In the realm of agricultural equipment, ensuring optimal performance relies heavily on a comprehensive understanding of the individual elements that comprise a machine. Familiarity with these components not only enhances maintenance practices but also extends the lifespan of the equipment. This section delves into the intricate assembly of a specific implement, highlighting its various elements and their interconnections.

The importance of each segment cannot be overstated; they work in unison to facilitate efficient operation. By breaking down the assembly into manageable parts, operators can better grasp how each piece contributes to the overall functionality. This exploration serves as a valuable resource for anyone looking to improve their knowledge and skills in handling such machinery.

Moreover, having access to a detailed breakdown aids in troubleshooting and repairs, empowering users to tackle issues confidently. This guide aims to provide insights that are not only informative but also practical, ensuring that all users can navigate their equipment with ease and proficiency.

Understanding King Kutter FM 60 Y

The FM 60 Y is a robust implement designed for efficient land management and agricultural tasks. This tool enhances productivity through its durable construction and effective performance, making it a popular choice among professionals and hobbyists alike. Its design incorporates various features that facilitate ease of use and maintenance, ensuring that operators can achieve optimal results with minimal effort.

This equipment excels in versatility, capable of tackling a range of applications from mowing to clearing brush. Its adaptability makes it suitable for different types of terrains, ensuring that users can rely on it in various conditions. Understanding its components and functionality is essential for maximizing its potential and ensuring longevity.

In addition to its performance, the implement is built with user safety and comfort in mind. The ergonomic design allows for better control and reduces operator fatigue during extended use. Familiarity with its specifications and features not only aids in effective operation but also simplifies troubleshooting and repair processes when necessary.

Ultimately, comprehending the nuances of this equipment can greatly enhance operational efficiency and contribute to successful land management practices. Whether you are a seasoned operator or a newcomer, grasping the key aspects of this implement will empower you to make informed decisions and achieve your agricultural goals.

Key Features of the Equipment

This section explores the essential characteristics that enhance the functionality and usability of the machinery. Understanding these features can help users maximize efficiency and effectiveness during operation.

Robust Construction

- Durable materials ensure longevity and reliability.

- Designed to withstand heavy-duty tasks.

- Sturdy frame minimizes vibrations during use.

Versatile Applications

- Suitable for various agricultural and landscaping projects.

- Adjustable settings allow for different soil types and conditions.

- Compatible with various attachments for enhanced functionality.

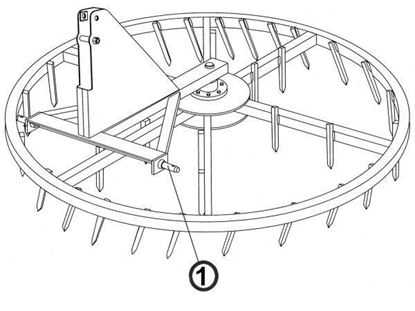

Importance of Parts Diagrams

Understanding the intricate components of any machinery is essential for effective maintenance and repair. Visual representations of these elements serve as invaluable tools, offering clarity and insight into how each piece fits within the overall system. This facilitates a deeper comprehension of operational functionality and streamlines troubleshooting processes.

Enhanced Clarity: Illustrative guides help users easily identify individual elements and their specific roles. This visual aid minimizes confusion, ensuring that technicians can locate and address issues swiftly and accurately.

Efficient Repairs: When attempting to fix or replace components, having a reference layout accelerates the process. It allows for quick identification of the necessary items, reducing downtime and improving overall productivity.

Training Resource: For those new to machinery, such visuals serve as excellent educational materials. They provide learners with a clear understanding of complex systems, making it easier to grasp operational principles and maintenance techniques.

Inventory Management: Visual representations also assist in tracking components during inventory audits. Knowing the exact configuration helps in ensuring that all necessary items are on hand, preventing delays in repairs and maintenance.

In summary, well-crafted visual aids are crucial for anyone involved in the maintenance and operation of machinery. They promote efficiency, enhance understanding, and ultimately lead to more effective management of mechanical systems.

Common Parts and Their Functions

This section explores various essential components commonly found in equipment designed for soil management and landscaping. Each element plays a crucial role in ensuring optimal performance and efficiency.

- Cutter Blades: These sharp implements are responsible for slicing through soil and vegetation, enabling effective cutting and tilling.

- Frame: The structural foundation that supports all other components, ensuring stability and durability during operation.

- Gearbox: This mechanism transmits power from the engine to the blades, allowing for adjustable speed and torque settings.

- Hitch: The attachment point that connects the machine to the towing vehicle, providing the necessary leverage for movement.

- Skids: These elements protect the blades from excessive wear and help regulate the working depth during operation.

Understanding these components enhances the ability to maintain and troubleshoot the equipment effectively, leading to improved performance and longevity.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By adopting a proactive approach, you can significantly extend its lifespan and maintain optimal performance.

Regular Inspections: Conduct frequent checks to identify wear and tear. Look for any signs of damage or corrosion that may require immediate action.

Proper Lubrication: Keep moving parts well-lubricated to reduce friction. Use the recommended lubricants and apply them as specified in the user manual.

Cleaning: Clean the machinery after each use to remove dirt and debris. This practice helps prevent buildup that could lead to mechanical issues.

Storage: Store equipment in a dry, sheltered area to protect it from harsh weather conditions. Consider using covers for additional protection.

Timely Repairs: Address any issues promptly to prevent further damage. Regular maintenance checks can help catch potential problems before they escalate.

Follow Manufacturer Guidelines: Always adhere to the recommended maintenance schedule and guidelines provided by the manufacturer for best results.

How to Order Replacement Parts

Acquiring necessary components for machinery can be a straightforward process if approached methodically. Understanding where to find the right items and how to place an order efficiently will ensure that your equipment remains functional and reliable.

Steps to Follow

- Identify the Required Component

- Consult the user manual for specifications.

- Check for model numbers or any identification codes.

- Locate a Supplier

- Visit authorized dealers or service centers.

- Explore online marketplaces that specialize in machinery components.

- Verify Compatibility

- Cross-check the specifications with your equipment.

- Read customer reviews or seek advice from professionals.

- Place Your Order

- Choose your preferred payment method.

- Provide accurate shipping information to avoid delays.

Tips for a Smooth Experience

- Keep records of previous orders for future reference.

- Contact customer service if you encounter any issues during the ordering process.

- Consider bulk orders if you frequently need replacements to save on shipping costs.

Diagnosing Issues with the FM 60 Y

Identifying problems with agricultural machinery is crucial for maintaining efficiency and productivity. When issues arise, a systematic approach can help pinpoint the root causes and facilitate timely repairs. This section outlines common troubleshooting strategies that can be employed to resolve various operational challenges.

- Check for Unusual Noises:

- Listen for grinding or clattering sounds.

- Inspect moving parts for wear or damage.

- Assess Performance:

- Monitor the effectiveness of the machine during operation.

- Evaluate if it meets expected output levels.

- Inspect Fluid Levels:

- Ensure hydraulic and lubricant fluids are at appropriate levels.

- Look for leaks that may indicate underlying issues.

- Examine Electrical Components:

- Test battery connections and wiring for signs of corrosion.

- Check switches and relays for proper functionality.

By following these guidelines, operators can effectively troubleshoot their equipment, ensuring longevity and optimal performance. Regular maintenance and careful monitoring play significant roles in preventing major breakdowns.

Where to Find Repair Manuals

Accessing reliable repair documentation is essential for maintaining and fixing equipment efficiently. Numerous sources are available that provide comprehensive guides, including official manufacturer websites, online marketplaces, and specialized forums dedicated to equipment maintenance.

One effective way to locate these manuals is to visit the official website of the manufacturer, where documentation is often available for download. Additionally, online retailers sometimes offer manuals as part of their product listings, ensuring you have the necessary resources at hand.

Another option is to explore community forums and social media groups focused on machinery enthusiasts. Members frequently share links to manuals or provide insights from their personal experiences, which can be invaluable for troubleshooting.

Finally, library resources and online databases may house extensive collections of repair manuals, offering another avenue to find the information you need.

User Experiences and Reviews

This section highlights the feedback and impressions of individuals who have utilized the equipment. Their insights can provide valuable information for potential users, revealing both strengths and areas for improvement.

Positive Feedback

- High durability and robust design.

- Excellent performance in various soil types.

- Easy to operate and maintain.

Areas for Improvement

- Initial setup can be complex for beginners.

- Weight may be challenging for some users during transport.

- Availability of accessories can be limited in certain regions.