When working with machinery, having a clear understanding of how different elements are arranged and connected is crucial. Whether you’re a professional technician or a dedicated enthusiast, knowing the structure of each system allows for easier maintenance and troubleshooting. A detailed visual guide can simplify the process of identifying parts and comprehending their functions within the overall assembly.

For efficient operation and long-term reliability, it’s important to become familiar with every crucial part and its role. This can range from the engine and transmission to smaller, intricate components that ensure the smooth functioning of the machine. A comprehensive layout or map of these elements can serve as an invaluable reference when performing repairs or upgrades.

In this context, the breakdown of components into manageable sections is essential. It provides clarity, aids in the identification of replacement needs, and helps prevent errors during reassembly. Whether you are looking to replace a broken piece or perform routine maintenance, such a visual guide ensures that you approach the task with confidence and accuracy.

Understanding the Kubota BX2230 Parts Diagram

This section aims to provide clarity on the intricate layout of components within a specific machinery model. By examining the configuration, users can gain insight into the function and interrelation of various elements, enhancing both maintenance and repair efforts.

Key Components Overview

- Engine assembly

- Transmission system

- Hydraulic mechanisms

- Chassis structure

Benefits of Familiarity

- Improved maintenance practices

- Efficient troubleshooting processes

- Informed purchasing decisions for replacements

Understanding the layout equips users to effectively engage with their equipment, ensuring optimal performance and longevity.

Key Components of Kubota BX2230 Tractor

The functionality and efficiency of a compact agricultural machine rely heavily on its core elements. Understanding these critical parts is essential for maintenance and optimal performance. This section delves into the significant components that play a vital role in the operation of this versatile vehicle.

Engine and Transmission

The heart of any machinery lies in its engine, providing the necessary power for various tasks. Coupled with an efficient transmission system, it ensures smooth operation and effective power delivery to the wheels. These elements work in harmony to enhance the performance, allowing for effective handling of different agricultural implements.

Hydraulic System

A robust hydraulic system is integral for operating attachments and implements. This system enables the user to perform tasks such as lifting, digging, and plowing with ease. Understanding the hydraulic components and their functions can significantly enhance the versatility and productivity of the machine in various farming applications.

How to Interpret the Parts Diagram

Understanding the visual representation of a machine’s components can seem overwhelming at first, but it’s a crucial skill for anyone looking to perform maintenance or repairs. These illustrations offer a detailed view of how various elements fit together, making them indispensable for identifying issues or ordering the correct replacements. By decoding these visuals, you can better understand the assembly and functionality of the equipment.

To effectively interpret these visuals, follow these key steps:

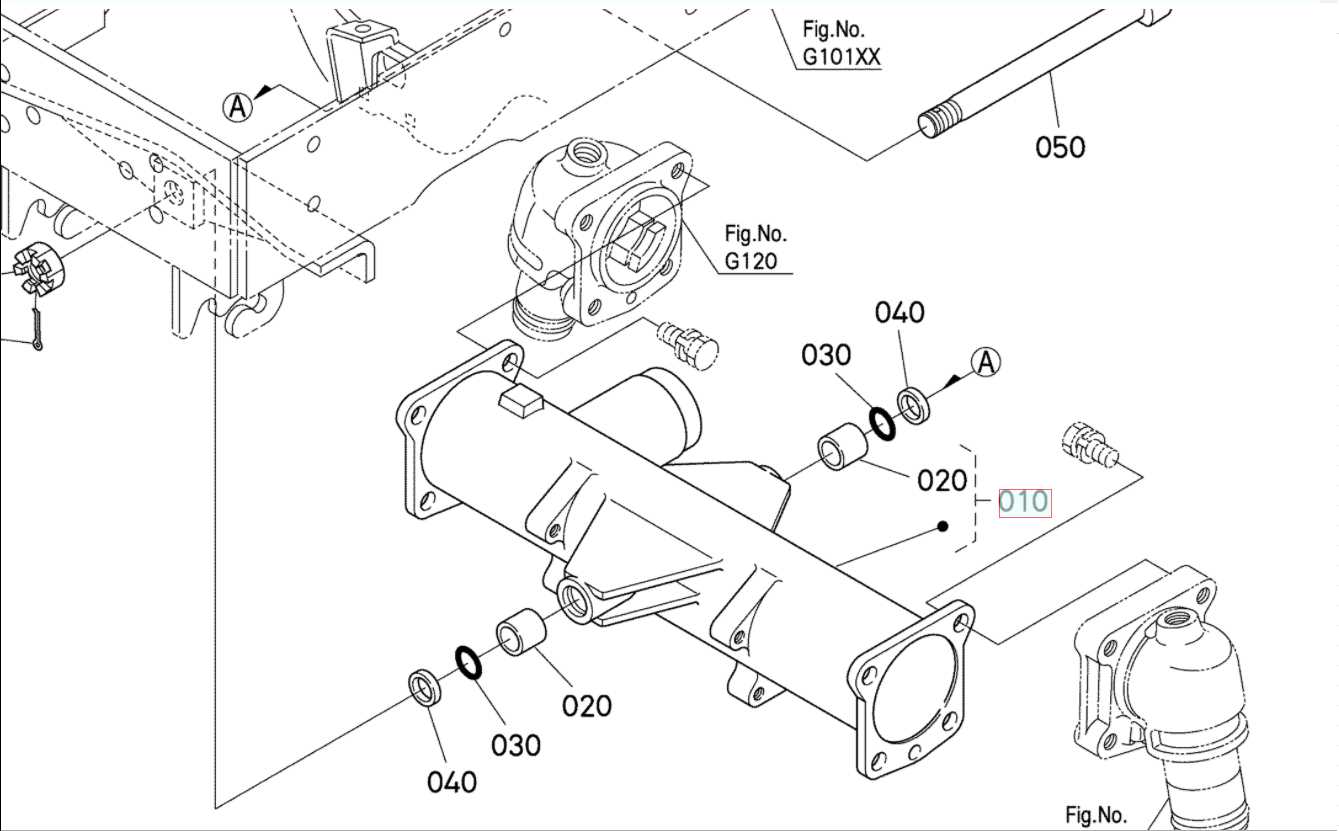

- Identify the key sections: Start by recognizing the major segments of the equipment, usually grouped according to functionality or location. This will give you an overview of the system and where each part fits within it.

- Use the reference numbers: Every component shown typically has a unique reference number. Cross-check these numbers with the accompanying list to identify the specific part name, model, or description.

- Pay attention to orientations: Ensure that you observe how the parts are positioned relative to one another. The orientation may affect how the part is installed or aligned during assembly or repair.

- Check for symbols and annotations: Look out for any symbols or additional notes included in the image. These might provide further details about maintenance, torque specifications, or other critical instructions for handling the parts.

- Look for exploded views: In some illustrations, components are shown in an exploded view, which separates the individual parts to clarify their positions and interactions with other elements. This approach makes it easier to identify each piece’s placement and function.

By carefully analyzing these details, you’ll gain a clear understanding of how the equipment operates, making it easier to troubleshoot problems or make informed decisions when acquiring replacement items.

Common Maintenance Tasks for Kubota BX2230

Regular upkeep is essential for ensuring optimal performance and longevity of any compact utility vehicle. Routine tasks such as checking fluid levels, inspecting components for wear and tear, and cleaning critical parts help prevent breakdowns and maintain smooth operation. Proper maintenance not only enhances the machine’s efficiency but also contributes to safety and reliability on the job.

Engine Care

The engine is the heart of any machine, and keeping it in top condition is vital. Regularly changing the engine oil, replacing filters, and ensuring the coolant is at the correct level are essential tasks that should be performed at recommended intervals. Over time, engine oil degrades, and filters become clogged, which can lead to overheating or reduced performance. Regularly checking the oil and coolant levels will keep the engine running smoothly and extend its life.

Transmission and Hydraulic System

Maintaining the transmission and hydraulic systems is also critical for the vehicle’s performance. Ensure the hydraulic fluid is topped up and check for leaks in the system. If the fluid appears dirty or contaminated, it should be replaced. Additionally, inspecting the belts and hoses in these systems helps prevent sudden malfunctions and ensures power is transmitted efficiently to the various attachments and wheels.

Regularly inspecting these key areas, coupled with periodic cleaning, ensures that your vehicle continues to operate effectively while minimizing the risk of costly repairs.

Where to Find Official Kubota Parts

For anyone seeking original components for their equipment, it is crucial to identify reliable sources that guarantee authenticity and quality. Official replacements are designed to ensure optimal performance and durability, so sourcing them from reputable vendors is highly recommended. There are various avenues available to access these high-quality items, from online platforms to physical stores.

Authorized Dealers

The most trustworthy option for obtaining genuine components is through authorized dealers. These locations are certified to offer factory-approved items and often provide expert advice and installation services. Authorized dealers maintain a direct connection with the manufacturer, ensuring that all components are up to standard and compatible with your machine.

- Locate a nearby dealer through the official manufacturer’s website.

- Visit dealer showrooms to view the available inventory and discuss your needs with knowledgeable staff.

- Many dealers offer shipping options for convenience, allowing you to order components online.

Official Online Stores

In addition to physical locations, there are several online stores operated directly by the manufacturer or its affiliates. These platforms often have a comprehensive catalog of components, including parts for maintenance or repairs. Buying online provides convenience and the ability to compare different components before making a purchase.

- Access the manufacturer’s website for a detailed list of available items and secure payment options.

- Look for trusted online platforms that specialize in equipment components for greater convenience.

- Ensure that the website guarantees original items and provides warranty support for purchases.

By choosing official sources, you can be confident that the components you obtain are designed specifically for your equipment, ensuring long-term functionality and performance.

Replacing Kubota BX2230 Parts: A Step-by-Step Guide

Maintaining your compact tractor requires periodic replacement of worn or damaged components to ensure smooth and efficient operation. Whether you are replacing a broken belt, a worn-out filter, or any other essential item, knowing the proper steps can make the job easier and safer. This guide will take you through the necessary steps for replacing these critical elements, helping you avoid unnecessary downtime.

Before beginning, gather all the necessary tools and replacement components. A few common tools you may need include wrenches, screwdrivers, pliers, and possibly a jack or lifting equipment if you need to raise the machine for access to certain areas. Make sure to have the correct parts that are compatible with your machine model, as using incorrect replacements can lead to further damage.

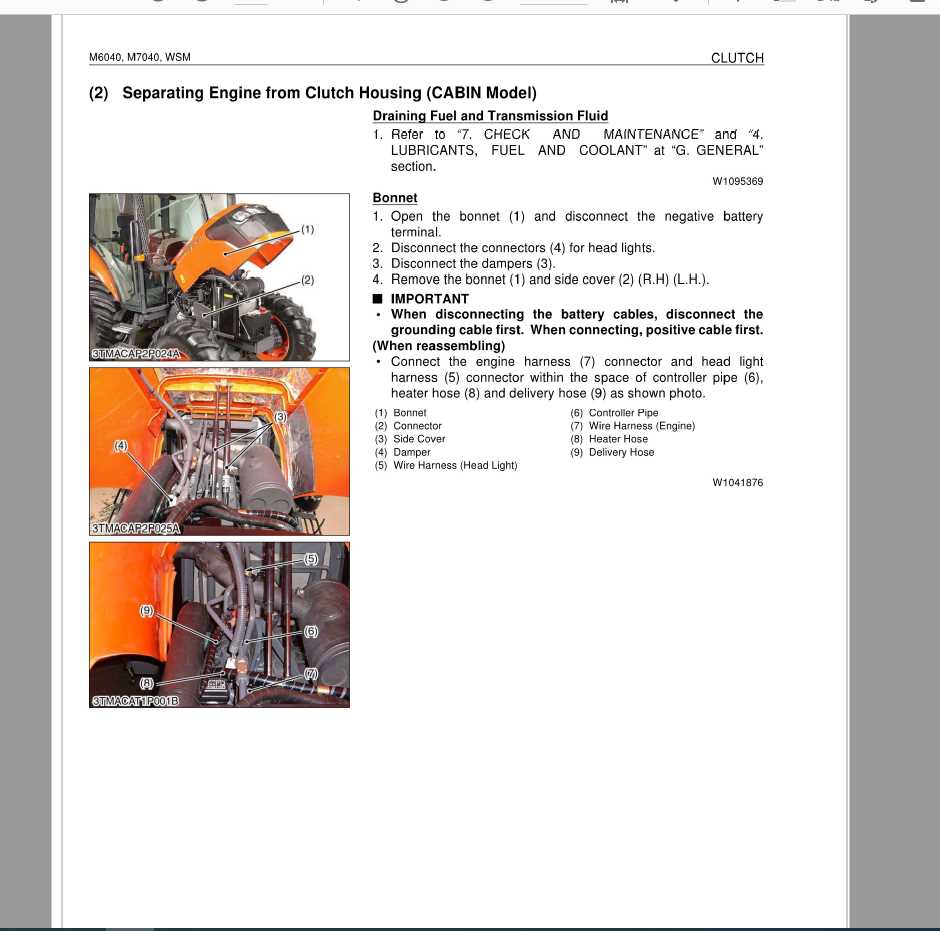

- Turn off the engine: Always start by ensuring the machine is turned off and the ignition key is removed. This prevents any accidental startups during the replacement process.

- Prepare the area: Clear the work area of any obstacles and ensure you have adequate lighting. It’s also helpful to have a clean space where you can organize the components you will be removing.

- Consult the manual: Refer to your equipment manual for the exact location and specifications of the component you are replacing. This step will guide you through specific instructions that may vary between models.

- Remove the old component: Depending on the part, you may need to remove fasteners, bolts, or clips to detach the damaged or worn-out item. Keep these fasteners in a safe place, as you might need them again.

- Install the new item: Once the old part is removed, position the new one and secure it with the appropriate fasteners. Make sure it is firmly in place and aligned correctly.

- Check functionality: After installation, double-check everything to ensure the new part is functioning as expected. If necessary, test the equipment briefly to confirm proper operation.

- Dispose of the old components properly: Finally, dispose of the old part in an environmentally-friendly manner. Some components may be recyclable, so consider that when discarding them.

By following these steps carefully, you can keep your tractor in optimal working condition. Regular maintenance and prompt replacement of faulty parts can extend the life of your machine and improve its performance.

Benefits of Using Genuine Kubota Parts

When it comes to maintaining and repairing machinery, using high-quality components is crucial for ensuring long-term performance and reliability. Genuine items, designed specifically for a particular brand, provide the best fit and function, preventing issues that could arise from using inferior or generic replacements. These authentic components are engineered to meet the same rigorous standards as the original equipment, helping to maintain the efficiency and longevity of the machine.

One of the key advantages of using original items is the assurance of compatibility. These parts are crafted to integrate seamlessly with the system, reducing the risk of mechanical failures caused by incorrect fit or performance. Moreover, opting for genuine replacements can preserve the manufacturer’s warranty and reduce the likelihood of future breakdowns.

Another benefit is the peace of mind that comes with knowing you are using components that have undergone stringent quality control processes. Genuine items are often backed by the manufacturer’s support, ensuring that if any issues arise, professional assistance is readily available. This is not always the case with third-party or off-brand alternatives.

Ultimately, choosing authentic components leads to improved machine performance, greater durability, and lower long-term maintenance costs. It’s an investment in both efficiency and reliability that pays off over time, ensuring your equipment continues to perform at its best in even the most demanding conditions.

Troubleshooting Issues with Kubota BX2230 Parts

Maintaining a compact utility vehicle can often lead to unexpected challenges. Identifying and resolving issues promptly is crucial for optimal performance. This section aims to provide guidance on diagnosing common problems and ensuring smooth operation.

When facing difficulties, consider the following steps:

- Identify Symptoms: Observe the vehicle for any unusual sounds, vibrations, or performance drops. Note specific issues such as:

- Difficulty starting

- Unresponsive controls

- Fluid leaks

Once you have identified the symptoms, proceed with the following diagnostic methods:

- Check Fluid Levels: Ensure that oil, coolant, and fuel levels are adequate. Low fluid levels can lead to overheating and engine failure.

- Inspect Filters: Dirty or clogged filters can impede performance. Regularly check air and fuel filters and replace them as needed.

- Examine Belts and Hoses: Look for signs of wear or damage. Cracks, fraying, or leaks may indicate the need for replacement.

After troubleshooting, implement regular maintenance routines to prevent future issues:

- Schedule routine inspections

- Change fluids according to the manufacturer’s recommendations

- Keep the exterior clean to avoid corrosion and buildup

By following these guidelines, you can effectively manage common challenges and extend the lifespan of your machinery.