The functionality of outdoor power equipment relies heavily on the precise arrangement of its various elements. Understanding how these components interconnect is essential for both maintenance and troubleshooting. A clear visual representation can significantly aid in grasping the intricate relationships among these essential parts.

In the realm of power tools, knowledge of each component’s role enhances operational efficiency and prolongs the lifespan of the machinery. By studying these illustrations, users can identify wear and tear, facilitating timely repairs and replacements. This proactive approach not only ensures optimal performance but also enhances safety during usage.

Whether you are an experienced technician or a novice enthusiast, familiarizing yourself with the assembly layout of your equipment will empower you to make informed decisions. Grasping the relationships between the various pieces contributes to a deeper understanding of how to keep your machinery running smoothly and effectively.

Understanding Husqvarna 359 Components

This section explores the essential elements and mechanisms of a well-known chainsaw model, providing insight into its structure and functionality. Each component plays a critical role in ensuring optimal performance and longevity, reflecting the intricate design and engineering behind the device. A thorough comprehension of these elements can enhance maintenance practices and improve overall usage experience.

Main Elements

Several key components contribute to the efficient operation of this cutting tool. Understanding their functions can aid in diagnosing issues and performing necessary repairs or upgrades.

| Component | Description |

|---|---|

| Engine | Power source that drives the cutting chain, providing necessary force for operation. |

| Chain | Looped metal link that rotates around the guide bar to cut through wood. |

| Guide Bar | Metal bar that supports and guides the chain during operation. |

| Fuel Tank | Container that holds the fuel necessary for engine operation. |

| Air Filter | Component that prevents dirt and debris from entering the engine, ensuring clean air intake. |

Additional Features

Beyond the fundamental elements, various features enhance usability and safety. These attributes often include anti-vibration systems, ergonomic handles, and automatic oilers, each contributing to a smoother operation and user comfort.

Overview of Husqvarna 359 Parts

This section provides a comprehensive examination of the components essential for the efficient operation of a popular chainsaw model. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity. Each part plays a significant role in the overall functionality, from the engine to the cutting mechanism.

Key Components

Among the various elements, the engine assembly stands out as the heart of the device, delivering the necessary power for cutting tasks. The cutting system, which includes the bar and chain, is equally vital, facilitating precise and effective wood cutting. Additionally, the air filter and fuel system are essential for maintaining proper engine function and efficiency.

Maintenance and Replacement

Regular upkeep of these components can prevent operational issues and prolong the life of the equipment. Identifying when to replace specific elements, such as the spark plug or chain, is vital for seamless functionality. Understanding the role of each component not only aids in troubleshooting but also empowers users to conduct effective repairs.

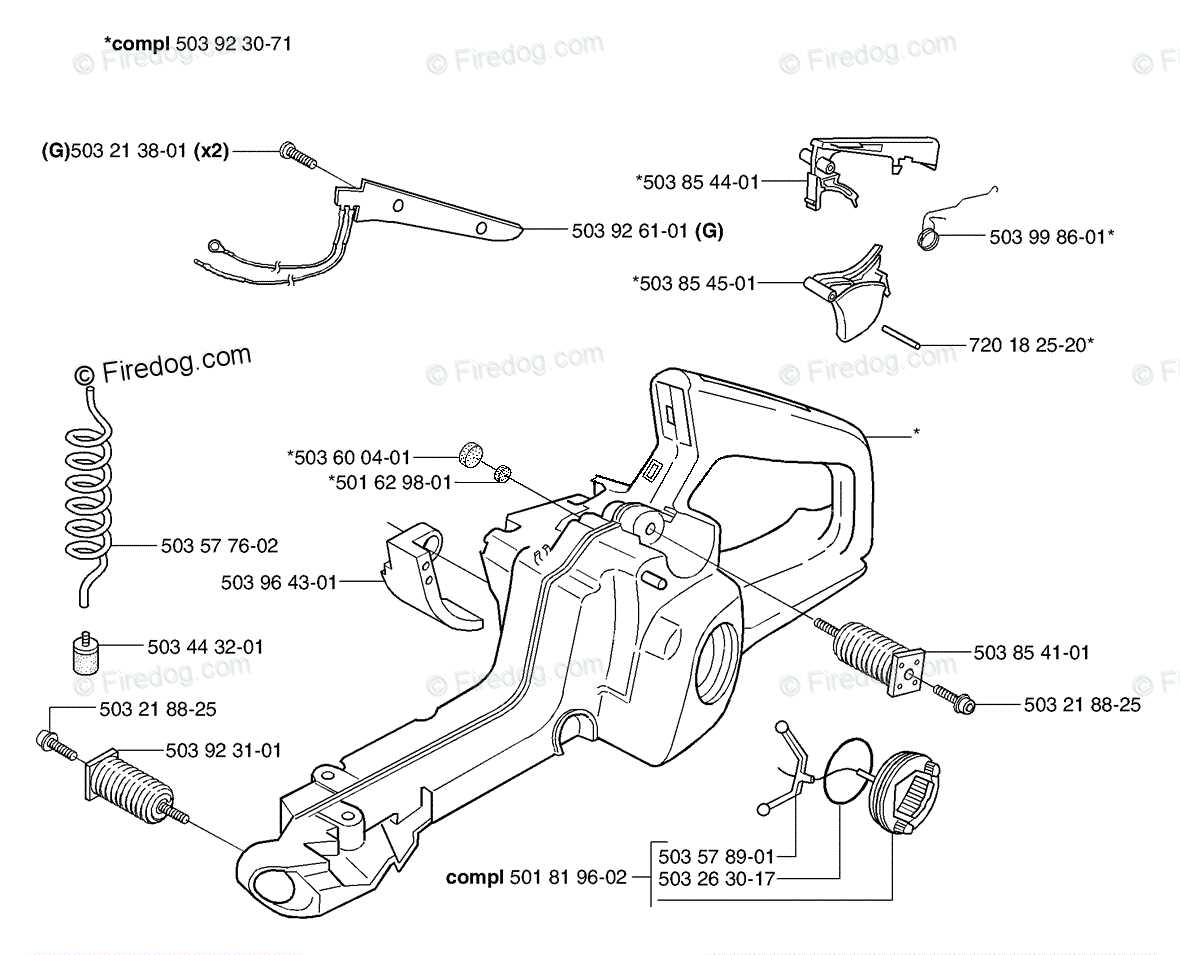

Exploring the Fuel System Layout

The arrangement of components within the fuel delivery mechanism plays a crucial role in the overall performance of the machinery. Understanding this configuration allows users to maintain efficiency and prevent potential issues. Each element in this system works synergistically to ensure optimal fuel flow and combustion, making it essential to comprehend their positions and functions.

Key components of the fuel system include:

- Fuel Tank: The primary reservoir where the fuel is stored before it is delivered to the engine.

- Fuel Lines: Tubes that transport the fuel from the tank to the engine, designed to withstand pressure and resist wear.

- Fuel Filter: A crucial part that removes impurities from the fuel, protecting the engine from damage.

- Fuel Pump: This component is responsible for drawing fuel from the tank and supplying it to the engine at the necessary pressure.

- Carburetor: An essential part that mixes fuel with air in the correct ratio for efficient combustion.

- Fuel Injector: In systems equipped with this part, it precisely delivers fuel directly into the combustion chamber, enhancing performance and efficiency.

Regular maintenance and inspection of these components can prevent common issues such as clogging and fuel leaks. Understanding their layout helps in troubleshooting problems effectively, ensuring smooth operation.

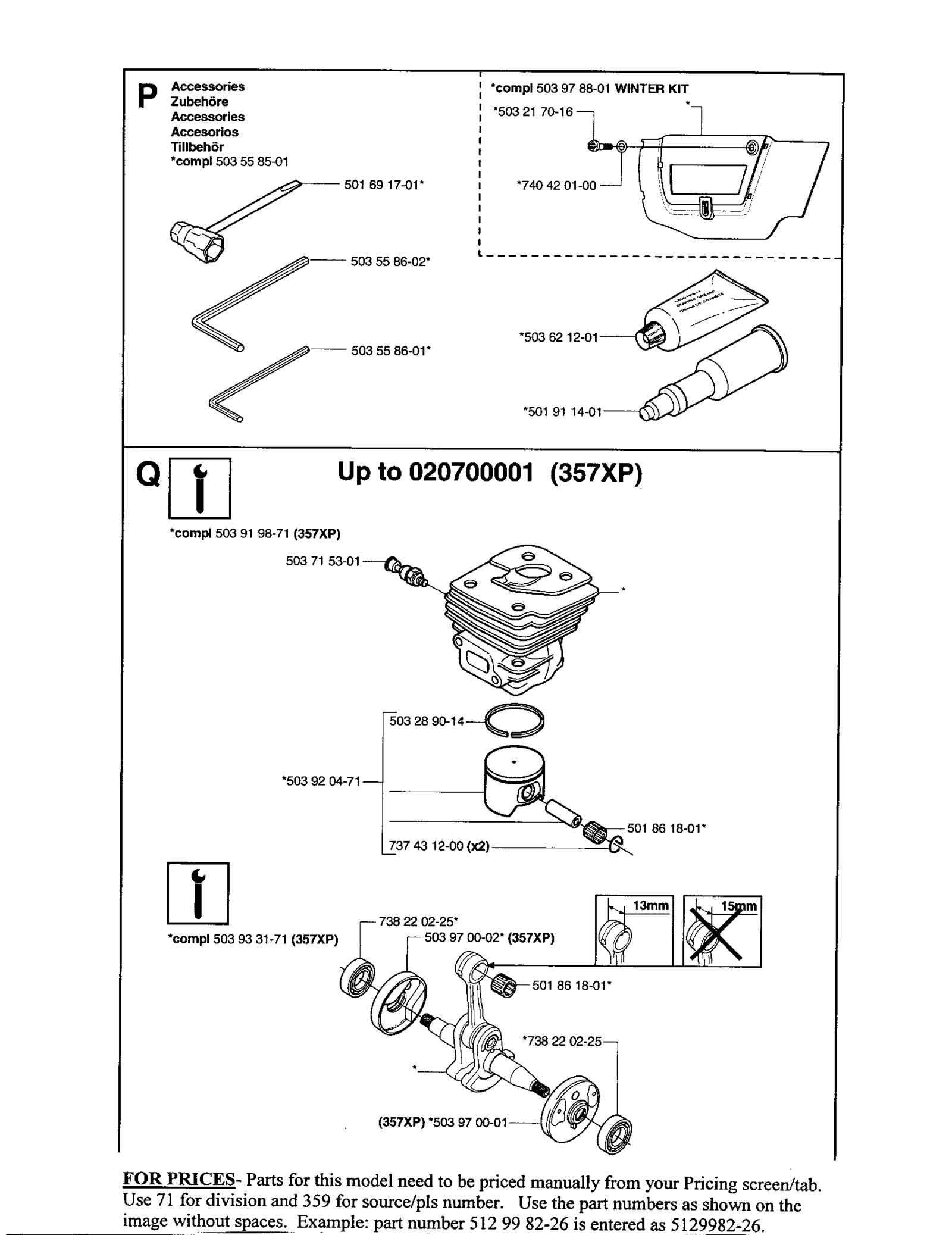

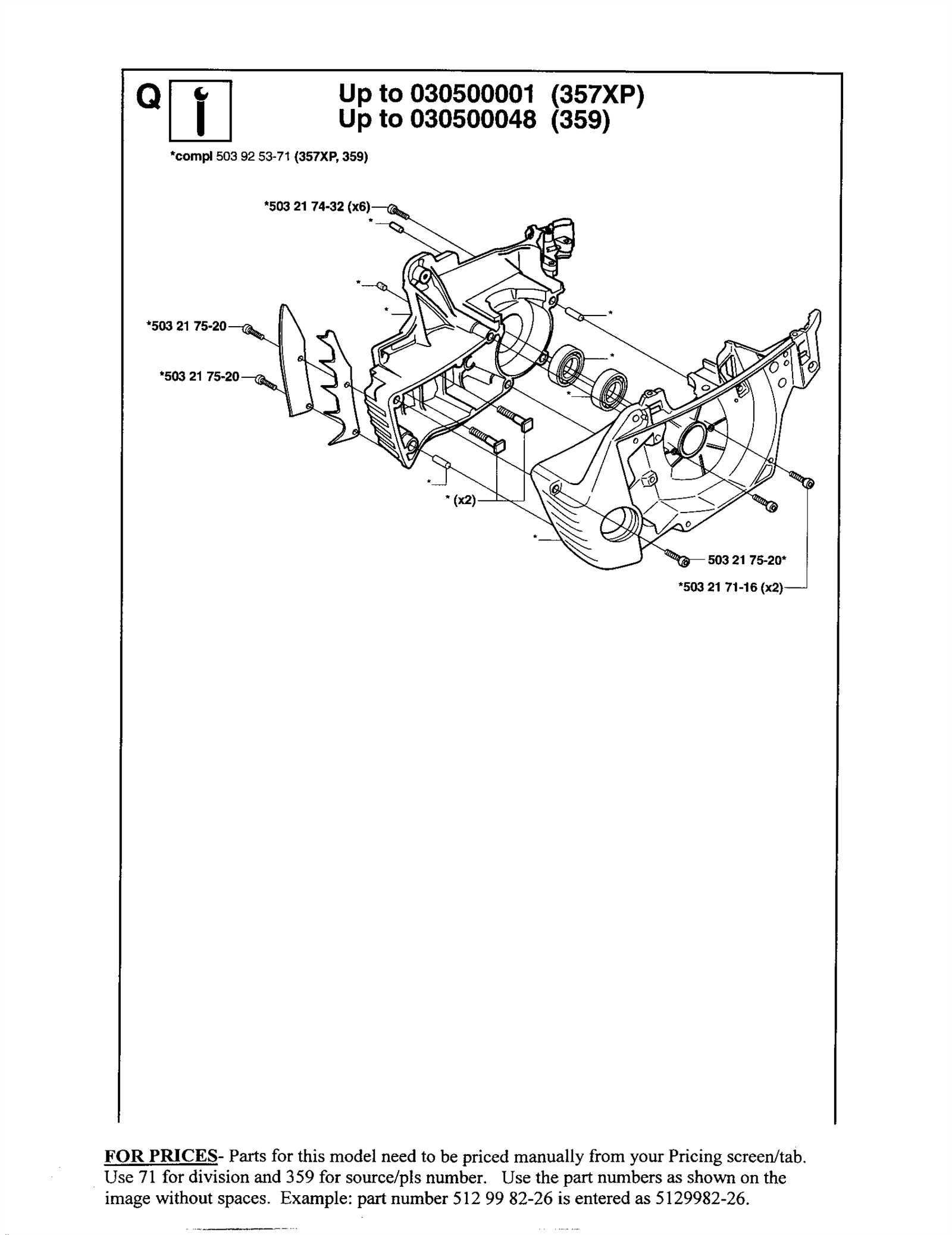

Key Features of the Engine Assembly

The engine assembly serves as the heart of any machinery, playing a critical role in its overall performance and efficiency. Understanding the key components and their functions can significantly enhance the operation and longevity of the unit. This section delves into the fundamental characteristics that define a high-performing engine assembly.

Essential Components

- Crankshaft: This vital part converts the linear motion of the pistons into rotational motion, driving the output of the engine.

- Piston: The piston moves within the cylinder, compressing the fuel-air mixture for ignition, crucial for generating power.

- Cylinder Head: Housing the combustion chamber, it contains valves that control the intake and exhaust of gases, ensuring efficient operation.

- Fuel System: Responsible for delivering the proper mixture of fuel and air, this system is essential for optimal engine performance.

Performance Enhancements

- Cooling System: Keeps the engine at an optimal temperature, preventing overheating and ensuring consistent performance.

- Lubrication: Reduces friction between moving parts, enhancing efficiency and prolonging the lifespan of the engine.

- Ignition System: Initiates the combustion process, critical for maintaining engine responsiveness and power output.

These features collectively contribute to the overall efficiency and reliability of the engine assembly, making it a crucial aspect of machinery design and functionality.

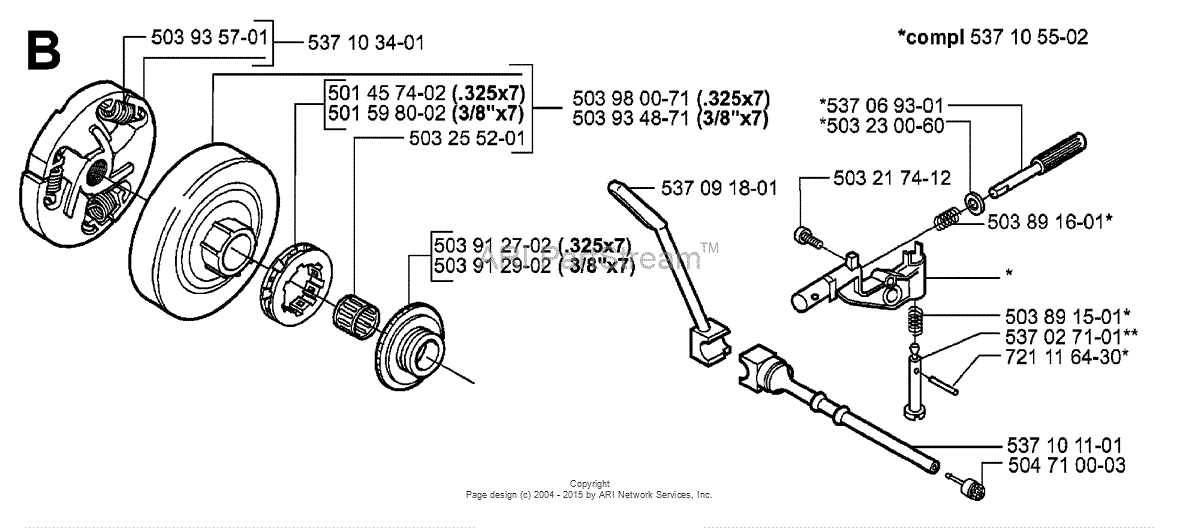

Chain and Bar Specifications Explained

Understanding the characteristics of the cutting chain and guide bar is essential for optimizing the performance of a cutting tool. These components play a critical role in the overall functionality and efficiency, influencing factors such as cutting speed, precision, and safety. A comprehensive grasp of these specifications enables users to select the appropriate equipment for various tasks.

Key specifications include:

- Chain Pitch: This refers to the distance between the links on the chain, affecting how the chain interacts with the guide bar.

- Chain Gauge: The thickness of the drive links that fit into the guide bar’s groove, crucial for ensuring a secure fit.

- Bar Length: The measurement of the guide bar from the front to the back, directly influencing the cutting capacity.

- Link Count: The total number of links in the chain, which impacts the overall length and compatibility with the guide bar.

When selecting a cutting tool, it is important to ensure that the chain and guide bar are compatible. Mismatched specifications can lead to inefficiencies and safety hazards. Proper maintenance of these components is also vital for optimal performance.

In conclusion, being aware of chain and bar specifications is essential for making informed choices and enhancing the longevity and effectiveness of cutting equipment.

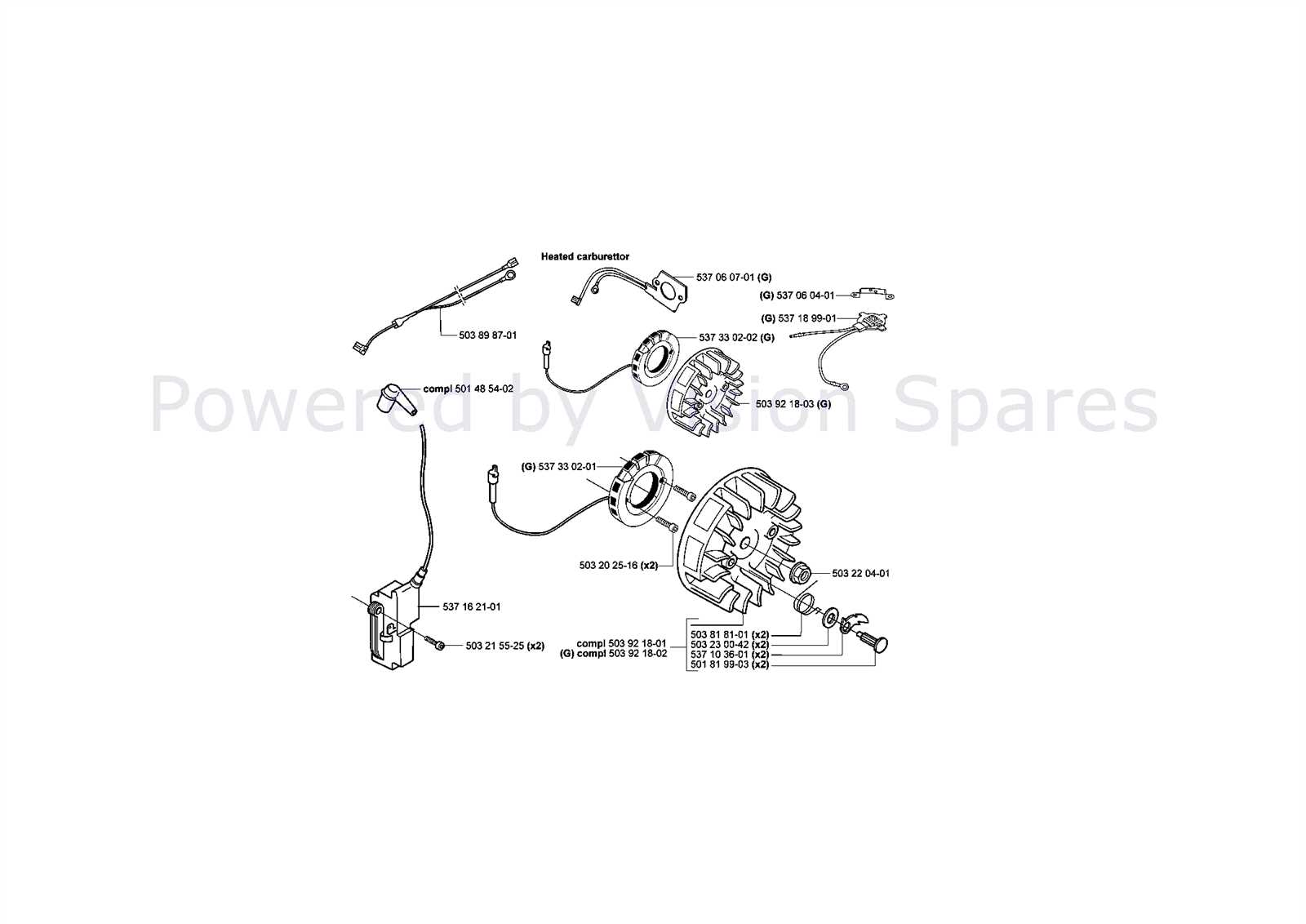

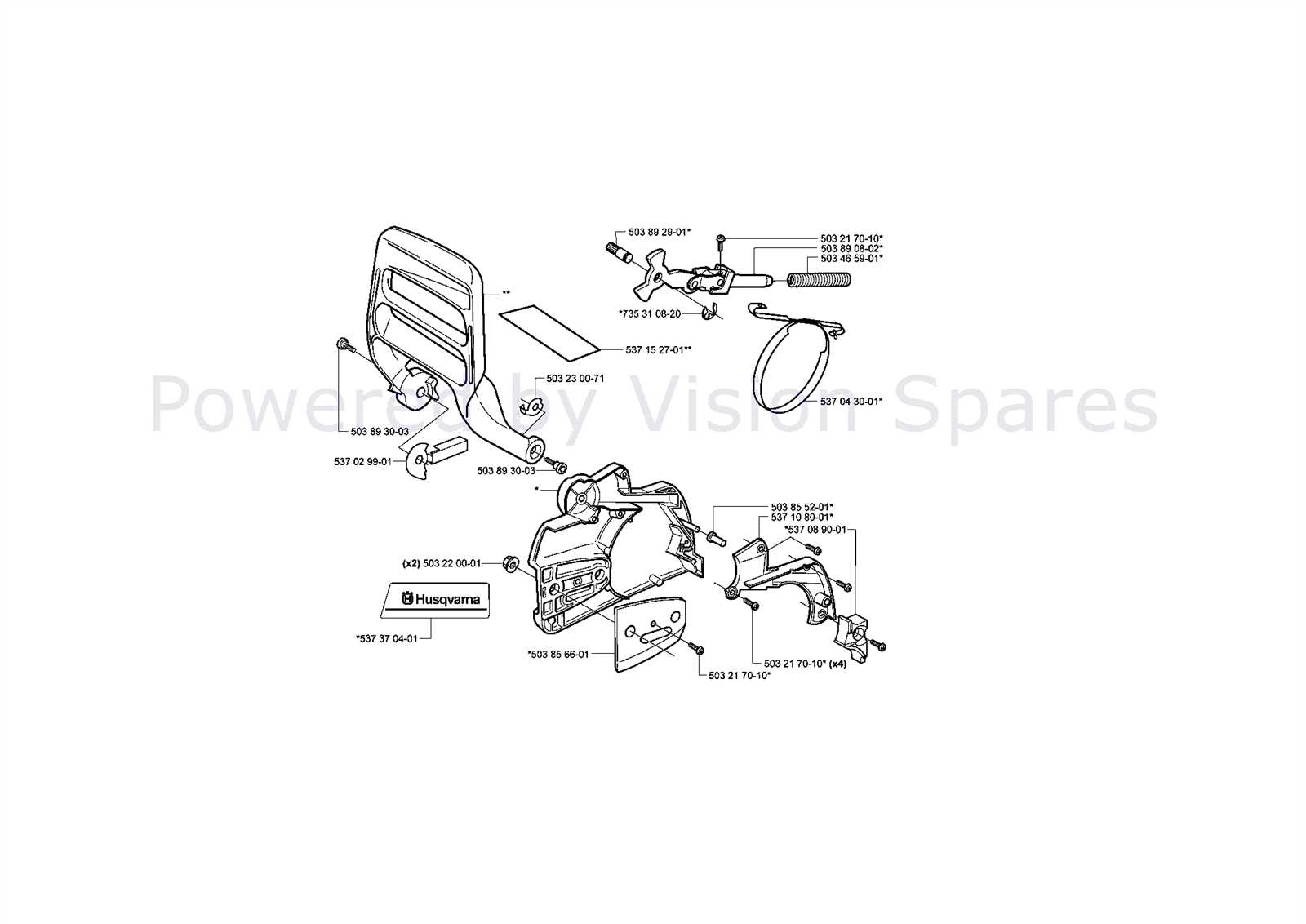

Electrical System Wiring and Parts

This section provides an overview of the electrical system components and their interconnections within the machine. Understanding these elements is essential for proper maintenance, troubleshooting, and ensuring optimal performance. A reliable electrical system enhances functionality and safety during operation.

Key Components

- Ignition Coil: Responsible for generating the spark needed for combustion.

- Starter Motor: Engages to initiate the engine’s operation.

- Battery: Supplies the necessary power for starting and powering electrical components.

- Switches: Control the flow of electricity, allowing for user operation of various features.

- Wiring Harness: Connects all electrical components, ensuring proper communication and functionality.

Wiring Connections

Proper wiring is crucial for the electrical system’s efficiency and reliability. Each component is connected through a series of wires that facilitate the flow of electricity. The following are common types of connections found within the system:

- Direct Connections: These involve a direct link between two components, ensuring immediate power transfer.

- Ground Connections: Essential for safety, grounding prevents electrical faults by directing excess current away from the system.

- Intermittent Connections: These may include connectors that allow for easy disconnection for maintenance or replacement.

Maintenance Tools for Husqvarna 359

Proper upkeep of outdoor machinery is essential for ensuring longevity and optimal performance. Utilizing the right implements not only simplifies the maintenance process but also enhances the efficiency of your equipment. Below is a selection of essential tools that are highly recommended for effective servicing of your machine.

| Tool | Description |

|---|---|

| Wrench Set | A collection of wrenches in various sizes to facilitate the tightening and loosening of bolts and nuts. |

| Socket Set | Includes a variety of sockets and a ratchet handle for easier access to fasteners in tight spaces. |

| Screwdriver Set | Various types and sizes to accommodate different screw heads, essential for disassembly and adjustment. |

| Fuel Mixing Container | Specifically designed for mixing fuel and oil in the correct ratio for optimal engine performance. |

| Chain Sharpener | A tool to maintain the sharpness of the cutting chain, ensuring efficient and safe operation. |

| Protective Gear | Safety equipment such as gloves, goggles, and ear protection to ensure user safety during maintenance tasks. |

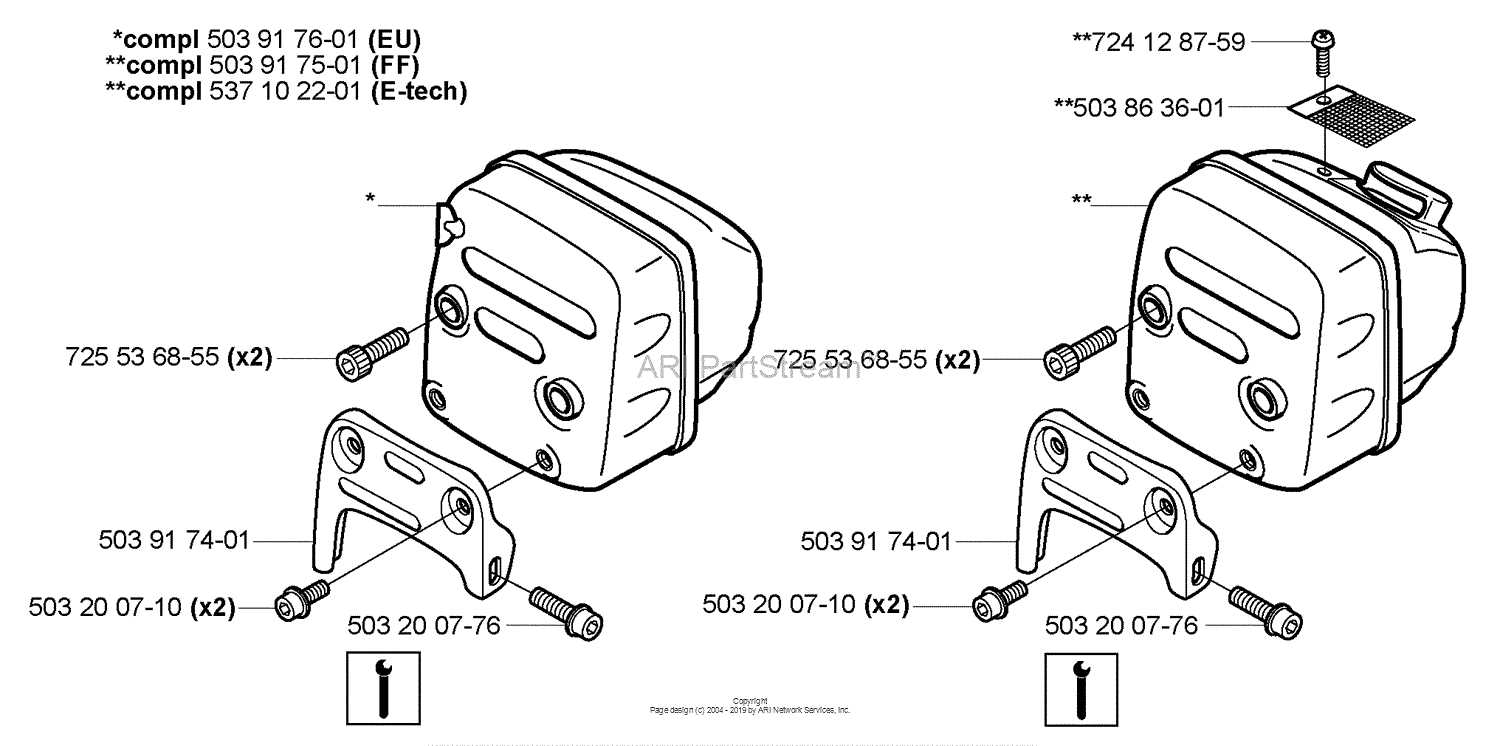

Common Replacement Parts Overview

When maintaining outdoor power equipment, understanding the typical components that may require substitution is essential for optimal performance. Various elements can wear down over time due to usage and environmental factors. This section highlights the most frequently replaced items that enhance the functionality and longevity of your equipment.

Key Components for Replacement

Here are some of the vital components that often need to be swapped out during routine maintenance or repairs:

| Component | Description | Purpose |

|---|---|---|

| Air Filter | Prevents dirt and debris from entering the engine. | Ensures clean air for efficient combustion. |

| Spark Plug | Ignites the fuel-air mixture within the engine. | Critical for engine starting and performance. |

| Chain Bar | The component that guides and supports the cutting chain. | Maintains cutting efficiency and accuracy. |

| Fuel Filter | Removes impurities from the fuel before reaching the engine. | Protects engine components from damage. |

| Throttle Cable | Controls the engine speed by adjusting the throttle. | Enables responsive power adjustments during operation. |

Importance of Timely Replacements

Regularly replacing worn components is vital to maintaining the performance and safety of your equipment. Timely substitutions can prevent more significant issues, ensuring reliability and longevity in you

Tips for Ordering Spare Components

When it comes to acquiring replacement items for your equipment, understanding the process can significantly enhance your experience and ensure compatibility. Knowing how to effectively source these components not only saves time but also minimizes the risk of purchasing incorrect or substandard items.

Here are some useful strategies to consider:

- Identify the Exact Component: Before placing an order, ensure you have the precise identification of the required item. This includes the model number, specifications, and any unique identifiers.

- Consult the Manual: Refer to the equipment’s manual for detailed information about the components. Manuals often provide valuable insights, including diagrams and part numbers.

- Utilize Online Resources: Many websites offer comprehensive catalogs for various equipment. Use these platforms to compare options and verify details about the components.

- Contact Authorized Dealers: Engaging with certified vendors guarantees access to quality components. They can also offer advice and support in selecting the right items for your needs.

- Check for Warranties: When ordering components, inquire about warranty options. This ensures that you are protected against defects and can return items if necessary.

- Review Customer Feedback: Investigate customer reviews and ratings for the components you intend to purchase. Feedback from other users can highlight reliability and performance.

By following these guidelines, you can streamline the process of obtaining necessary components, ensuring that your equipment remains functional and efficient.