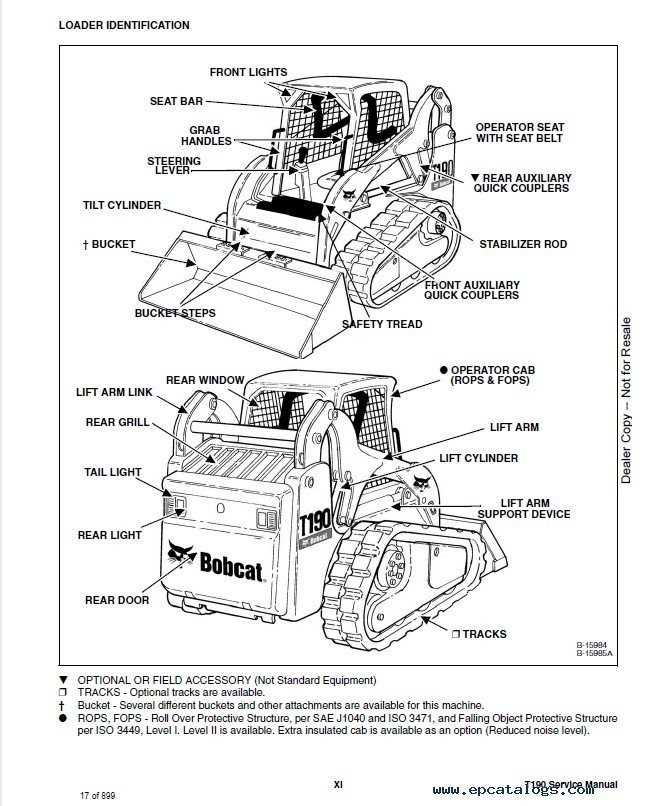

When it comes to maintaining heavy machinery, having a clear and detailed understanding of each component’s layout is essential. Whether you’re performing routine maintenance or tackling a complex repair, knowing the exact arrangement of parts helps ensure that everything fits correctly and functions as intended. The layout of individual machine components is often provided in a comprehensive, visual format, offering technicians and operators a helpful guide for identification and assembly.

These visual representations serve as an invaluable tool for those who need to locate, replace, or service specific sections of the machine. By examining such diagrams, users can quickly identify potential issues, understand how parts interact, and make informed decisions regarding repairs. This level of clarity reduces the risk of errors and minimizes downtime, making the process of maintenance more efficient and cost-effective.

In this section, we will explore how these detailed component layouts can improve your understanding of the machine’s structure. Whether you’re an experienced technician or a first-time user, having access to these resources will help you manage the upkeep of your equipment with greater confidence and precision.

Understanding Bobcat T190 Parts Layout

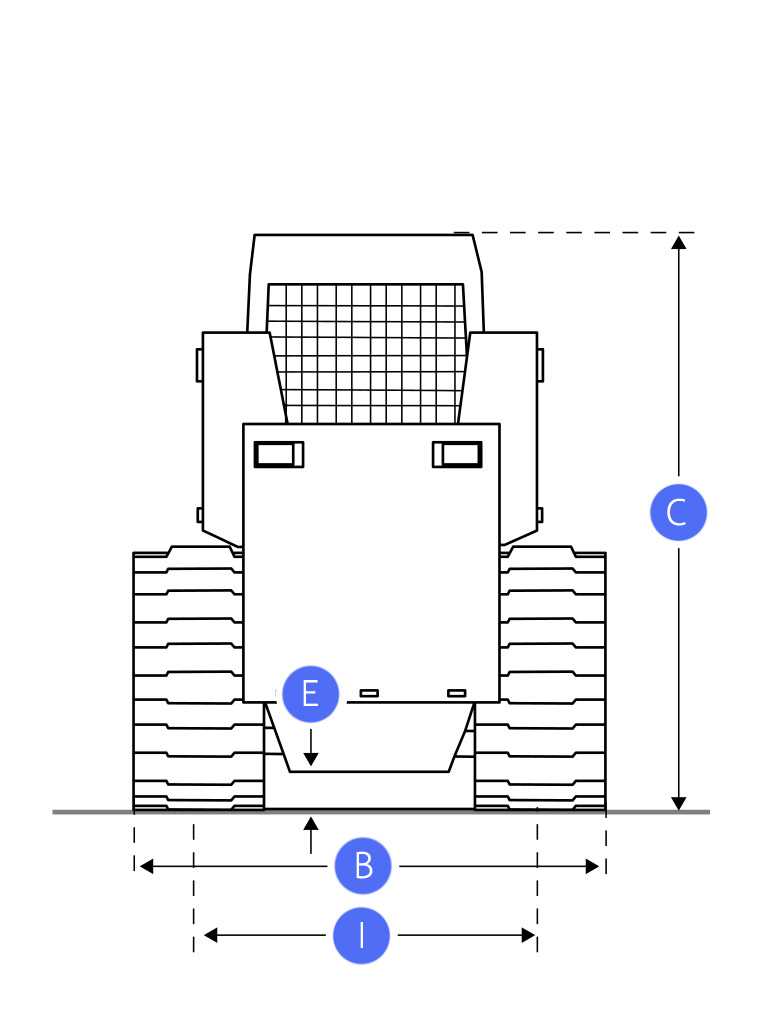

Comprehending the arrangement of components in heavy machinery is crucial for efficient maintenance and repair. A clear visualization of how various elements interconnect can enhance both functionality and longevity. This section explores the layout of a specific compact track loader, emphasizing the importance of knowing each section for optimal performance.

Key Component Areas

The structure of this equipment can be divided into several critical zones, each serving a unique purpose. Familiarizing oneself with these regions allows operators and technicians to pinpoint issues quickly and perform necessary interventions.

| Component Area | Description |

|---|---|

| Engine Compartment | Housing the power unit, this area is essential for the machine’s operation and requires regular checks for optimal performance. |

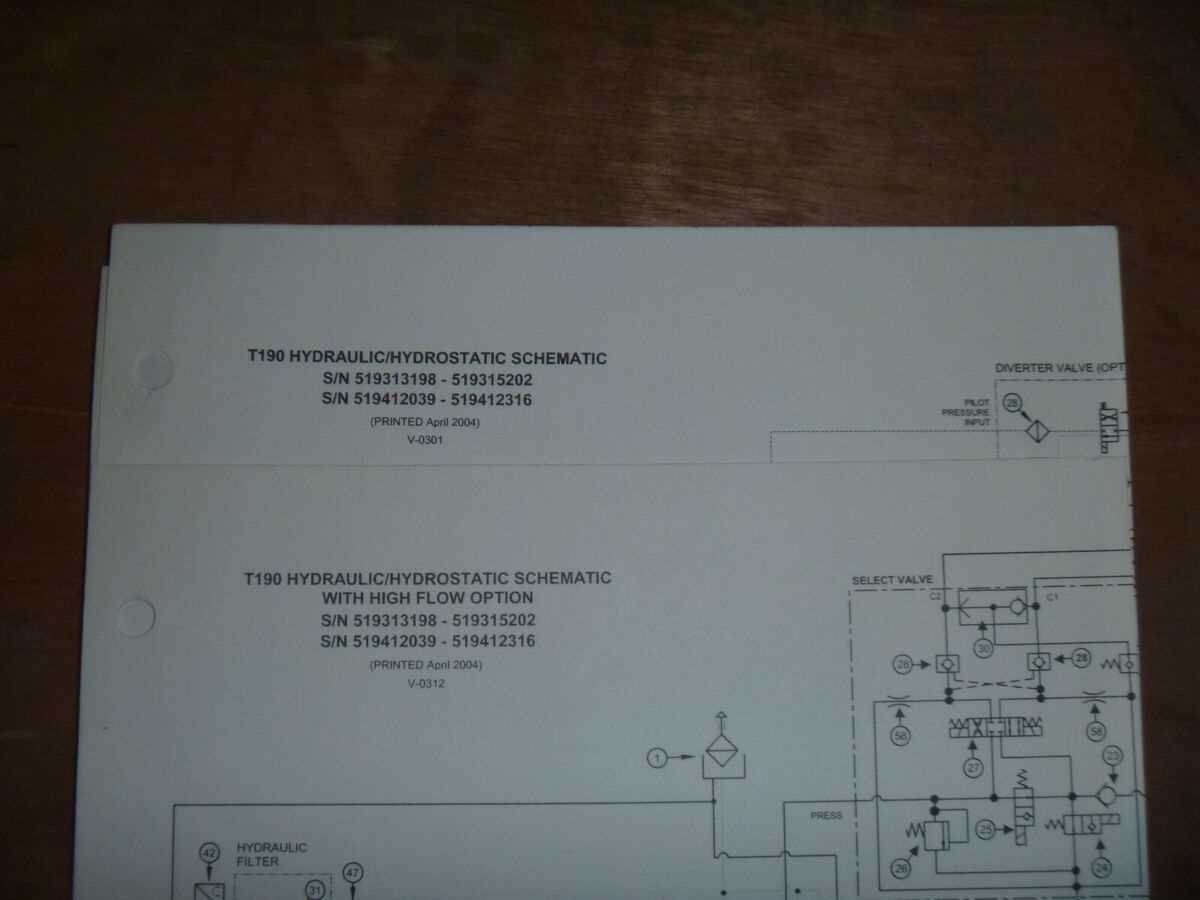

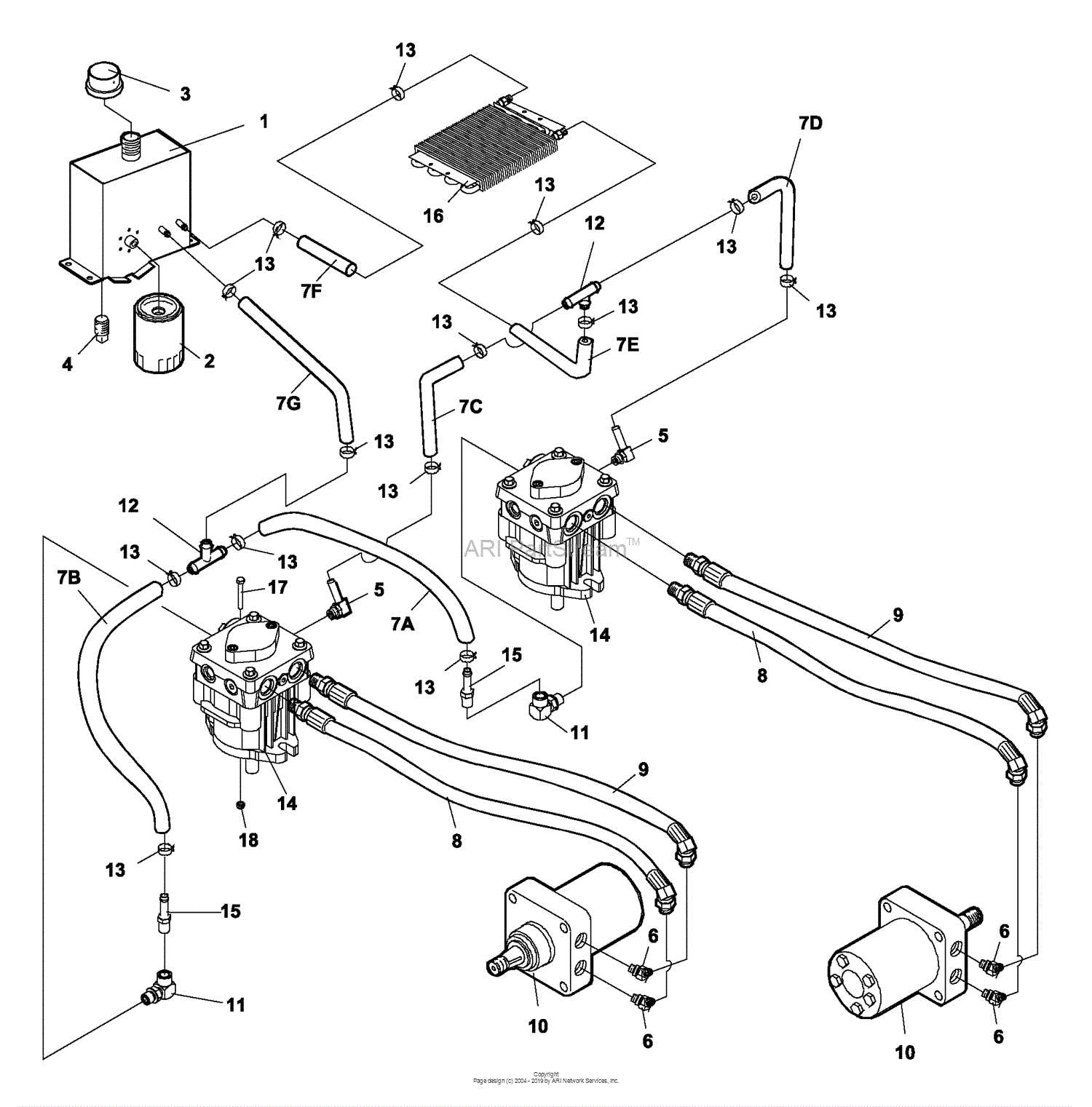

| Hydraulic System | This section contains essential hydraulic components, facilitating various movements and functions of the loader. |

| Operator Cabin | The control center for the operator, equipped with necessary instruments for navigating and managing the machinery. |

| Undercarriage | This region supports mobility and stability, crucial for handling diverse terrains effectively. |

Importance of Component Familiarity

Understanding the layout of each area not only aids in troubleshooting but also assists in preventative measures. Recognizing wear patterns and potential failures before they escalate can save time and resources, ensuring smooth operations over time.

Key Components of Bobcat T190

Understanding the essential elements of a compact loader is crucial for its optimal performance and longevity. This section highlights the major systems and parts that contribute to the machine’s overall functionality. These components play a vital role in ensuring efficient operation, reliable performance, and ease of maintenance. Below is an overview of the primary mechanical and hydraulic parts that are integral to the loader’s performance.

| Component | Description |

|---|---|

| Hydraulic System | This system is responsible for powering the loader’s lifting arms and other attachments, ensuring smooth operation and heavy lifting capability. |

| Engine | The heart of the machine, providing the necessary power to drive the wheels and operate all attached implements efficiently. |

| Tracks or Tires | These provide traction and stability on various terrains, allowing the machine to move with ease while supporting its weight and operations. |

| Cab | The operator’s station that includes controls, seating, and safety features. It is designed for comfort and accessibility during operation. |

| Lift Arms | The lift arms are critical for raising and lowering various attachments, such as buckets or forks, to perform a wide range of tasks. |

| Cooling System | This system ensures the engine and hydraulic components remain within optimal temperature ranges, preventing overheating during heavy use. |

How to Read Bobcat T190 Diagrams

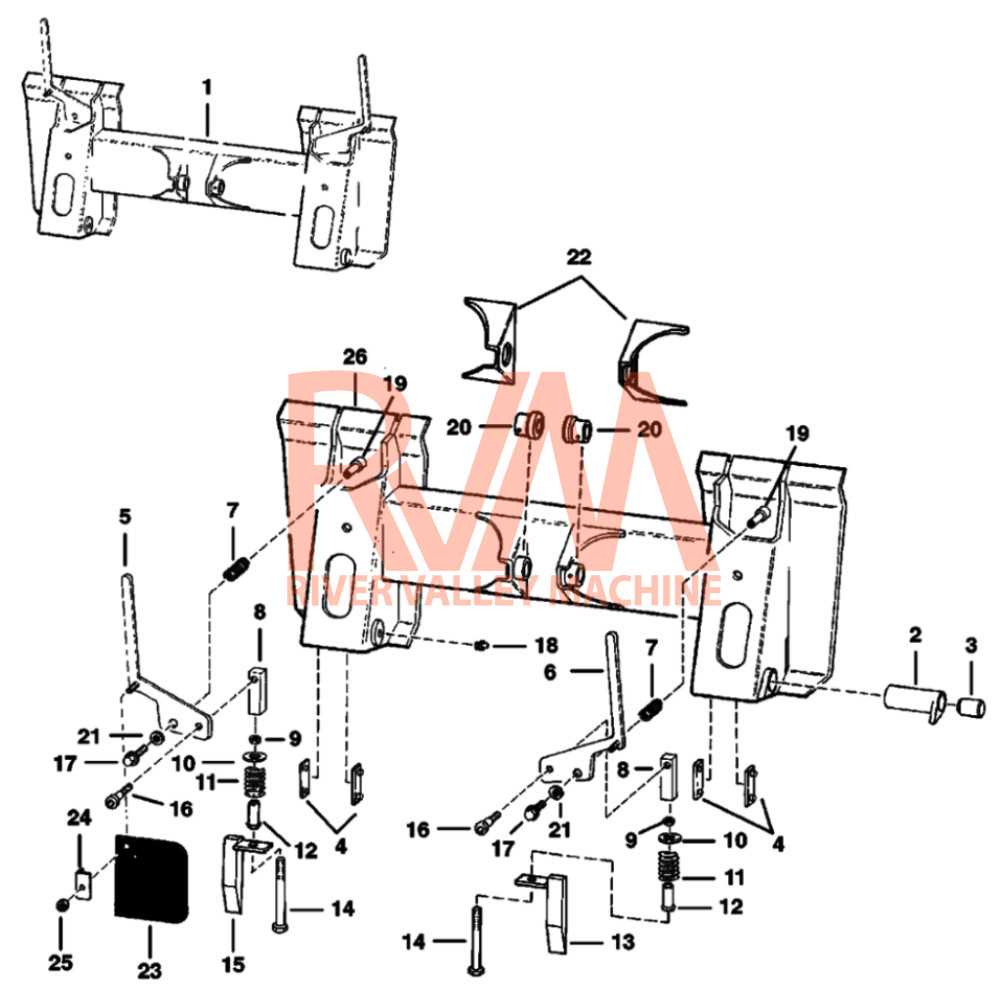

Understanding technical illustrations for machinery can significantly enhance your maintenance and repair capabilities. These visual representations provide essential information about components, their functions, and how they interact within the overall system. Mastering the ability to interpret these images allows for more efficient troubleshooting and part replacement.

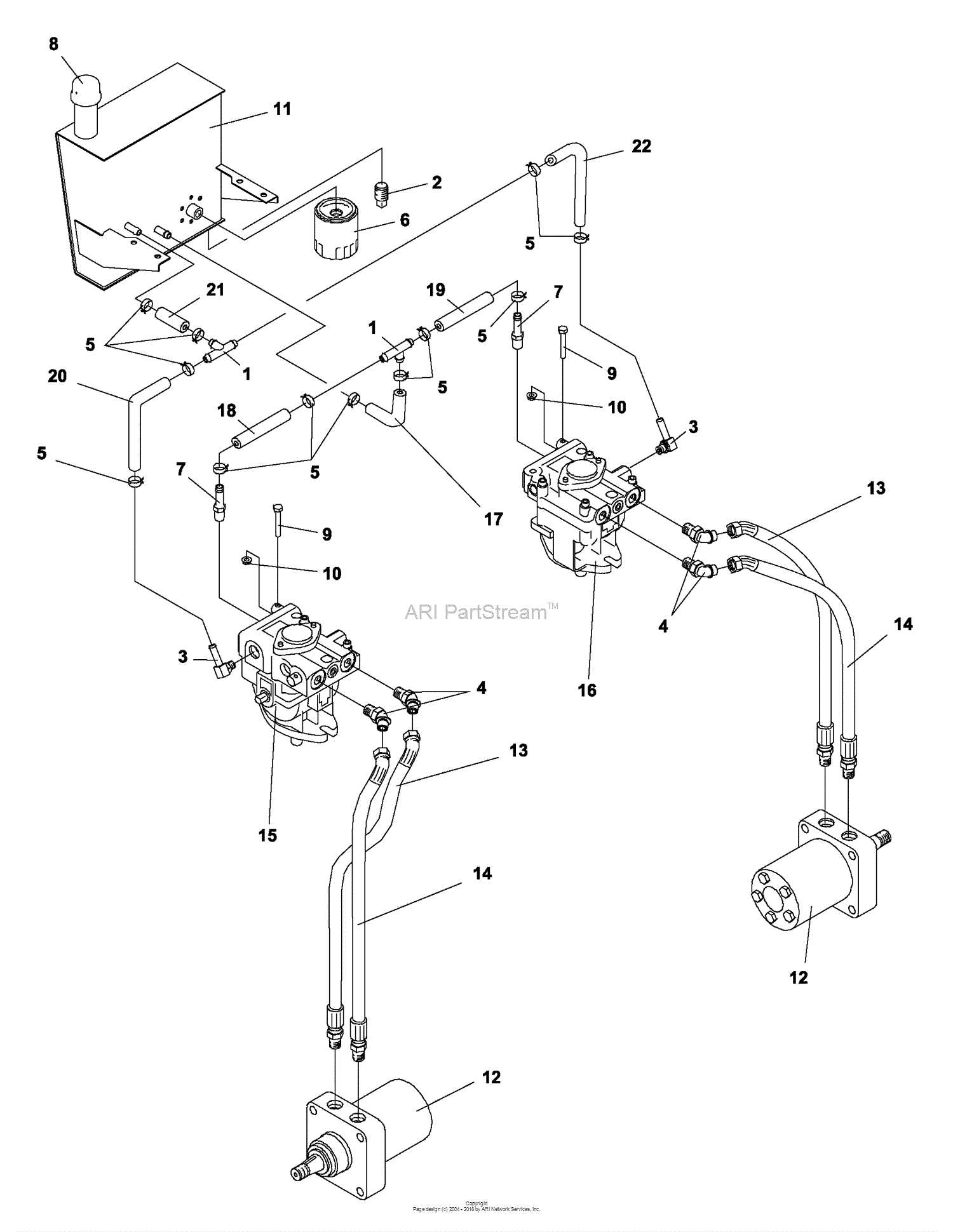

Identifying Key Components

Begin by familiarizing yourself with the symbols and labels used in the illustrations. Each element is typically represented by a specific icon or shape, which corresponds to various parts of the machine. Take note of the numbering system, as it often indicates the order of assembly or the relationship between different parts.

Understanding Connections and Flow

Next, focus on the connections shown in the visual guides. Arrows and lines typically denote pathways for fluids, electricity, or movement. Recognizing these pathways helps in understanding how different components work together to achieve the machine’s functionality. Pay attention to any notes or legends that may clarify specific details or provide additional context.

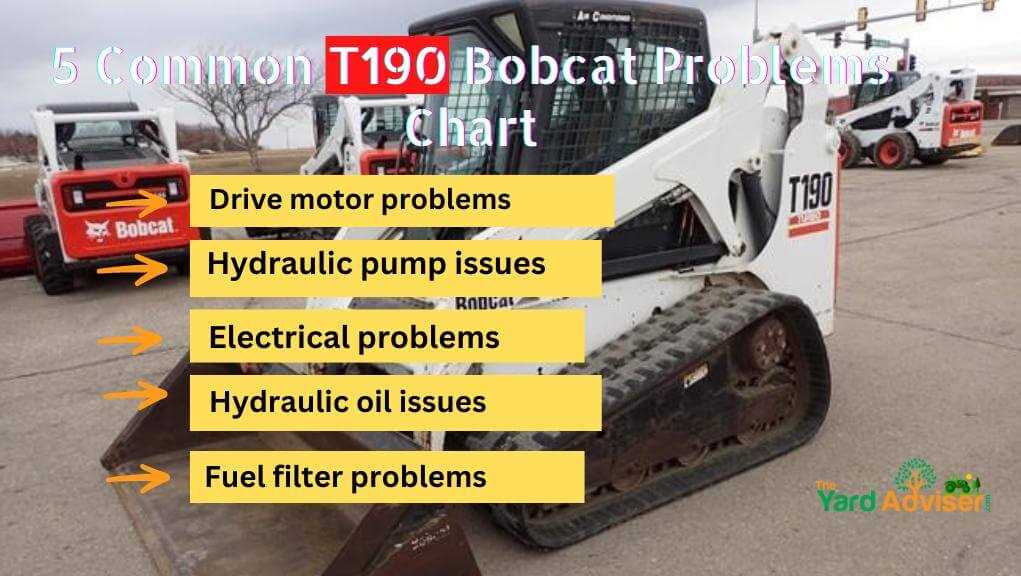

Common Issues in Bobcat T190 Parts

When dealing with machinery, certain components often experience wear and tear over time. These components may require attention to maintain performance and prevent costly repairs. Regular maintenance is key to identifying and addressing issues before they become more severe. Below are some common problems with critical elements of the system.

- Hydraulic System Failures: Leaks, loss of pressure, or malfunctioning pumps are common issues that can lead to diminished lifting capacity and slower response times.

- Engine Performance Issues: Reduced power, engine stalling, or unusual noises can signal problems in the engine or related systems such as fuel delivery or ignition.

- Transmission Problems: Gear slipping or difficulty in shifting gears may occur, usually due to issues with the internal transmission components or fluid levels.

- Cooling System Overheating: The cooling system may become clogged or experience a failure in the radiator or hoses, causing the engine to overheat, leading to potential damage.

- Track and Undercarriage Wear: Constant exposure to rough terrain can cause wear in tracks, rollers, and other undercarriage parts, impacting stability and mobility.

Addressing these common problems as soon as they arise helps to extend the lifespan of critical machine components and ensures smooth operation on the job site.

Maintenance Tips for Bobcat T190 Components

Regular upkeep of machinery components is essential for optimal performance and longevity. By adhering to a structured maintenance routine, operators can enhance efficiency and reduce the likelihood of unexpected breakdowns.

- Inspect Regularly: Schedule frequent inspections to identify wear and tear on essential elements.

- Clean Thoroughly: Remove dirt and debris from surfaces to prevent corrosion and damage.

- Lubricate Moving Parts: Ensure all moving components are adequately lubricated to minimize friction.

- Replace Worn Parts: Timely replacement of degraded components prevents further issues.

- Monitor Fluid Levels: Check hydraulic and engine fluids regularly to maintain proper operation.

Following these guidelines can significantly enhance the durability and functionality of your equipment, ultimately leading to improved productivity.

Replacing Parts in Bobcat T190 Model

Maintaining and replacing components of heavy machinery is an essential aspect of ensuring its optimal performance and longevity. Over time, wear and tear or mechanical failure can necessitate the removal and substitution of specific elements. Understanding the correct procedure for replacing these items is critical for operators and technicians alike.

Before beginning any replacement task, it is important to have the necessary tools, new components, and a clear step-by-step process. Whether addressing a malfunctioning hydraulic system, a worn-out drive motor, or a damaged frame part, each replacement has its own set of instructions and precautions.

The following guidelines can help simplify the process:

- Assessment and Diagnosis: Thoroughly inspect the machine to identify which components are in need of replacement. Checking for unusual noises, leaks, or lack of performance is the first step in pinpointing the issue.

- Preparation: Gather the necessary replacement items, ensuring compatibility with the machine’s specifications. Always use high-quality, manufacturer-approved parts for optimal performance and safety.

- Disassembly: Safely detach any obstructing parts that may prevent easy access to the faulty component. Follow the proper disassembly procedures to avoid damaging surrounding areas.

- Replacement: Install the new component, ensuring a secure fit and proper alignment. Double-check all connections, including hydraulic, electrical, or mechanical links, to ensure proper functionality.

- Testing: After installation, run a series of tests to confirm that the issue has been resolved and that the machinery is operating smoothly.

By following these steps, you can ensure that the machinery will continue to function efficiently and effectively, reducing downtime and improving overall productivity.

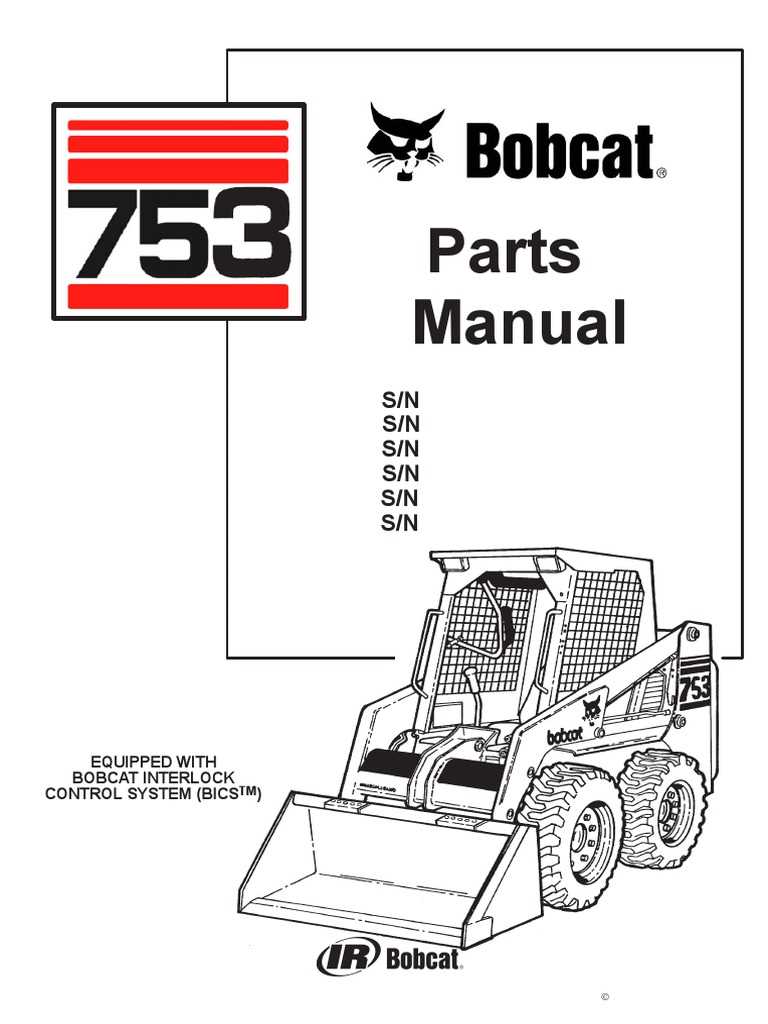

Where to Find Bobcat T190 Diagrams

Accessing detailed schematics and illustrations for heavy machinery is essential for effective maintenance and repairs. Knowing where to locate these resources can save time and ensure proper functionality of equipment.

Online Resources

- Manufacturer’s Official Website

- Specialized Equipment Forums

- Third-Party Parts Retailers

Printed Manuals

- Service Manuals Available for Purchase

- Local Dealerships and Distributors

- Library Resources or Online Archives

Benefits of Accurate Parts Identification

Proper identification of components in machinery ensures efficiency, longevity, and smooth operation. When each element is correctly recognized and understood, it leads to optimal performance and reduces the risk of costly mistakes. A clear understanding of each piece’s role enhances the ability to carry out repairs and maintenance with precision, ensuring minimal downtime and maximizing productivity.

Accurate recognition of components helps prevent unnecessary replacements, saving both time and money. It ensures that only the parts that need attention are addressed, preventing over-maintenance and prolonging the lifespan of the equipment. This accuracy also plays a significant role in reducing operational errors, as knowing exactly what to replace or repair eliminates guesswork and avoids potential damage.

Another key benefit is the improved safety of the equipment. When all parts are correctly identified, maintenance personnel can quickly detect any issues, ensuring that repairs are made before problems escalate. This not only safeguards the machine’s integrity but also reduces the risk of accidents or malfunctions during operation, providing a safer environment for operators.

Essential Tools for Bobcat T190 Repairs

When performing repairs on construction machinery, having the right set of tools is crucial to ensure efficiency and precision. Whether you’re working on hydraulic systems, engine components, or the undercarriage, the proper equipment allows for quicker and safer fixes. This guide outlines the essential tools that every technician should have at their disposal when working on compact loaders or similar equipment.

Basic Hand Tools

Start with a solid collection of hand tools that can cover most minor and routine repairs. These include:

- Socket wrench set with various sizes

- Adjustable wrenches for different fasteners

- Heavy-duty screwdrivers (flathead and Phillips)

- Plier sets for gripping and twisting

- Hammer and mallet for gentle tapping

Hydraulic and Electrical Tools

For more complex repairs, such as hydraulic system servicing or electrical troubleshooting, specialized tools are necessary:

- Hydraulic pressure gauge to check system integrity

- Wire crimping tool for electrical repairs

- Multimeter for diagnosing electrical faults

- Leak detection kit for hydraulic fluid issues