In the realm of small engine maintenance and repair, having a clear understanding of the various components and their interrelations is essential. A well-structured visual representation can significantly enhance the efficiency of repairs, making it easier to identify parts and comprehend their functions. Such resources serve as invaluable tools for both novice enthusiasts and seasoned professionals alike.

When tackling engine-related issues, familiarity with the specific arrangement of elements allows for quicker diagnostics and streamlined repairs. An effective layout not only illustrates where each piece fits but also highlights how they interact with one another, ensuring a comprehensive grasp of the machine’s inner workings. This knowledge empowers users to perform maintenance tasks with confidence and precision.

Moreover, having access to a detailed visual guide simplifies the ordering of replacement components, minimizing downtime and enhancing the overall repair experience. By bridging the gap between theoretical knowledge and practical application, these representations are indispensable for anyone looking to maintain their engine in optimal condition.

Kohler CV23S Overview

This section provides an insightful look into a powerful engine designed for various applications, emphasizing its robust performance and reliability. With advanced engineering and innovative features, it stands out in its category, catering to the needs of both commercial and residential users.

Key Features

Notable for its durability, this engine incorporates advanced cooling systems and high-efficiency components. Users benefit from reduced maintenance requirements and enhanced fuel efficiency, making it a practical choice for demanding tasks.

Applications

This engine is widely utilized in landscaping equipment, generators, and agricultural machinery, highlighting its versatility. Its performance in diverse environments ensures that it meets the expectations of users seeking both power and dependability.

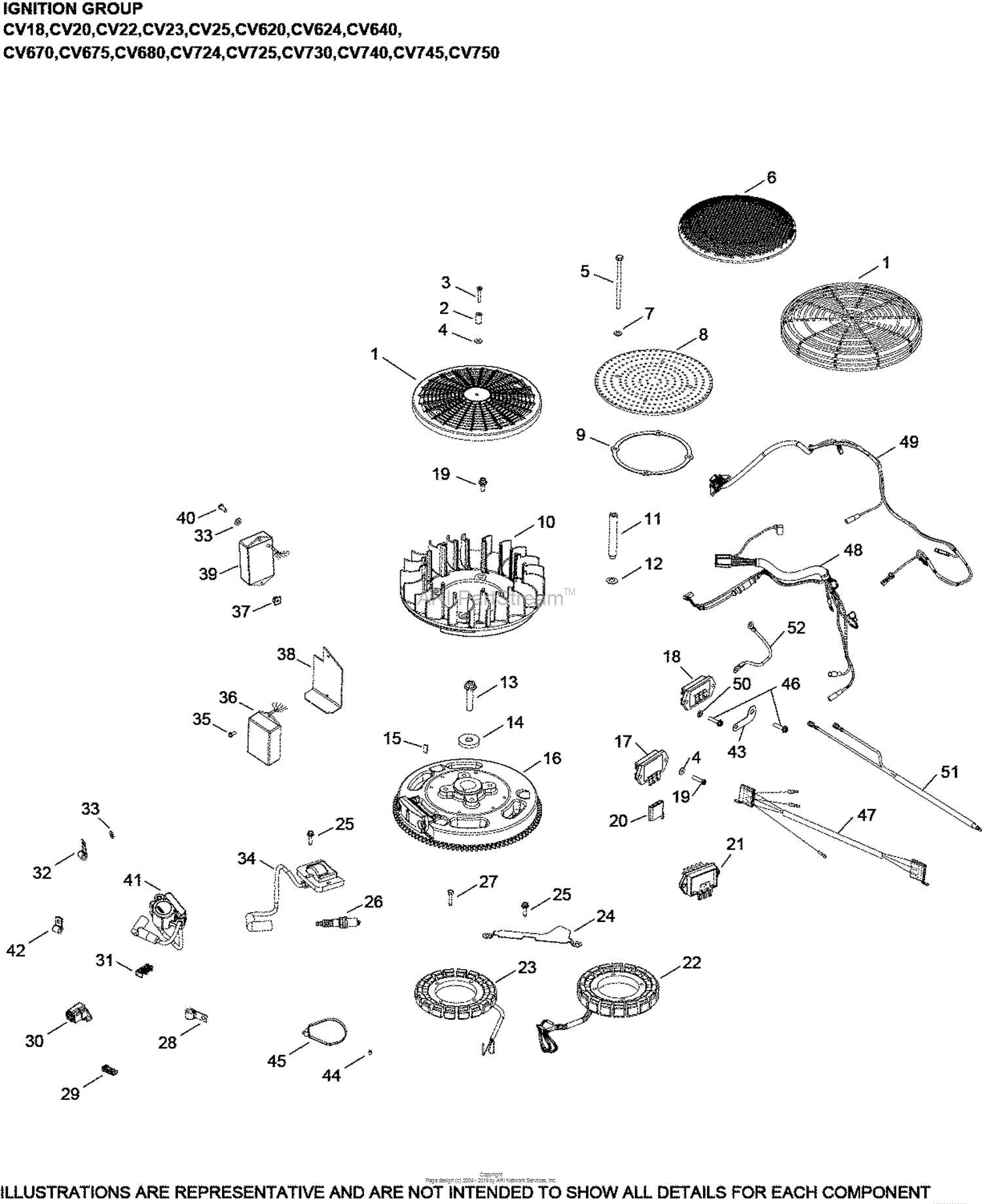

Importance of Parts Diagrams

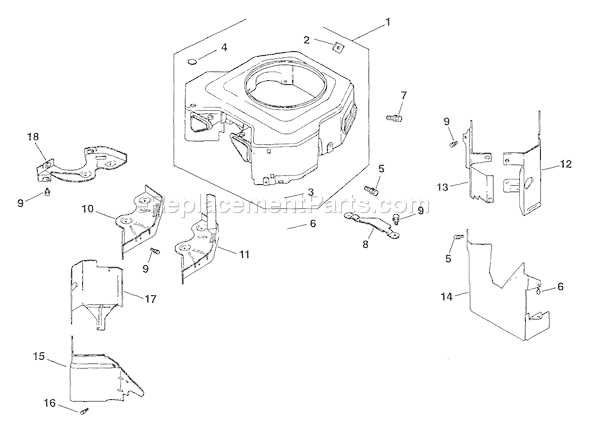

Understanding the structure and components of machinery is essential for effective maintenance and repair. Visual representations of these elements serve as crucial tools for technicians and enthusiasts alike, enhancing comprehension and facilitating efficient service procedures.

Enhanced Clarity

Diagrams provide a clear view of the assembly, allowing users to:

- Identify individual components easily

- Understand their relationships and functions

- Visualize the assembly process

Efficient Troubleshooting

Having a visual guide can significantly speed up the diagnostic process. It allows users to:

- Quickly locate issues within the system

- Determine which parts may need replacement or repair

- Minimize downtime by streamlining the repair process

Identifying Key Components

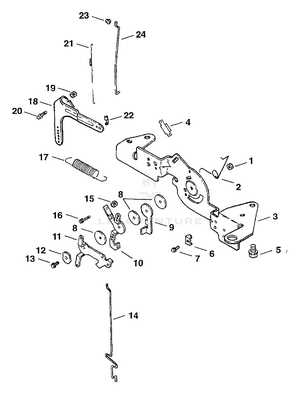

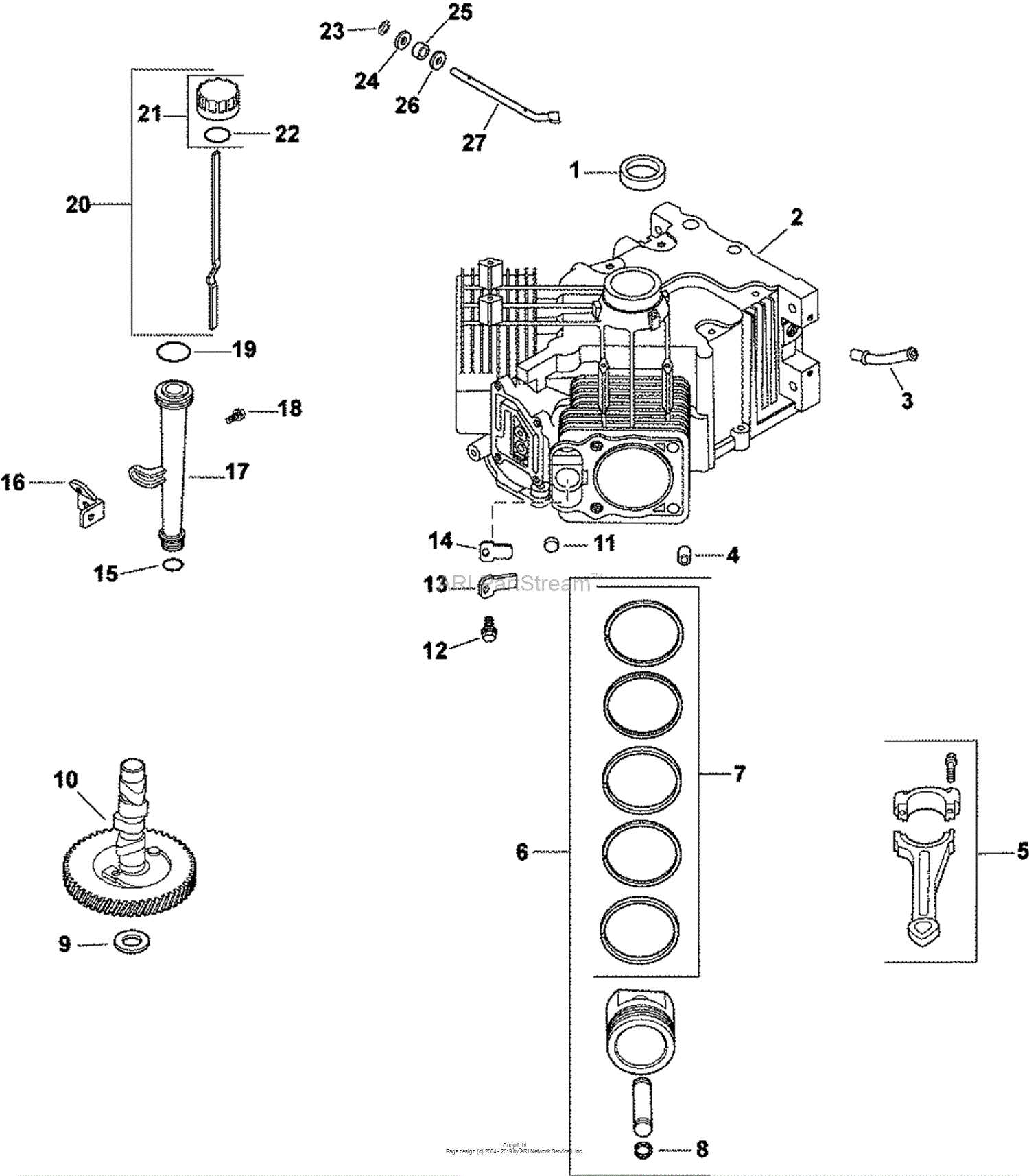

Understanding the essential elements of an engine is crucial for effective maintenance and troubleshooting. Each component plays a significant role in ensuring optimal performance and efficiency. Familiarity with these parts allows for better diagnostics and informed decisions during repairs.

Engine Block: The foundation of the engine, housing critical internal mechanisms. Its integrity is vital for overall function.

Crankshaft: This part transforms linear motion into rotational energy, driving the vehicle’s movement.

Camshaft: Responsible for controlling valve timing, it ensures the engine breathes properly, optimizing power output.

Fuel System: Comprising injectors and pumps, this system delivers fuel to the combustion chamber, playing a key role in engine efficiency.

Ignition System: Essential for initiating combustion, this system includes spark plugs and coils, which create the necessary spark for the fuel-air mixture.

Cooling System: Prevents overheating by circulating coolant, maintaining optimal operating temperatures for performance longevity.

By grasping the function of these components, one can effectively delve into the intricacies of engine operation, ultimately enhancing maintenance efforts.

Common Issues and Solutions

When dealing with small engine machinery, certain challenges frequently arise that can affect performance and reliability. Identifying these common problems and implementing effective solutions is essential for maintaining optimal functionality and extending the lifespan of your equipment.

1. Engine Won’t Start

This is a prevalent issue that can stem from various factors. First, check the fuel supply; stale or contaminated fuel can prevent ignition. Ensure the spark plug is in good condition and properly gapped. Cleaning or replacing it may solve the problem.

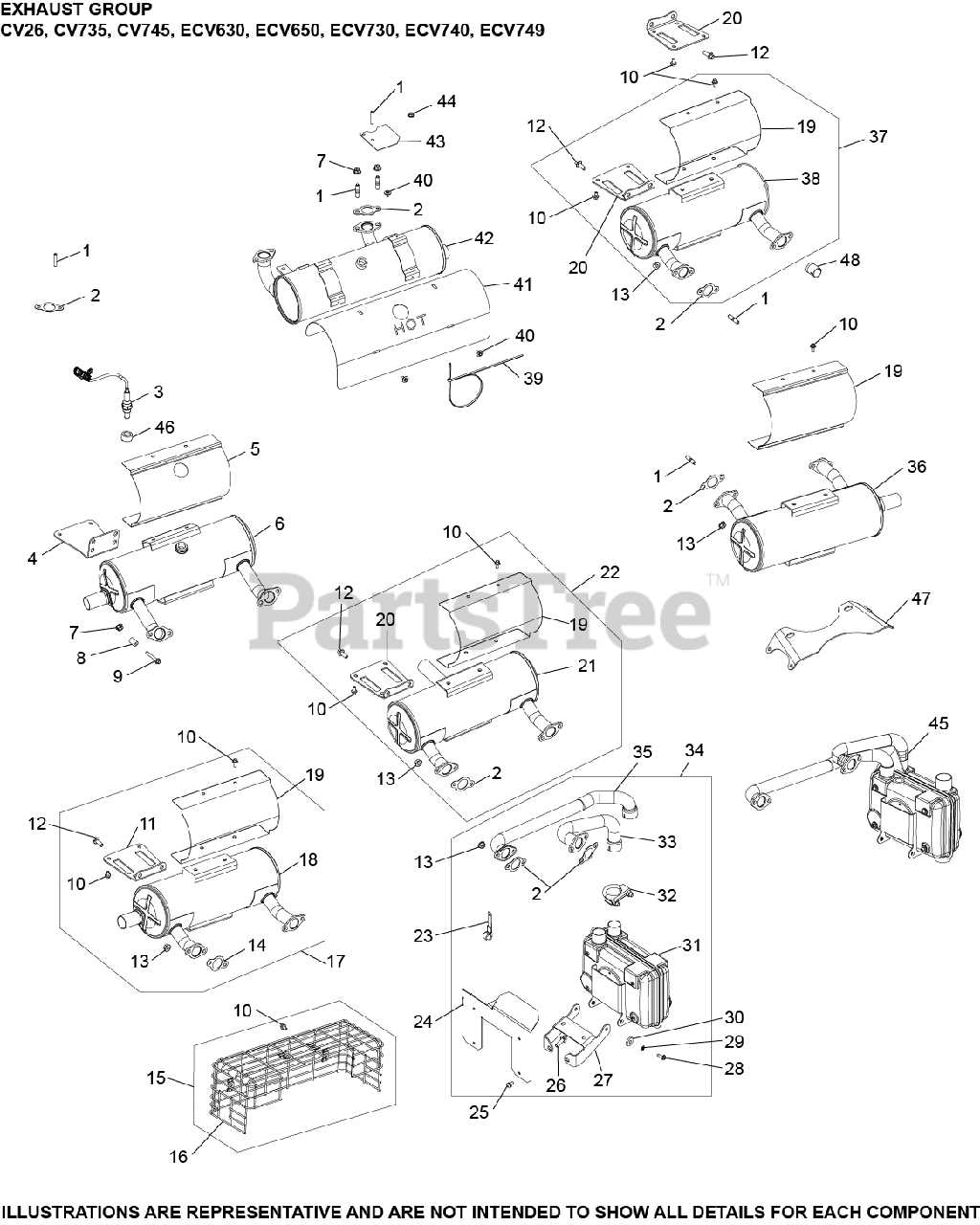

2. Overheating

Excessive heat can lead to severe damage. Ensure the cooling fins are clean and unobstructed. A faulty cooling system or low oil levels can also contribute to overheating. Regular maintenance and checks can help mitigate this issue.

3. Poor Performance

Loss of power or uneven running may indicate fuel system problems. Inspect the carburetor for clogs and ensure the air filter is clean. Adjusting the throttle or replacing a worn governor may also improve performance.

4. Unusual Noises

Strange sounds can indicate mechanical issues. Inspect the engine for loose parts or wear in the bearings. Lubricating moving components and tightening bolts can often resolve these noises.

5. Fuel Leaks

Leaks can lead to inefficient operation and safety hazards. Examine fuel lines and connections for wear or damage. Replacing damaged hoses and ensuring all connections are secure can prevent leaks from occurring.

By understanding these common issues and their respective solutions, operators can ensure their machinery runs smoothly and efficiently for years to come.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your equipment requires regular attention and care. Implementing a consistent maintenance routine can significantly enhance efficiency, reduce downtime, and extend the overall lifespan of your machinery. By following a few essential practices, you can keep your engine running smoothly for years to come.

Regular Inspections

Conduct frequent assessments of your engine components. Look for signs of wear and tear, leaks, or loose fittings. Addressing small issues promptly can prevent them from escalating into major problems. Additionally, check fluid levels regularly to maintain optimal operation.

Proper Cleaning and Lubrication

Keeping the engine clean is crucial for preventing debris buildup, which can hinder performance. Use appropriate cleaning agents and tools to remove dirt and grime. Furthermore, ensure that all moving parts are adequately lubricated. This reduces friction and minimizes the risk of overheating, ultimately promoting smoother operation.

By adhering to these practices, you can significantly enhance the reliability and durability of your equipment, ensuring it serves you well for the long haul.

Where to Find Replacement Parts

Locating components for machinery can often be a daunting task, yet it is essential for maintaining optimal performance. Understanding where to source these items can save both time and money. Various options exist, each offering unique advantages depending on the specific needs and circumstances.

Online Retailers

Numerous online platforms specialize in offering a wide range of replacement components. These websites often provide detailed descriptions and user reviews, enabling you to make informed decisions. Comparing prices across multiple sites can lead to significant savings.

Local Dealers and Distributors

Visiting local dealerships and distributors can be beneficial, as they often have direct access to the latest stock and can provide expert advice. Engaging with knowledgeable staff allows for a more personalized experience and can facilitate quicker acquisition of necessary items. Additionally, supporting local businesses contributes positively to the community.

DIY Repair vs. Professional Help

When faced with a malfunctioning piece of equipment, many individuals find themselves weighing the benefits of tackling the repair independently versus seeking assistance from a qualified expert. Each approach carries its own set of advantages and challenges that can significantly impact the outcome of the repair process.

Choosing to undertake repairs on your own can foster a sense of accomplishment and save money. Engaging in hands-on work allows individuals to gain a deeper understanding of their machinery and can lead to valuable skills development. However, this option often requires a certain level of expertise, access to tools, and a willingness to troubleshoot issues as they arise.

On the other hand, hiring a professional guarantees a higher likelihood of success, as these experts bring experience and specialized knowledge to the table. Their ability to diagnose problems quickly can save time and reduce the risk of further damage. Nevertheless, this route typically comes with a financial cost and may lead to longer wait times for service, depending on the availability of the technician.

Ultimately, the decision between DIY repairs and professional assistance hinges on personal capability, the complexity of the issue, and the value placed on time and quality outcomes. Weighing these factors can help individuals determine the most effective approach to restoring their equipment to optimal functioning condition.

Understanding Part Numbers and Codes

In the world of machinery and equipment, the identification and categorization of components play a crucial role in ensuring proper maintenance and functionality. Each element is assigned a unique identifier, which not only facilitates easy reference but also aids in procurement and inventory management. Understanding these identifiers is essential for anyone involved in equipment maintenance or repair.

The Importance of Unique Identifiers

Unique codes provide a systematic way to track and manage various components. They often contain valuable information about the specifications, compatibility, and application of each part. By familiarizing oneself with these identifiers, users can streamline their repair processes and minimize the risk of errors during maintenance tasks.

Decoding the Structure

The format of these codes can vary widely, often including alphanumeric characters that convey specific meanings. Prefixes may indicate the manufacturer or category, while numbers might represent dimensions or compatibility details. Understanding this structure allows for more efficient searches and better decision-making when selecting components for repairs.