In the world of culinary arts, efficiency and precision are paramount. Specialized devices designed for cutting and processing ingredients play a crucial role in streamlining kitchen operations. To fully grasp their functionality, it is essential to explore the intricate assembly that allows these machines to perform their tasks with such effectiveness.

The inner workings of these tools consist of various elements that contribute to their overall performance. Each component serves a specific purpose, and together they create a harmonious system capable of delivering consistent results. Familiarity with these features not only enhances operational knowledge but also aids in maintenance and troubleshooting, ensuring longevity and reliability.

As we delve deeper into the structure of these culinary aids, it becomes evident that understanding their layout is invaluable. By examining the relationship between each segment, one can appreciate the engineering and design that underpin these indispensable kitchen companions. This knowledge empowers users to maximize the potential of their equipment, transforming the food preparation process into a seamless and enjoyable experience.

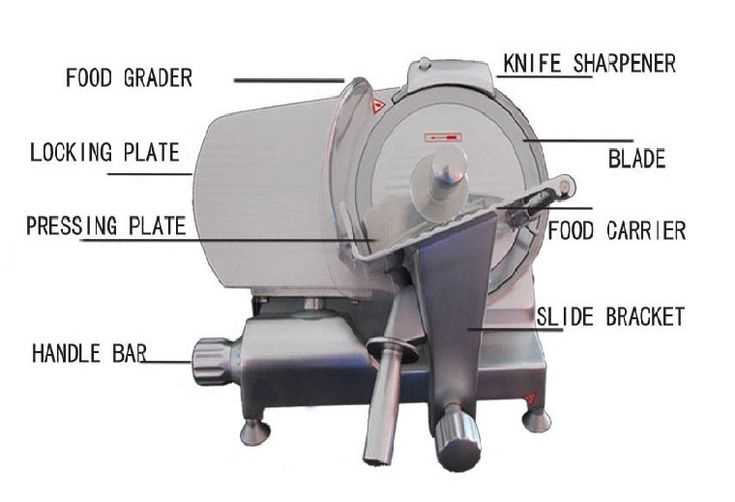

Understanding Meat Slicer Components

Grasping the intricacies of food preparation tools is essential for optimal performance and safety. Each element of these devices plays a crucial role in their functionality, ensuring efficiency and precision during usage. By familiarizing oneself with these essential components, users can enhance their skills and maintain equipment in peak condition.

First and foremost, the cutting mechanism is vital, as it directly influences the quality of the results. This element must be sharp and well-maintained to ensure clean, uniform slices. Additionally, the feed system allows for controlled and consistent movement of the food item towards the blade, contributing to safety and effectiveness during operation.

Another important component is the safety guard, designed to protect the user from accidental contact with the sharp edge. This feature is indispensable in any high-functioning kitchen. Furthermore, the base provides stability and support, ensuring that the device remains secure during operation, which is essential for both safety and efficiency.

Lastly, regular maintenance of these components, including cleaning and occasional replacements, is critical for longevity and reliability. Understanding these elements allows users to operate with confidence, maximizing both performance and safety in their culinary endeavors.

Importance of Slicer Maintenance

Regular upkeep of cutting equipment is crucial for ensuring efficiency, safety, and longevity. Neglecting maintenance can lead to performance issues, increased risk of accidents, and higher operational costs. A well-maintained unit not only performs better but also contributes to the overall quality of food preparation.

Benefits of Proper Maintenance

- Enhanced Performance: Regular checks ensure optimal functionality.

- Increased Safety: Reduces the risk of accidents and injuries.

- Cost Efficiency: Prevents costly repairs and replacements.

- Quality Assurance: Maintains the integrity of the product being processed.

Key Maintenance Practices

- Regular Cleaning: Remove debris and residues after each use.

- Inspection: Check for wear and tear, ensuring all components are in good condition.

- Sharpening Blades: Keep cutting edges sharp for efficient operation.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction.

Types of Meat Slicer Blades

The selection of cutting tools is crucial for achieving optimal results in food preparation. Different blade designs cater to various slicing needs, ensuring precision and efficiency. Understanding the variety of available options can greatly enhance the overall performance and versatility of the machine.

Standard Blades are the most common type, featuring a smooth edge that allows for even slicing of most food items. These blades are ideal for general purposes and can handle a range of products with ease.

Serrated Blades, on the other hand, are designed with a saw-like edge, making them perfect for cutting through tougher textures. They excel in slicing bread and other crusty items, providing a clean cut without crushing the material.

Adjustable Blades offer versatility by allowing users to modify the thickness of the slices. This feature is particularly useful for recipes that require specific slice dimensions, enabling greater control over the final product.

Specialty Blades are tailored for specific tasks, such as julienne or dicing. These blades enhance creativity in food presentation and can simplify complex preparations by providing unique cutting styles.

In summary, choosing the right blade type is essential for achieving desired outcomes in culinary tasks. Each design has its unique advantages, making it important to match the blade to the intended use for optimal performance.

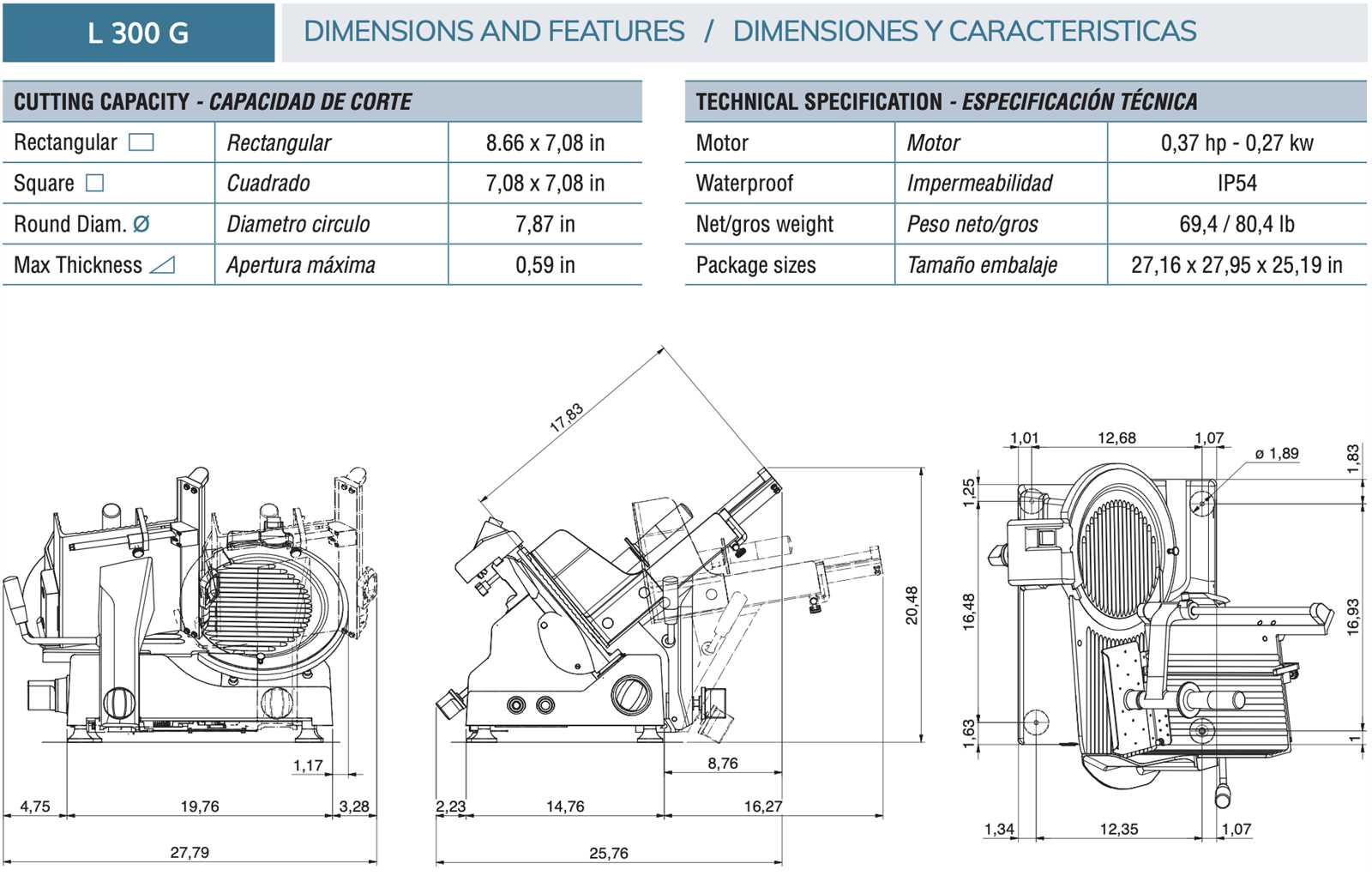

Identifying Electrical Parts

Understanding the components that provide power and functionality to your appliance is crucial for effective maintenance and troubleshooting. By recognizing these elements, users can ensure optimal performance and safety during operation.

Common Electrical Components

Several key components play a vital role in the functionality of electrical appliances. Familiarizing yourself with these can help in identifying issues that may arise over time.

| Component | Function |

|---|---|

| Motor | Converts electrical energy into mechanical motion. |

| Power Cord | Transmits electrical energy from the outlet to the device. |

| Switch | Controls the flow of electricity to the appliance. |

| Fuse | Protects against overcurrent by breaking the circuit if necessary. |

Safety Considerations

When examining these components, always prioritize safety. Ensure the appliance is unplugged before conducting any inspections or repairs, and use appropriate tools to avoid electrical hazards.

Safety Features of Meat Slicers

Ensuring safety in the kitchen is paramount, especially when using equipment designed for precision cutting. Various mechanisms and technologies are integrated into these machines to minimize the risk of accidents and injuries. Understanding these safety features is crucial for users to operate them confidently and effectively.

Blade Guard: One of the primary safety components is the blade guard, which covers the cutting edge when not in use. This feature prevents accidental contact with the sharp surface, significantly reducing the likelihood of cuts.

Automatic Shut-Off: Many devices are equipped with an automatic shut-off system that activates when the machine is not in operation for a specified duration. This ensures that the equipment does not remain powered on inadvertently, minimizing potential hazards.

Emergency Stop Button: An easily accessible emergency stop button allows users to halt the operation immediately in case of an unforeseen situation. This feature is essential for rapid response during emergencies.

Non-Slip Feet: Stability is vital during operation. Non-slip feet help secure the machine in place, preventing it from moving while in use, which enhances safety and control.

Safety Interlocks: These mechanisms ensure that the device cannot operate unless all safety features are correctly engaged. This provides an additional layer of protection by preventing accidental activation.

By incorporating these safety mechanisms, users can ensure a safer environment while enjoying the efficiency and convenience that these tools provide in food preparation.

Common Issues and Troubleshooting

This section addresses frequent challenges users may encounter with their slicing equipment, providing insights for effective resolution. Understanding these common problems can enhance performance and longevity.

Frequent Challenges

- Inconsistent thickness of slices

- Difficulty in starting the machine

- Noisy operation

- Sticking or jamming during use

Troubleshooting Tips

- Check the blade sharpness; dull blades can cause uneven cuts.

- Ensure the power source is functional and connections are secure.

- Inspect for debris or residue that may be obstructing movement.

- Lubricate any moving parts as recommended by the manufacturer.

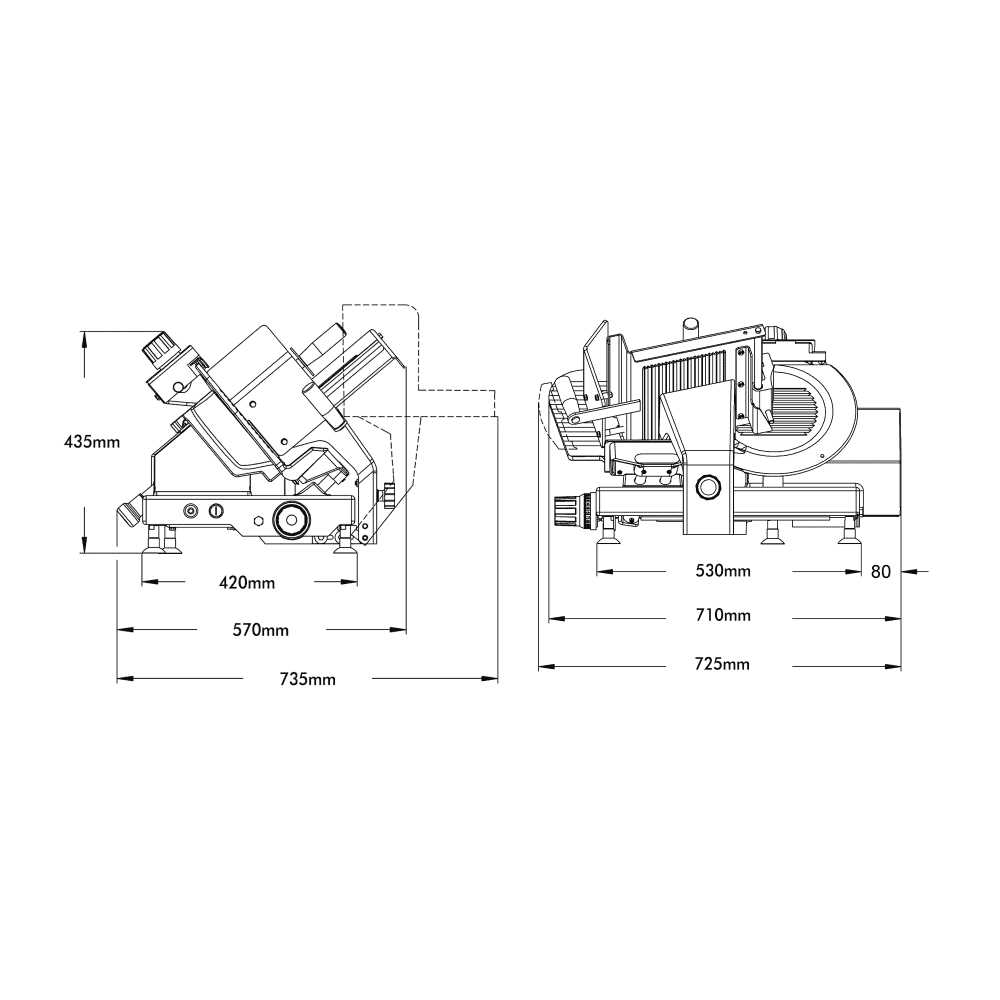

Assembly and Disassembly Guide

This section provides a comprehensive approach to the process of assembling and disassembling essential components of a slicing machine. Understanding these steps is crucial for maintaining functionality and ensuring safety during operation.

Key Steps for Assembly

Begin by organizing all necessary components. Ensure each item is clean and free from debris. Following the manufacturer’s instructions, connect the primary elements securely, verifying that all fittings are tight. Pay attention to alignment for optimal performance.

Safe Disassembly Procedures

Before disassembling, unplug the device to prevent accidental activation. Carefully remove each component in reverse order of assembly, taking care to avoid damage. Store the parts safely to maintain their condition for future use. Regular checks during this process enhance longevity and reliability.

Enhancing Efficiency with Upgrades

In the quest for improved productivity and operational excellence, upgrading essential equipment can yield significant benefits. Implementing modern enhancements not only boosts performance but also streamlines processes, allowing businesses to operate more effectively.

To achieve optimal functionality, consider the following upgrades:

- Blade Quality: Investing in high-grade cutting edges can result in cleaner cuts and reduced wear over time.

- Motor Power: Upgrading to a more powerful motor can enhance speed and efficiency, enabling faster output.

- Safety Features: Adding advanced safety mechanisms ensures a secure working environment, minimizing risks during operation.

- Automatic Feed: Integrating an automated feeding system can enhance consistency and reduce manual labor.

- Cleaning Mechanisms: Implementing self-cleaning systems facilitates easier maintenance and hygiene compliance.

By focusing on these key areas, businesses can not only improve their workflow but also adapt to changing market demands, ultimately leading to increased profitability and customer satisfaction.