When it comes to maintaining a lush and healthy lawn, the right machinery plays a pivotal role. Familiarity with the inner workings of your equipment can enhance both performance and longevity. In this section, we will explore the intricate components that contribute to the effective functioning of your machinery.

By delving into the specifics of each element, you can ensure that your tools operate at peak efficiency. Whether it’s for routine maintenance or troubleshooting issues, a clear understanding of the individual pieces will empower you to tackle any challenge that arises. Knowledge in this area not only saves time but also reduces the likelihood of costly repairs.

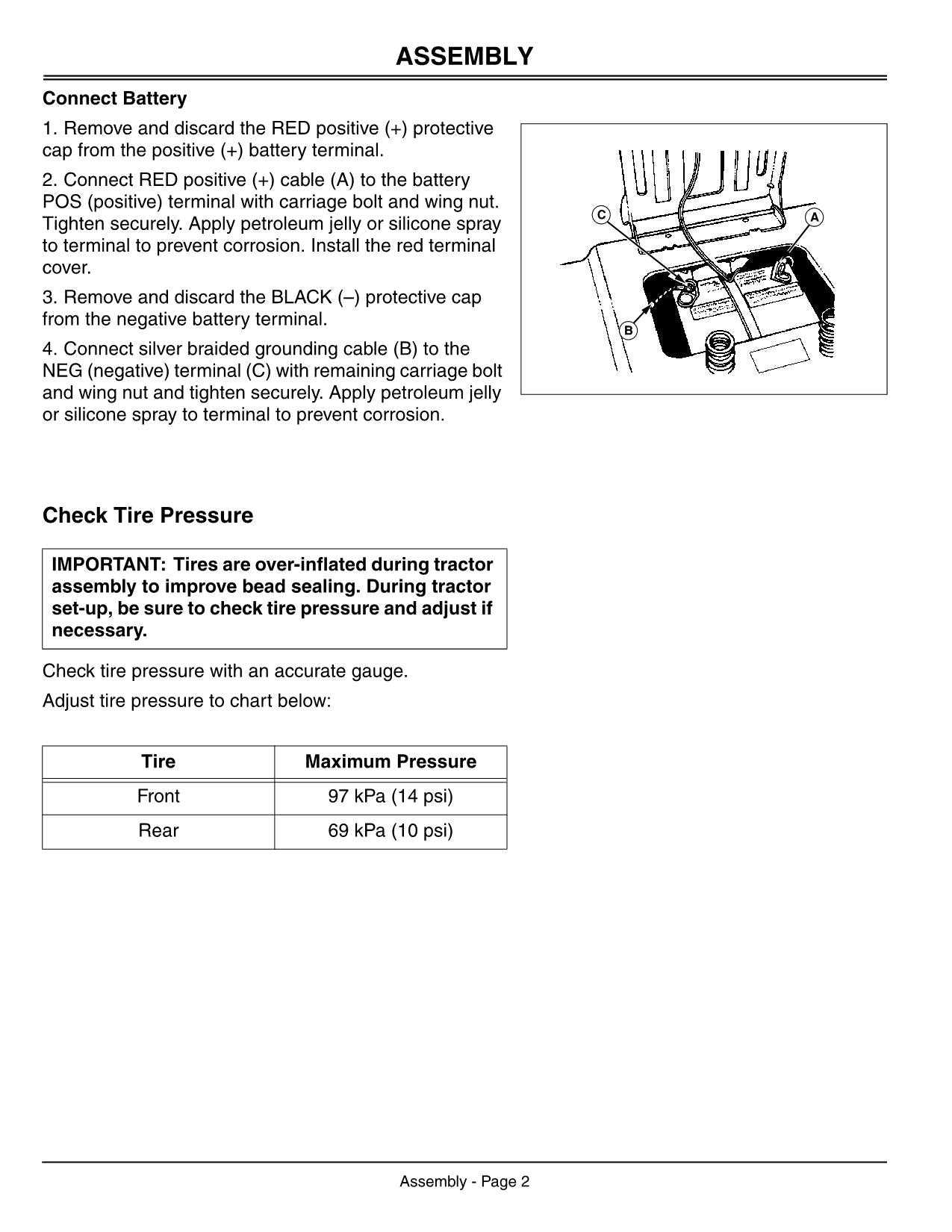

For those who wish to maximize their equipment’s capabilities, recognizing how each part interacts within the larger system is essential. This comprehensive insight can lead to improved usage, better maintenance practices, and ultimately, a more vibrant and thriving outdoor space.

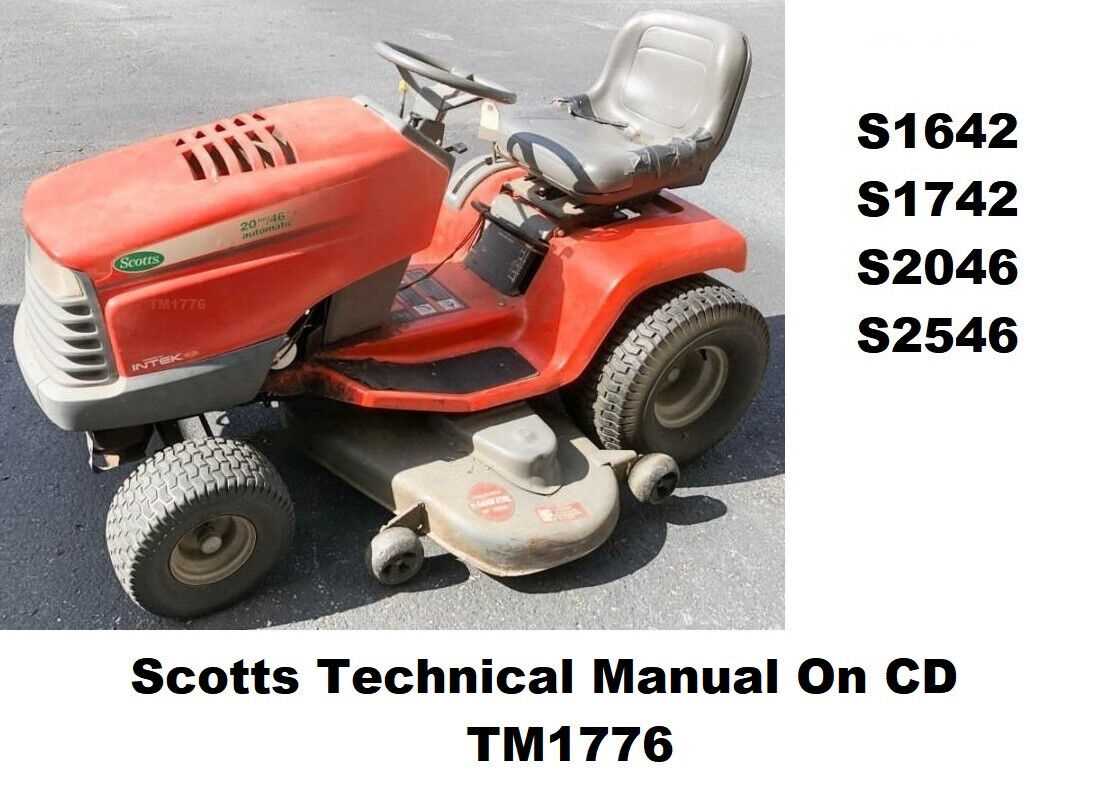

Understanding the Scotts S1742 Model

This section provides an in-depth exploration of a particular model, highlighting its features and functionality. By examining its components and operational mechanisms, users can gain valuable insights into its effective use and maintenance.

Key Features

- Efficient engine performance

- User-friendly controls

- Durable construction for longevity

- Versatile for various tasks

Maintenance Tips

- Regularly check and replace oil.

- Inspect blades for sharpness.

- Clean air filters frequently.

- Store in a dry location to prevent rust.

Key Features of the S1742

This section highlights the essential characteristics of a particular model known for its efficiency and versatility. Understanding these features can enhance user experience and maintenance.

- Robust construction for longevity

- Advanced engine technology for optimal performance

- Ergonomic design ensuring comfort during use

- Efficient fuel consumption promoting sustainability

- Innovative controls for ease of operation

These attributes collectively contribute to its reputation as a reliable choice for various outdoor tasks.

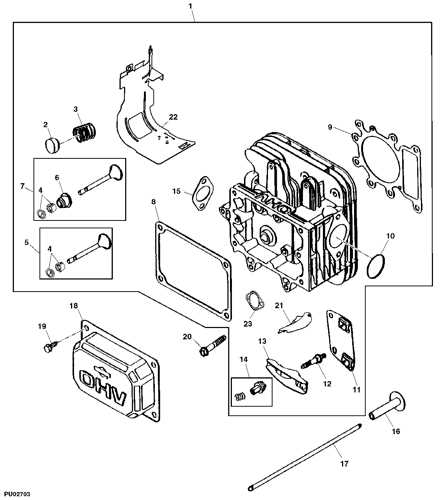

Importance of Parts Diagrams

Understanding the intricacies of machinery and equipment is essential for effective maintenance and repair. Visual representations of components serve as invaluable tools in this process, enabling users to identify and locate individual elements quickly. This clarity not only enhances efficiency but also minimizes the risk of errors during servicing.

Detailed illustrations provide a roadmap for technicians, ensuring that they can navigate complex systems with ease. By breaking down the assembly into manageable sections, these visuals facilitate a deeper comprehension of how each piece interacts within the overall framework. This knowledge is crucial for troubleshooting issues and performing accurate replacements.

Moreover, effective documentation contributes to better inventory management. By clearly showing what parts are required for specific tasks, users can maintain optimal stock levels and avoid delays caused by shortages. This proactive approach not only saves time but also reduces operational costs.

In summary, well-crafted visual guides are essential for anyone involved in the maintenance and repair of machinery. They promote efficiency, enhance understanding, and streamline the entire process, ultimately leading to improved performance and longevity of equipment.

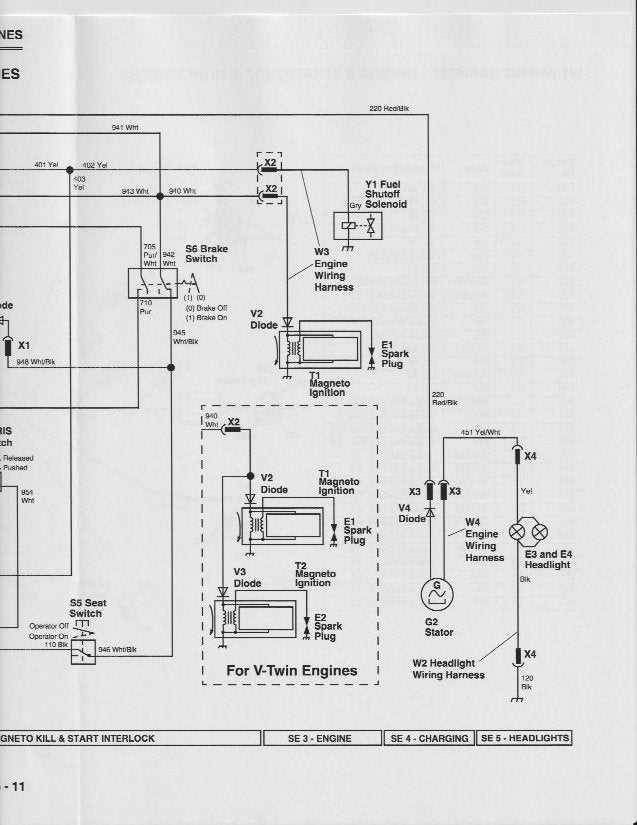

Identifying Components in the Diagram

Understanding the various elements represented in a technical illustration is crucial for effective maintenance and repair. Each symbol or label corresponds to a specific piece, contributing to the overall functionality of the machine. Familiarity with these components enhances one’s ability to troubleshoot issues and perform necessary adjustments.

Key Features to Look For

When examining the illustration, focus on the shape and placement of each element. Typically, crucial parts are highlighted with distinct markings or are positioned centrally within the layout. Pay attention to annotations that may provide additional context, such as part numbers or descriptions, which can aid in identifying replacements or compatible units.

Utilizing the Illustration Effectively

To maximize the utility of the visual representation, cross-reference the components with a list of specifications. This practice ensures that you can quickly locate and verify the necessary items needed for repairs. Additionally, understanding how these pieces interact within the system will deepen your comprehension and ability to maintain optimal performance.

Common Repairs for the S1742

Maintaining and repairing outdoor power equipment is essential for optimal performance and longevity. Understanding the most frequent issues and their solutions can greatly enhance the reliability of your machine. Below are some common repairs that users often encounter, along with helpful tips to address them effectively.

-

Engine Troubles:

- Check the spark plug for wear and replace if necessary.

- Inspect the air filter for blockages; clean or replace as needed.

- Ensure proper fuel levels and quality to avoid stalling.

-

Cutting Deck Issues:

- Examine the blades for dullness or damage; sharpen or replace them.

- Clear any debris buildup under the deck to prevent clogs.

- Check the belt tension and replace if it appears worn or frayed.

-

Electrical System Problems:

- Inspect all wiring for signs of wear or corrosion.

- Test the battery and connections for proper voltage.

- Replace blown fuses to restore electrical functionality.

-

Transmission Concerns:

- Verify that the drive belt is properly adjusted and not slipping.

- Check for fluid leaks around the transmission housing.

- Clean and lubricate the gears as part of regular maintenance.

By staying proactive with these common repairs, you can ensure that your equipment remains in excellent working condition and is ready for use whenever needed.

Where to Find Replacement Parts

Finding suitable components for your lawn care equipment is essential for maintaining its efficiency and longevity. Several avenues exist for sourcing these necessary items, ensuring that your machine continues to operate smoothly. Whether you prefer shopping online or visiting a local retailer, a variety of options are available to meet your needs.

Online Retailers

The internet is a valuable resource for locating components. Numerous websites specialize in outdoor equipment, offering a wide range of choices and often providing detailed specifications. Be sure to compare prices and check customer reviews to ensure you are purchasing quality items.

Local Supply Stores

Visiting nearby hardware or garden centers can also yield fruitful results. These establishments often stock essential components and can provide personalized assistance. Additionally, staff members may offer insights into compatible items and alternative solutions.

| Source | Benefits |

|---|---|

| Online Retailers | Wide selection, convenience, customer reviews |

| Local Supply Stores | Personal assistance, immediate availability, expert advice |

Maintaining Your Scotts Lawn Mower

Proper upkeep of your lawn care equipment is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also ensures a pristine lawn. By following a few key practices, you can keep your machine running smoothly and effectively.

Routine Checks

Conducting regular inspections is crucial. Check the oil levels and replace it as necessary to prevent engine wear. Examine the blades for sharpness; dull blades can tear grass rather than cut it cleanly. Cleaning the deck after each use prevents grass buildup, which can lead to rust.

Seasonal Maintenance

At the start of each season, give your mower a thorough check-up. Change the air filter to ensure proper airflow and combustion. Additionally, replace the spark plug to enhance starting reliability. Storing your machine properly during the off-season will also contribute to its longevity.

Tips for Troubleshooting Issues

When facing challenges with outdoor maintenance equipment, it is essential to adopt a systematic approach to identify and resolve the underlying problems. By following a few strategic steps, users can effectively diagnose and fix issues, ensuring optimal performance and longevity of their tools.

Step-by-Step Diagnosis

Begin by observing the symptoms. Note any unusual sounds, vibrations, or performance drops. Use this information to create a checklist of potential causes. This methodical approach will streamline the troubleshooting process.

| Symptom | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Fuel issues | Check fuel level and quality; replace if stale. |

| Inefficient cutting | Dull blades | Sharpen or replace blades as necessary. |

| Excessive vibrations | Loose components | Tighten bolts and screws; inspect for wear. |

Preventative Measures

Regular maintenance is crucial in preventing common issues. Clean equipment after use, check for signs of wear, and follow manufacturer guidelines for servicing. Keeping a maintenance log can also help track any recurring problems.