In the world of machinery, comprehending the intricate details of various elements is crucial for effective maintenance and operation. A clear visual representation of the assembly can significantly enhance one’s ability to identify, replace, and repair essential components. This knowledge not only streamlines the servicing process but also prolongs the lifespan of the equipment.

Having access to a detailed schematic allows operators and technicians to navigate the complexities of mechanical systems with confidence. It serves as a valuable reference for troubleshooting and understanding how different parts interact within the overall framework. Recognizing the significance of each segment fosters better decision-making and promotes efficient practices in equipment management.

Moreover, familiarity with these visuals empowers users to undertake repairs independently, potentially reducing downtime and service costs. As such, acquiring this knowledge can be instrumental in ensuring that machinery remains in optimal working condition, ready to tackle the demands of various tasks with reliability.

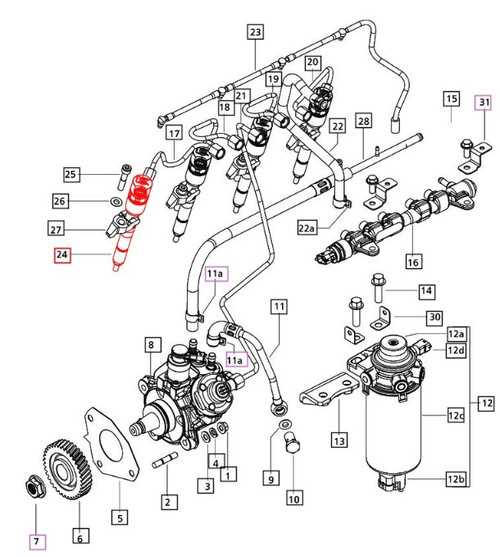

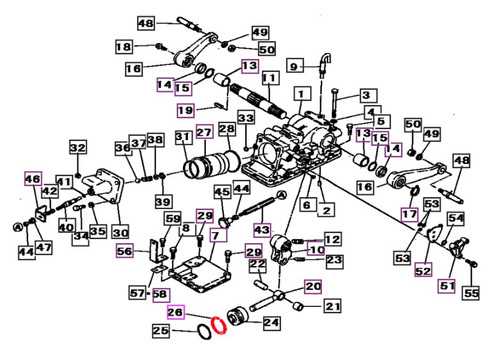

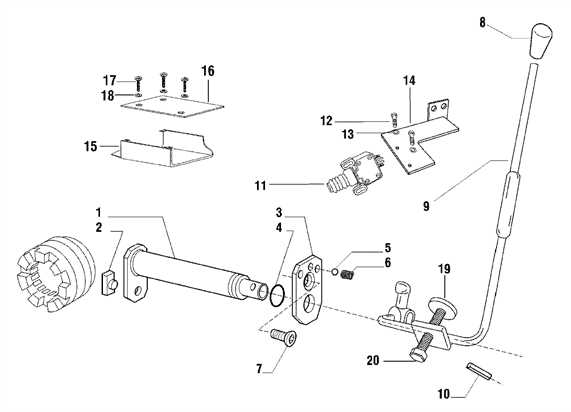

Understanding the Mahindra 4025 Parts Diagram

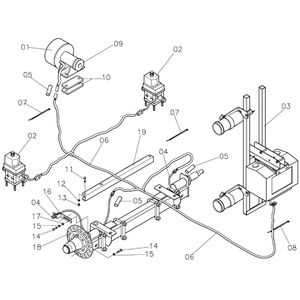

Grasping the intricacies of a machinery component layout is essential for effective maintenance and repair. This visual representation serves as a valuable tool, enabling users to identify and locate individual elements within a complex assembly. By familiarizing oneself with this schematic, operators can enhance their understanding of how various parts interact and contribute to overall functionality.

Importance of Component Familiarity

Being knowledgeable about the various elements in a mechanical setup fosters better troubleshooting skills. Recognizing each part’s role can significantly streamline repair processes and reduce downtime. Additionally, understanding the relationship between different components ensures that users can execute modifications or upgrades with confidence.

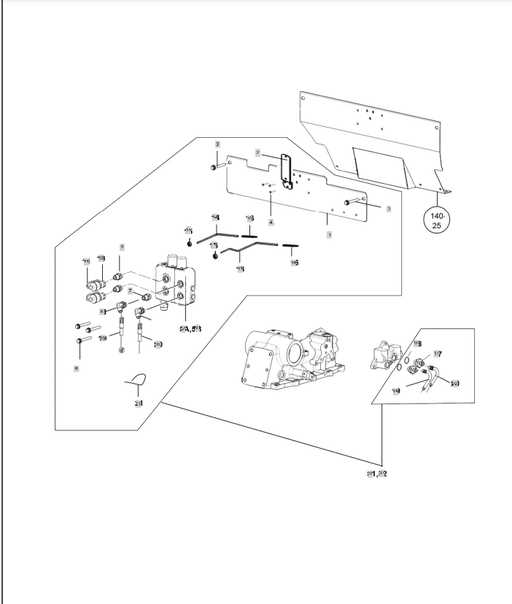

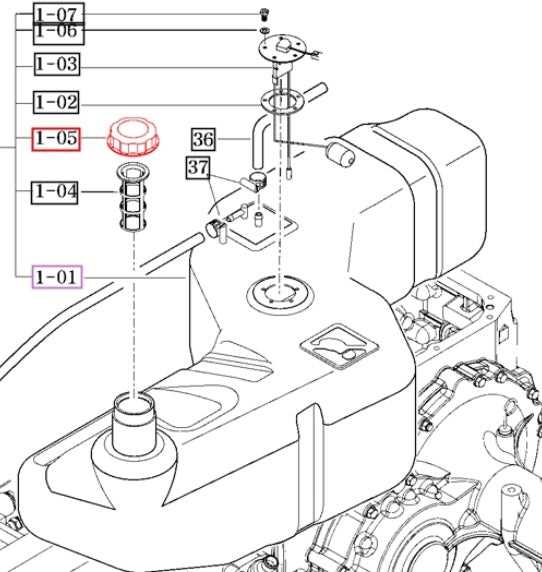

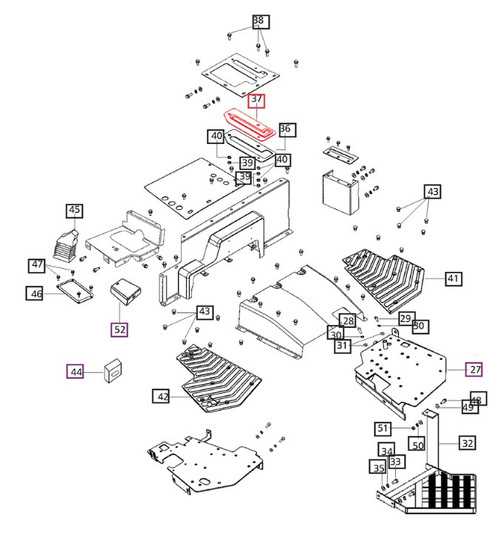

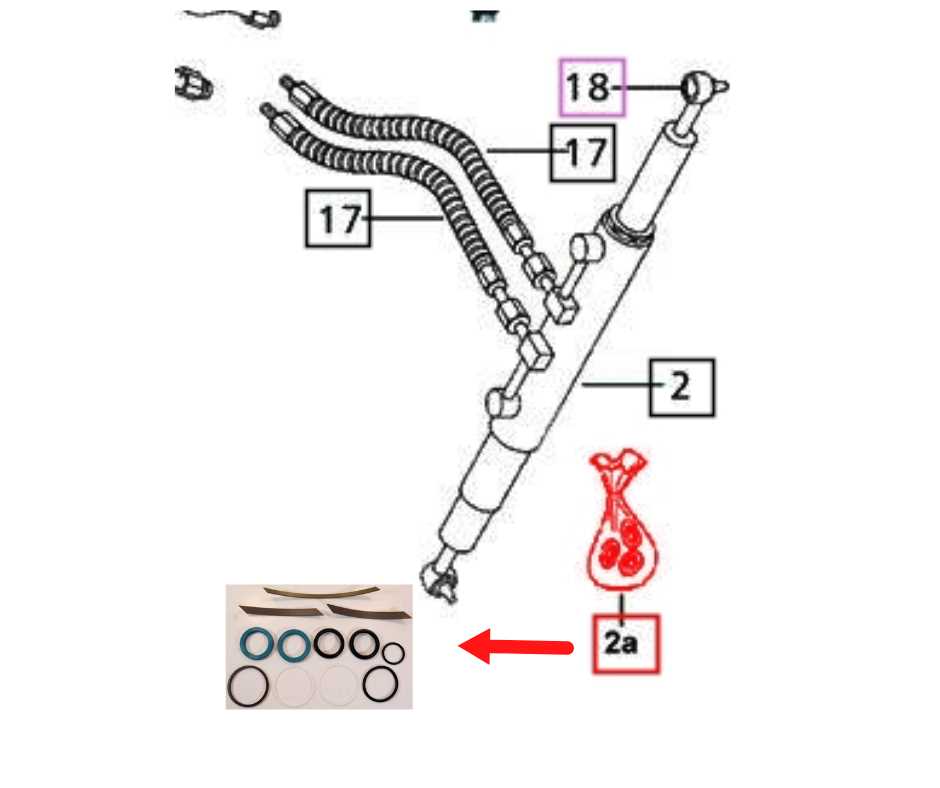

Navigating the Visual Guide

When exploring the layout, focus on key sections, noting the labels and numbering systems used to designate each component. This familiarity can aid in pinpointing issues during inspections. Moreover, this organized approach allows for easier communication with technicians or parts suppliers when seeking replacements or repairs.

In summary, mastering the layout of machine components is crucial for efficient maintenance. With a clear understanding of each element’s function and positioning, users can optimize performance and extend the longevity of their equipment.

Importance of Accurate Parts Identification

Identifying components correctly is crucial for maintaining the efficiency and longevity of any machinery. When operators and technicians have a clear understanding of each element involved, it minimizes the risk of errors during repairs and replacements. This clarity ensures that the equipment functions optimally, reducing downtime and enhancing productivity.

Enhancing Maintenance Efficiency

Proper recognition of elements facilitates timely and precise maintenance. When individuals can easily pinpoint what needs to be replaced or repaired, it streamlines the process, allowing for quicker resolutions. This efficiency not only saves time but also cuts costs associated with unnecessary labor or incorrect replacements.

Ensuring Equipment Longevity

Accurate identification plays a vital role in prolonging the life of machinery. Using the right components tailored for specific functions reduces wear and tear. Inadequate substitutions can lead to more significant issues, ultimately resulting in costly repairs. Therefore, understanding the intricacies of each component contributes to a more sustainable and reliable operation.

Common Issues and Maintenance Tips

Regular upkeep and awareness of frequent challenges can significantly enhance the lifespan and efficiency of machinery. Understanding typical problems and implementing preventive measures can help users avoid costly repairs and ensure smooth operation. This section highlights common difficulties encountered and offers practical advice for effective maintenance.

Frequent Challenges

Users often face several issues that can disrupt functionality. Here are some prevalent concerns:

| Issue | Description |

|---|---|

| Overheating | Insufficient cooling or debris in the radiator can lead to excessive heat, causing performance issues. |

| Fluid Leaks | Leaks can result from worn seals or damaged hoses, affecting overall efficiency. |

| Battery Problems | A weak battery can result in starting difficulties, especially in colder weather. |

| Poor Performance | Dirty filters or improper fuel quality can lead to reduced power output. |

Maintenance Recommendations

To mitigate these issues, regular maintenance is essential. Here are some tips:

- Check and clean the cooling system regularly to prevent overheating.

- Inspect all fluid levels and watch for leaks; replace worn hoses and seals promptly.

- Maintain battery terminals and connections, and test battery health periodically.

- Replace air and fuel filters as needed to ensure optimal performance.

By staying vigilant and proactive, users can enhance reliability and extend the life of their equipment.

Where to Find Quality Replacement Parts

Finding high-quality components for machinery is essential for maintaining optimal performance and longevity. With various options available, it is crucial to identify reliable sources that offer durable and dependable alternatives. Whether you are looking for specific items or general supplies, understanding where to search can make all the difference.

Authorized Dealers: One of the best places to start your search is through authorized dealerships. These suppliers typically provide genuine items that meet manufacturer standards, ensuring compatibility and quality. Additionally, they often have knowledgeable staff who can assist you in selecting the right components for your needs.

Online Retailers: The internet has revolutionized the way we shop, making it easier to find components from the comfort of your home. Reputable online marketplaces often feature a wide selection of options, allowing you to compare prices and read customer reviews. Always verify the credibility of the seller before making a purchase to ensure you receive a quality product.

Local Auto Parts Stores: Visiting local stores can also be beneficial. These establishments often carry a variety of components and can provide personalized assistance. Additionally, supporting local businesses fosters community relationships and may yield better service.

Aftermarket Suppliers: If you’re seeking alternatives to original manufacturer offerings, consider aftermarket suppliers. Many companies specialize in creating high-quality replacements that may offer better value. Research their reputation and product reviews to ensure you are making a wise investment.

Forums and Community Groups: Engaging with online forums or local community groups can provide valuable insights. Experienced users often share their recommendations for reliable sources and specific components, guiding you toward trustworthy options.

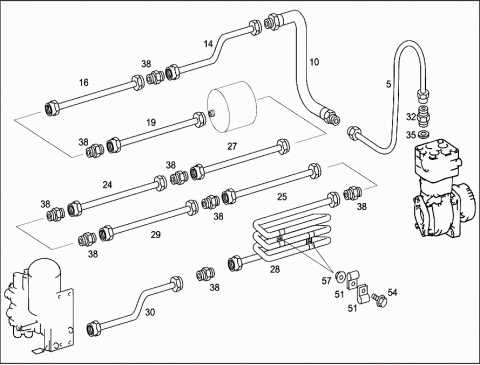

How to Read the Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These visual aids provide critical information about the arrangement and interrelationships of various elements within a system, facilitating easier identification and procurement of necessary components.

Key Elements to Look For

- Labels: Each part is usually labeled with a specific identifier, which may include a number or code. Familiarizing yourself with these labels will help you locate parts quickly.

- Reference Points: Look for reference markers that indicate how components connect to one another. These may be illustrated through lines or arrows.

- Legend or Key: Many schematics include a legend that explains the symbols and notation used. Always consult this section to clarify any unfamiliar symbols.

Steps to Interpret the Representation

- Identify the Main Components: Start by locating the major parts to understand the overall layout.

- Follow Connections: Trace the lines or arrows to see how each component is connected, paying attention to any special notes about assembly or disassembly.

- Cross-Reference with Manuals: Use any accompanying documentation to gain a deeper insight into the function and specifications of each part.

By mastering the interpretation of these visual aids, you will enhance your troubleshooting skills and streamline the process of obtaining replacement components.

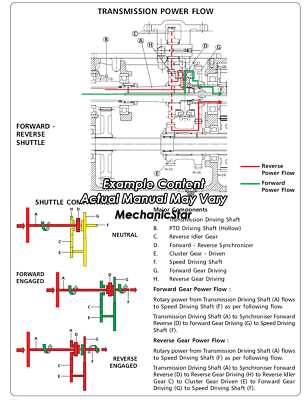

Comparing Mahindra Models and Their Diagrams

When evaluating various agricultural machinery options, it becomes essential to understand the differences between models. Each version offers unique features and components that cater to specific needs. By analyzing the schematics associated with each machine, operators can gain insights into their functionalities, maintenance requirements, and overall efficiency.

Understanding Differences is crucial for making informed choices. Different versions may have distinct layouts and specifications, which can significantly impact performance and usability. By closely examining these configurations, users can identify which model aligns best with their operational goals.

Visual representations play a pivotal role in this process. They not only showcase the assembly of parts but also highlight the innovation behind each machine. Observing these illustrations allows for better comprehension of how various components interact, enabling more effective troubleshooting and repairs when necessary.

Ultimately, a thorough comparison empowers users to select the most suitable machinery, ensuring optimal productivity and satisfaction in their agricultural endeavors. Understanding the intricate details of each model through their visual guides is a vital step towards achieving success in the field.

Frequently Asked Questions about Mahindra Parts

This section addresses common inquiries regarding components and accessories for agricultural machinery. Understanding these elements is crucial for maintaining optimal performance and ensuring the longevity of your equipment.

- What should I do if I need a replacement for a broken component?

- Consult your equipment manual for part specifications.

- Contact a local dealer or authorized service center for assistance.

- Consider aftermarket options if applicable.

- How can I ensure I’m purchasing the correct accessory?

- Verify compatibility with your specific model.

- Check reviews and ratings of the product.

- Request assistance from customer service if unsure.

- Are there warranties available for new components?

- Most manufacturers provide warranties for genuine items.

- Review warranty terms before purchasing.

- Keep your receipt for future reference.

- How often should I inspect components for wear and tear?

- Conduct regular inspections as part of routine maintenance.

- Look for signs of damage, rust, or excessive wear.

- Follow the manufacturer’s recommendations for maintenance intervals.

Tools Needed for Parts Replacement

When undertaking the task of component substitution, having the right instruments at your disposal is essential. Proper tools ensure efficiency, safety, and accuracy, ultimately leading to successful repairs and maintenance.

Essential Instruments

- Wrenches

- Screwdrivers

- Pliers

- Socket set

- Torque wrench

Additional Equipment

- Jack stands

- Shop manual

- Cleaning supplies

- Safety goggles

- Gloves

Best Practices for Equipment Care

Maintaining machinery in optimal condition is crucial for ensuring longevity and performance. Regular attention to care routines not only enhances efficiency but also prevents costly repairs. By adopting systematic practices, operators can ensure that their equipment remains reliable and functional over time.

Routine Maintenance Checklist

Implementing a routine maintenance checklist is essential for monitoring the health of your machinery. Regular inspections can help identify potential issues before they escalate into major problems. Below is a sample checklist to follow:

| Task | Frequency | Notes |

|---|---|---|

| Check fluid levels | Weekly | Ensure oils and fluids are at recommended levels. |

| Inspect filters | Monthly | Replace air and fuel filters as needed. |

| Tighten bolts and connections | Monthly | Prevent loosening due to vibrations. |

| Clean exterior surfaces | Weekly | Remove dirt and debris to prevent corrosion. |

| Test safety features | Quarterly | Ensure all safety mechanisms function properly. |

Proper Storage Techniques

Effective storage of equipment can greatly extend its lifespan. When not in use, ensure that machines are kept in a dry, sheltered location. Covering equipment can protect it from dust and environmental elements. Additionally, periodically running the machinery helps keep internal components lubricated and functioning well.