For anyone engaged in metal fabrication, grasping the intricacies of their equipment is essential for optimal performance and maintenance. A comprehensive understanding of each element within your apparatus can significantly enhance its functionality and longevity. This exploration delves into the various segments that constitute your welding setup, providing clarity on their roles and interrelations.

Proper knowledge of these components not only aids in troubleshooting but also empowers users to undertake effective repairs and upgrades. By familiarizing yourself with the layout and function of each segment, you can ensure that your machine operates smoothly and efficiently. This guide will serve as a valuable resource for both novices and seasoned professionals, demystifying the essential features of your equipment.

As you navigate through the details, you will discover how each part contributes to the overall efficacy of your welding process. Whether you are looking to improve your skills or maintain your device, understanding these crucial elements is key to achieving successful results in your projects.

Understanding Lincoln Weld Pak 100

This section delves into the essential features and components of a popular entry-level fabrication machine, designed to provide both novices and experienced users with reliable performance. Understanding its functionality and structure is crucial for effective operation and maintenance.

At the core of this equipment lies its versatility, allowing users to tackle various projects with ease. From home repairs to more complex tasks, its user-friendly design simplifies the welding process, making it accessible for individuals of all skill levels.

Additionally, familiarity with the mechanical elements enhances operational efficiency. Knowing how to properly adjust settings and replace specific components can significantly impact the quality of the work produced. This insight not only improves results but also prolongs the lifespan of the device.

Ultimately, comprehending the intricacies of this welding machine empowers users to maximize its capabilities while ensuring safe and effective usage.

Key Features of Lincoln Weld Pak 100

This model is designed to cater to both beginners and experienced users, offering a range of functionalities that enhance performance and usability. Its intuitive interface and robust construction make it an ideal choice for various welding applications, from home repairs to more complex projects.

Versatility and Performance

Equipped with multiple settings, this equipment allows users to adjust voltage and wire speed, ensuring optimal results on different materials. Whether working with thin sheets or thicker metals, its adaptability ensures high-quality welds every time.

User-Friendly Design

The thoughtful layout of controls and features makes operation straightforward, minimizing the learning curve for new users. Additionally, its compact size allows for easy transportation, making it a convenient option for on-site tasks or workshops.

Essential Parts of the Welder

Understanding the fundamental components of a welding machine is crucial for both novice and experienced users. Each element plays a vital role in ensuring effective and safe operation, contributing to the overall performance and reliability of the equipment.

| Component | Description |

|---|---|

| Power Source | Provides the necessary electrical energy to initiate and sustain the welding arc. |

| Control Panel | Allows the operator to adjust settings such as voltage and wire feed speed for optimal results. |

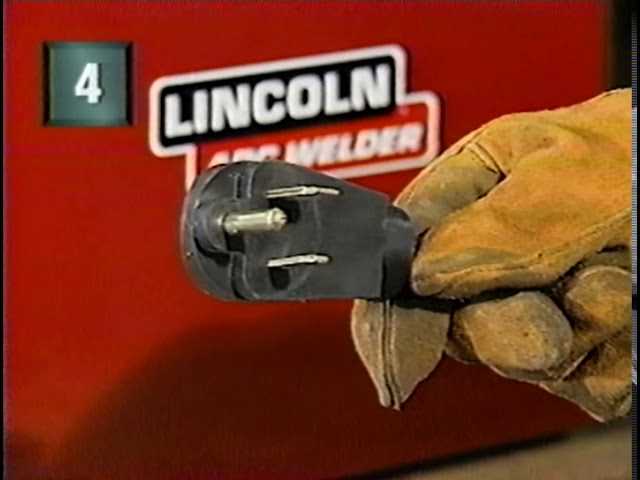

| Welding Gun | The tool through which the welding wire is fed and the arc is directed onto the workpiece. |

| Wire Feed Mechanism | Ensures a consistent supply of welding wire, crucial for maintaining a stable arc. |

| Ground Clamp | Connects the workpiece to the machine, completing the electrical circuit and ensuring safety. |

| Gas Supply System | Delivers shielding gas to protect the weld pool from contamination during the process. |

Common Issues and Solutions

In the world of metal fabrication, various challenges can arise, impacting performance and efficiency. Understanding these common problems and their resolutions can greatly enhance the user experience and extend the life of the equipment.

Inconsistent Welding Results: One frequent issue is the variability in the quality of welds. This can often be attributed to improper settings or feed problems. Solution: Always ensure that the voltage and wire feed speed are correctly calibrated for the material being worked on.

Overheating: Equipment may overheat during prolonged use, leading to potential damage. Solution: Allow regular breaks and ensure proper ventilation to maintain optimal operating temperatures.

Wire Jamming: Another common challenge is wire tangling or jamming within the mechanism. Solution: Regularly inspect and clean the feed system, ensuring that the wire is correctly loaded and aligned.

Inadequate Power Supply: Insufficient power can lead to weak welds or complete failure to operate. Solution: Verify that the power source meets the required specifications and check for any loose connections.

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs. This guide will help you navigate through the schematic, ensuring you can identify each element and its function within the overall system.

Key Elements to Identify

- Labels: Look for clear annotations that specify each component.

- Connections: Pay attention to lines that indicate how parts are interconnected.

- Legend: Familiarize yourself with any symbols or codes used for clarification.

Steps to Follow

- Start by examining the overall layout to understand the structure.

- Identify the main components and their respective locations.

- Use the legend to decipher any unfamiliar symbols.

- Cross-reference with the user manual for additional insights.

Maintaining Your Welding Equipment

Routine Maintenance Tasks

- Clean the equipment after each use to remove dust, debris, and spatter.

- Inspect cables and connectors for signs of wear or damage.

- Check gas hoses for leaks and ensure proper connections.

- Lubricate moving parts according to the manufacturer’s recommendations.

Periodic Inspections

- Examine the power source for any irregularities in operation.

- Replace worn-out or damaged components immediately to avoid further damage.

- Calibrate settings to maintain precision in your projects.

- Review safety features to ensure they are functioning correctly.

By following these guidelines, you can keep your welding tools in peak condition, ensuring reliable performance for all your projects.

Ordering Replacement Parts Online

When it comes to maintaining your equipment, securing the right components is essential for optimal performance. With the convenience of online shopping, finding and ordering the necessary items has never been easier. Understanding how to navigate this process effectively can save you time and ensure that you get exactly what you need.

Finding Reliable Retailers

Start by identifying reputable online vendors that specialize in your type of machinery. Look for customer reviews and ratings to gauge their reliability. It’s important to choose sellers who offer clear product descriptions, specifications, and images to help you make informed decisions.

Ensuring Compatibility

Before placing an order, double-check that the components you wish to purchase are compatible with your specific model. Consult the user manual or manufacturer’s website for detailed information. This step is crucial to avoid the hassle of returns and to ensure a seamless repair process.

In summary, the process of ordering components online can be straightforward if you focus on finding trustworthy sources and confirming compatibility. Embrace the convenience of the digital marketplace while ensuring that your equipment remains in top condition.

Upgrading Your Welding Experience

Enhancing your metal joining skills can significantly impact both the quality of your work and the enjoyment you derive from the process. Investing in the right accessories and tools not only boosts performance but also ensures greater precision and safety. This guide aims to provide insights into various upgrades that can elevate your craft.

Essential Accessories for Better Performance

Incorporating additional tools can lead to a smoother workflow and improved results. Below are some key accessories that every enthusiast should consider:

| Accessory | Benefits |

|---|---|

| Automatic Darkening Helmet | Provides instant protection and improved visibility during the process. |

| Upgraded Torch | Enhances control and precision, allowing for intricate work. |

| Cooling System | Prevents overheating, ensuring longevity and consistent performance. |

| High-Quality Filler Rods | Improves bonding strength and reduces defects in joints. |

Safety First: Important Considerations

As you enhance your setup, don’t overlook safety measures. Proper protective gear and equipment maintenance are crucial to prevent accidents. Regularly inspect your tools, ensure adequate ventilation in your workspace, and always wear the appropriate safety gear.