Every efficient fastening tool relies on a precise combination of mechanical elements working together. To ensure smooth operation and optimal performance, it is essential to have a clear understanding of how each component functions. In this section, we will explore the crucial elements that make these tools both reliable and durable, offering insights into their structure and operation.

Powerful fastening equipment is designed with multiple interconnected parts that perform specific roles, allowing for effective and consistent work in various projects. By examining the layout and purpose of each individual piece, users can maintain and repair their equipment with greater ease, ensuring longevity and reliability.

With a deeper look into the internal structure, you will gain knowledge about the key mechanisms that drive these tools. From the control systems to the components responsible for delivering energy, this guide aims to provide clarity for anyone interested in enhancing their technical skills or troubleshooting issues.

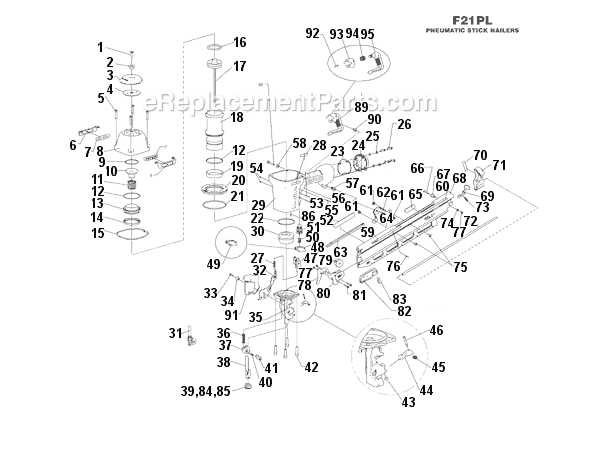

Understanding the Bostitch Nail Gun Components

To effectively maintain and troubleshoot your fastening tool, it’s essential to understand the different elements that make up its system. Each component has a specific function that contributes to the overall performance and precision of the device. A closer look at these elements will help ensure long-term durability and efficiency.

- Magazine Assembly: This part holds the fasteners and ensures they are fed smoothly into the device for consistent performance.

- Trigger Mechanism: Responsible for initiating the fastening process, the trigger allows for controlled firing, ensuring accuracy and safety during use.

- Piston and Driver Blade: These internal parts work together to push the fasteners out with the correct force, making them crucial for the tool’s core operation.

- Exhaust Vent: Directs the airflow away from the operator and helps in maintaining balance in air pressure during use, ensuring smoother performance.

- Air Compressor Connector: The link between the device and the air compressor, this connector ensures that the tool receives a con

Exploring the Mechanism of the Nail Gun

Understanding the inner workings of a fastening tool reveals a fascinating blend of engineering and innovation. This device operates through a carefully designed system that efficiently drives fasteners into various materials, showcasing the intricacies of mechanics and energy transfer. By examining its core components, we gain insights into how this powerful instrument achieves its purpose with precision and speed.

Core Components

At the heart of the fastening tool lies a powerful mechanism that converts energy into motion. This is often achieved through a combination of springs, pistons, and chambers that work in unison. The energy source, whether pneumatic or electric, initiates a sequence of actions that propel the fastener forward, ensuring a secure attachment to the surface. Understanding these elements is crucial for anyone looking to appreciate the efficiency and reliability of this handy device.

Operational Principles

The operational principles of the fastening tool revolve around the transformation of stored energy into kinetic energy. When activated, the device releases the energy stored in its components, creating a rapid movement that drives the fastener into the material. This process not only highlights the importance of design but also emphasizes the role of safety features that prevent accidental discharges, ensuring user protection while maintaining high performance.

Common Parts Found in a Bostitch Tool

Understanding the essential components of a fastening instrument can significantly enhance its performance and longevity. Familiarity with these elements allows users to maintain and troubleshoot effectively, ensuring optimal operation in various tasks.

- Trigger Mechanism: Initiates the fastening action, providing control over operation.

- Piston Assembly: Drives the fastening element into the material, crucial for efficiency.

- Magazine: Holds and feeds the fasteners, enabling continuous work without frequent interruptions.

- Housing: The outer shell that protects internal components and provides structural integrity.

- Air Filter: Prevents dust and debris from entering, maintaining internal cleanliness and functionality.

- Drive Blade: Ensures proper engagement and penetration of the fastening element into the surface.

By becoming acquainted with these key components, users can perform better maintenance and make informed decisions regarding repairs or replacements when necessary.

How to Identify Key Gun Components

Understanding the primary elements of a fastening device is crucial for effective operation and maintenance. Familiarity with these components enhances performance and ensures safety during use. Here’s a guide to help you recognize the essential features of your tool.

Below are the key components to look for:

- Trigger: This is the mechanism that initiates the action of the device. Recognizing its location and function is vital for safe handling.

- Pusher: Responsible for advancing the fasteners into the chamber. Identifying this part helps in troubleshooting feeding issues.

- Chamber: The area where fasteners are loaded. Familiarity with this part allows for efficient reloading and maintenance.

- Safety Mechanism: A critical feature designed to prevent accidental activation. Knowing how it operates is essential for safe usage.

- Exhaust Port: This component releases air from the device, preventing pressure buildup. Understanding its role is important for ensuring optimal performance.

By familiarizing yourself with these components, you can ensure proper usage and maintenance, leading to improved efficiency and safety.

Troubleshooting Issues with Nail Gun Parts

Addressing common challenges that arise with fasteners and their components is essential for maintaining optimal performance and ensuring safe operation. Various factors can lead to malfunctions, and recognizing these issues is the first step toward effective solutions.

One frequent concern involves the improper feeding of fasteners, which can result from debris accumulation or wear in the feeding mechanism. Regular cleaning and inspection can help mitigate this problem, allowing for smoother operation. Additionally, it is important to check for the correct alignment of the components, as misalignment can impede functionality.

Another common issue is inconsistent power delivery. This may stem from low air pressure in pneumatic systems or battery-related problems in cordless models. Verifying the power source and adjusting settings according to the manufacturer’s recommendations can often resolve this inconsistency.

Leakage of air or fluid can also indicate problems within the internal mechanisms. Identifying the source of the leak and replacing worn seals or gaskets is crucial for maintaining efficiency. Proper lubrication is necessary to ensure that moving parts operate smoothly, preventing unnecessary friction and wear.

Finally, if fasteners are not driving fully into the material, it may be necessary to assess the depth adjustment settings or check if the tool is appropriate for the specific application. Consulting the user manual for guidance can provide clarity on troubleshooting techniques and maintenance procedures.

Maintaining Your Bostitch Nail Gun Effectively

Proper upkeep of your tool is essential to ensure its longevity and optimal performance. Regular maintenance not only enhances functionality but also prevents common issues that can arise from neglect. By following a structured approach, you can keep your equipment in top condition, ready to tackle any project with ease.

Routine Inspection and Cleaning

Performing routine inspections is crucial for identifying wear and tear before it escalates into significant problems. After each use, take a moment to check for any visible damage or debris that may affect the tool’s operation. Cleaning the exterior and interior components will help maintain smooth functionality. Use a soft brush to remove dust and buildup, and wipe surfaces with a damp cloth for a thorough clean.

Lubrication and Storage Tips

Regular lubrication is vital for the internal mechanisms of your device. Apply appropriate oil to the moving parts to reduce friction and ensure seamless operation. When not in use, store your tool in a cool, dry place, and consider using a protective cover to prevent dust accumulation. Proper storage will help extend its lifespan and keep it ready for the next task.

Incorporating these maintenance practices into your routine will significantly improve the reliability and efficiency of your tool, allowing you to focus on your projects without unnecessary interruptions.

Where to Find Replacement Bostitch Parts

Finding the right components for your tools can ensure optimal performance and longevity. When it comes to sourcing these essential elements, there are several reliable avenues to explore.

- Official Manufacturer Website: The primary source for authentic replacements is the official website of the manufacturer. They often provide comprehensive catalogs and user manuals that can guide you in identifying the correct components.

- Authorized Retailers: Many authorized dealers carry a range of genuine items. It’s advisable to check their online platforms or physical stores for availability.

- Online Marketplaces: Websites such as Amazon, eBay, and other e-commerce platforms frequently have listings for various components. Ensure to read reviews and verify the seller’s reputation to avoid counterfeit goods.

- Local Hardware Stores: Many local shops have a selection of tool accessories. Visiting these stores can provide immediate options and the chance to consult with knowledgeable staff.

- Repair Shops: Specialized repair services may have spare components available for sale. They can also assist in identifying the correct items you need.

By exploring these options, you can find the necessary replacements to keep your tools in top condition.

Upgrading Your Nail Gun for Better Performance

Enhancing your equipment can significantly improve its efficiency and reliability. By focusing on specific components and features, you can ensure that your tool operates at its best, providing consistent results for various projects. This section will explore various upgrades that can elevate your device’s functionality and lifespan.

Here are some key areas to consider when upgrading:

- Power Source: Switching to a more efficient power supply can provide better performance and reduce downtime.

- Firing Mechanism: Opting for a more advanced firing mechanism can increase speed and accuracy.

- Depth Adjustment: Look for models that offer precise depth control, ensuring that fasteners are driven to the correct level every time.

In addition to the above, consider the following enhancements:

- Air Pressure Regulation: Fine-tuning air pressure can optimize the force applied, resulting in improved performance.

- Ergonomic Design: Upgrading to a model with a better grip and lighter weight can reduce fatigue during extended use.

- Maintenance Features: Choose tools with easy-to-access maintenance points for quicker servicing and improved reliability.

By focusing on these upgrades, you can ensure your equipment not only meets but exceeds your expectations, ultimately enhancing your work experience.

Guide to Properly Assembling Bostitch Components

Understanding the intricacies of assembling mechanical devices is crucial for achieving optimal performance and longevity. This section provides essential insights into the correct arrangement of components, ensuring that each piece functions harmoniously within the system. Whether you are a novice or a seasoned technician, mastering the assembly process is key to maximizing efficiency and reliability.

Essential Tools and Equipment

Before starting the assembly process, gather the necessary tools. Common implements include screwdrivers, pliers, and wrenches. Ensure that all components are clean and free from debris to prevent operational issues. Having a well-organized workspace will facilitate a smoother assembly experience.

Step-by-Step Assembly Instructions

Begin with the foundational elements, carefully aligning each part as specified in the manufacturer’s guidelines. Pay attention to the orientation of each component, as improper placement can lead to malfunction. Once the main structure is complete, proceed to integrate secondary elements, ensuring that connections are secure. Test the functionality at each stage to identify any issues early on, allowing for prompt adjustments and corrections.