Understanding the inner workings of your off-road vehicle requires a solid grasp of how its core elements interact. This section is designed to provide a clear and structured look at the layout and arrangement of crucial elements within the vehicle’s structure. With a well-organized visual breakdown, you’ll be able to navigate through various elements and gain insight into how they connect to ensure smooth operation.

From the engine to suspension systems, every element plays a vital role in delivering a reliable and powerful performance. Whether you’re troubleshooting an issue or simply enhancing your technical knowledge, exploring the arrangement of these mechanical components will give you the clarity needed for effective maintenance and upgrades. This guide offers a detailed map of the critical systems that keep your vehicle in optimal condition.

By understanding the layout of each essential element, you equip yourself with the tools necessary to maintain and optimize performance. This guide breaks down every key feature, offering clarity and practical knowledge for both enthusiasts and professionals alike.

Essential Components for Off-Road Maintenance

Maintaining a robust off-road vehicle requires understanding its key mechanical systems and ensuring each one is in optimal condition. Frequent exposure to harsh environments can lead to wear and tear, making regular inspection crucial. Identifying which elements need attention helps prevent breakdowns and ensures smooth operation during demanding terrain navigation.

Engine and Transmission

The engine and transmission are the heart of any utility vehicle. Regular checks of the motor’s performance, fuel delivery system, and transmission fluid levels are vital. Keeping these components in top shape ensures power delivery and efficiency, especially when navigating rugged environments.

Suspension and Braking System

The suspension system absorbs the shocks from uneven surfaces, while the brakes ensure safety during sudden stops. Inspecting the suspension for any loose or damaged parts and keeping the brake system in check prevents issues that could compromise handling or control during off-road excursions.

Understanding the Engine System Layout

The structure of the engine system is crucial for maintaining optimal performance and ensuring smooth operation. A well-organized configuration of components allows for efficient power delivery and helps prevent mechanical issues. Understanding how each element connects and interacts can significantly aid in troubleshooting and regular maintenance.

Key areas to focus on include:

- Power source alignment and placement

- Cooling mechanisms for temperature control

- Fuel delivery paths for efficient combustion

- Exhaust system configuration for emission management

Each of these components works in harmony to support the overall functionality of the vehicle, ensuring durability and longevity. Proper understanding of the system can also simplify repairs and part replacements, ultimately enhancing the system’s reliability.

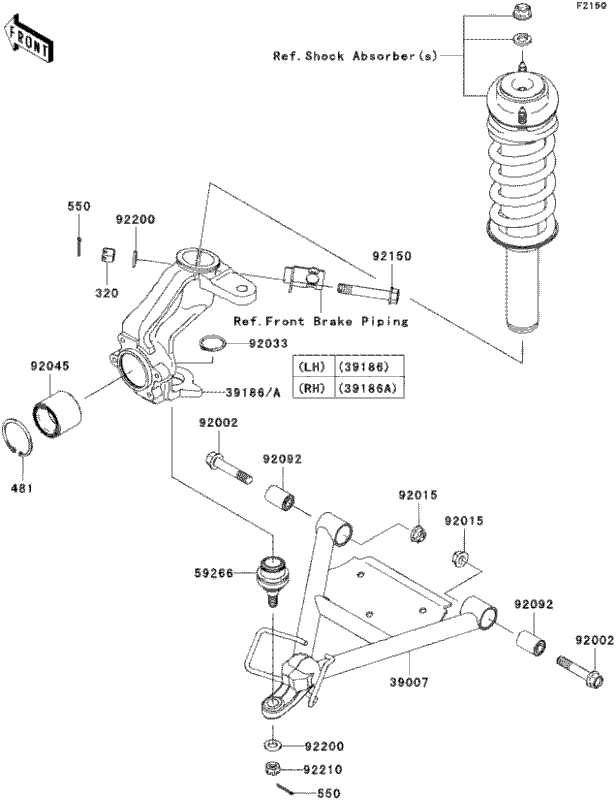

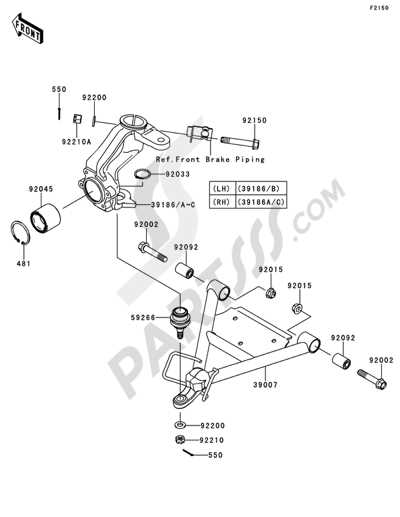

Suspension Structure and Key Elements

The suspension system in any vehicle plays a crucial role in providing stability, control, and comfort while traversing various terrains. By efficiently distributing the weight and absorbing shocks, it ensures a smoother ride and protects other essential components from excessive wear. Understanding its structure and vital parts can help in maintaining optimal performance and durability over time.

Core Components of the Suspension System

Several fundamental elements make up the suspension system, each contributing to its overall function. Key elements include springs, which absorb impact, and shock absorbers that help manage the movement of the springs. Together, these components provide balance and minimize vibrations during operation.

The Role of Control Arms and Linkages

Control arms and linkages are crucial for maintaining proper alignment and allowing the suspension to move smoothly. They ensure that the wheels stay in contact with the ground, enhancing traction and handling. These elements are typically designed to withstand significant stress while providing flexibility in various driving conditions.

Brake Mechanism Overview and Maintenance Tips

The braking system plays a crucial role in ensuring the safety and control of any vehicle. Understanding how it functions and knowing how to maintain it properly can prevent potential issues and prolong its effectiveness. Regular checks and proper upkeep are essential for optimal performance, helping to avoid unexpected malfunctions.

Regular Inspection: It’s important to frequently assess the condition of the braking components. Worn-out elements may reduce the efficiency of the entire system. Keep an eye on any signs of wear, such as unusual noises or reduced responsiveness when applying pressure.

Cleaning and Lubrication: Dirt and debris can accumulate over time, causing the mechanism to work less efficiently. Periodically cleaning and applying the correct lubricants to key areas ensures smooth operation and prolongs the life of the system.

Timely Replacement of Worn Components: Whenever parts show signs of significant wear, replacing them promptly is essential to maintain safety. Neglecting this step may lead to more extensive damage and costly repairs in the future.

Electrical Wiring Layout and Troubleshooting

Understanding the structure of the electrical system in utility vehicles is essential for both maintenance and fault detection. A well-organized approach to examining wires, connectors, and components can help identify issues more efficiently. This section offers an overview of how to map out the electrical circuits and provides guidance on common problems.

Layout of the Electrical System

The electrical wiring in utility vehicles typically follows a systematic path from the power source to various components. Each circuit is designed to power a specific function, such as lighting, ignition, or other auxiliary systems. By following the wiring layout, you can trace the route of each wire and understand its role in the overall system.

Common Troubleshooting Techniques

When electrical issues arise, some common methods can help pinpoint the source of the problem. Checking for loose or corroded connections is a primary step, followed by testing continuity with a multimeter. Identifying breaks in circuits or faulty components often leads to quick fixes, ensuring the system runs smoothly again.

Fuel System Parts and Optimization

The fuel delivery mechanism plays a crucial role in the efficient operation of any utility vehicle. Understanding the components involved and how they work together is essential for enhancing performance and ensuring reliability. This section delves into the various elements of the fuel system, highlighting their functions and optimization techniques.

Key components of the fuel delivery system include:

- Fuel Tank: Stores the fuel and supplies it to the engine.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel to protect the engine.

- Fuel Injectors: Atomizes the fuel for better combustion within the engine cylinders.

- Fuel Lines: Pathways that transport fuel throughout the system.

To optimize the performance of the fuel system, consider the following strategies:

- Regular Maintenance: Frequently inspect and clean the fuel filter to ensure efficient flow.

- Quality Fuel: Use high-quality fuel to reduce deposits and maintain system integrity.

- Check for Leaks: Regularly examine fuel lines and connections for any signs of leaks that could impair performance.

- Monitor Fuel Pressure: Ensure the fuel pump is operating at the correct pressure to support engine demands.

- Upgrade Components: Consider aftermarket options for injectors and pumps that enhance flow and efficiency.

Steering Assembly and Performance Enhancements

The steering system plays a crucial role in ensuring optimal maneuverability and control in utility vehicles. A well-designed steering assembly contributes significantly to the overall performance, allowing for precise navigation and stability during various operations. Understanding the components involved and potential upgrades can enhance driving experience and operational efficiency.

Key Components of the Steering Assembly

The steering mechanism consists of several vital parts, including the steering wheel, column, gear assembly, and linkage. Each component is engineered to work harmoniously, providing feedback and responsiveness. Regular maintenance and inspections of these elements are essential to prevent wear and tear, ensuring smooth operation.

Performance Enhancements

To improve handling and responsiveness, several modifications can be implemented. Upgrading to high-performance steering gear can reduce steering effort and enhance feedback. Additionally, installing an aftermarket steering stabilizer can help mitigate vibrations and improve control on uneven terrain. Evaluating tire pressure and tread condition also contributes to better traction and steering precision.

Cooling System Configuration and Upgrades

The efficiency and longevity of any utility vehicle heavily rely on its thermal management. Proper configuration of the cooling apparatus is essential for preventing overheating and ensuring optimal performance. Upgrading these components can significantly enhance durability and reliability, making it crucial to explore various enhancements available for the system.

Understanding the Basics: The cooling system generally consists of several key elements, including the radiator, water pump, hoses, and cooling fans. Each component plays a vital role in dissipating heat generated by the engine, ensuring that temperatures remain within safe limits during operation.

Potential Upgrades: Enhancements may include high-performance radiators that provide increased surface area for heat exchange, thus improving cooling efficiency. Additionally, upgrading the water pump to a high-flow model can enhance coolant circulation, resulting in more effective thermal regulation. Consideration should also be given to the quality of hoses, as using reinforced materials can prevent leaks and maintain pressure.

Installation Considerations: When implementing upgrades, it’s essential to ensure compatibility with existing components. Proper installation techniques, such as using appropriate sealants and fasteners, can help maintain system integrity and prevent future issues. Regular maintenance checks are advisable to assess the functionality of upgraded parts and to address any emerging concerns promptly.

Transmission Parts and Repair Guide

The transmission system is crucial for the effective operation of utility vehicles, ensuring power is transferred from the engine to the wheels. Understanding the components and their functions is essential for maintenance and troubleshooting. This section provides an overview of the key elements involved in the transmission assembly and offers guidance on repair procedures.

- Transmission Housing: The protective casing that encloses the transmission components, shielding them from dirt and damage.

- Gear Set: A series of gears that facilitate various speed ratios, allowing the vehicle to adapt to different terrains and loads.

- Clutch Mechanism: Engages and disengages the engine from the transmission, enabling smooth gear shifts.

- Shift Lever: The control used by the operator to select the desired gear, influencing the vehicle’s speed and power output.

- Fluid Reservoir: Contains the transmission fluid, which lubricates components and aids in heat dissipation.

Regular inspection of these components can prevent costly repairs and extend the lifespan of the transmission system. Here are some common issues and their solutions:

- Fluid Leaks: Check for leaks around the housing. Replace worn seals and gaskets to maintain fluid levels.

- Strange Noises: Unusual sounds may indicate gear wear or damage. Inspect the gear set and replace any faulty components.

- Slipping Gears: If the vehicle unexpectedly changes gears, it may suggest issues with the clutch or shift mechanism. Investigate these areas for necessary adjustments or replacements.

Maintaining the integrity of the transmission system is vital for reliable performance. Regular servicing and prompt repairs will ensure that the vehicle operates smoothly and efficiently.