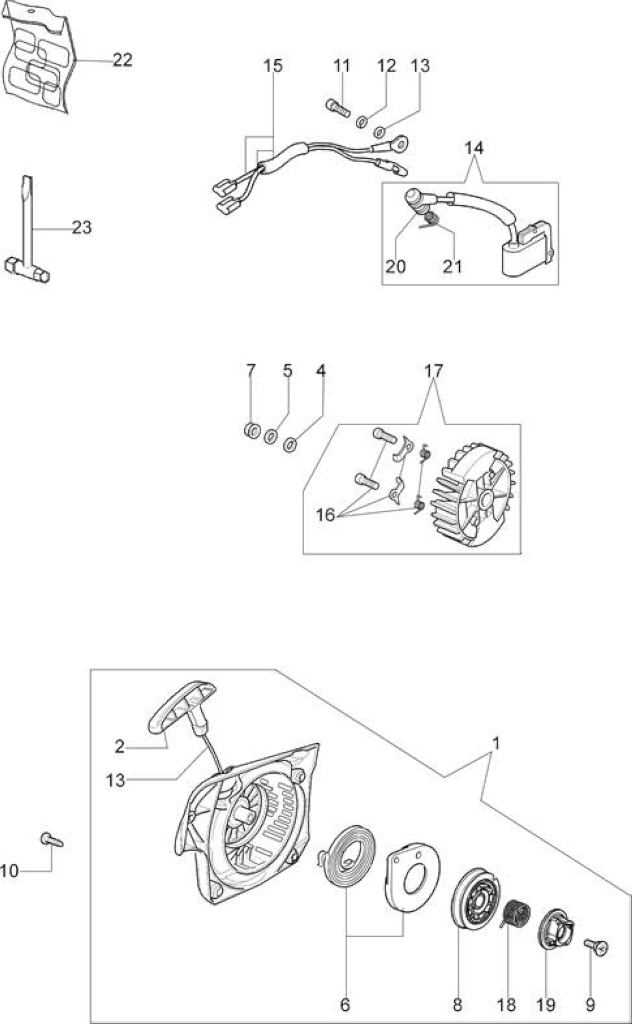

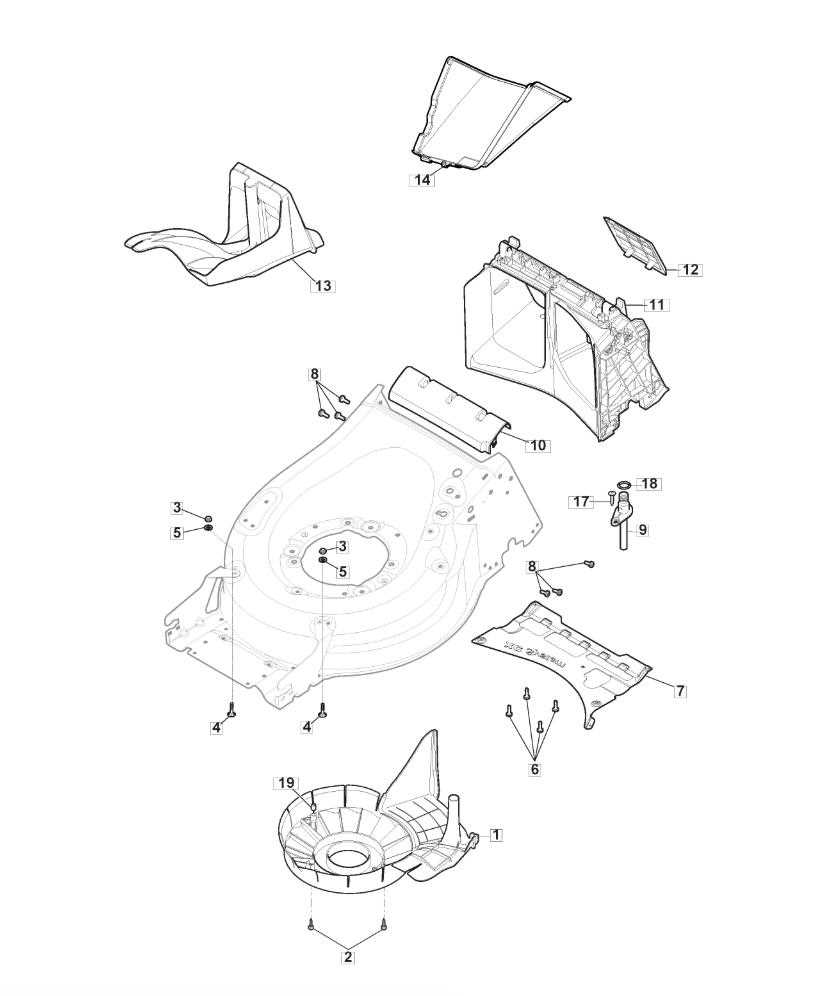

When it comes to maintaining and repairing outdoor machinery, having a clear visual reference of the various elements is crucial. Such representations serve as invaluable tools for both novices and seasoned users, facilitating a deeper understanding of how different parts interconnect and function together. This insight ultimately enhances efficiency during repairs and routine maintenance.

By examining a detailed layout, one can easily identify each piece’s role and ensure that everything operates smoothly. Whether you’re troubleshooting an issue or planning a service, this comprehensive approach allows for a more systematic and organized method of addressing any challenges that may arise. It’s essential to familiarize yourself with these illustrations to enhance your overall experience with your equipment.

In this guide, we will delve into the specifics of these visual aids, offering a breakdown that highlights the ultimate importance of each component in the machinery. Such knowledge empowers users to take control of their maintenance tasks confidently, ensuring longevity and optimal performance of their tools.

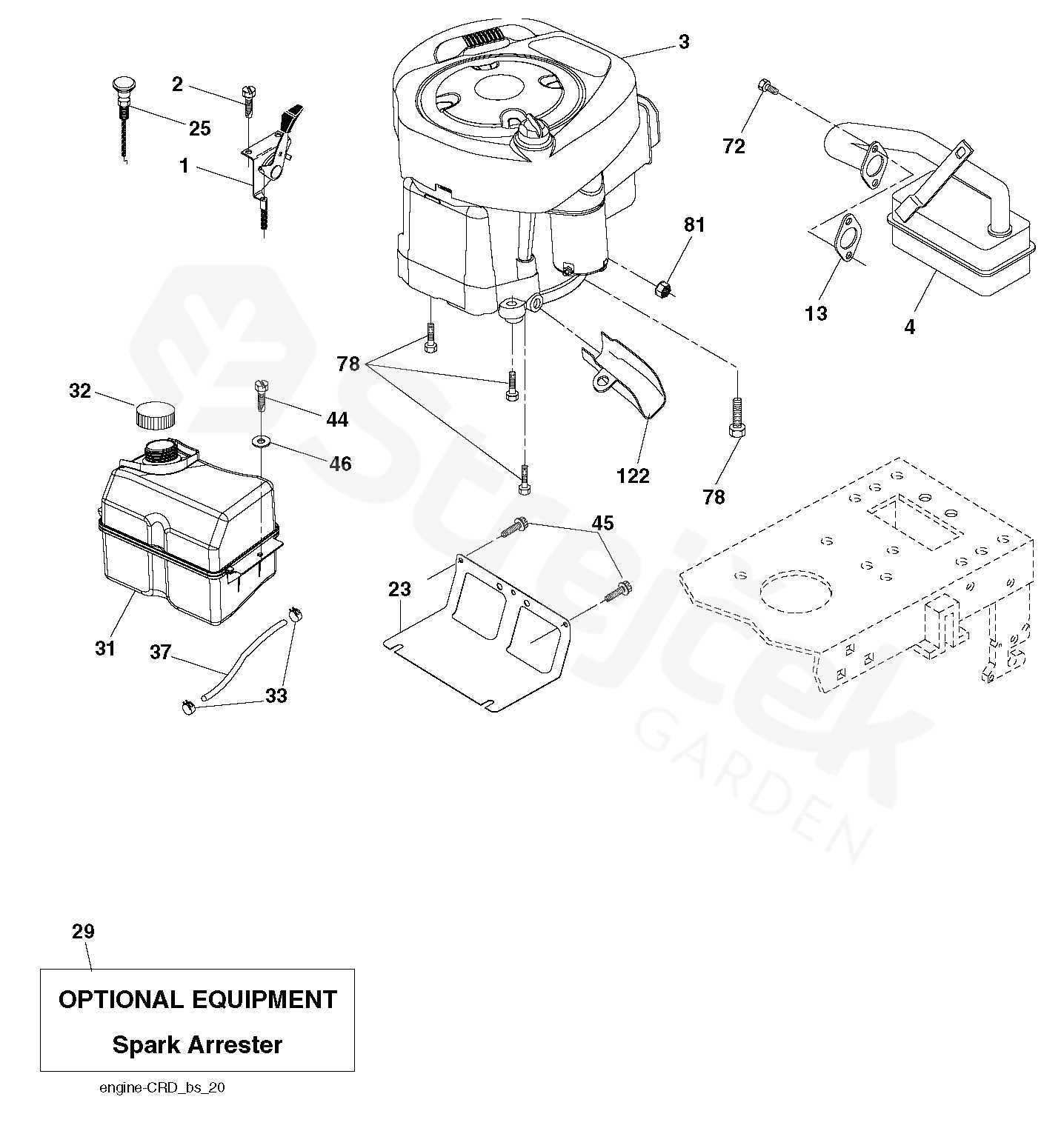

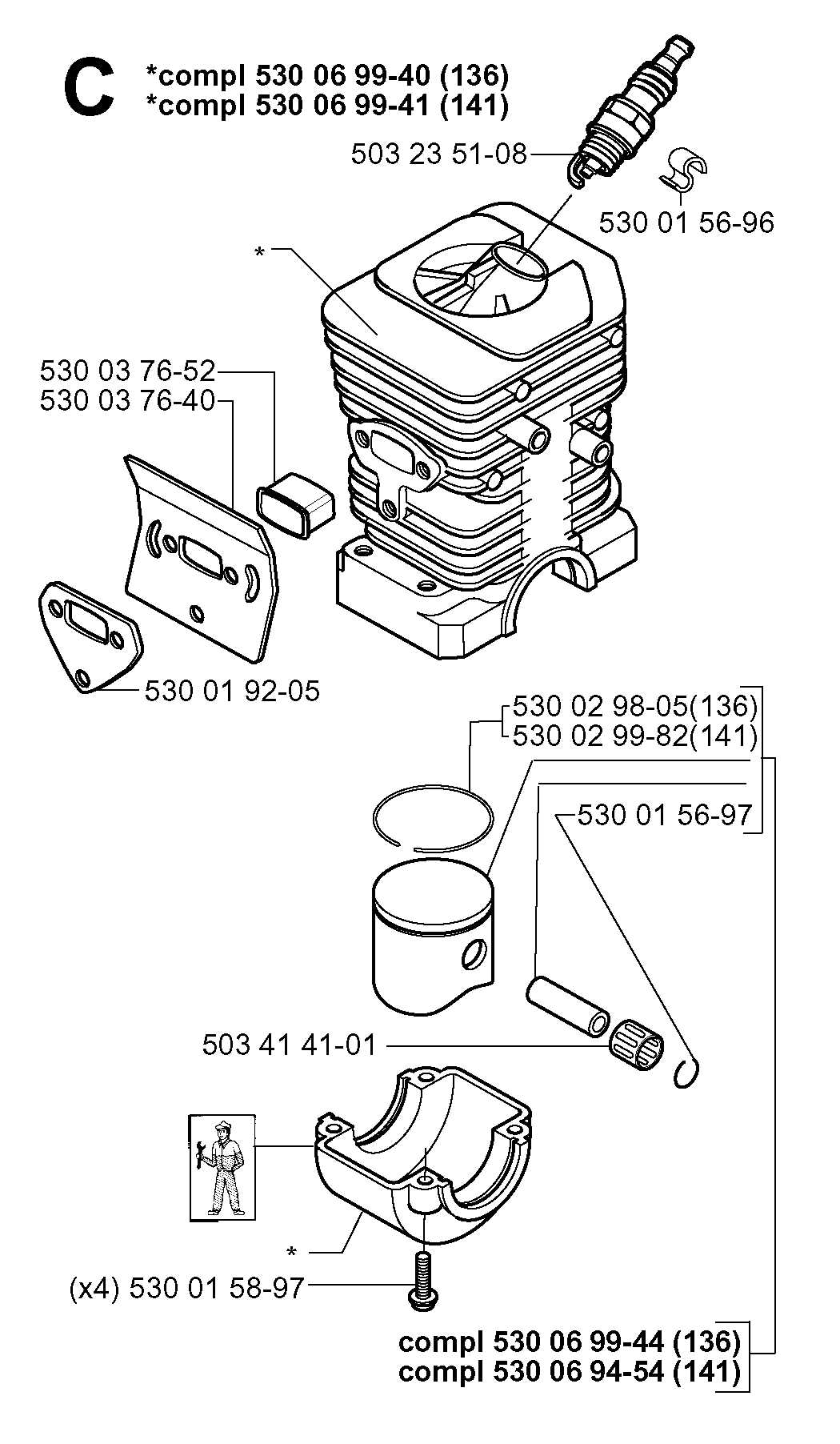

Understanding Husqvarna 141 Components

To truly appreciate the mechanics of outdoor power tools, one must explore the various elements that work in harmony. Each component plays a crucial role, contributing to the overall functionality and efficiency of the machine. Gaining insight into these elements enhances user experience and aids in effective maintenance.

Key elements include the engine, which serves as the powerhouse, and the cutting mechanism, which directly influences performance. Additional features such as the fuel system and ignition contribute significantly to operation, ensuring reliability and ease of use. Understanding how these components interact is essential for troubleshooting and repairs.

Moreover, knowing the structure can lead to better decision-making when selecting replacement components or upgrading. As users delve deeper into the intricacies of these tools, they gain the ultimate advantage in achieving optimal performance and longevity.

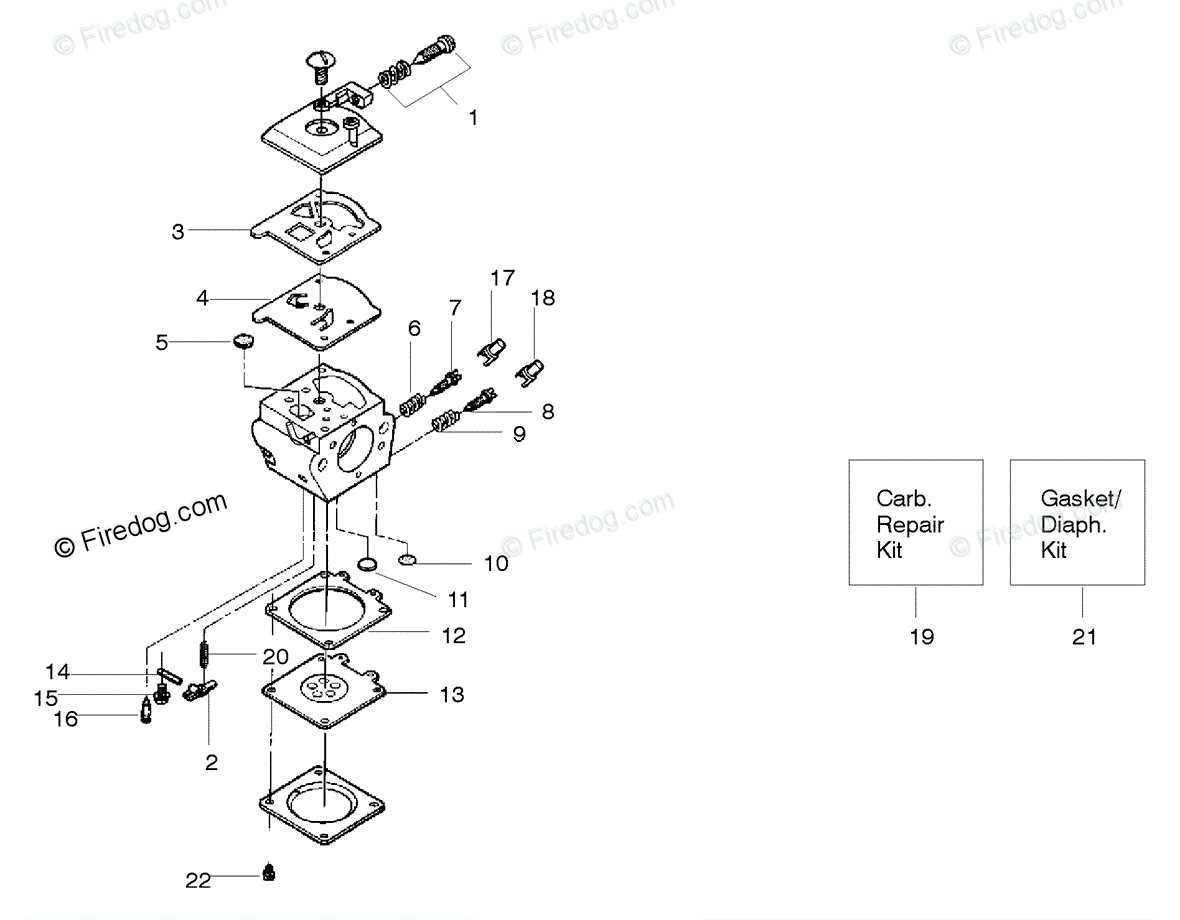

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery. They provide clarity, allowing users to identify each element’s function and relationship within the system. This understanding is essential for effective maintenance and repair.

Enhanced Understanding

By utilizing these visual guides, users can quickly grasp the assembly and disassembly processes. This knowledge minimizes errors during repairs and ensures that every piece is correctly reassembled.

Facilitating Efficient Repairs

Having access to these illustrations streamlines the repair process, saving both time and resources. When individuals can easily pinpoint the necessary elements, they can focus on solutions rather than confusion.

Common Issues with Husqvarna 141

When operating a popular chainsaw model, users often encounter specific challenges that can affect performance and reliability. Understanding these common problems can help in maintaining optimal functionality and prolonging the lifespan of the tool. Below are some prevalent issues that owners may face.

Frequent Starting Problems

Many users report difficulty in starting their equipment, which can stem from various factors. These include fuel quality, spark plug condition, and air filter blockage. Ensuring proper maintenance can alleviate these concerns.

Overheating and Performance Drops

Another typical issue is overheating, which may lead to reduced power output. This can occur due to inadequate lubrication or a clogged cooling system. Regular inspections and timely replacements are essential for preventing these problems.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Starting Issues | Poor fuel, faulty spark plug, dirty air filter | Use high-quality fuel, replace spark plug, clean or replace filter |

| Overheating | Insufficient lubrication, blocked cooling fins | Regularly check oil levels, clean cooling system |

| Vibration Problems | Worn components, unbalanced chain | Inspect and replace parts as needed, adjust chain tension |

How to Identify Parts Quickly

Recognizing components swiftly is essential for efficient repairs and maintenance. By familiarizing yourself with specific identifiers and utilizing available resources, you can streamline the process of finding what you need.

| Identifier | Description |

|---|---|

| Model Number | A unique sequence that designates a specific tool or device. |

| Serial Number | A distinct code assigned to each unit, useful for tracking and support. |

| Catalogs | Printed or digital collections that list components and their specifications. |

| Online Resources | Websites and forums where enthusiasts share insights and diagrams. |

Utilizing these methods will enhance your ability to pinpoint necessary elements efficiently, ensuring a smoother repair experience.

Where to Find Replacement Parts

Locating components for your outdoor equipment can be a straightforward process if you know where to look. Whether you need a specific element for maintenance or a complete replacement, various resources are available to ensure you find what you need quickly and efficiently.

Online Retailers

The internet offers a plethora of options for sourcing equipment components. Many dedicated websites specialize in outdoor machinery and accessories, providing detailed catalogs and user-friendly search functions. These platforms often feature customer reviews and ratings, helping you make informed decisions about your purchases.

Local Dealerships and Repair Shops

Visiting nearby dealerships or repair shops can be beneficial as well. Not only can you find genuine components, but you can also receive expert advice from knowledgeable staff. Many of these establishments can assist with installation and maintenance tips, ensuring your equipment runs smoothly for years to come.

Maintenance Tips for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires regular upkeep and attention to detail. By implementing a consistent maintenance routine, you can enhance performance, reduce wear, and prevent costly repairs.

Start by regularly cleaning the components to prevent debris buildup that can hinder functionality. Check and replace air filters as needed to maintain proper airflow and engine efficiency. Additionally, inspecting and sharpening cutting blades will improve performance and accuracy during operation.

Lubrication is essential for moving parts; ensure that all necessary components are well-greased to minimize friction. Pay attention to the fuel system, using fresh fuel and stabilizers to prevent engine issues. Lastly, consult the manufacturer’s guidelines for any specific maintenance intervals to keep your equipment running at its best.

Comparing Husqvarna 141 to Other Models

When evaluating the features and performance of a particular chainsaw, it is essential to consider how it stacks up against its competitors. Different models can offer varying power levels, weight distributions, and user-friendly features, which can significantly affect usability and efficiency in various tasks. Understanding these differences can help users make informed decisions based on their specific needs.

Power and Performance: One notable aspect to compare is the engine capacity and cutting power. While some models excel in raw horsepower, others may focus on fuel efficiency and reduced emissions, catering to environmentally conscious users.

Weight and Ergonomics: Another important factor is the weight of the equipment. Lightweight options are often preferred for extended use, reducing fatigue, while heavier models may provide added stability during operation.

User Features: Additionally, some machines come equipped with advanced safety features and easier starting mechanisms, making them more accessible to novice users. Evaluating these aspects can lead to an ultimate choice that aligns with individual preferences and requirements.

DIY Repairs and Safety Guidelines

Engaging in self-repairs can be a rewarding experience, allowing individuals to save costs and gain valuable skills. However, it’s crucial to approach these tasks with a clear understanding of safety measures and best practices. By adhering to proper guidelines, you can ensure a successful repair while minimizing risks.

Safety first: Always prioritize your well-being by wearing appropriate personal protective equipment. This may include gloves, safety goggles, and hearing protection. A well-lit and organized workspace is essential to prevent accidents and make the process smoother.

Know your tools: Familiarize yourself with the tools required for the task. Using the right equipment not only makes the job easier but also enhances safety. Ensure all tools are in good condition and appropriate for the specific job.

Follow instructions: Refer to manuals or guides specific to your equipment. Understanding the assembly and disassembly process is crucial to avoid mistakes. Take your time and don’t rush through the steps.

Handle components carefully: When working with various parts, be cautious to avoid damage. Use the correct techniques for removal and installation to maintain the integrity of each component.

Disconnect power sources: Always ensure that the device is unplugged or the power source is disconnected before starting any repairs. This simple step can prevent accidents and electrical hazards.

By following these guidelines, you can confidently tackle repairs while ensuring a safe and effective work environment.

Upgrades and Modifications for Efficiency

Enhancing the performance of your equipment can lead to significant improvements in efficiency and longevity. By focusing on specific areas for upgrades, you can maximize productivity and minimize downtime. This section explores several effective modifications that can elevate the operational capabilities of your machinery.

Engine Enhancements

Upgrading the engine components can lead to better power output and fuel efficiency. Consider replacing stock parts with high-performance alternatives that are designed to withstand more demanding conditions. This can include air filters, spark plugs, and exhaust systems that facilitate improved airflow and combustion efficiency.

Weight Reduction Techniques

Reducing the overall weight of your machinery can enhance maneuverability and reduce strain on components. Techniques such as replacing heavy materials with lightweight alternatives or removing non-essential features can contribute to better handling and reduced fuel consumption.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Engine Tuning | Adjusting fuel and air mixtures for optimal performance. | Increased power and efficiency. |

| Lightweight Components | Using materials like aluminum or carbon fiber. | Improved handling and reduced energy consumption. |

| Aftermarket Accessories | Installing enhancements such as better grips and ergonomic handles. | Increased comfort and user control. |