Heating systems play a vital role in maintaining comfortable indoor environments, especially during colder months. A comprehensive knowledge of their various elements can greatly enhance the efficiency and longevity of these systems. In this section, we will explore the intricate layout and functionality of different components that contribute to effective heating solutions.

Recognizing how each component interacts within the heating mechanism is essential for troubleshooting and maintenance. Familiarity with these elements allows homeowners and technicians alike to identify issues swiftly and apply the necessary remedies. This understanding ultimately promotes better performance and reliability in ensuring warmth throughout the living space.

Moreover, a well-structured overview of these elements can serve as a valuable reference for those looking to undertake repairs or upgrades. With the right information at hand, individuals can make informed decisions about the upkeep and enhancement of their heating systems, ensuring optimal operation for years to come.

Understanding Intertherm Furnace Components

Grasping the essential elements of heating systems is vital for ensuring efficient operation and maintenance. Each component plays a crucial role in the overall functionality, contributing to the effective regulation of indoor climate and comfort levels. Recognizing how these individual pieces work together enables better troubleshooting and enhances longevity.

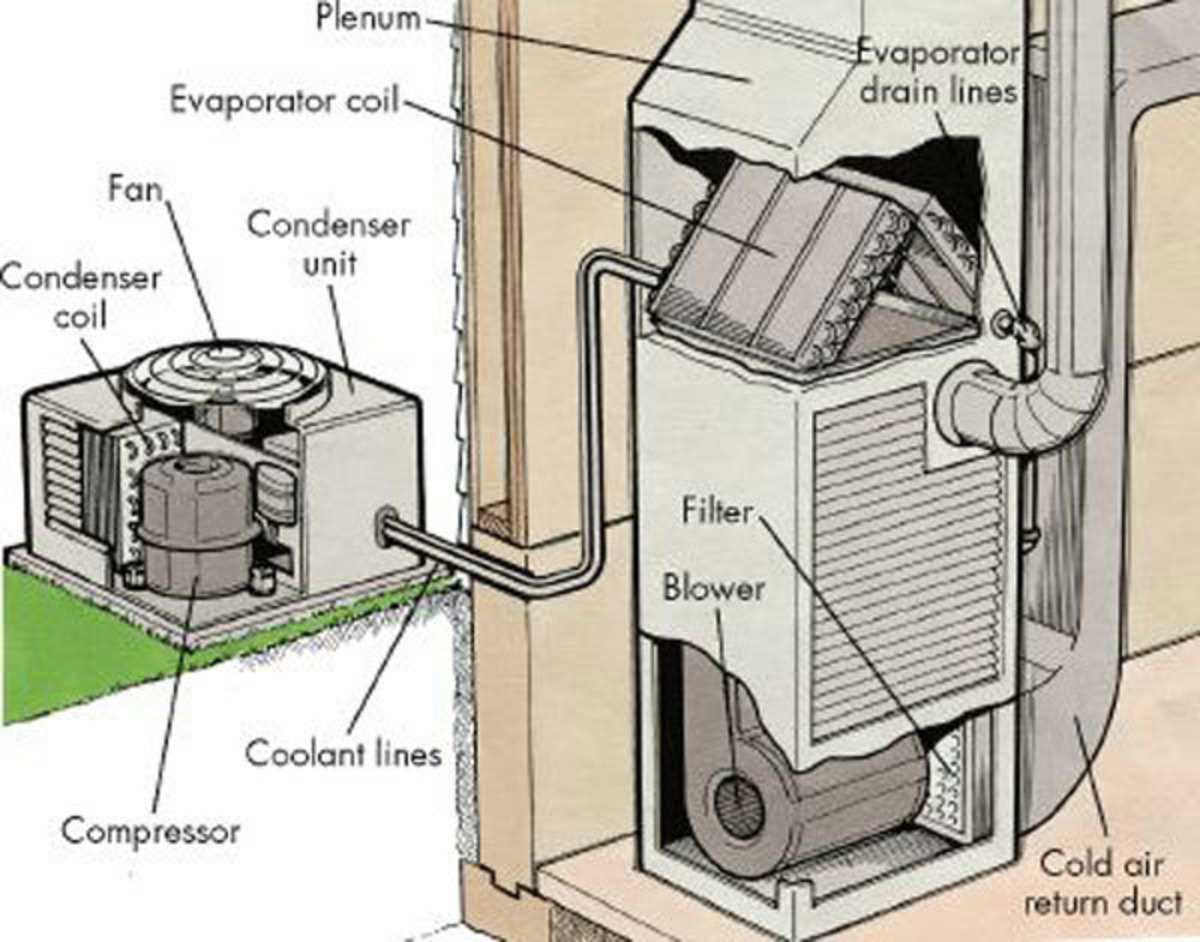

Key Elements: A heating mechanism typically consists of a heat exchanger, blower, ignition system, and various safety features. The heat exchanger is responsible for transferring warmth, while the blower circulates air throughout the space. The ignition system ensures that combustion occurs safely and reliably, and safety mechanisms protect against potential hazards.

Maintenance Insights: Regular inspection and upkeep of these components can prevent common issues. For instance, ensuring the cleanliness of the heat exchanger and blower can significantly enhance efficiency. Furthermore, timely replacement of worn parts ensures that the entire system operates optimally, reducing the risk of breakdowns during peak usage times.

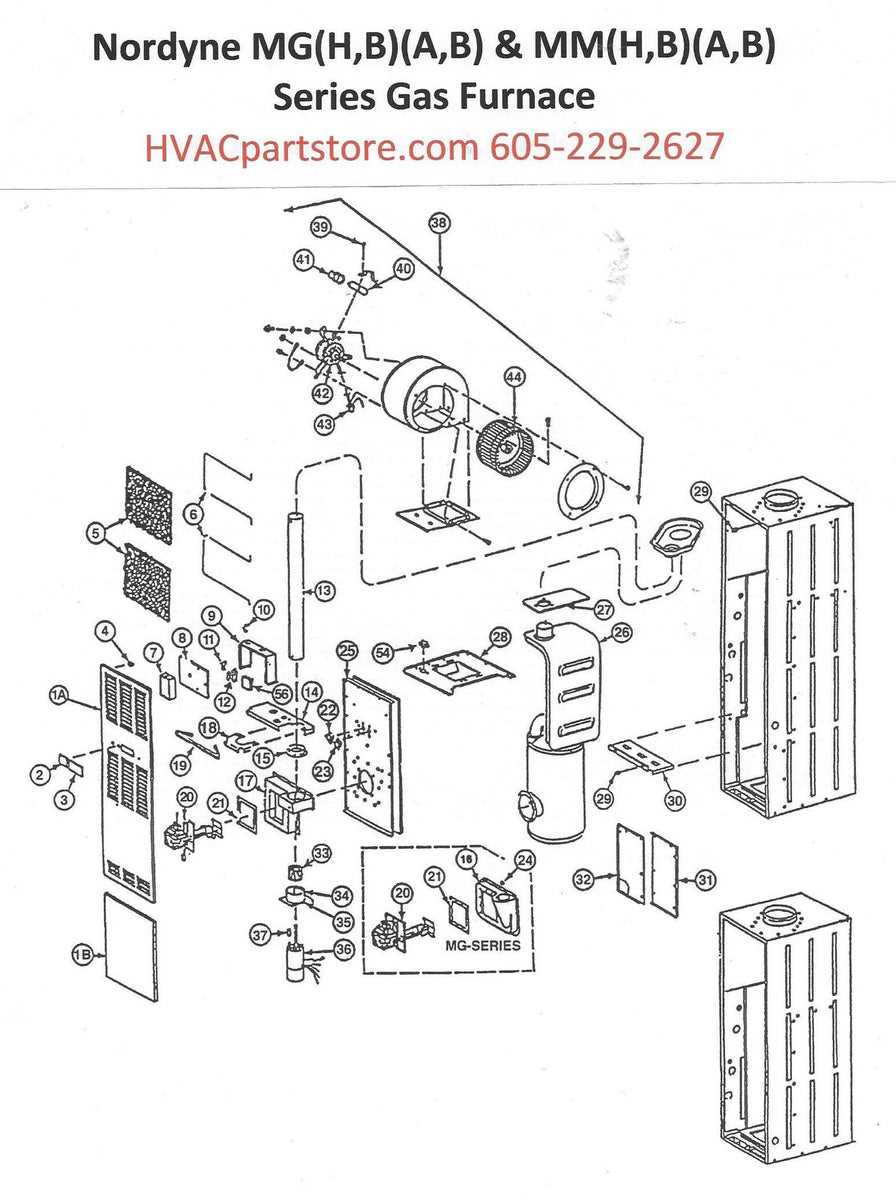

Key Parts of Intertherm Furnaces

Understanding the essential components of heating systems is crucial for efficient operation and maintenance. Each unit contains several integral elements that work together to ensure reliable performance, comfort, and energy efficiency. Familiarity with these components can help in troubleshooting issues and planning for necessary replacements or repairs.

| Component | Description |

|---|---|

| Heat Exchanger | Transfers heat from combustion gases to the air circulating through the system, enhancing efficiency. |

| Burner Assembly | Responsible for igniting the fuel and producing heat, crucial for the system’s operation. |

| Blower Motor | Powers the fan that circulates air throughout the space, maintaining a comfortable environment. |

| Limit Switch | Monitors the temperature and shuts off the system if it overheats, ensuring safety. |

| Thermostat | Regulates the temperature by controlling the operation of the heating system based on set preferences. |

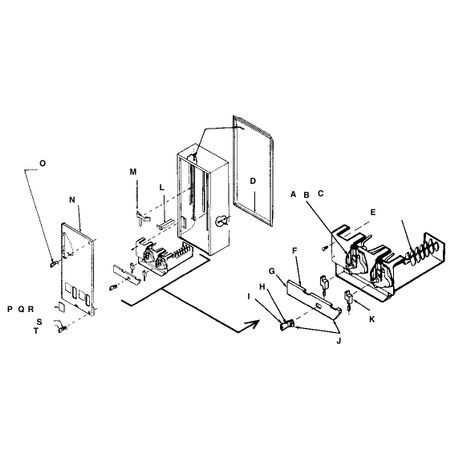

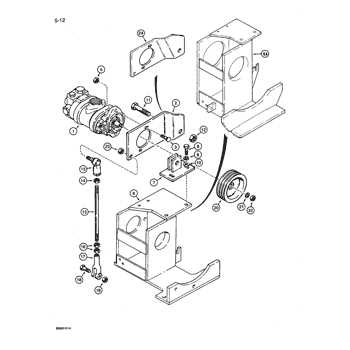

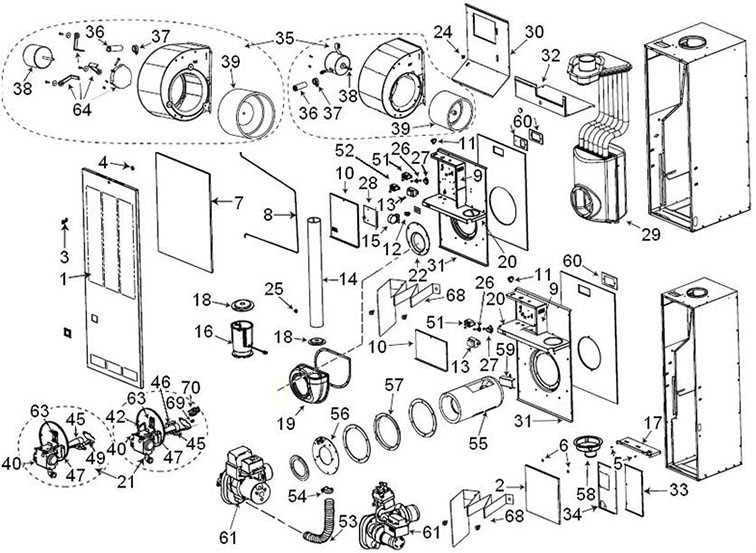

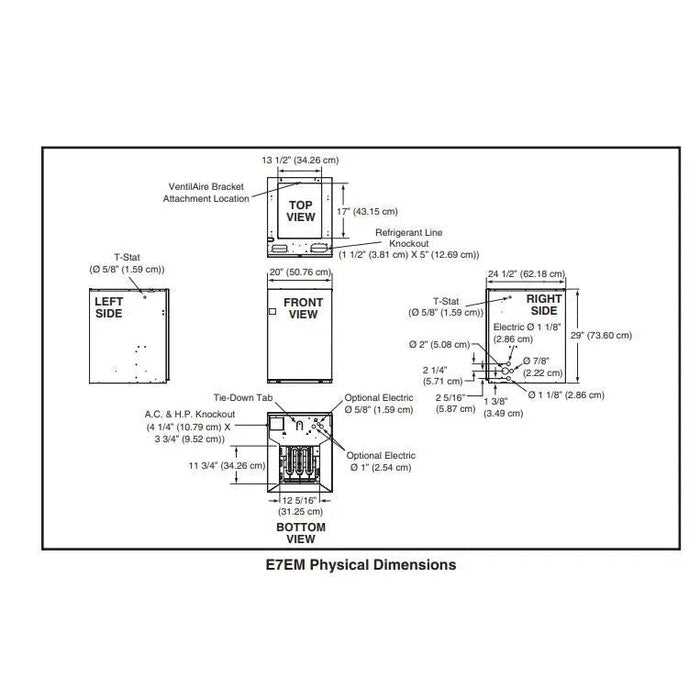

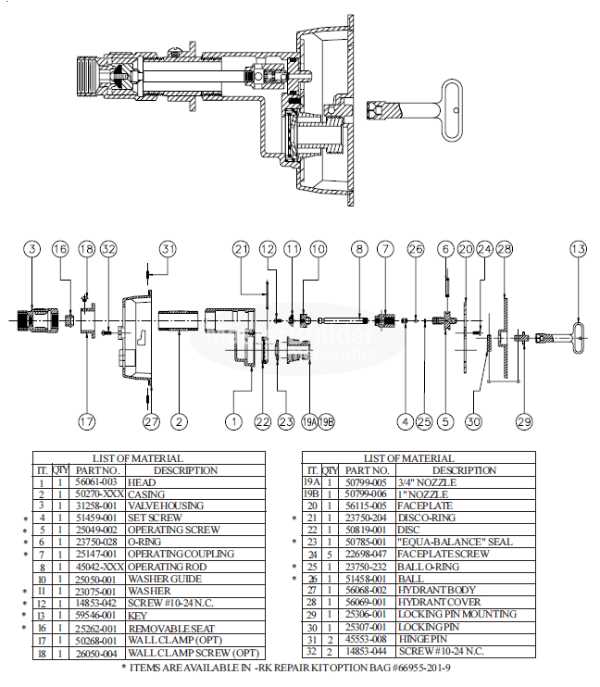

How to Read the Parts Diagram

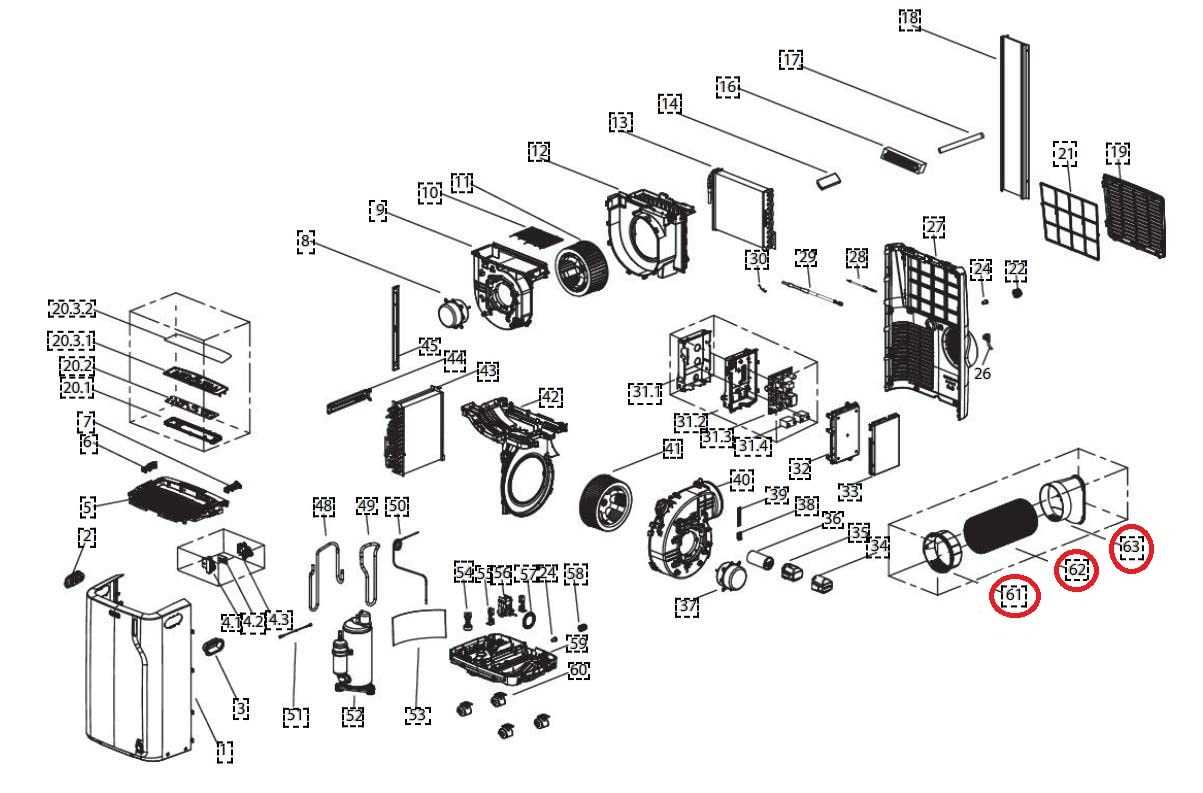

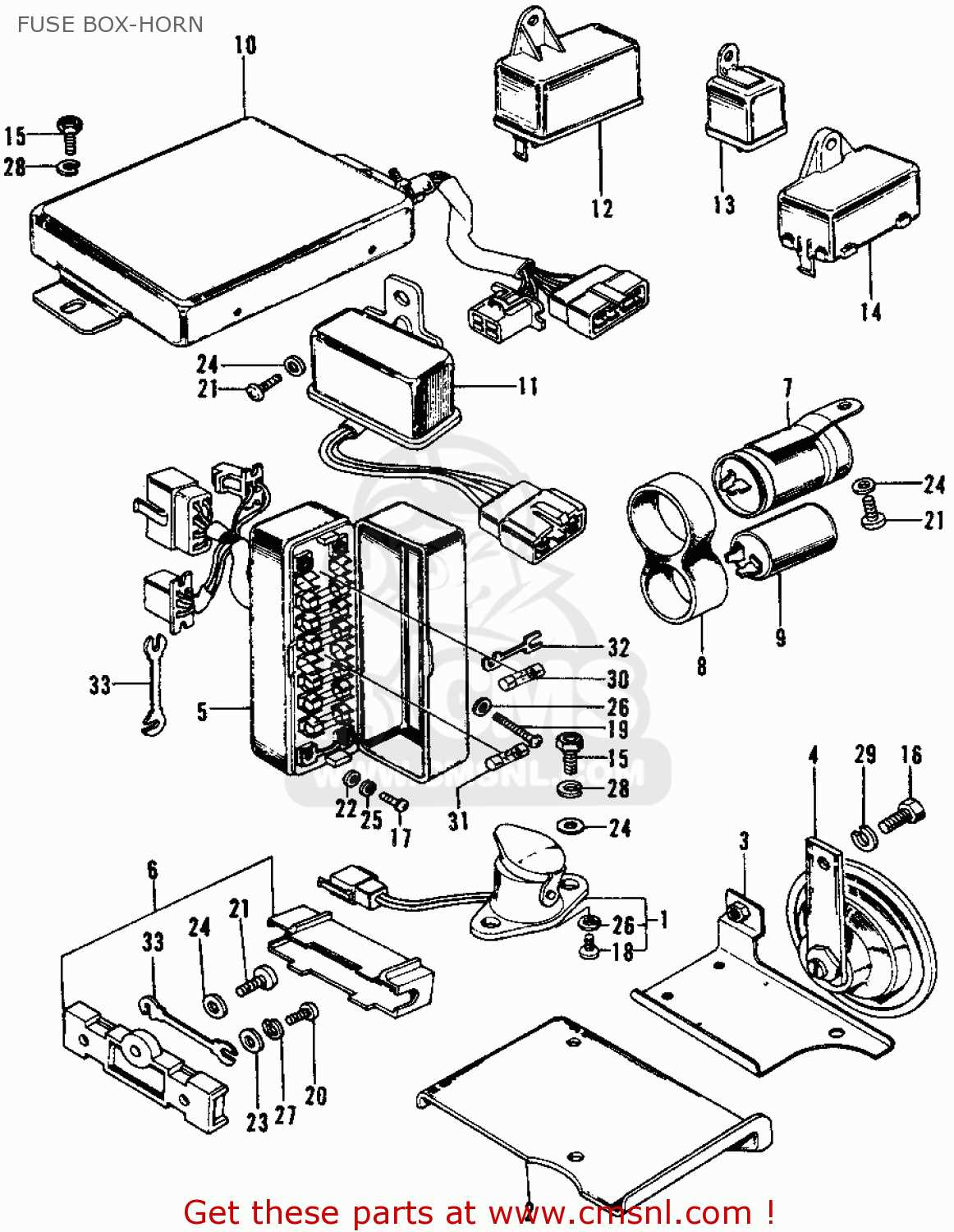

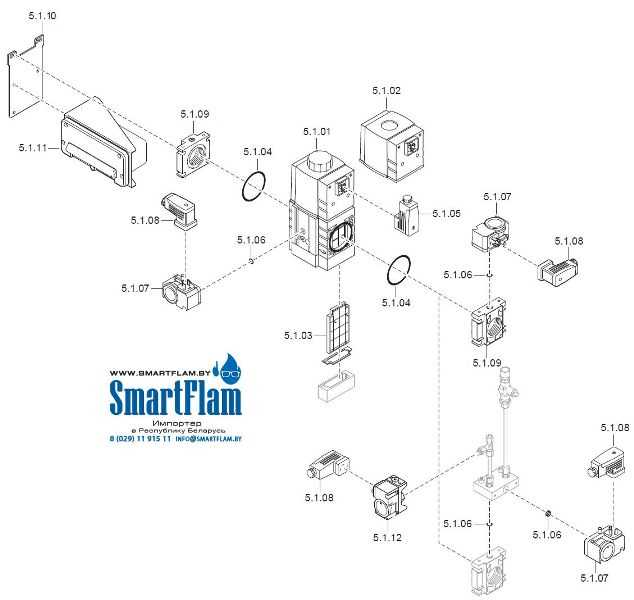

Understanding the layout of components in a heating appliance is essential for effective maintenance and troubleshooting. This section will guide you through the essential steps to interpret the schematic representation of the system, enabling you to identify various elements and their functions accurately.

Familiarizing Yourself with the Layout

The initial step involves examining the overall structure of the schematic. Start by locating the main assembly, which often serves as the focal point. Surrounding this central unit are various associated elements, each represented by specific symbols or labels. Pay attention to these indicators, as they will provide insight into the relationship between components.

Understanding Symbols and Labels

Every symbol on the representation corresponds to a particular component. It is crucial to refer to the accompanying legend, which will clarify the meaning of each symbol. This understanding will assist in distinguishing between similar-looking elements and recognizing their unique roles in the heating process.

| Symbol | Component | Function |

|---|---|---|

| Transformer | Converts voltage levels for the system. | |

| ⚪ | Relay | Controls the operation of the heating cycle. |

| Sensor | Monitors temperature and provides feedback. |

Common Issues with Furnace Parts

In any heating system, various components can encounter problems that affect overall functionality. Identifying these issues is essential for maintaining efficiency and ensuring comfort in the environment. This section highlights frequent complications associated with different elements of the heating mechanism.

Malfunctions in Heating Elements

Heating elements are critical for generating warmth. Common malfunctions include burnt-out coils or blockages due to dirt and debris. When these issues arise, it can lead to insufficient heat output or uneven temperature distribution. Regular maintenance and cleaning can help mitigate these concerns.

Electrical Connection Problems

Another frequent source of difficulty is related to electrical connections. Loose wiring or corroded terminals can disrupt power flow, causing the system to shut down unexpectedly. It’s crucial to inspect connections periodically to ensure they are secure and free of corrosion to maintain reliable operation.

Identifying Components in the Diagram

Understanding the layout of various elements within a heating system is essential for effective maintenance and troubleshooting. Familiarizing yourself with the key components will enable you to identify potential issues quickly and ensure optimal performance. This section will guide you through the essential features present in the visual representation.

Main Elements Overview

The representation includes several crucial elements, each playing a specific role in the overall functionality. The most notable components are those responsible for heat generation, air circulation, and safety mechanisms. Recognizing these parts will help in assessing their condition and effectiveness.

Common Features and Their Functions

Heat Exchanger: This component is responsible for transferring heat from the combustion process to the air that circulates throughout the space.

Blower Motor: A vital element for air movement, ensuring that warm air reaches the intended areas efficiently.

Limit Switch: A safety device that shuts down the system if temperatures exceed safe levels, preventing potential hazards.

Maintenance Tips for Furnace Parts

Regular upkeep of heating systems is essential for ensuring optimal performance and longevity. By following a few key practices, homeowners can prevent common issues and enhance efficiency. Proper care not only extends the life of components but also contributes to a safer environment.

1. Schedule Regular Inspections: Routine check-ups by a qualified technician can identify potential problems early. Schedule these inspections at least once a year to ensure everything is functioning correctly.

2. Clean or Replace Filters: Dirty filters can restrict airflow and reduce efficiency. Check filters monthly and clean or replace them as needed to maintain optimal airflow.

3. Ensure Proper Ventilation: Adequate airflow is crucial for safe operation. Make sure that vents are clear of obstructions and that the area around the heating unit is free of debris.

4. Monitor Thermostat Settings: Keeping an eye on thermostat settings can prevent unnecessary energy consumption. Ensure the thermostat is set to an appropriate temperature for comfort and efficiency.

5. Check for Leaks: Inspect the system for any signs of leaks in gas lines or other connections. Addressing leaks promptly can prevent safety hazards and improve efficiency.

6. Keep an Eye on Noise Levels: Unusual sounds can indicate underlying issues. If you hear strange noises, it’s essential to investigate further, as this may signal the need for repairs.

7. Insulate Ductwork: Proper insulation can help maintain temperature and reduce energy costs. Ensure that ductwork is insulated and sealed to improve overall system performance.

Implementing these practices will help maintain the efficiency and safety of heating systems, ensuring comfortable living spaces throughout the colder months.

Replacement Parts for Intertherm Units

Maintaining the efficiency and functionality of heating systems is crucial for optimal performance. Over time, components may wear out or require replacement to ensure seamless operation. Identifying reliable alternatives and understanding their compatibility can enhance the longevity and effectiveness of your heating unit.

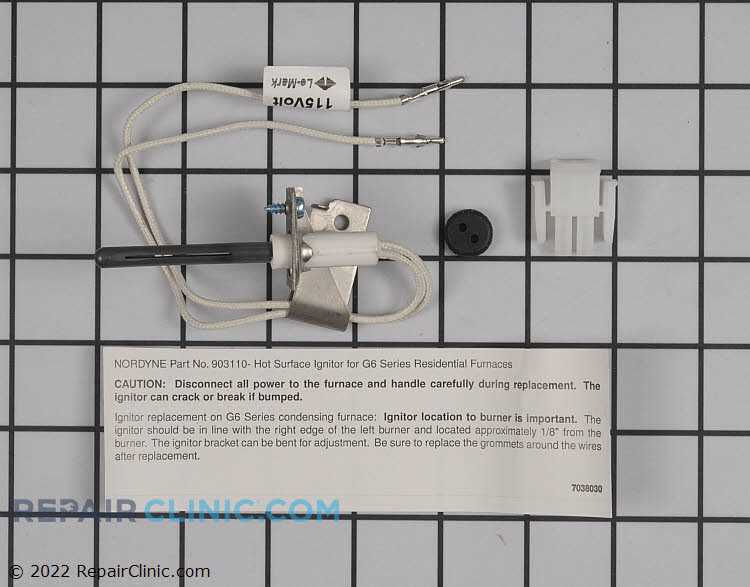

Common Replacement Components

Key elements often necessitating replacement include control mechanisms, ignition systems, and circulation fans. Ensuring that these components are sourced from reputable suppliers can significantly impact the overall reliability of the system. Proper installation and periodic maintenance of these items are essential for achieving consistent heating performance.

Upgrading Options

In addition to standard replacements, exploring advanced alternatives can offer improved efficiency and energy savings. Enhanced components, such as programmable thermostats and high-efficiency ignition systems, can provide better control and comfort. Considering upgrades during replacement can lead to long-term benefits and improved user satisfaction.

Tools for Furnace Repair and Maintenance

Proper maintenance and repair of heating equipment require specific instruments to ensure efficiency and safety. Having the right tools on hand can make troubleshooting and servicing much easier, allowing for prompt action when issues arise. This section will cover essential instruments that aid in the upkeep and repair of these systems.

Essential Tools

- Screwdrivers: A set of various sizes, both Phillips and flathead, is crucial for opening access panels and securing components.

- Wrenches: Adjustable wrenches and socket sets are necessary for loosening and tightening bolts and nuts in tight spaces.

- Pliers: Needle-nose and standard pliers help grip, twist, and cut wires and other materials.

- Multimeter: This device measures voltage, current, and resistance, making it vital for electrical diagnostics.

- Vacuum Cleaner: A specialized vacuum for removing dust and debris ensures optimal airflow and performance.

Safety Equipment

- Gloves: Protective gloves prevent injuries from sharp edges and electrical components.

- Safety Glasses: Wearing safety eyewear shields the eyes from debris and sparks during maintenance tasks.

- Face Mask: A mask can protect against dust and allergens released during cleaning.

Using the right tools not only facilitates efficient maintenance but also enhances safety during repair tasks. Ensuring that these instruments are available and in good condition can lead to better overall performance and longevity of heating systems.

Finding Professional Help for Repairs

When it comes to maintaining your heating system, enlisting the help of a skilled technician can make a significant difference. Whether facing an unexpected malfunction or planning routine upkeep, professional assistance ensures that the job is done efficiently and safely. Experts in the field possess the necessary knowledge and experience to address various issues, providing peace of mind for homeowners.

Assessing Your Needs

Before seeking help, it’s essential to evaluate the specific issues affecting your heating equipment. Identifying symptoms such as unusual noises, inadequate warmth, or frequent cycling can assist in conveying accurate information to the technician. This preliminary assessment can help streamline the repair process and allow professionals to diagnose the problem effectively.

Choosing the Right Technician

Finding the right expert for the job involves researching local service providers and checking their credentials. Look for licensed technicians with positive customer reviews and relevant experience. Additionally, obtaining quotes from multiple specialists can help you make an informed decision based on your budget and the complexity of the repair required.