The intricate design of modern lawn machinery often requires a thorough comprehension of its various elements. Each component plays a critical role in ensuring optimal performance and longevity. Whether you’re a seasoned professional or a dedicated enthusiast, grasping the relationships between these parts can significantly enhance your maintenance and repair skills.

In this exploration, we will delve into the specifics of essential machinery elements, shedding light on their functions and interconnections. Recognizing how these pieces work together not only aids in troubleshooting but also empowers users to perform informed upgrades and repairs.

Furthermore, a well-organized reference for these components can simplify the process of identifying and sourcing replacements when necessary. By familiarizing yourself with the layout and roles of each section, you can ensure your equipment remains in peak condition, ready to tackle any landscaping challenge.

Understanding Scag Cheetah Components

Gaining insight into the various elements of a lawn maintenance machine is essential for effective operation and maintenance. Each component plays a crucial role in the overall functionality, contributing to efficiency and durability. Recognizing these parts helps users make informed decisions about repairs and enhancements.

| Component | Function |

|---|---|

| Engine | Provides power for operation |

| Deck | Houses the cutting blades and ensures even grass trimming |

| Transmission | Transfers power from the engine to the wheels |

| Blades | Cut the grass at desired heights |

| Wheels | Facilitate movement and maneuverability |

Overview of Scag Cheetah Design

This section explores the fundamental structure and engineering principles of a high-performance lawn maintenance machine, focusing on its innovative design features that enhance efficiency and durability.

Key aspects of this design include:

- Robust construction materials for longevity.

- Streamlined chassis for optimal maneuverability.

- Advanced cutting technology for superior grass management.

Each component plays a crucial role in the overall functionality, contributing to the machine’s ultimate performance.

- Ergonomic controls for user comfort.

- Powerful engine options for varied applications.

- Effective cooling systems to ensure reliable operation.

By delving into these features, users can appreciate the meticulous engineering that defines this exceptional equipment.

Key Parts of the Cheetah Model

This section delves into the essential components that contribute to the overall functionality and efficiency of this particular mowing machine. Understanding these elements is crucial for effective maintenance and optimal performance.

- Engine: The powerhouse that drives the entire unit, ensuring robust performance.

- Transmission: Responsible for transferring power from the engine to the wheels, allowing for smooth operation.

- Deck: The cutting assembly that determines the width and quality of the cut.

- Wheels: Provide stability and maneuverability, essential for navigating various terrains.

- Control System: The interface that allows the operator to manage speed and direction effectively.

Each of these components plays a vital role in the operation of the machine, and understanding their functions can help users troubleshoot issues and perform maintenance more effectively.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. By following specific maintenance practices, you can extend the lifespan of your machinery and enhance its performance. Here are some essential tips to keep your equipment in optimal condition.

- Regular Cleaning: Dirt and debris can accumulate and cause wear. Clean your machinery after each use.

- Check Fluid Levels: Regularly inspect oil and coolant levels. Top them off as needed to prevent overheating and mechanical failure.

- Inspect Belts and Cables: Look for signs of wear or fraying. Replace any damaged components promptly to avoid larger issues.

In addition to these practices, consider the following:

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer.

- Store Properly: Keep your equipment in a dry, sheltered location to protect it from the elements.

- Use Quality Parts: When replacements are necessary, choose high-quality components to ensure compatibility and reliability.

By implementing these maintenance strategies, you can ensure that your machinery remains efficient and effective for years to come.

Common Issues and Solutions

In the realm of outdoor power equipment, users often encounter a variety of challenges that can impede functionality. Understanding these frequent problems and their respective remedies is essential for maintaining optimal performance and prolonging the lifespan of the machinery.

Engine Performance Problems

A common issue that arises is related to engine performance. Symptoms such as stalling, rough idling, or reduced power output can often be traced back to fuel quality or air filter blockages. Regular maintenance is crucial; ensure that you replace the air filter periodically and use high-quality fuel to prevent these issues. Additionally, checking for loose connections or worn spark plugs can significantly enhance performance.

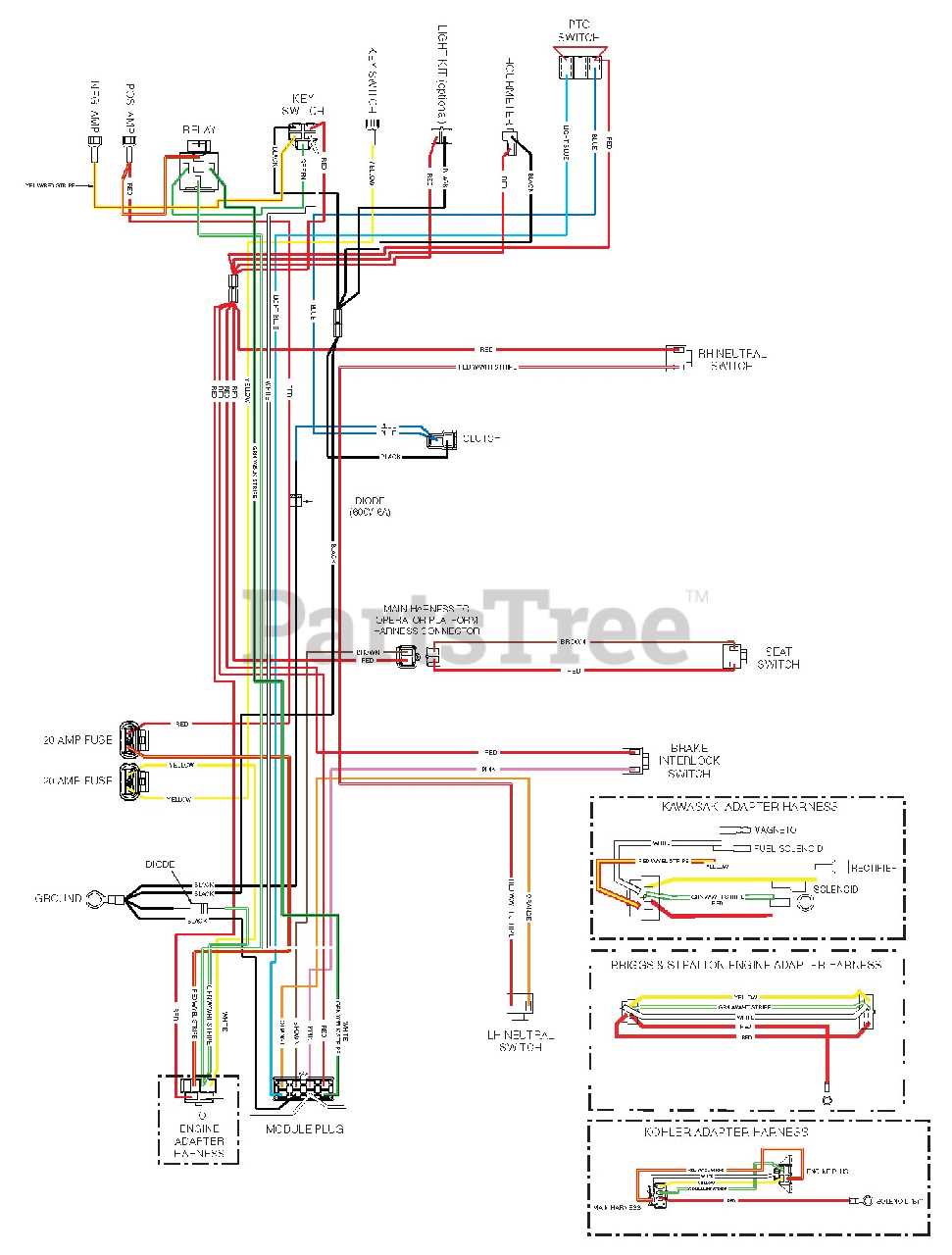

Electrical System Failures

Another area where difficulties may arise is within the electrical system. Problems such as failure to start or inconsistent operation can often be attributed to battery issues or faulty wiring. It’s advisable to inspect the battery for corrosion and ensure all connections are secure. If problems persist, consider consulting a professional to evaluate the wiring integrity and rectify any potential faults.

Replacement Parts Availability and Sourcing

When it comes to maintaining outdoor equipment, understanding the accessibility of components is crucial for ensuring optimal performance. Users often seek reliable sources to acquire necessary replacements, which can significantly impact equipment longevity and functionality.

Numerous avenues exist for sourcing essential elements, each offering unique advantages. The table below outlines various options available to consumers:

| Source Type | Description | Pros | Cons |

|---|---|---|---|

| Authorized Dealers | Official retailers providing genuine components. | Quality assurance, expert advice. | Higher prices, limited stock. |

| Online Marketplaces | Web-based platforms for a wide range of options. | Convenience, competitive pricing. | Variable quality, shipping delays. |

| Local Repair Shops | Service centers that often stock common components. | Immediate availability, local support. | Limited selection, potential higher costs. |

| Aftermarket Suppliers | Manufacturers offering compatible alternatives. | Lower prices, diverse options. | Quality inconsistency, warranty issues. |

By exploring these resources, users can effectively manage their equipment’s needs, ensuring smooth operation for years to come.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for efficiency and safety. Proper tools ensure that repairs are executed smoothly and effectively, minimizing the risk of damage and maximizing performance. Below is a list of necessary implements that can aid in the repair process.

- Wrenches: Essential for loosening and tightening various bolts and nuts.

- Screwdrivers: Necessary for handling screws of different types and sizes.

- Socket Set: Provides versatility for working with various fasteners in tight spaces.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

- Multimeter: Ideal for diagnosing electrical issues and measuring voltage, current, and resistance.

- Fuel and Oil Containers: Essential for safe storage and handling of liquids needed for operation.

In addition to these basic tools, having a well-stocked toolkit with various sizes and types can greatly enhance repair capabilities. Regular maintenance not only extends the life of the equipment but also ensures optimal performance.

Comparing Cheetah with Other Models

This section aims to provide a thorough examination of a specific model in relation to its counterparts in the market. Understanding the distinctions and similarities among various options can greatly influence consumer choices, particularly in terms of performance, efficiency, and features.

Performance Analysis

- Speed: Different models exhibit varying levels of speed, which can affect productivity.

- Durability: Comparing build quality and material resilience helps identify which options withstand harsh conditions.

- Handling: The ease of maneuverability is a crucial factor, especially in tight spaces.

Feature Set Comparison

- Engine Power: Variations in horsepower can lead to significant differences in capability.

- Cutting Width: The range of cutting widths available influences efficiency for different tasks.

- Technological Integrations: Advanced features, such as intuitive controls and monitoring systems, enhance user experience.

By evaluating these factors, users can make informed decisions tailored to their specific needs, ensuring optimal performance and satisfaction with their chosen equipment.

User Experiences and Testimonials

This section highlights the insights and reflections of users who have engaged with our equipment. Their stories provide a window into the reliability, efficiency, and overall satisfaction that come from using our products.

John D. shares, “After switching to this mower, my lawn care routine became much more enjoyable. The precision is unmatched, and I find myself finishing tasks quicker than ever.”

Linda R. notes, “The durability is impressive. I’ve faced tough conditions, and this machine continues to perform flawlessly. It has truly exceeded my expectations.”

Mark T. reflects, “The ease of maintenance is a game changer. I appreciate how accessible everything is, making my upkeep process straightforward and hassle-free.”

These testimonials illustrate the ultimate satisfaction users find in the performance and design of our equipment, making their experiences all the more valuable.