The effective operation of winter machinery relies on a comprehensive understanding of its individual elements. Each component plays a vital role in ensuring optimal performance during challenging weather conditions. Familiarity with these parts allows users to troubleshoot issues and maintain their equipment efficiently.

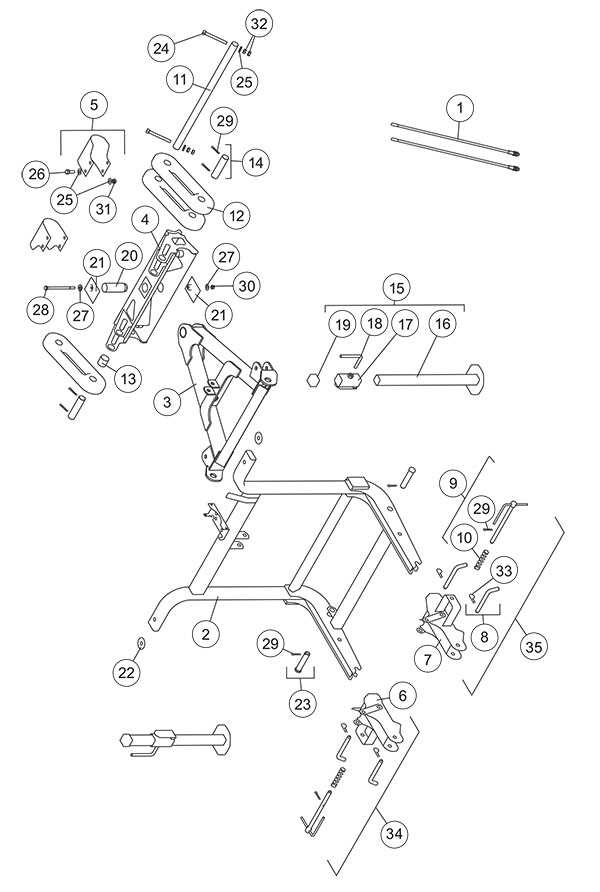

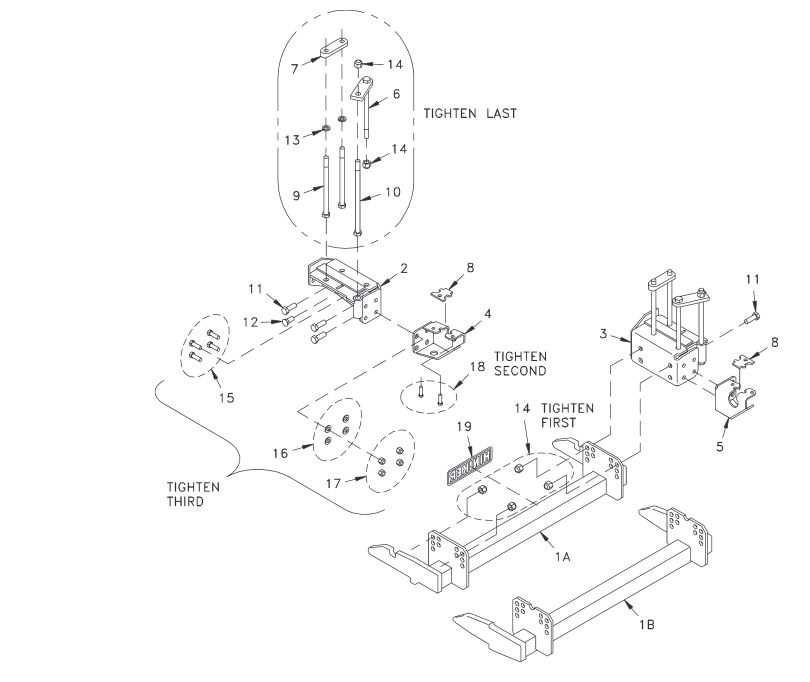

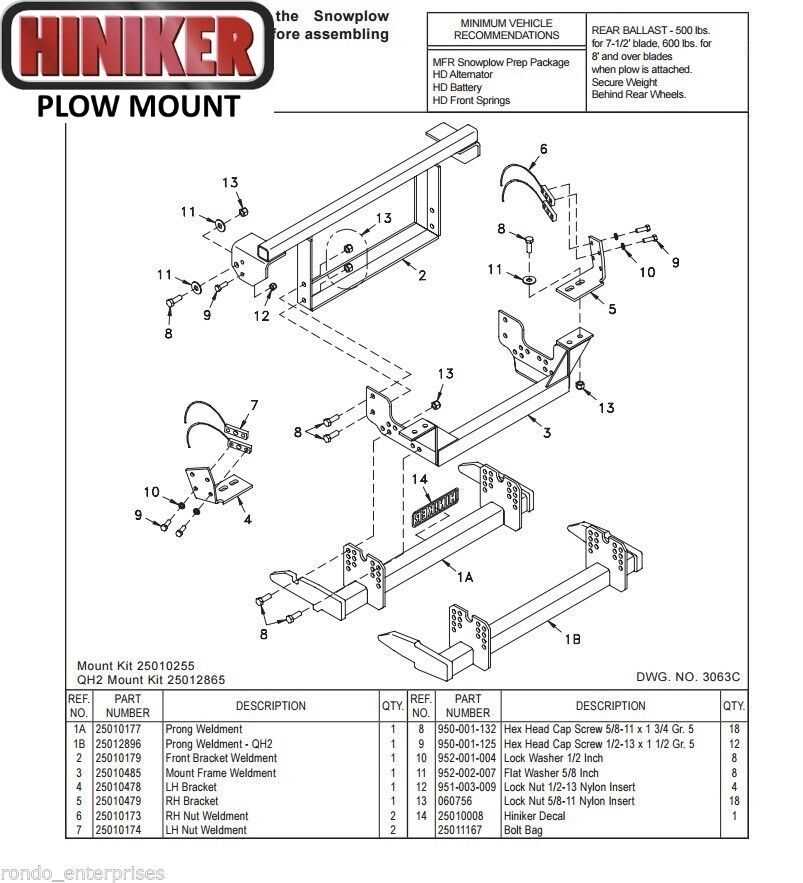

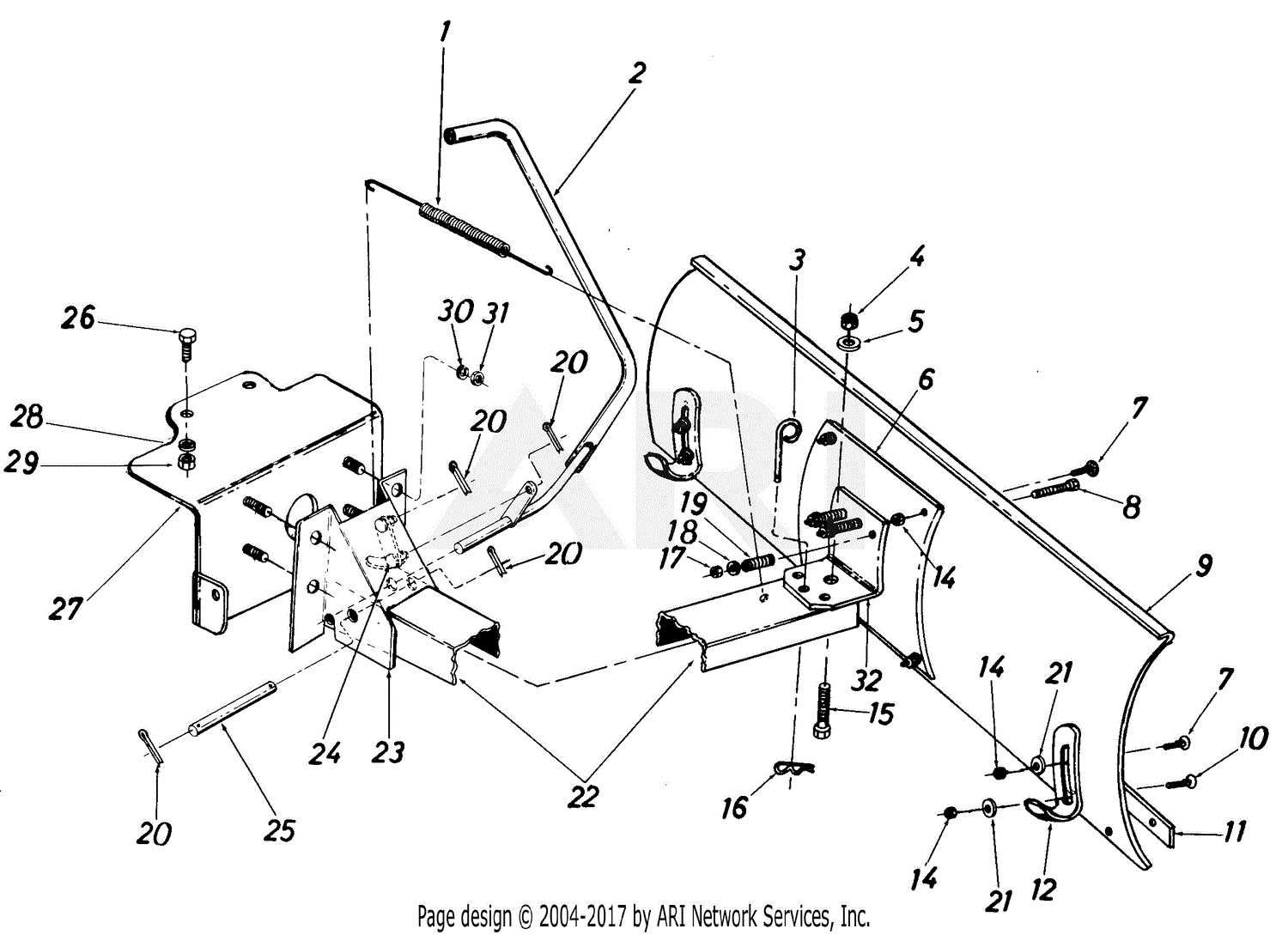

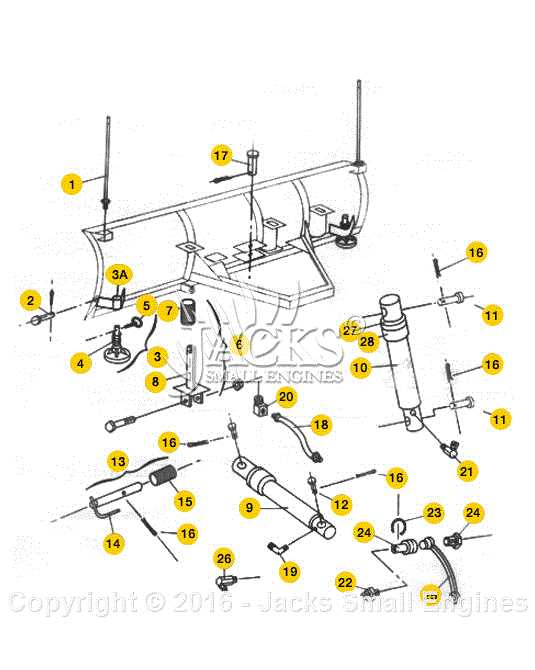

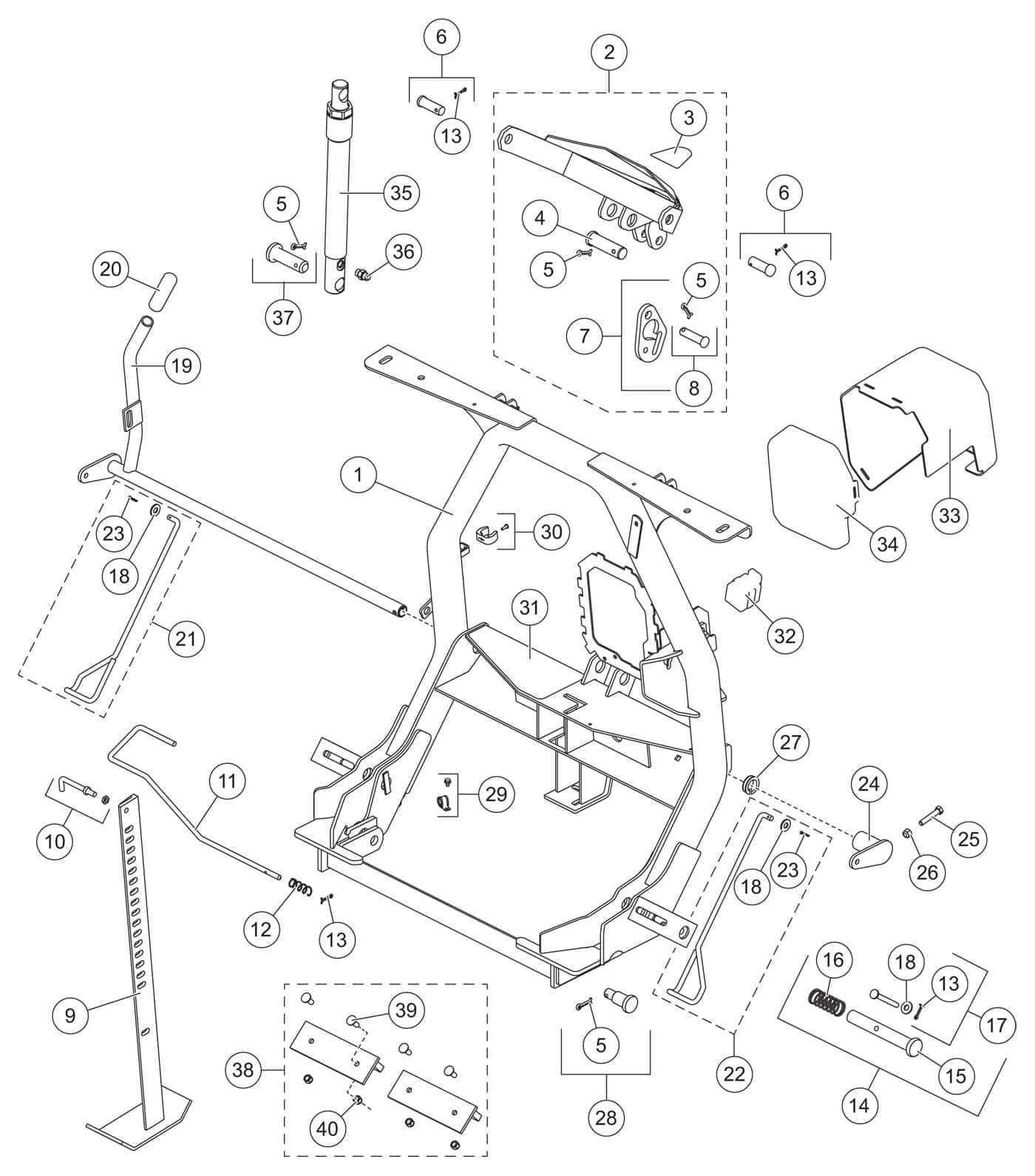

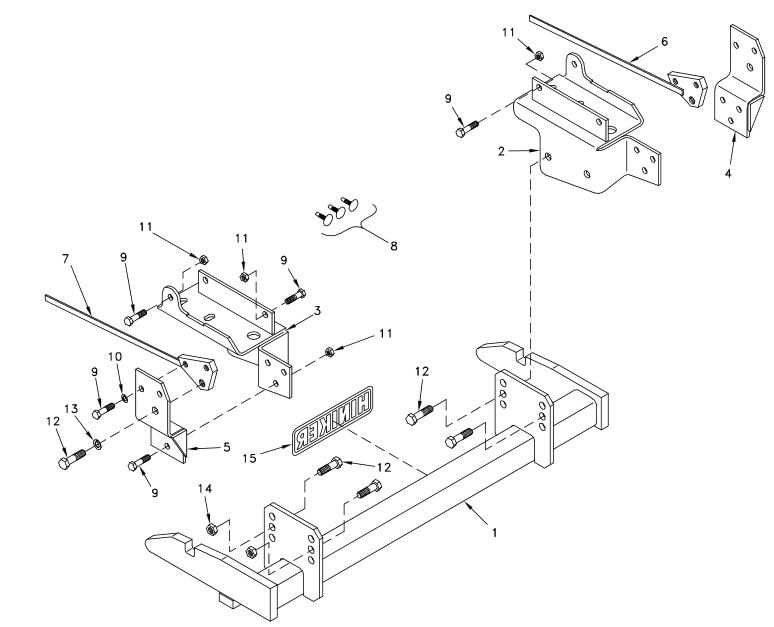

Visual representations serve as invaluable tools in grasping the intricate relationships between various elements. By studying these illustrations, operators can quickly identify essential features and understand how they work together to achieve functionality. This knowledge not only enhances operational efficiency but also extends the lifespan of the machinery.

Moreover, a clear layout of components enables effective communication among users, mechanics, and suppliers. Whether seeking replacement items or planning maintenance schedules, a well-organized reference enhances the overall experience, promoting a proactive approach to equipment care and reliability in performance.

Understanding Hiniker Snow Plow Parts

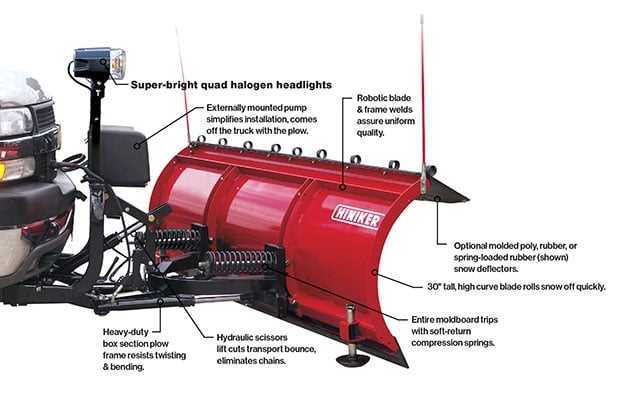

Grasping the components of a winter preparation apparatus is essential for optimal performance and longevity. Each element plays a crucial role in ensuring efficiency, and recognizing their functions can significantly enhance operational effectiveness. By examining the structure and interconnections, one can achieve a more comprehensive understanding of the machinery.

Key Components and Their Functions

Every unit consists of various segments, including the frame, blade, and hydraulic systems. The frame serves as the backbone, providing stability, while the blade is responsible for directing snow and debris. The hydraulic systems facilitate movement and adjustments, making them vital for maneuverability.

Maintenance Tips for Longevity

Regular inspection of each element is paramount to ensure optimal functionality. Lubricating moving parts, checking for wear, and addressing any signs of damage promptly can prevent larger issues down the line. Keeping the equipment in peak condition guarantees not only performance but also safety during operation.

Importance of Snow Plow Diagrams

Understanding the layout and components of essential equipment is crucial for effective maintenance and repair. Visual representations serve as valuable tools, allowing operators to quickly identify parts and their functions, ensuring efficient troubleshooting. By grasping the overall structure, users can enhance their operational proficiency and extend the lifespan of their machinery.

Diagrams play a pivotal role in facilitating communication between technicians and users, making complex systems more accessible. With a clear overview, even those with minimal experience can navigate repairs confidently.

Ultimately, leveraging these visual guides not only improves safety but also maximizes performance, enabling users to tackle winter challenges with ease.

Key Components of Hiniker Models

This section explores the essential elements that contribute to the functionality and efficiency of various equipment models designed for winter conditions. Understanding these components is crucial for optimal performance and maintenance.

| Component | Description |

|---|---|

| Blade Assembly | The main part that contacts the surface, designed for effective removal of materials. |

| Hydraulic System | Controls the movement and angle of the blade for precise operations. |

| Mounting Frame | Provides the structural support and stability needed for attachment to the vehicle. |

| Control Mechanism | Allows the operator to adjust settings and positions from within the vehicle. |

| Wear Components | Parts that experience friction and abrasion, requiring regular inspection and replacement. |

Common Issues with Snow Plow Parts

Maintaining equipment designed for winter conditions can often reveal various challenges that users must navigate. Understanding these common complications can lead to more efficient operation and increased longevity of the machinery. Frequent problems can arise from wear and tear, inadequate maintenance, or environmental factors, which ultimately impact performance.

One prevalent issue is corrosion, especially in components exposed to harsh elements. Regular inspections and protective coatings can mitigate this risk. Additionally, improper alignment can lead to uneven wear, making it crucial to ensure all components are correctly positioned and calibrated.

Another common concern involves hydraulic systems, where leaks or low fluid levels can severely affect functionality. Monitoring these systems and addressing any leaks promptly can prevent more significant malfunctions. Finally, electrical failures, such as faulty wiring or blown fuses, can disrupt operation, highlighting the importance of routine electrical checks.

How to Read Parts Diagrams

Understanding the visual representations of components is crucial for effective maintenance and repair. These illustrations serve as a roadmap, guiding users through the various elements and their functions within a larger system.

Key Elements to Identify

- Labels: Each section typically features clear annotations to specify the function or identification of each component.

- Symbols: Familiarize yourself with common icons that indicate specific actions or types of parts.

- Connections: Pay attention to lines and arrows that show how components interact and are linked.

Steps to Follow

- Start by locating the main assembly or group to understand the overall layout.

- Identify individual elements and match them with corresponding labels.

- Use the visual cues to assess how each component contributes to the system’s functionality.

Maintenance Tips for Snow Plows

Keeping your equipment in optimal condition is essential for ensuring reliable performance during harsh winter conditions. Regular care not only prolongs the lifespan of the machinery but also enhances safety and efficiency. Here are some effective strategies to maintain your gear throughout the winter season.

Regular Inspections

Frequent checks are crucial to identify any wear or potential issues before they escalate. Focus on the following:

- Inspect hydraulic systems for leaks or damage.

- Examine cutting edges for signs of wear.

- Check all connections and fasteners for security.

Proper Lubrication

Ensuring that moving parts are well-lubricated is vital for smooth operation. Consider these tips:

- Use appropriate lubricants as specified in the manual.

- Lubricate pivot points and joints regularly.

- Monitor and refill fluid levels for hydraulic systems as needed.

By adhering to these maintenance practices, you can ensure your equipment performs effectively, reducing the risk of breakdowns and enhancing your overall productivity during winter operations.

Finding Replacement Parts Online

Locating suitable components for machinery can be streamlined by utilizing online resources. The digital marketplace offers a vast selection of alternatives, allowing users to compare prices, quality, and availability with ease.

Start by researching reputable websites that specialize in equipment accessories. Look for platforms that provide detailed information and customer reviews, as these insights can greatly influence your decision-making process.

Utilize search engines to input specific terms related to the item you need. This will help you discover various vendors and possible options that match your requirements. Don’t forget to check for discounts or seasonal sales that can provide significant savings.

Additionally, consider joining online forums or communities dedicated to equipment enthusiasts. Engaging with others can lead to valuable recommendations and firsthand experiences regarding where to find high-quality replacements.

Customizing Your Hiniker Snow Plow

Enhancing the functionality and performance of your equipment can greatly improve your efficiency and effectiveness during challenging conditions. Tailoring specific features to meet your unique needs allows for a more personalized experience, making your tasks easier and more enjoyable.

Upgrading Accessories

One of the most effective ways to customize your machinery is by adding or upgrading accessories. Various attachments can enhance maneuverability and effectiveness, catering to specific job requirements.

| Accessory | Description | Benefits |

|---|---|---|

| Blade Extensions | Increase the width of your equipment’s blade. | Wider coverage reduces time spent on large areas. |

| Quick-Release Mounts | Facilitate easy attachment and detachment. | Streamlines workflow and saves time during operations. |

| Heated Handles | Provide warmth during cold weather tasks. | Improves comfort and grip, enhancing control. |

Adjusting Performance Settings

Modifying the performance settings of your equipment can significantly enhance its capabilities. Fine-tuning aspects like speed and sensitivity allows for improved handling and responsiveness, tailored to your specific environment.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components related to winter equipment maintenance and repair. Understanding these elements can enhance the performance and longevity of your machinery, ensuring efficient operation during the cold months.

| Question | Answer |

|---|---|

| What should I check before purchasing new components? | Always verify compatibility with your equipment model and inspect for any specific manufacturer recommendations. |

| How can I identify the correct component for my unit? | Refer to the user manual or consult online resources that provide detailed specifications and images of each item. |

| Are aftermarket items reliable? | Aftermarket options can be viable, but ensure they come from reputable suppliers with positive reviews. |

| How often should I replace components? | Replacement frequency depends on usage and wear; regularly inspect items for signs of damage or fatigue. |

| Where can I find technical support for my equipment? | Many manufacturers offer customer support lines, online chat, or forums where you can seek assistance. |