agricultural cutting equipment, it’s essential to grasp the various elements that make up these machines. Each component plays a pivotal role in the overall functionality and efficiency, ensuring effective operation in the field.

Main Elements of the Equipment

- Cutter Bar: The primary area where the cutting action occurs, typically equipped with rotating blades.

- Blades: Sharp, durable pieces that slice through the material; they must be regularly maintained for peak performance.

- Gearbox: This component transfers power from the tractor to the cutter, essential for achieving the necessary speed and torque.

- Frame: The structural support that holds all components together, designed for stability and durability.

Support and Control Features

- Hitch: The attachment mechanism that connects the equipment to the towing vehicle.

- Skid Shoes: Adjustable elements that control cutting height and protect the blades from ground contact.

- Hydraulic System: Enables the adjustment of the machine’s position and operation, providing ease of use during fieldwork.

- Safety Guards: Protective barriers designed to shield operators from moving parts, enhancing safety during use.

Understanding these fundamental components will not only aid in better maintenance but also enhance overall operational efficiency, leading to improved results in agricultural practices.

Importance of Maintenance for Equipment

Regular upkeep of machinery is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to unexpected breakdowns, reduced efficiency, and increased operational costs. A proactive approach to care not only enhances the reliability of equipment but also safeguards the investment made in it.

Routine inspections and timely repairs can identify potential issues before they escalate into major problems. This approach minimizes downtime, allowing for continuous operation and productivity. Moreover, well-maintained machinery operates more efficiently, often resulting in lower energy consumption and reduced wear and tear on components.

In addition to enhancing performance, consistent maintenance helps in adhering to safety standards. Equipment that is regularly serviced is less likely to malfunction, which significantly lowers the risk of accidents and injuries in the workplace. Furthermore, maintaining equipment properly can contribute to a positive reputation for the organization, showcasing a commitment to quality and reliability.

In summary, prioritizing maintenance is essential for the effective functioning of machinery. By investing time and resources into upkeep, operators can ensure sustained performance, safety, and efficiency, ultimately leading to greater success and productivity in their operations.

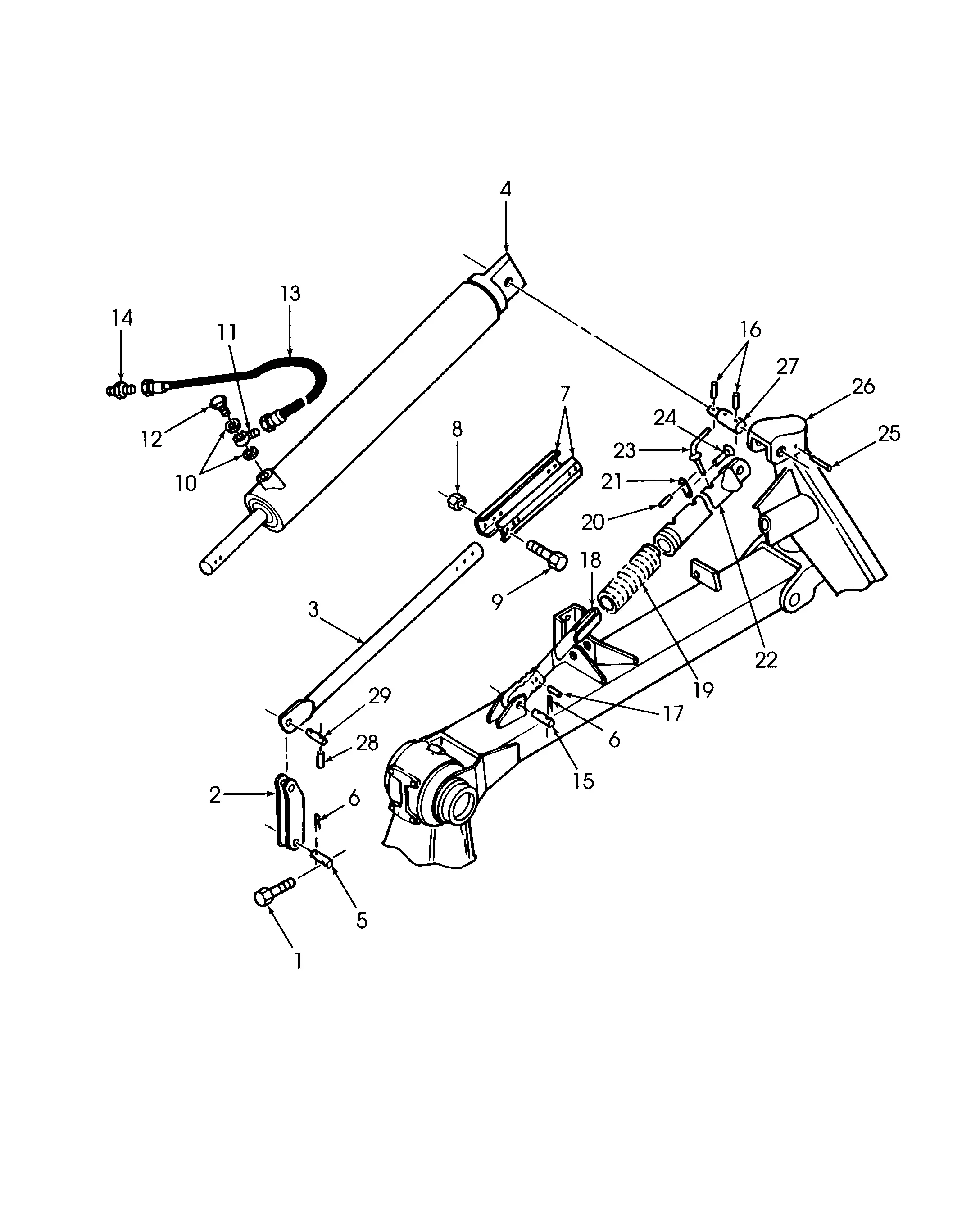

How to Read Parts Diagrams

Understanding the visual representation of components is essential for effective maintenance and repairs. These illustrations serve as guides to identify individual pieces and their relationships, making it easier to navigate complex assemblies.

Here are some key elements to consider when interpreting these illustrations:

| Element | Description |

|---|---|

| Labels | Numerical or alphabetical identifiers indicating specific items. |

| Legend | A section explaining symbols and markings used throughout the visual. |

| Sections | Divided areas showcasing different assemblies or functionalities. |

| Connections | Lines showing how components link or interact with each other. |

By familiarizing yourself with these aspects, you can navigate the illustrations with confidence and ensure efficient troubleshooting and replacement of components.

Common Issues with Kuhn GMD 600

Operating agricultural machinery can present various challenges, and the equipment in question is no exception. Users often encounter a range of complications that can affect performance and efficiency. Understanding these common problems can aid in timely maintenance and repairs, ensuring optimal functionality.

Wear and Tear: One prevalent issue is the natural deterioration of components over time. Regular usage can lead to the degradation of blades and bearings, which may result in reduced cutting efficiency and uneven performance. Regular inspections can help identify these signs early.

Clogging: Another frequent concern is clogging, often caused by excessive moisture or dense vegetation. This can hinder the machine’s operation, leading to reduced productivity. Clearing debris and ensuring proper cutting height can mitigate this issue.

Hydraulic System Failures: The hydraulic system plays a crucial role in the operation of this machinery. Leaks or malfunctions in hydraulic lines can lead to performance drops and even complete operational failure. Routine checks for leaks and maintaining fluid levels are essential for preventing these problems.

Drive Belt Issues: Problems with drive belts, such as wear or misalignment, can significantly impact performance. Regular monitoring and timely replacement of worn belts can prevent further damage and ensure smooth operation.

Electrical Failures: Electrical components can also pose challenges, with issues ranging from faulty connections to malfunctioning sensors. Regular maintenance of electrical systems is vital for reliable performance and to avoid unexpected breakdowns.

By being aware of these common issues and implementing a proactive maintenance approach, operators can enhance the longevity and effectiveness of their machinery, ultimately leading to more successful operations.

Where to Find Replacement Parts

Finding the right components for agricultural equipment is essential for maintaining optimal performance and longevity. Various sources offer a range of options, ensuring that you can locate the specific items needed to keep your machinery running smoothly.

Authorized Dealers

Official distributors are often the best choice for acquiring genuine items. They provide assurance of quality and compatibility, along with expert advice tailored to your equipment’s requirements.

Online Marketplaces

Numerous e-commerce platforms feature a wide selection of components from various manufacturers. Comparing prices and reviews can help you make informed decisions, while customer feedback often highlights the reliability of different suppliers.

Upgrades for Enhanced Performance

Enhancing the functionality of agricultural equipment can significantly improve efficiency and output. By focusing on specific modifications and improvements, operators can optimize performance, reduce downtime, and ensure that their machinery operates at peak capacity. This section will explore various enhancements that can be implemented for superior results.

Precision Components

Investing in high-quality precision components is crucial for maximizing operational efficiency. Upgrading to durable, high-performance parts can lead to smoother operation and reduced wear and tear. Enhanced blades, for instance, can ensure cleaner cuts, allowing for better handling of materials and improved overall productivity.

Advanced Technology Integration

The integration of modern technology into traditional machinery can lead to remarkable advancements in performance. Implementing GPS tracking and automated controls can improve accuracy and streamline processes. Additionally, using sensors to monitor machine conditions allows for proactive maintenance, reducing the likelihood of unexpected failures and extending the lifespan of the equipment.

Safety Tips for Operating Mowers

Operating agricultural cutting equipment requires careful attention to safety to prevent accidents and injuries. Understanding the potential hazards and adhering to best practices can ensure a secure working environment.

Always wear appropriate protective gear, including sturdy footwear, gloves, and eye protection. This reduces the risk of injury from flying debris and sharp components.

Before starting, inspect the equipment for any signs of wear or damage. Ensuring everything is in proper working condition can help prevent mechanical failures while in use.

Maintain a clear work area by removing obstacles, such as rocks and branches, that could interfere with operation. A tidy environment minimizes the chances of accidents.

Stay alert and avoid distractions while operating machinery. Concentration is key to responding quickly to any unexpected situations that may arise.

Finally, familiarize yourself with the operator’s manual and all safety features of the equipment. Knowledge of the machinery enhances both effectiveness and safety during use.