The efficient functioning of heavy machinery relies on the precise interplay of its various elements. Understanding these components is essential for maintenance and troubleshooting, ensuring that the equipment performs optimally in demanding environments. A detailed examination of these parts not only facilitates better repair practices but also enhances overall operational safety.

In this section, we will delve into the intricate design and arrangement of the fundamental elements that contribute to the performance of vibratory equipment. By breaking down these components, we can uncover the significance of each part and how they collaborate to generate powerful vibrations necessary for effective ground compaction.

Familiarizing oneself with the structure of this machinery empowers operators and technicians alike, enabling them to identify potential issues and execute necessary interventions promptly. Equipped with this knowledge, users can enhance the longevity of their equipment while maximizing productivity on the job site.

Understanding Wacker Plate Compactor Design

The design of soil compaction machinery is a crucial aspect that influences its efficiency and effectiveness in various construction tasks. Each component plays a specific role, contributing to the overall performance and durability of the equipment. A deeper comprehension of these elements can enhance maintenance practices and improve operational outcomes.

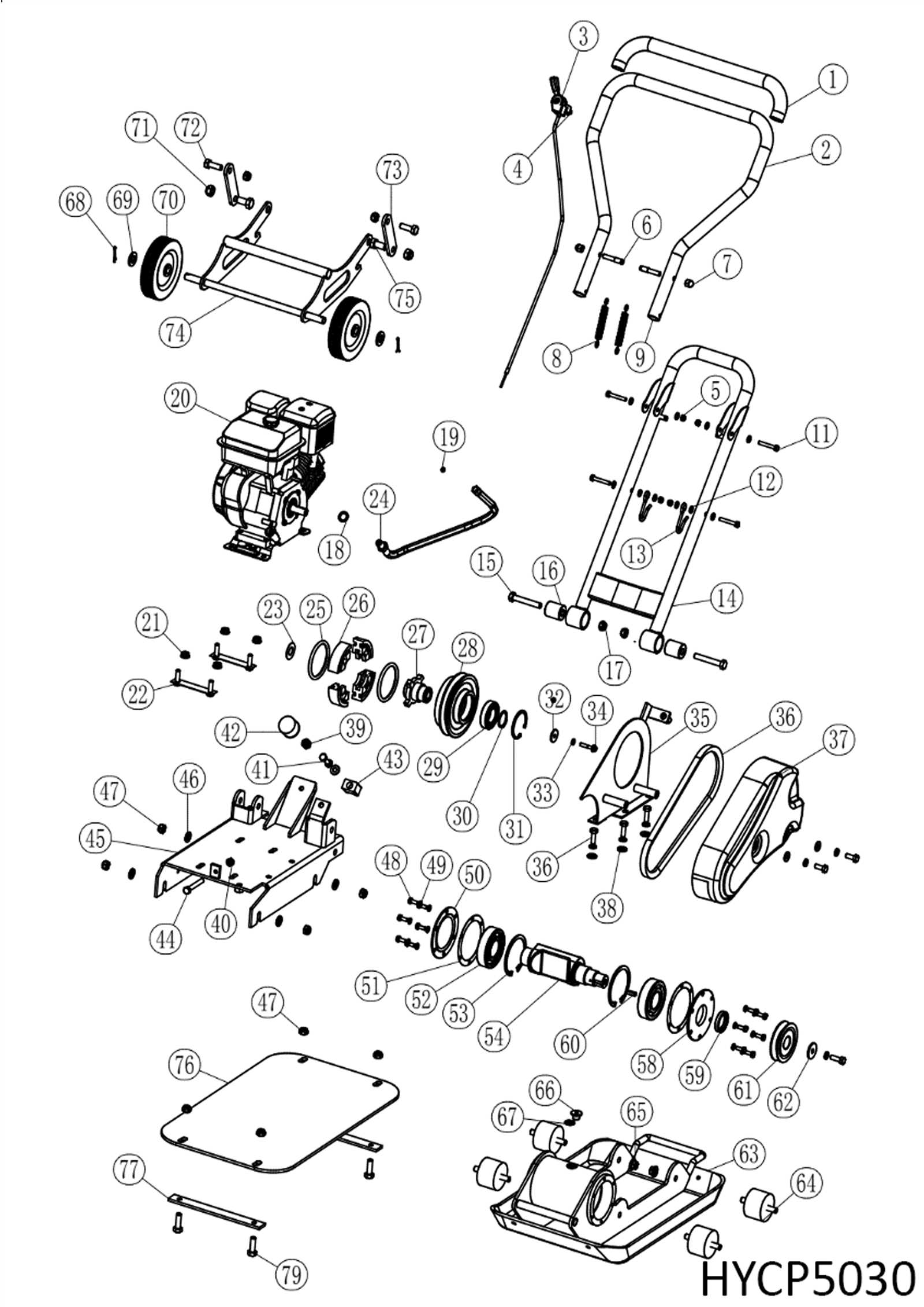

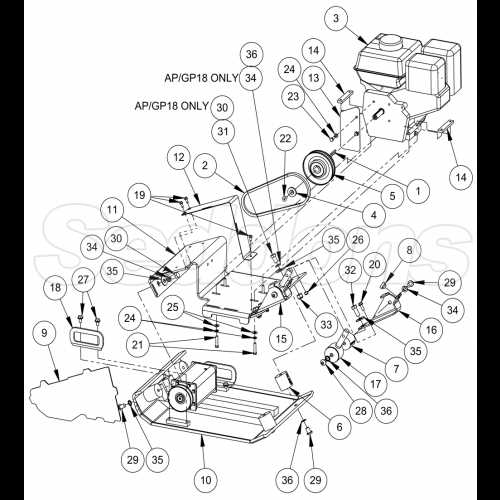

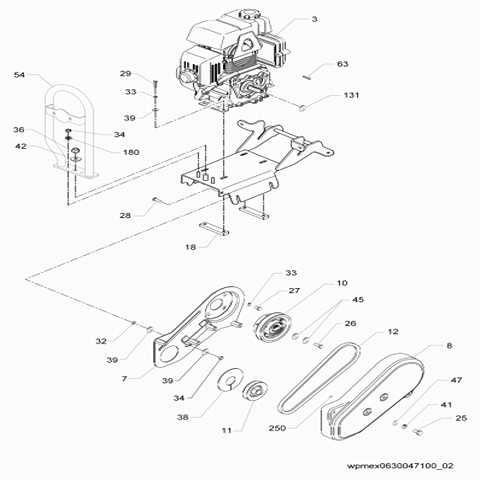

Key Components and Their Functions

At the heart of this machinery lies the engine, which provides the necessary power for movement and vibration. The base plate serves as the foundation, distributing weight evenly across the surface, while the vibration mechanism creates the necessary force to compact the soil. Understanding the interaction between these components is essential for optimizing performance.

Importance of Design Efficiency

Efficient design is not merely about aesthetics; it significantly affects productivity and user comfort. Features such as ergonomic handles and noise reduction technologies enhance the operator’s experience while minimizing environmental impact. Additionally, the choice of materials influences durability, making it imperative to select high-quality components for long-term use.

Key Components of the Compactor

Understanding the fundamental elements of this equipment is crucial for effective operation and maintenance. Each part plays a significant role in ensuring optimal performance and durability during use. Below, we explore the essential components that contribute to the overall functionality of the machine.

Essential Elements

- Engine: Provides the necessary power for operation, driving all other components.

- Base Plate: The flat surface that contacts the ground, crucial for stability and weight distribution.

- Vibration Mechanism: Generates vibrations that compact the material, enhancing density.

- Handle: Allows for maneuverability and control, ensuring ease of operation.

- Fuel Tank: Stores the fuel needed to power the engine, influencing operational efficiency.

Supportive Components

- Air Filter: Protects the engine from debris, promoting longevity.

- Drive Belt: Transmits power from the engine to the vibration mechanism, essential for movement.

- Weight Plates: Additional elements that can be added for increased compaction force.

- Shock Absorbers: Mitigate vibrations felt by the operator, enhancing comfort during use.

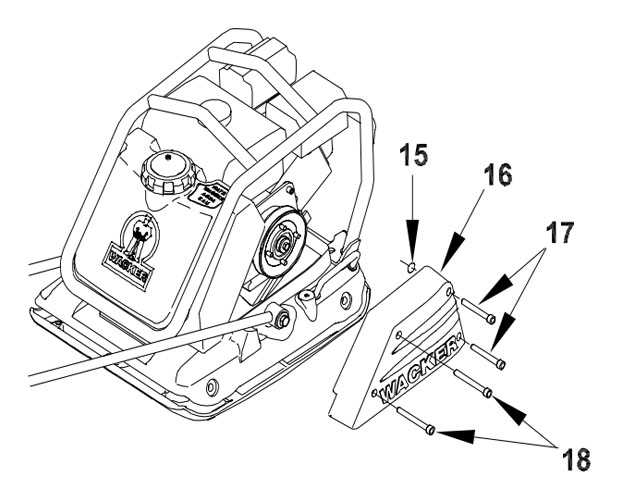

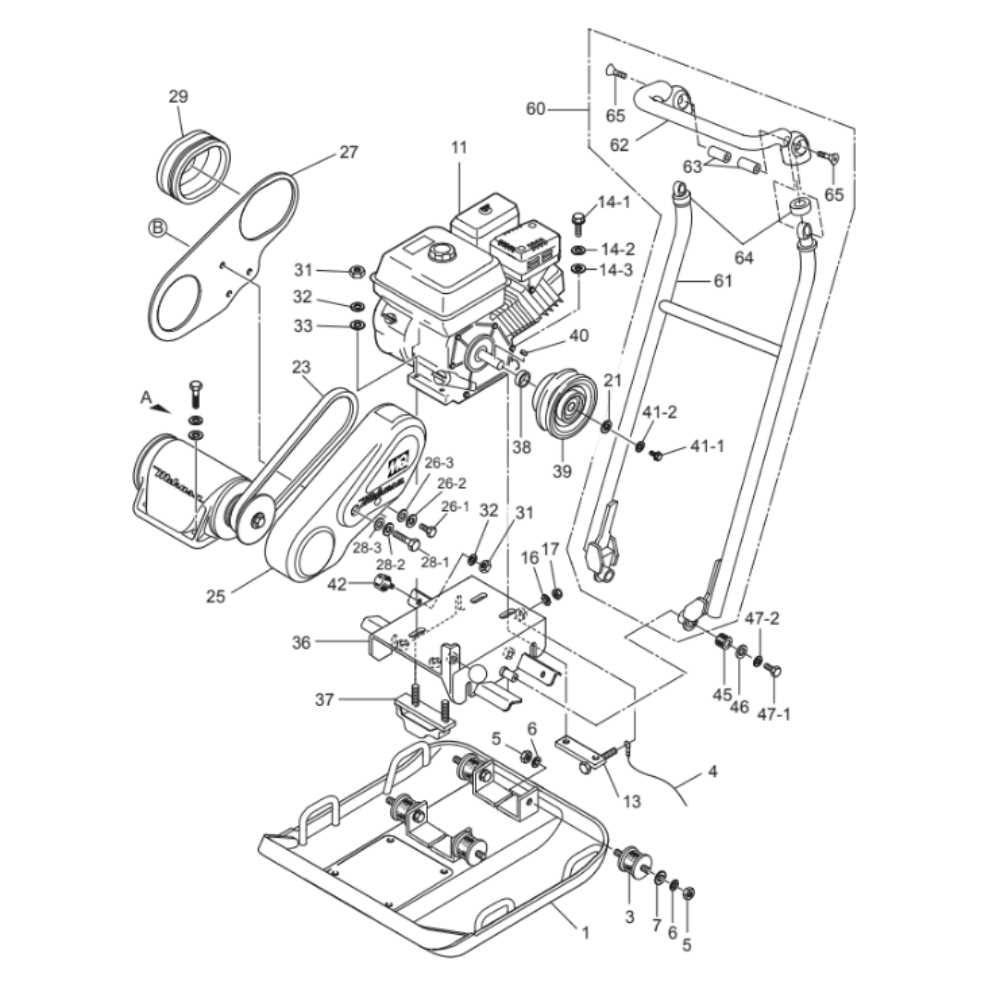

How to Read a Parts Diagram

Understanding the layout of a component illustration is essential for effective maintenance and repair. These visual guides provide a clear representation of various elements and their relationships within a machine. Familiarity with this type of illustration allows for easier identification of specific items and their functions.

When approaching an illustration, start by examining the legend or key, which usually explains the symbols and numbering used throughout. This will help in comprehending the overall structure and terminology applied to each section.

| Element | Description |

|---|---|

| Numbers | Often correspond to a parts list, helping you find specific items quickly. |

| Symbols | Represent various types of components, indicating their role and functionality. |

| Lines | Show connections or relationships between different components, clarifying how they interact. |

| Sections | Divided parts may illustrate different assembly areas, making it easier to focus on specific tasks. |

Pay close attention to these features to enhance your understanding of the illustration. This knowledge not only aids in repairs but also promotes better communication with technicians and suppliers when ordering new items or discussing maintenance issues.

Common Issues with Compactor Parts

In the realm of construction machinery, various challenges can arise with essential components. Understanding these problems can enhance maintenance practices and prolong equipment lifespan. Below are some frequent complications faced by operators.

- Vibration Problems:

- Excessive shaking can lead to uneven compaction.

- Loose fasteners may contribute to increased vibrations.

- Power Issues:

- Insufficient power output can affect performance.

- Fuel system blockages may cause starting difficulties.

- Wear and Tear:

- Components can wear down over time, reducing efficiency.

- Regular inspections help identify parts needing replacement.

- Hydraulic Failures:

- Leaking seals may compromise hydraulic functions.

- Low fluid levels can lead to erratic operation.

- Electrical Malfunctions:

- Faulty wiring can disrupt operations and cause safety hazards.

- Corroded connections may lead to intermittent failures.

By being aware of these common challenges, operators can take proactive measures to maintain their equipment, ensuring reliable performance and safety on the job site.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By following specific maintenance practices, you can extend the lifespan of your machinery and maintain optimal performance.

Regular Inspections

- Check for any signs of wear and tear, such as cracks or loose components.

- Inspect hydraulic systems for leaks and ensure fluid levels are adequate.

- Examine belts and hoses for fraying or deterioration.

Routine Cleaning

- Remove dirt and debris from the exterior to prevent corrosion.

- Clean air filters regularly to ensure proper airflow.

- Keep the engine compartment free of obstructions to facilitate cooling.

Adhering to these guidelines will not only enhance the performance of your equipment but also help avoid costly repairs down the line.

Replacing Worn Out Components

Maintaining optimal performance of your equipment is crucial for efficiency and longevity. Over time, certain elements can become degraded due to regular usage, leading to diminished functionality. Addressing these issues promptly ensures that your machinery operates smoothly and effectively.

Identifying signs of wear is the first step in the replacement process. Common indicators include unusual noises, decreased performance, or visible damage to components. Regular inspections can help catch these problems early, allowing for timely replacements and preventing further damage.

When it comes to replacing worn elements, always opt for high-quality replacements that meet or exceed the manufacturer’s specifications. Following the correct procedures for removal and installation is essential to avoid complications. Make sure to consult the relevant manuals and diagrams to ensure a proper fit.

Additionally, after replacing the damaged components, perform routine maintenance to extend the life of your equipment. This includes regular cleaning, lubrication, and checks on all critical systems to maintain optimal performance.

Identifying Parts by Model Number

Understanding how to recognize components based on their specific model identifier is crucial for effective maintenance and repair. Each identifier carries essential information that facilitates the correct selection of necessary items, ensuring optimal functionality and longevity of your equipment.

Model numbers serve as unique identifiers that connect users to the exact specifications of a machine. By referencing these numbers, one can easily access detailed information about each individual element, including size, compatibility, and manufacturer recommendations.

To streamline the process of identification, always keep the model number readily available. This can often be found on the equipment itself or in the accompanying documentation. Once located, consult manufacturer resources or authorized dealers to find precise details regarding the components associated with your specific model.

In summary, knowing how to identify components through model numbers enhances repair efficiency and helps in sourcing the correct replacements, ultimately saving time and reducing costs.

Importance of Quality Spare Parts

When it comes to machinery maintenance, the significance of high-quality replacement components cannot be overstated. These elements play a crucial role in ensuring that equipment operates efficiently, safely, and reliably over time. Using subpar substitutes may lead to performance issues, increased wear and tear, and ultimately, costly repairs.

Enhancing Performance and Longevity

Utilizing superior-quality components can greatly enhance the functionality of your machinery. Such components are designed to meet precise specifications, ensuring a perfect fit and optimal operation. This not only improves performance but also extends the lifespan of the equipment, making it a wise investment for any operator.

Ensuring Safety and Compliance

Incorporating high-grade elements is vital for maintaining safety standards. Quality parts are engineered to withstand rigorous conditions, reducing the risk of failure during operation. Moreover, using reliable components helps ensure compliance with industry regulations, protecting both the operator and the surrounding environment.

In conclusion, the choice of replacement components is fundamental for maintaining machinery efficiency, safety, and durability. Investing in quality ensures peace of mind and optimal performance in the long run.