In the world of construction and maintenance, understanding the makeup of essential tools can greatly enhance both their usage and longevity. By analyzing the individual elements that make up these instruments, users can gain valuable insight into how each piece contributes to overall functionality and effectiveness. This knowledge is particularly useful for those looking to maintain or repair their equipment.

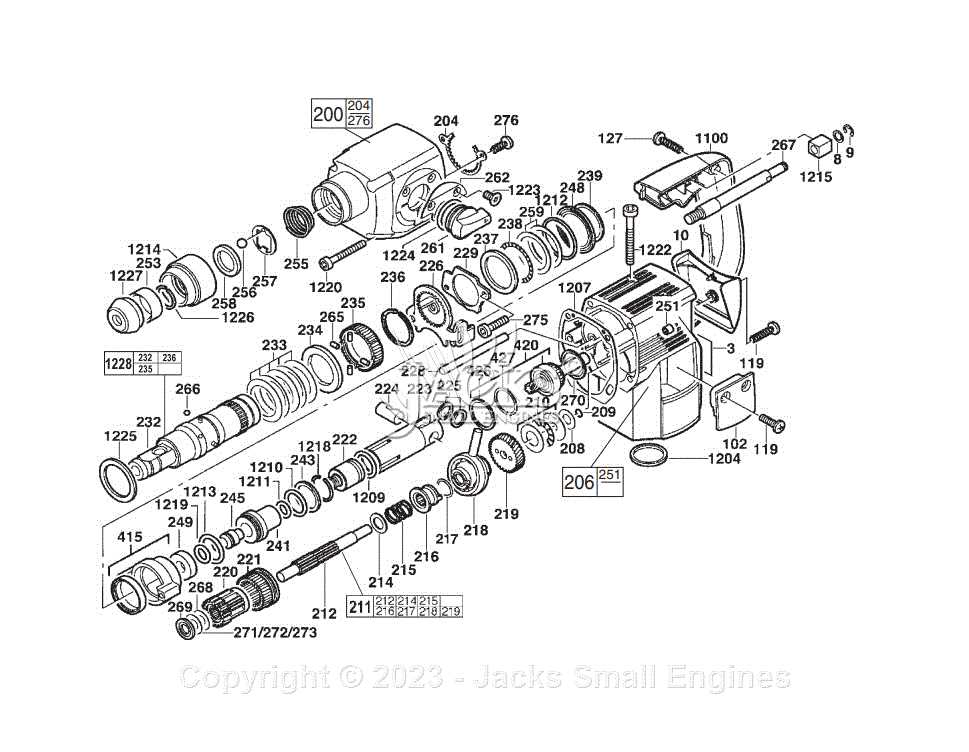

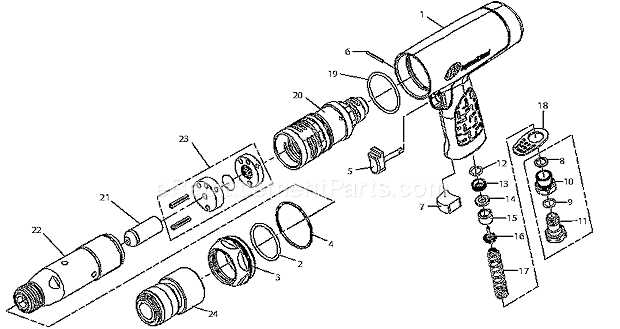

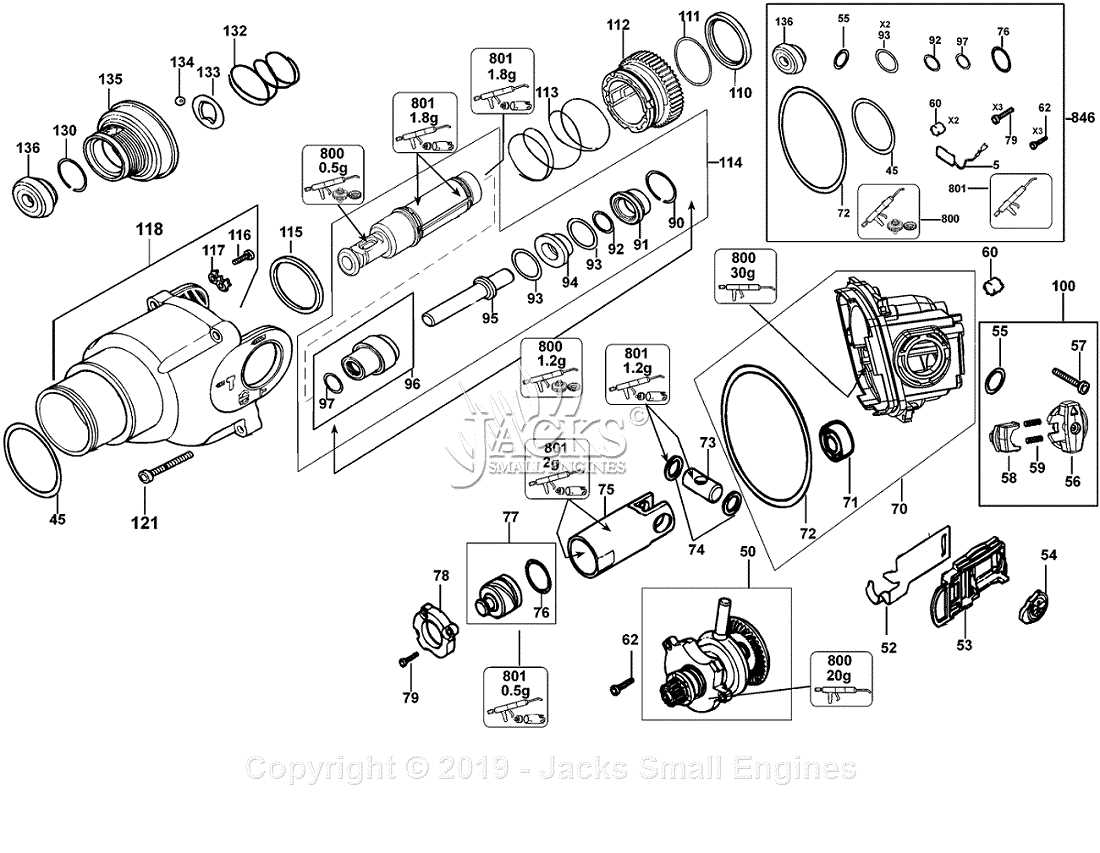

Each mechanical tool consists of a series of interconnected elements that work together to achieve its purpose. Whether it’s the force distribution, the precision of movement, or the structural integrity, every aspect plays a crucial role. A detailed breakdown of these components allows for better troubleshooting, improving both efficiency and safety in various applications.

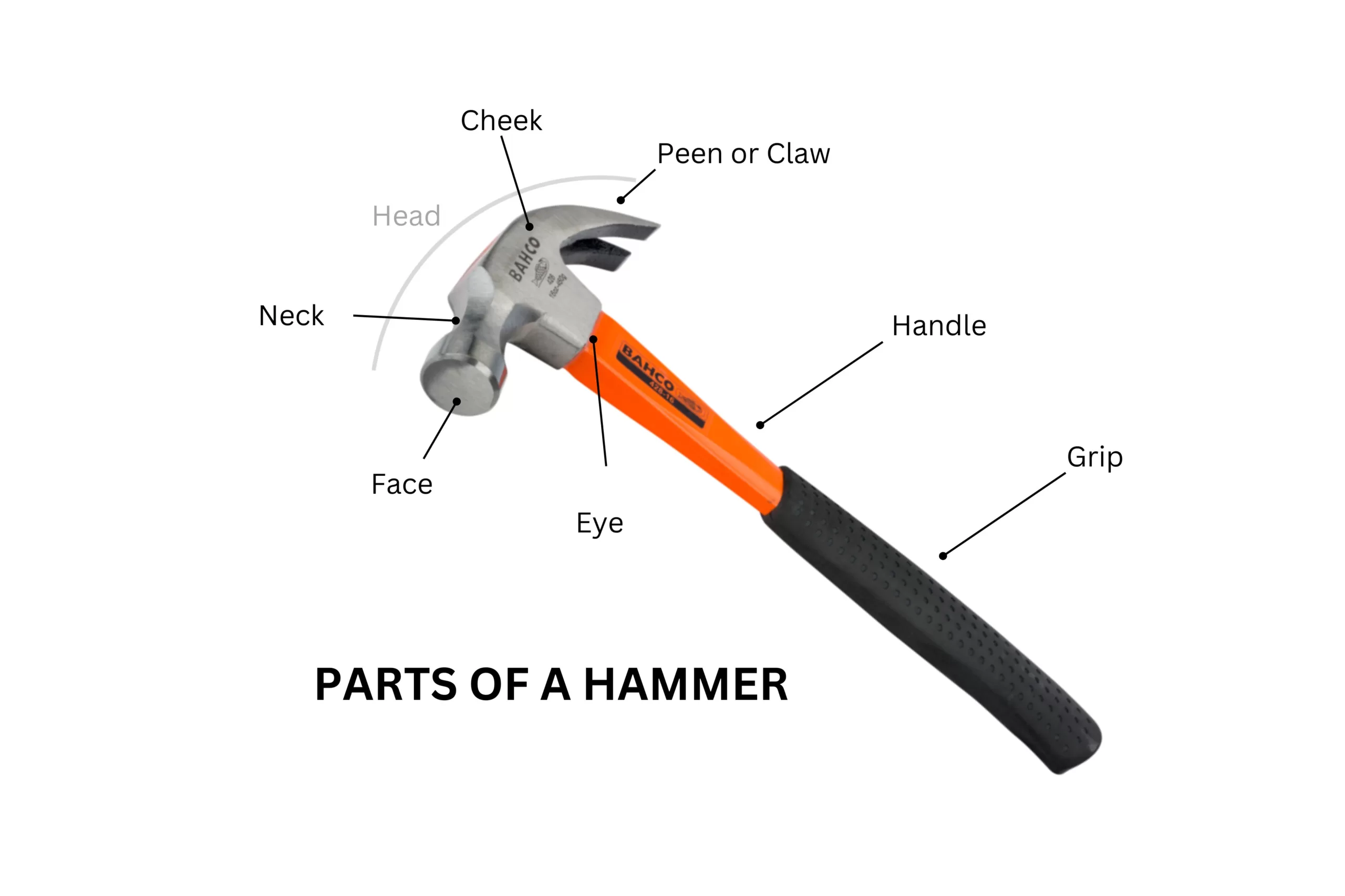

Overview of Hammer Mechanism Components

This section provides a comprehensive look at the main elements that contribute to the operation and efficiency of a striking tool. By understanding how these components work together, it becomes easier to grasp the fundamental principles of its overall function and design.

Main Structural Elements

The assembly consists of several key elements that work in unison to ensure effective performance. These include parts responsible for delivering impact force, controlling movement, and maintaining stability during operation. Each of these elements plays a vital role in the reliability of the tool.

Component Interaction

Different components must interact precisely to achieve optimal performance. The balance between force application and control mechanisms defines the effectiveness and lifespan of the entire assembly. Below is an overview of how the core components relate to each other:

Main Functional Elements of a HammerThe design of a striking tool combines several key components that work together to deliver force and precision. These elements, while varying slightly depending on the specific type and purpose, share a common purpose of providing control, balance, and efficiency during use. Understanding these fundamental elements helps to appreciate how this tool operates in different environments and applications.

| Component | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Impact Element | Delivers the primary force necessary for operation. | ||||||||||

| Component | Function | ||||||||||

| Handle | Provides grip and leverage, allowing the user to control the tool with precision and power. | ||||||||||

| Head | Delivers impact to the target surface, designed for striking with varying levels of force. | ||||||||||

| Face | The flat or rounded surface of the head that makes direct contact, ensuring effective transfer of force. | ||||||||||

| Claw |

Detailed Breakdown of Handle Materials

When selecting the appropriate grip for a tool, understanding the variety of materials available is essential. Each material offers unique properties, providing distinct benefits and trade-offs that influence durability, comfort, and performance. Whether for professional tasks or everyday use, choosing the right material can make a significant difference in the overall experience. Wooden Handles

Wood has long been a preferred material due to its balance of strength and shock absorption. It’s lightweight, providing good control, and is often favored for its natural feel. The main types used include hickory, oak, and ash, each known for their resilience and ability to handle impact without excessive vibration. Synthetic OptionsModern synthetic materials, such as fiberglass and plastic composites, offer enhanced durability and resistance to weather conditions. These handles are often reinforced to prevent cracking and splitting, providing consistent performance in various environments. Key Factors in Choosing Hammer HandlesWhen selecting a tool for impact work, one must consider several critical aspects related to the design and material of its handle. This choice directly influences the efficiency, comfort, and durability of the tool during use. Making an informed decision ensures that the right balance between control and power is achieved, leading to better outcomes in various tasks. Material and Durability

The material used in the handle is a key factor that determines its durability and ability to withstand force over time. Common materials range from wood to modern composites, each offering different levels of strength and shock absorption. For those seeking long-term reliability, it’s important to evaluate the resilience of the chosen material under continuous strain. Grip and ComfortComfort during extended use is equally important, as a well-designed grip reduces hand fatigue and increases precision. Ergonomically designed handles often feature textured surfaces or cushioning to enhance control and minimize slippage. Ensuring a secure grip can significantly affect the overall performance, especially when performing repetitive tasks. Analysis of Head Design and Variations

Understanding the design of the top section of impact tools reveals a fascinating array of forms and purposes. This component, often regarded as the most critical for effective performance, comes in different shapes and materials depending on its intended use. Each variation offers distinct advantages, optimizing the tool for specific tasks, whether it’s focused on delivering precise force or designed for heavier impacts. The structural aspects of this section vary significantly across models. Some are designed to distribute weight evenly for improved balance, while others focus on maximizing striking power. Additionally, the surface texture and shape influence how the tool interacts with various materials, providing a wide range of options for users depending on the application. By examining these differences, one can better appreciate the role of this element in enhancing overall efficiency and durability. Influence of Different Head Shapes on PerformanceThe shape of the striking surface plays a crucial role in determining the effectiveness and efficiency of a tool. Various configurations can lead to distinct outcomes when it comes to precision, force distribution, and overall handling. Understanding these differences allows users to select the most suitable tool for their specific tasks. Round heads are often favored for tasks requiring a broad impact area, making them ideal for driving nails or performing tasks where a gentle touch is necessary. The curved surface helps in dispersing energy evenly, reducing the risk of damage to the material being worked on. Flat heads, on the other hand, are designed for tasks demanding precision and power. Their wide, flat surfaces provide a concentrated strike that is effective in driving objects deep into surfaces. This design is particularly beneficial in construction and demolition applications, where maximum force is required. Another common shape is the claw head, which incorporates a dual-purpose function. The design not only allows for driving but also facilitates the removal of nails and other fasteners. This versatility makes it a popular choice among those who need an all-in-one solution for various tasks. In summary, the head configuration significantly impacts how a tool performs. By considering the specific requirements of a project, users can choose the right shape to enhance their productivity and achieve optimal results. Exploring the Claw Functionality in Hammers

The unique design of certain striking tools features an essential component that enhances their versatility and effectiveness. This section delves into the mechanics and practical applications of this remarkable feature, which serves multiple purposes beyond simply driving objects into surfaces. Mechanics of the Claw

At its core, the claw serves as a critical element for leverage and grip. Its curved shape allows users to easily grasp and extract nails or other fasteners from various materials. The angle and design of this part enable a combination of force application and finesse, making it an indispensable tool in construction and repair tasks. Applications and Benefits

This component not only aids in removal but also offers benefits such as reducing effort and preventing damage to surrounding materials. The ergonomic design allows for comfortable handling, providing users with the ability to execute precise movements. The multifunctional aspect of this tool is a testament to its importance in various settings, from home improvement to professional construction.

Effective Uses of the Claw for Nail Removal

The claw is a versatile tool feature that excels in extracting fasteners from various surfaces. Understanding its proper application can enhance efficiency and prevent damage to the surrounding material. Below are some effective strategies for utilizing this tool in nail extraction tasks.

By mastering these techniques, one can efficiently remove fasteners while maintaining the integrity of the surrounding materials, making this tool an essential companion for any project. Specialty Hammers: Unique Parts and Functions

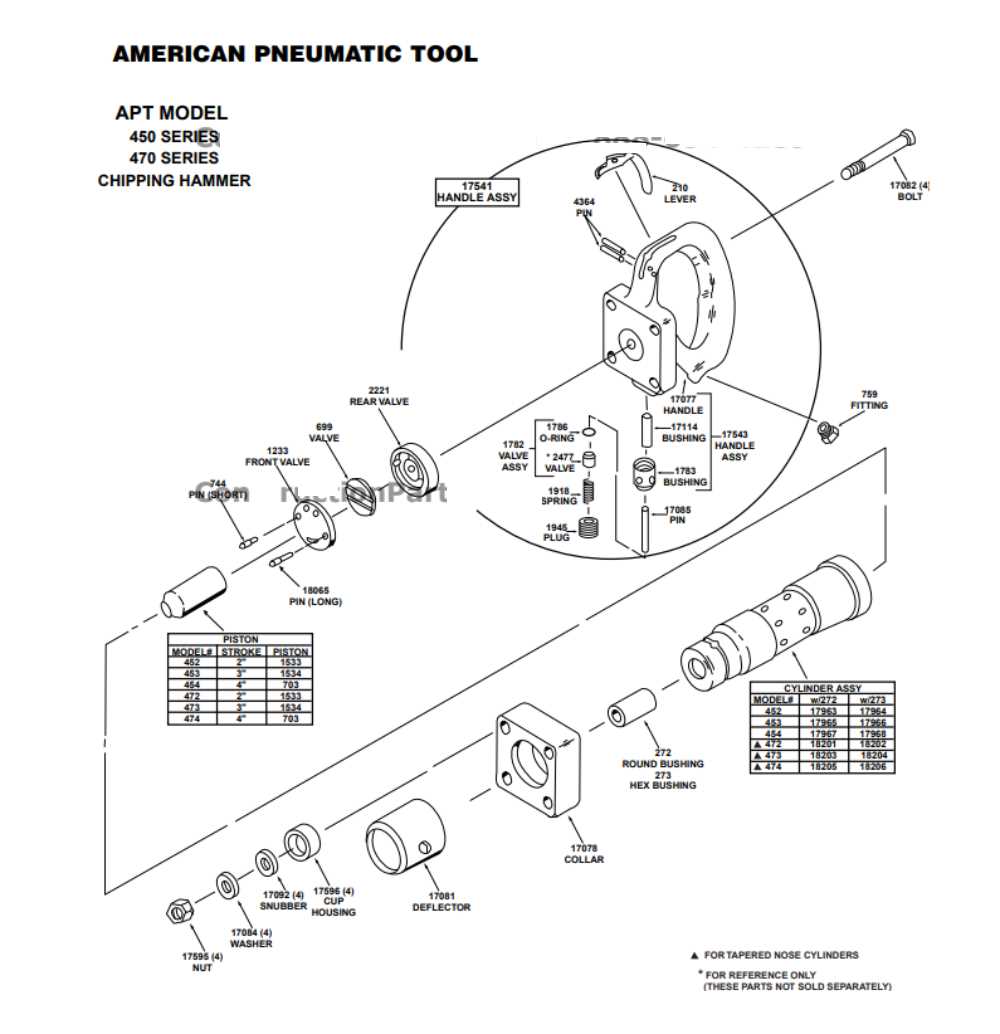

In the realm of striking tools, there exists a diverse array of specialized instruments designed for specific applications. Each of these unique implements is engineered to provide tailored functionality, ensuring optimal performance across various tasks. The distinct characteristics of these tools set them apart from conventional varieties, allowing users to achieve precise results in their respective projects. Among these specialized instruments, certain models feature distinct heads, enabling them to serve unique purposes. For instance, a tool with a weighted head excels in driving nails deep into surfaces, while another with a softer material is perfect for delicate applications where minimizing surface damage is crucial. Additionally, the handle design can vary significantly, influencing grip and control during use. Ergonomically crafted handles ensure comfort and reduce fatigue, making them ideal for prolonged tasks. Furthermore, various attachments or accessories can enhance the versatility of these instruments. Some may include interchangeable heads or striking surfaces, allowing users to switch between functions seamlessly. This adaptability makes them indispensable for professionals who require a multifaceted approach to their work. By understanding the specific features and functions of these specialized tools, users can select the right instrument for any task, thereby improving efficiency and effectiveness. Comparing Common and Specialty Hammer Variations

When exploring the tools designed for impact applications, it is essential to distinguish between standard models and those tailored for specific tasks. Each variation offers unique features that cater to different needs, allowing users to choose the most effective tool for their projects. Understanding these distinctions helps in making informed decisions based on functionality and efficiency. Standard models are typically designed for general use, making them versatile and accessible for a wide range of activities. These tools often feature a balanced weight distribution and a comfortable grip, allowing users to apply force effectively while minimizing strain. They are ideal for everyday tasks such as driving nails or assembling furniture. In contrast, specialty designs focus on particular applications, offering enhanced performance for specific tasks. For example, tools designed for demolition purposes may have heavier heads and more robust construction to withstand increased force. Similarly, models meant for delicate work might feature softer striking surfaces to prevent damage to materials. By understanding the unique characteristics of both categories, users can select the right tool to suit their specific requirements. Ultimately, recognizing the differences between these variations not only improves the quality of work but also enhances safety and efficiency. Whether one is tackling a home improvement project or engaging in professional craftsmanship, choosing the appropriate tool is crucial for achieving optimal results. |