The efficient operation of any piece of equipment relies heavily on the intricate interplay of its individual elements. A comprehensive overview of these components can significantly enhance maintenance practices and troubleshooting efforts. Knowing how each part functions within the system is crucial for optimal performance.

By examining the layout and relationship between various elements, users can gain valuable insights into assembly and disassembly processes. This exploration is essential for anyone looking to ensure longevity and reliability in their machinery. The clarity of these visual representations aids both novices and seasoned operators in their understanding.

Furthermore, delving into detailed schematics allows for quicker identification of issues and enhances repair strategies. Ultimately, this knowledge empowers users to make informed decisions regarding repairs and upgrades, ensuring that their equipment remains in peak condition.

Understanding the Kubota ZD221

This section provides an overview of a well-regarded machine in the lawn care and landscaping industry. It emphasizes the importance of comprehending the various components and their functions to ensure optimal performance and maintenance. By familiarizing oneself with the structure and mechanics, users can enhance their operational efficiency and prolong the lifespan of the equipment.

Key Features

The highlighted model is designed for efficiency and durability. Its robust engine delivers reliable power, while the ergonomic design ensures ease of use. Understanding these key attributes can help users leverage the equipment’s full potential.

Maintenance Considerations

| Component | Function |

|---|---|

| Engine | Provides power for operation |

| Transmission | Controls speed and torque delivery |

| Cutting Deck | Ensures efficient grass cutting |

| Wheels | Facilitates mobility across various terrains |

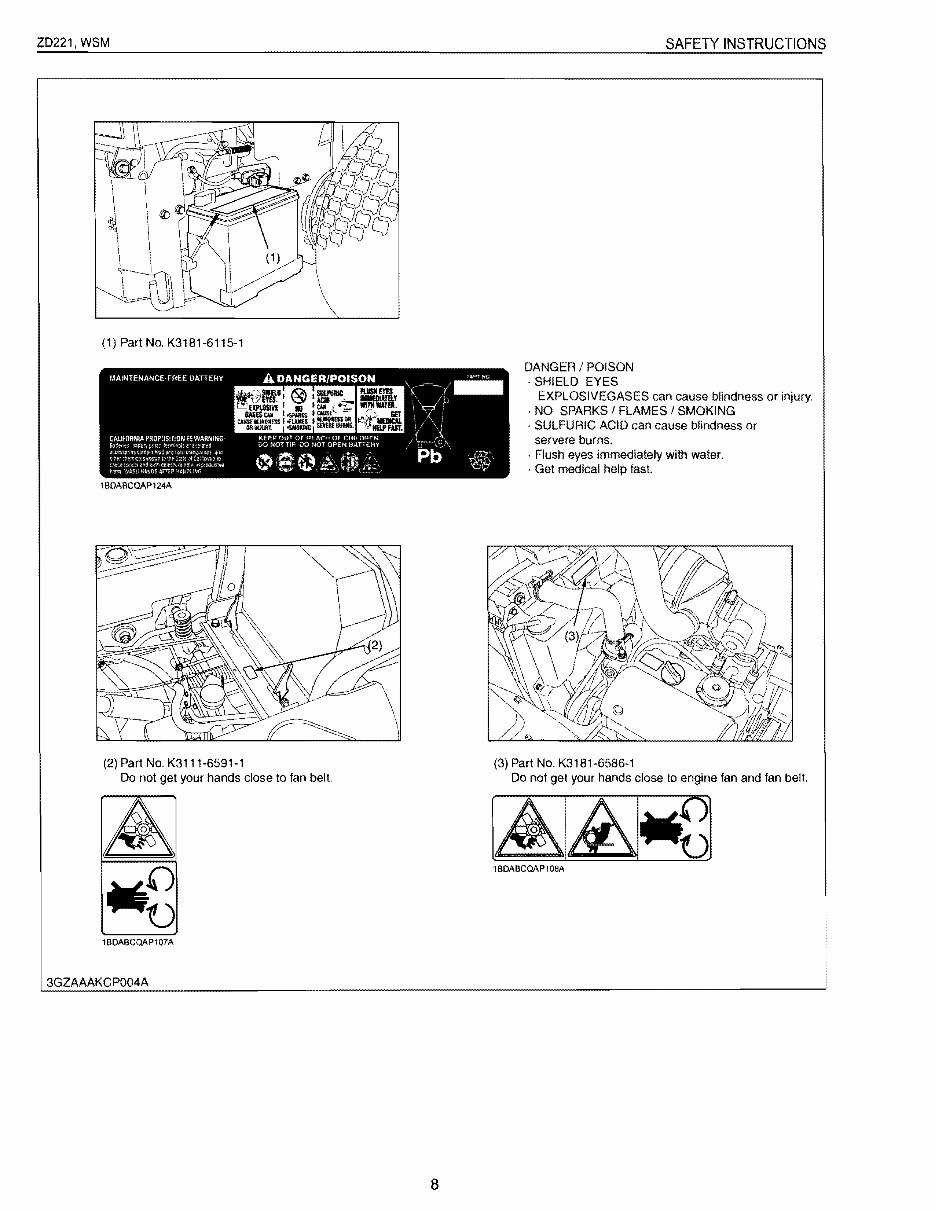

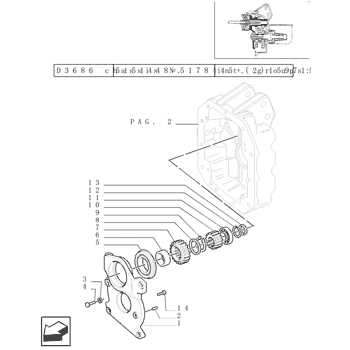

Importance of Parts Diagrams

Understanding the structure and components of machinery is essential for effective maintenance and repair. Visual representations provide clarity, helping users identify each element and its function.

- Enhances troubleshooting efficiency.

- Facilitates accurate ordering of replacements.

- Improves understanding of assembly and disassembly processes.

- Supports preventive maintenance strategies.

By utilizing these illustrations, operators can delve deeper into their equipment’s design, leading to more informed decisions and ultimately extending the lifespan of their machines.

Key Components of the ZD221

This section explores the essential elements that contribute to the overall functionality and efficiency of the machine. Understanding these components allows users to maintain and optimize their equipment effectively, ensuring it operates at peak performance.

Engine and Power System

The heart of any machinery lies in its power unit. This specific model features a robust engine that provides the necessary torque and horsepower for demanding tasks. The design incorporates advanced technology to enhance fuel efficiency and reduce emissions, making it an environmentally friendly choice.

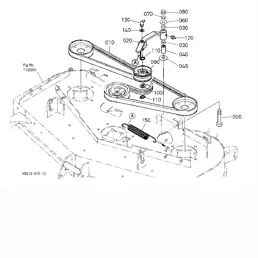

Cutting Mechanism

The cutting system is engineered for precision and versatility. Equipped with high-quality blades, it allows for a clean and even cut, regardless of terrain. The adjustable height settings ensure that users can customize the cutting depth, accommodating various lawn types and conditions.

| Component | Description |

|---|---|

| Engine | High-efficiency power unit with advanced emission control |

| Cutting Deck | Durable structure designed for optimal grass cutting |

| Transmission | Reliable system providing smooth speed adjustments |

| Chassis | Sturdy framework ensuring stability and maneuverability |

How to Access Parts Diagrams

Finding detailed illustrations of components is essential for maintenance and repairs. These visual guides provide clarity on the assembly and parts of machinery, aiding in efficient troubleshooting. Accessing these resources can streamline the process of identifying and ordering the necessary items.

To locate these visual references, start by visiting the manufacturer’s official website, where they often provide a dedicated section for product documentation. Additionally, many authorized dealers offer access to these resources, either online or in-store. Utilize search features by entering the model number or related keywords to pinpoint the correct resources quickly.

Another valuable method is joining online forums or communities where enthusiasts and professionals share their insights. Engaging in these discussions can lead to direct links or shared experiences regarding where to find these important resources. Lastly, consider using third-party websites that specialize in machinery parts, as they may also host useful illustrations and information.

Common Issues with ZD221 Parts

When it comes to maintenance and repairs, certain components often present challenges that can affect overall performance. Understanding these common problems can help owners anticipate issues and address them proactively. This section explores frequent difficulties encountered with various elements of the equipment.

Wear and Tear: Over time, several components experience natural degradation. Regular inspection is essential to identify signs of wear, such as cracks or erosion, which can lead to malfunctions if not addressed promptly.

Connection Failures: Loose or corroded connections can result in disruptions in functionality. Ensuring that all connections are secure and free from rust is vital for maintaining optimal performance.

Fluid Leaks: Leaks can occur in hydraulic systems and other fluid-carrying elements, potentially causing significant issues. Monitoring fluid levels and checking for leaks regularly can help prevent further damage.

Electrical Issues: Electrical components may fail due to age or environmental factors. Regular checks of wiring and connections are necessary to ensure reliable operation and to avoid unexpected breakdowns.

Compatibility Problems: Using non-compatible replacements can lead to poor performance or further damage. It is crucial to ensure that any replacements meet the specifications required for proper function.

By being aware of these common issues, operators can take necessary steps to maintain equipment effectively and minimize downtime.

Replacement Parts and Compatibility

Ensuring the right components for your machinery is essential for optimal performance and longevity. Understanding the various options available and their compatibility with specific models can greatly enhance your maintenance efforts and reduce downtime.

Identifying Compatible Components

When looking for substitutes, it’s crucial to verify that the selected items meet the specifications of your equipment. Checking manufacturer recommendations and utilizing reliable resources can guide you toward the most suitable choices.

Quality and Performance Considerations

Opting for high-quality replacements can significantly impact the efficiency and durability of your machinery. Investing in reputable brands often results in better performance and peace of mind, as these alternatives typically offer similar, if not superior, functionality.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires consistent care and attention. By adhering to a few essential maintenance practices, you can enhance performance and minimize the likelihood of breakdowns. Here are some crucial tips to keep your equipment in optimal condition.

- Regular Inspections: Schedule routine checks to identify any wear and tear early. Look for loose components, leaks, or unusual noises.

- Cleanliness: Keep the machinery clean to prevent dirt and debris buildup, which can hinder performance and lead to damage over time.

- Fluid Levels: Regularly monitor and maintain appropriate fluid levels, including oil and coolant, to ensure smooth operation.

Additionally, focusing on the following areas will contribute significantly to longevity:

- Replace Filters: Change air and oil filters at recommended intervals to maintain efficiency.

- Tire Maintenance: Check tire pressure regularly and inspect for wear to ensure safety and proper handling.

- Battery Care: Keep battery terminals clean and check for corrosion to avoid starting issues.

Implementing these practices will not only enhance the performance of your equipment but also save you time and money in the long run.

Where to Buy Kubota Parts

Finding reliable sources for components is essential for maintaining the efficiency of your machinery. Various options are available, catering to different needs and preferences. Knowing where to look can save time and ensure quality replacements.

Online Retailers

- Specialized Websites: Many online platforms focus solely on equipment components. They often provide detailed descriptions and customer reviews.

- General E-commerce: Major websites offer a wide range of options, sometimes at competitive prices. Make sure to check seller ratings.

- Manufacturer’s Website: Directly purchasing from the manufacturer ensures authenticity and access to the latest products.

Local Dealers

- Authorized Dealers: Local representatives typically offer a comprehensive selection and expert advice. They can assist with specific requirements.

- Repair Shops: Many repair services sell components directly to customers, often providing installation support as well.

- Farm Supply Stores: These retailers frequently stock essential items for agricultural equipment and may carry compatible options.

DIY Repairs Using the Diagram

Understanding the components of your machinery can empower you to tackle repairs independently. By utilizing a visual representation of parts, you can identify issues more effectively and enhance your maintenance skills. This approach not only saves time and money but also gives you the confidence to manage basic repairs.

Steps for Effective DIY Repairs

- Gather the necessary tools and replacement components.

- Refer to the visual representation to locate the part needing attention.

- Follow the indicated steps to disassemble and replace the component.

- Reassemble the machine carefully, ensuring all parts are securely fitted.

Tips for Success

- Always consult the maintenance manual for specific guidance.

- Take photos during disassembly to aid reassembly.

- Work in a well-lit area to avoid missing small components.