When it comes to maintaining and optimizing machinery, a comprehensive understanding of its individual components is crucial. Each part plays a significant role in ensuring smooth operation and longevity of the overall system. This section aims to provide clarity on the essential elements that contribute to the efficiency of your equipment.

In exploring the intricate network of pieces, users can not only identify what needs attention but also gain insights into upgrades or replacements. By delving into the specifics, one can achieve the ultimate performance from their machinery, enhancing both productivity and reliability.

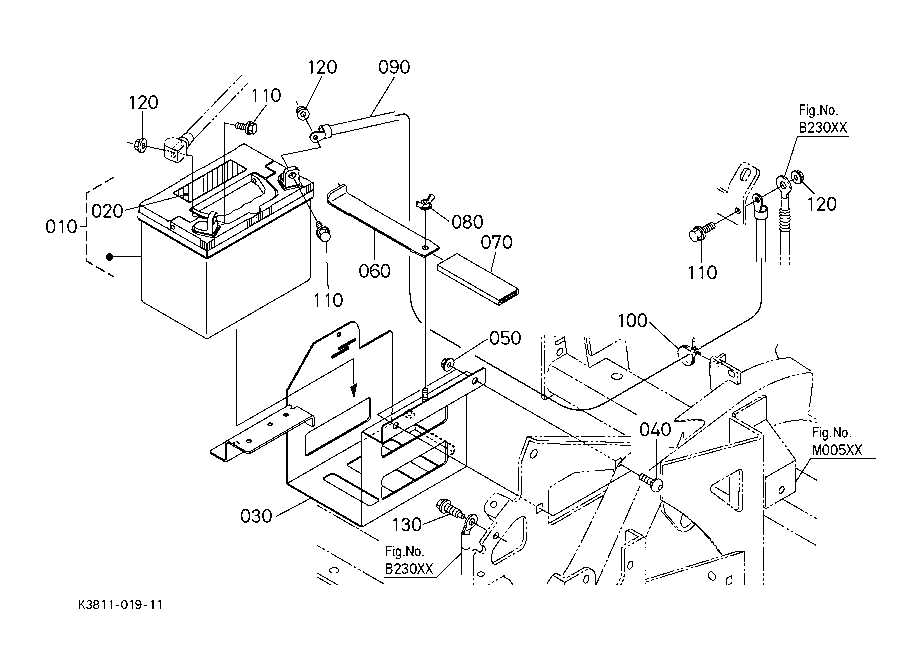

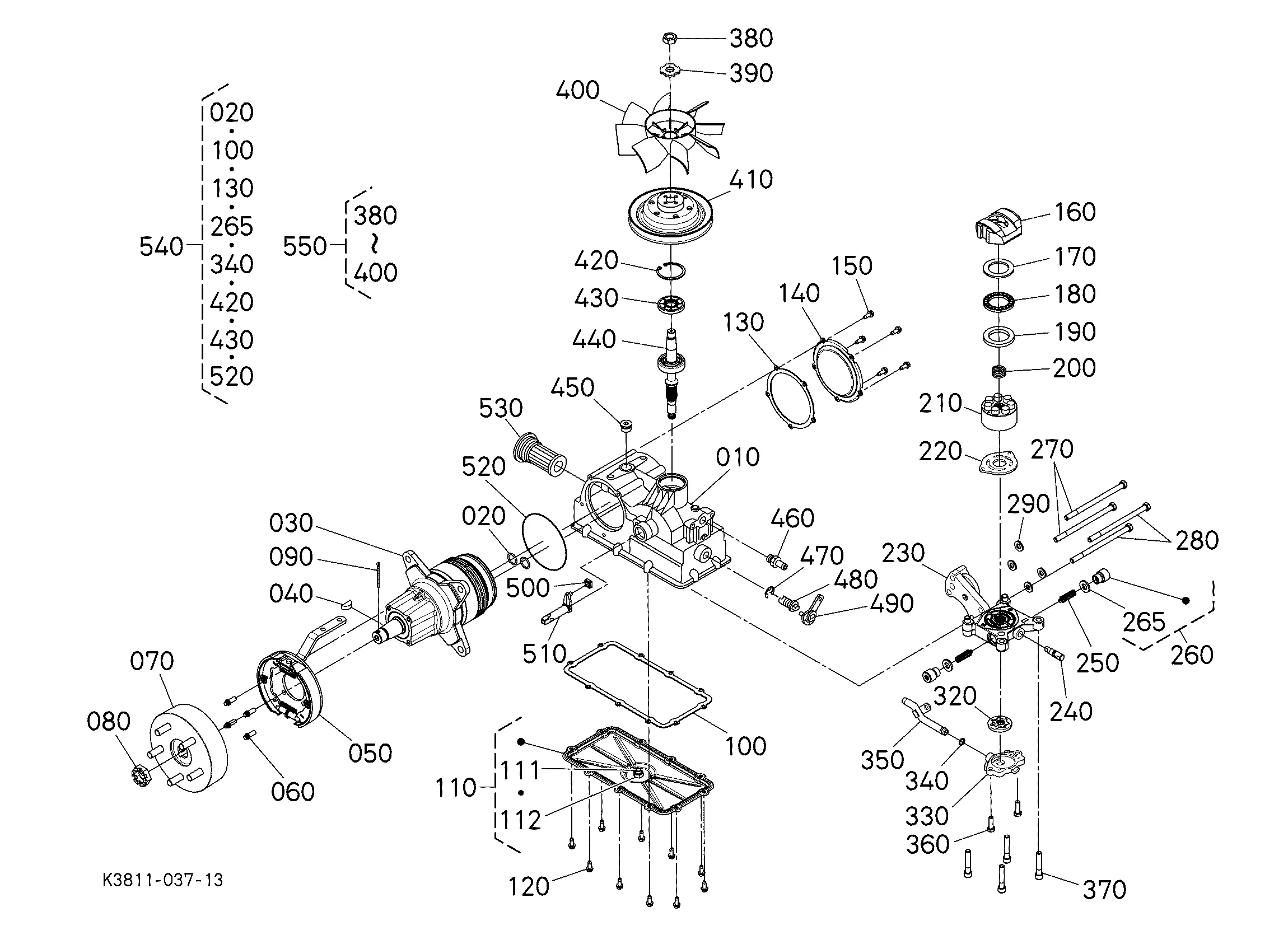

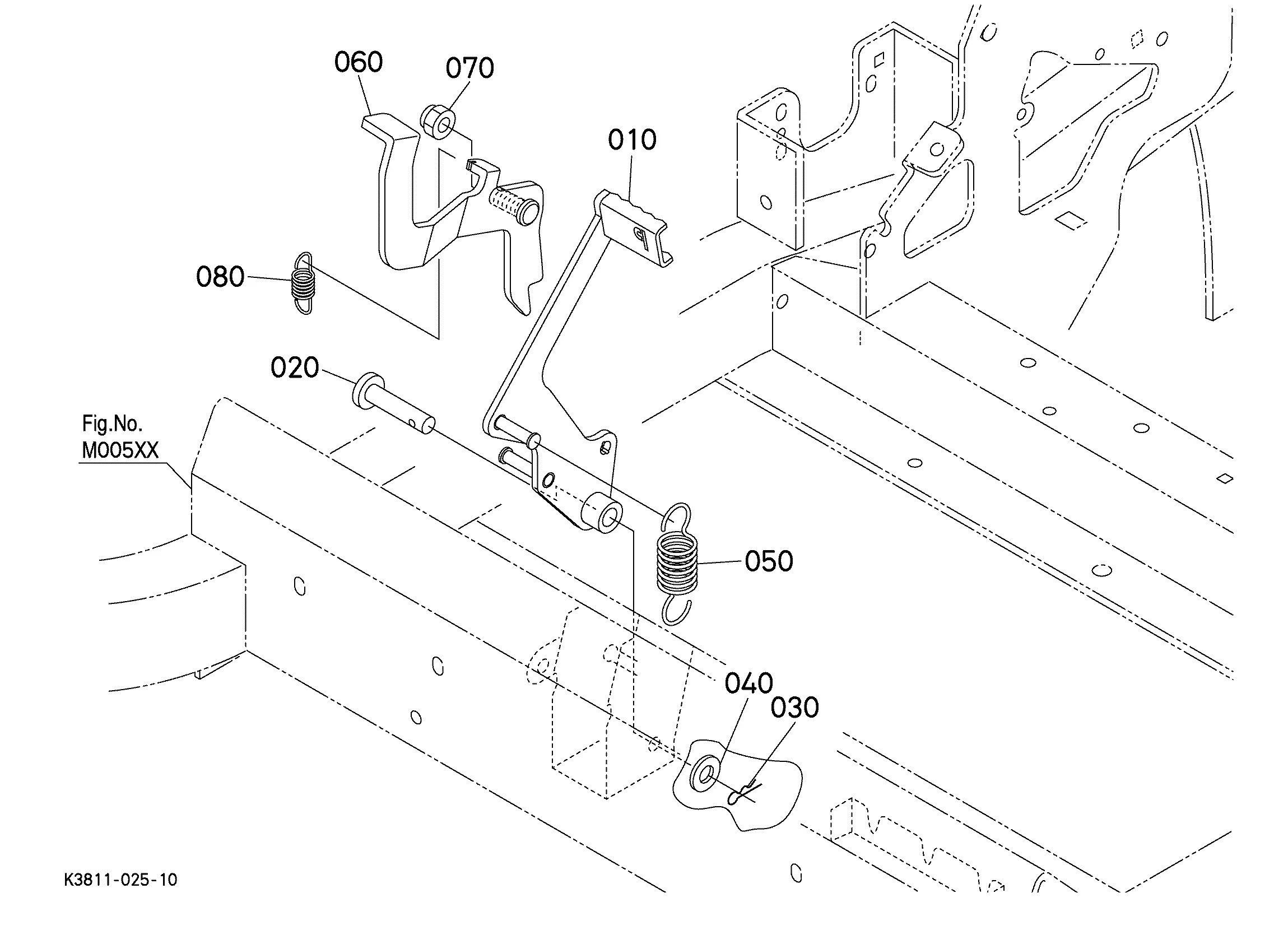

Visual aids, such as detailed representations, serve as invaluable tools for both novice and experienced operators. They facilitate a better grasp of assembly and disassembly processes, making repairs and maintenance tasks more manageable and efficient.

Kubota Z725 Overview

This section provides a comprehensive look at a specific model of compact machinery designed for efficiency and versatility in various landscaping and agricultural tasks. The unit combines robust engineering with user-friendly features, making it an excellent choice for both professionals and enthusiasts.

Key features of this machinery include:

- Powerful engine performance

- Exceptional maneuverability

- Durable construction for longevity

- Advanced ergonomic design for operator comfort

Ideal for tasks such as mowing, hauling, and grading, this model stands out due to:

- High productivity levels, enabling quick completion of tasks

- Adaptability to various attachments for different functions

- Low maintenance requirements, ensuring minimal downtime

- Environmental efficiency, reducing fuel consumption

Overall, this machinery represents a reliable investment for those seeking to enhance their operational capabilities in outdoor maintenance and land management.

Understanding Parts Diagrams

Comprehending the visual representations of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, detailing the intricate relationships between various elements of a machine. By exploring these visual aids, users can gain clarity on assembly, disassembly, and troubleshooting processes.

Why Visual Aids Matter

These graphic layouts simplify complex information, allowing users to quickly identify specific items and their functions. They enhance understanding by providing a clear overview, which is particularly valuable when dealing with intricate machinery.

Interpreting the Symbols

Familiarizing oneself with the symbols and annotations used in these visuals is crucial. Each representation conveys important details, from size to compatibility, ensuring that users can make informed decisions regarding repairs and replacements.

Maximizing Efficiency

By mastering the interpretation of these visuals, individuals can significantly enhance their efficiency. This knowledge empowers users to tackle maintenance tasks confidently, ultimately prolonging the lifespan of their equipment.

Key Components of Z725

Understanding the essential elements of this model is crucial for effective maintenance and operation. Each component plays a significant role in the overall functionality and efficiency of the machine. Below is an overview of the primary parts that contribute to its performance.

| Component | Function |

|---|---|

| Engine | Provides the necessary power to operate the machinery. |

| Transmission | Facilitates the transfer of power from the engine to the wheels. |

| Hydraulic System | Enables the operation of various attachments and implements. |

| Chassis | Serves as the framework, supporting all components and ensuring stability. |

| Cutting Deck | Responsible for trimming grass and managing landscaping tasks. |

Benefits of Using Diagrams

Utilizing visual representations in any technical field enhances comprehension and facilitates effective communication. These illustrations serve as valuable tools for both beginners and experts, breaking down complex information into digestible segments.

| Benefit | Description |

|---|---|

| Clarity | Visual aids clarify intricate processes and components. |

| Efficiency | Quickly reference essential information, saving time during repairs. |

| Learning | Enhances understanding through visual learning techniques. |

| Collaboration | Facilitates discussion among team members, fostering teamwork. |

| Problem-Solving | Identifies issues rapidly, allowing for quicker resolutions. |

Finding Replacement Parts

Locating suitable components for your machinery can be a straightforward task if approached methodically. Understanding the specific needs of your equipment and having access to reliable resources is essential. Whether you are a professional technician or a dedicated hobbyist, ensuring you have the right pieces will maintain optimal performance.

Start by consulting the manual that accompanies your equipment. This document often contains vital information regarding specifications and compatible components. If the manual is unavailable, various online platforms offer comprehensive catalogs that can guide you in identifying the necessary items.

Engaging with forums and communities dedicated to machinery enthusiasts can also provide valuable insights. Experienced users frequently share their recommendations on where to source quality components. Additionally, consider reaching out to authorized dealers or local suppliers, as they typically have access to authentic replacements and can assist in identifying the correct options.

Finally, keep in mind the importance of comparing prices and reading reviews to ensure you are making a wise investment. With careful research, you can successfully find the exact components you need to keep your machinery running smoothly.

Common Issues and Solutions

Equipment can often encounter various challenges during operation. Identifying these common problems early can help prevent more significant issues and ensure smooth functionality. Below are frequent complications along with practical solutions to address them effectively.

Frequent Complications

- Engine performance issues

- Hydraulic system malfunctions

- Electrical faults

- Wear and tear on components

- Difficulty in starting

Proposed Solutions

- Engine performance issues:

- Check fuel quality and filters.

- Inspect air intake systems for blockages.

- Ensure regular maintenance intervals are followed.

- Hydraulic system malfunctions:

- Examine hydraulic fluid levels and replace if necessary.

- Inspect hoses and connections for leaks.

- Clean or replace filters regularly.

- Electrical faults:

- Test battery health and connections.

- Check wiring for any signs of damage.

- Replace faulty fuses as needed.

- Wear and tear on components:

- Conduct routine inspections of parts.

- Replace worn-out components promptly.

- Utilize high-quality replacement items.

- Difficulty in starting:

- Ensure the battery is fully charged.

- Examine the starter motor and solenoid.

- Review ignition system components for malfunctions.

By proactively addressing these common challenges, users can enhance the reliability and efficiency of their machinery, extending its lifespan and optimizing performance.

Maintenance Tips for Z725

Regular upkeep is essential for the longevity and efficiency of your equipment. Implementing a structured maintenance routine not only enhances performance but also minimizes the risk of unexpected breakdowns. This section provides practical advice to ensure your machinery remains in optimal condition.

1. Routine Inspections: Conduct regular checks on all critical components. Look for signs of wear and tear, fluid leaks, and any unusual noises during operation. Early detection of issues can save time and costs in the long run.

2. Fluid Levels: Keep an eye on hydraulic fluid, oil, and coolant levels. Maintaining these fluids at proper levels ensures effective operation and prevents overheating or damage to vital parts.

3. Cleaning: Regularly clean the exterior of your machinery. Removing dirt and debris not only improves visibility but also prevents rust and corrosion. Pay special attention to filters, as clean filters enhance performance and efficiency.

4. Blade Maintenance: If applicable, ensure that blades are sharp and free of debris. Dull blades can strain the engine and lead to poor performance. Sharpening or replacing blades as needed can make a significant difference.

5. Tire Care: Check tire pressure frequently and inspect for any signs of damage or wear. Properly inflated tires improve traction and fuel efficiency, while also extending the life of the tires.

6. Battery Maintenance: Regularly inspect battery terminals for corrosion and ensure connections are tight. A well-maintained battery is crucial for reliable starting and overall performance.

7. Follow the Manual: Always refer to the manufacturer’s manual for specific maintenance schedules and recommendations. Adhering to these guidelines ensures your equipment operates as intended.

Where to Buy Kubota Parts

Finding the right components for your machinery can significantly enhance its performance and longevity. Whether you need replacement items or upgrades, various options are available to ensure you get quality solutions that meet your requirements.

One of the most reliable sources is authorized dealers, who offer genuine products backed by warranties. Online marketplaces also provide convenience and a wide selection, allowing you to compare prices easily. Additionally, local repair shops often stock essential items and can provide expert advice on your specific needs.

For those seeking budget-friendly alternatives, consider aftermarket suppliers, which can offer similar quality at reduced prices. Online forums and community groups may also be useful for recommendations on where to find specific items.

Ultimately, assessing your specific requirements and exploring multiple avenues will help you secure the best components for your equipment.