Maintaining and troubleshooting machinery requires a clear understanding of its individual elements. Each component plays a crucial role in the overall functionality, and knowing how they fit together can simplify repairs and enhance performance. This knowledge empowers operators to effectively manage their equipment, ensuring longevity and reliability.

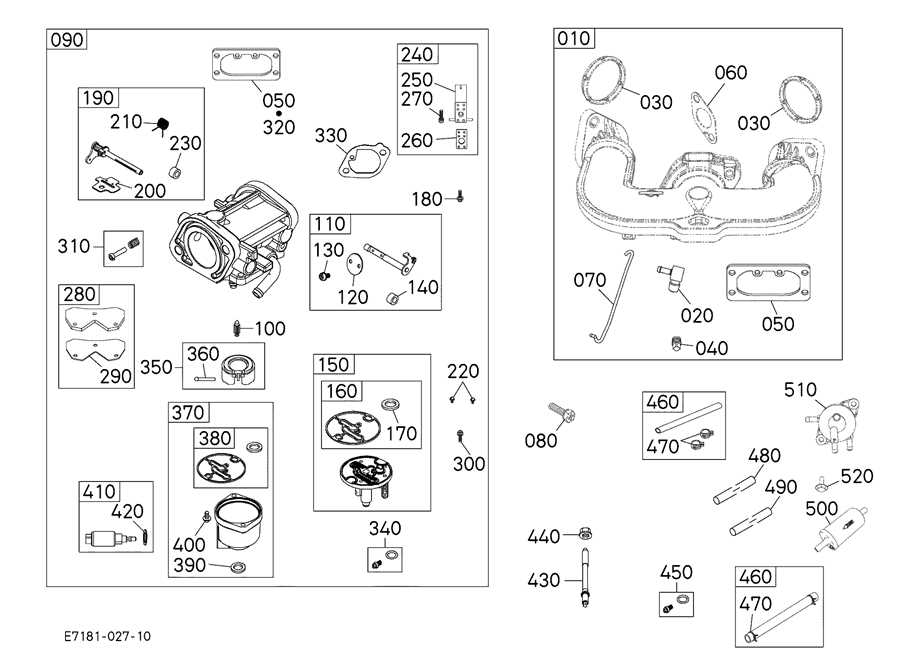

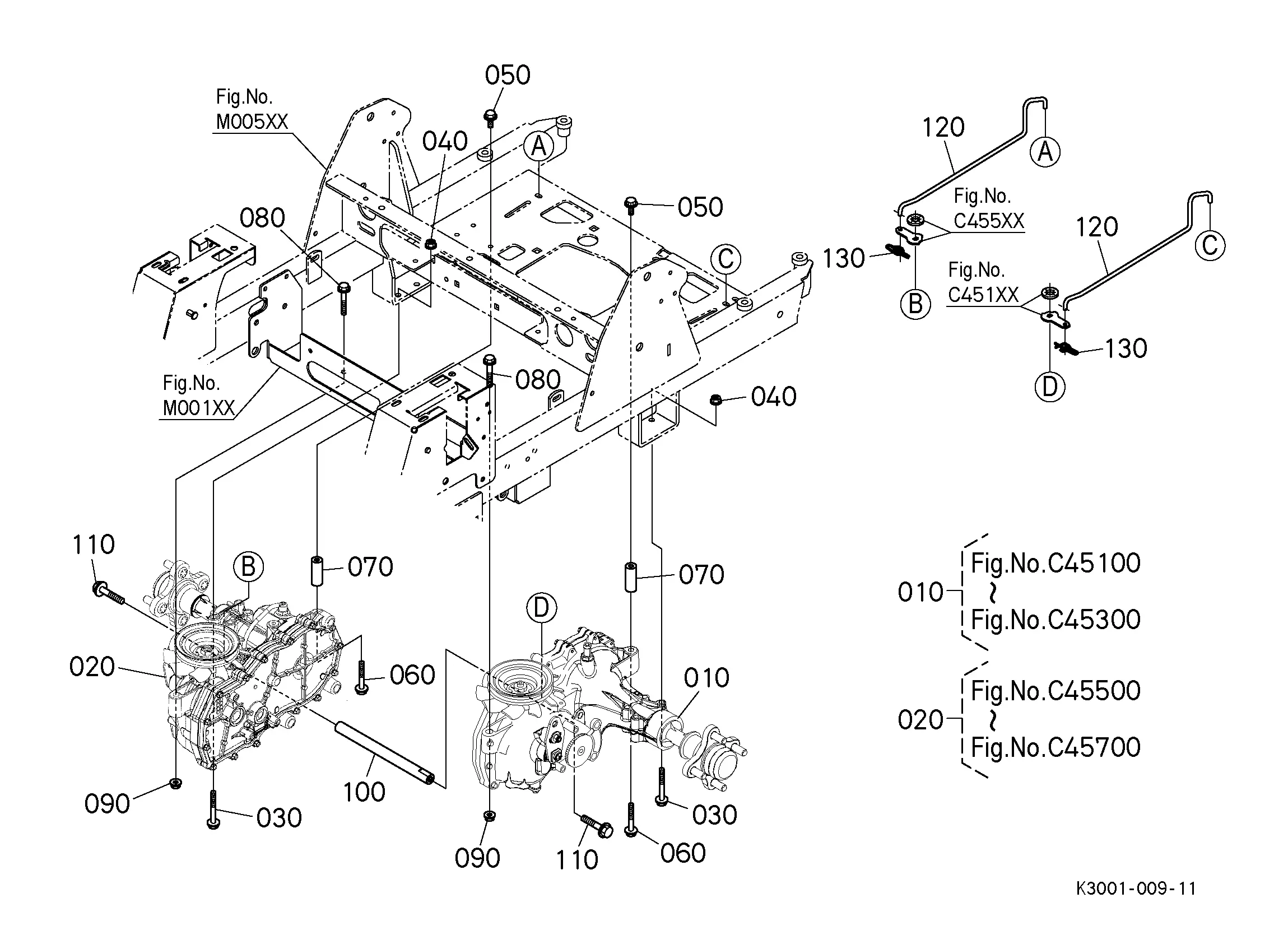

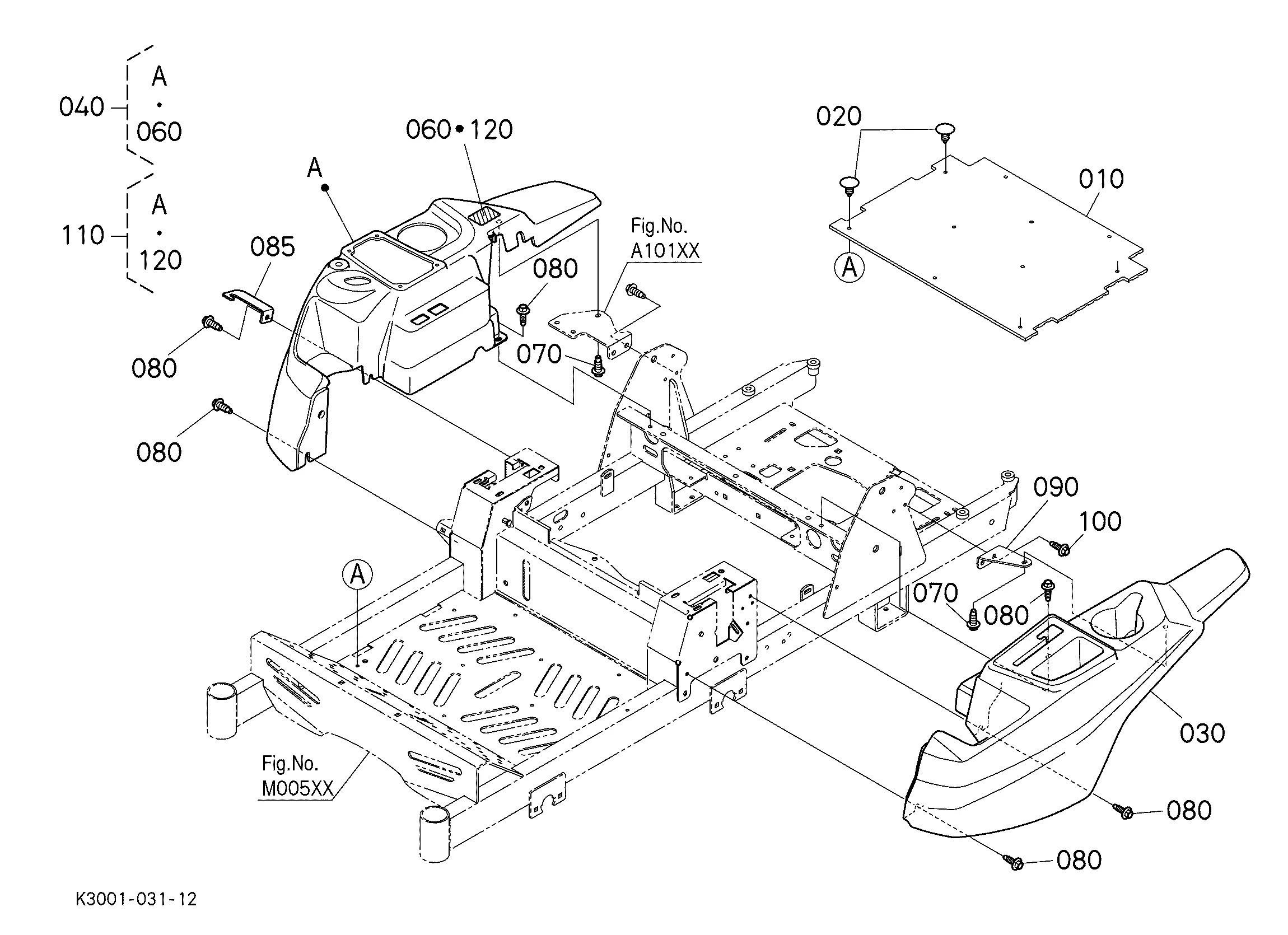

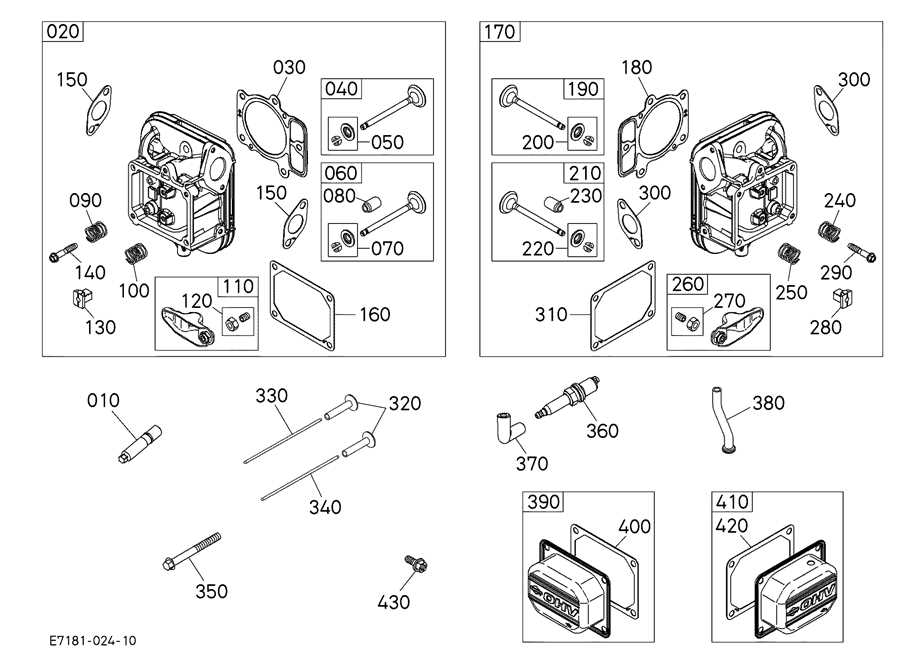

Visual representations of these components provide invaluable insights. They serve as a roadmap, guiding users through the intricate network of parts, while highlighting their interconnections. This clarity can be particularly beneficial when diagnosing issues or planning maintenance schedules.

Whether you are a seasoned technician or a novice user, having access to detailed illustrations can significantly streamline your workflow. By familiarizing yourself with the layout and function of each part, you can make informed decisions and tackle challenges with confidence.

Kubota Z122R Overview

This section provides a comprehensive look at a compact and efficient machine designed for optimal performance in various landscaping tasks. Engineered with user-friendly features, it serves both homeowners and professionals seeking reliability and ease of use.

Performance: The equipment boasts a powerful engine that delivers impressive torque, ensuring smooth operation even in challenging conditions. Its robust design allows for efficient maneuverability, making it ideal for tight spaces.

Comfort: Designed with operator comfort in mind, it includes an ergonomic seat and intuitive controls. This focus on user experience helps reduce fatigue during extended periods of operation, allowing for greater productivity.

Versatility: The model is compatible with a range of attachments, making it suitable for various applications, from mowing to snow removal. This adaptability enhances its utility throughout the seasons.

Maintenance: Regular upkeep is straightforward, thanks to accessible components and a logical layout. This feature ensures that users can easily perform routine checks and repairs, prolonging the machine’s lifespan.

Importance of Parts Diagrams

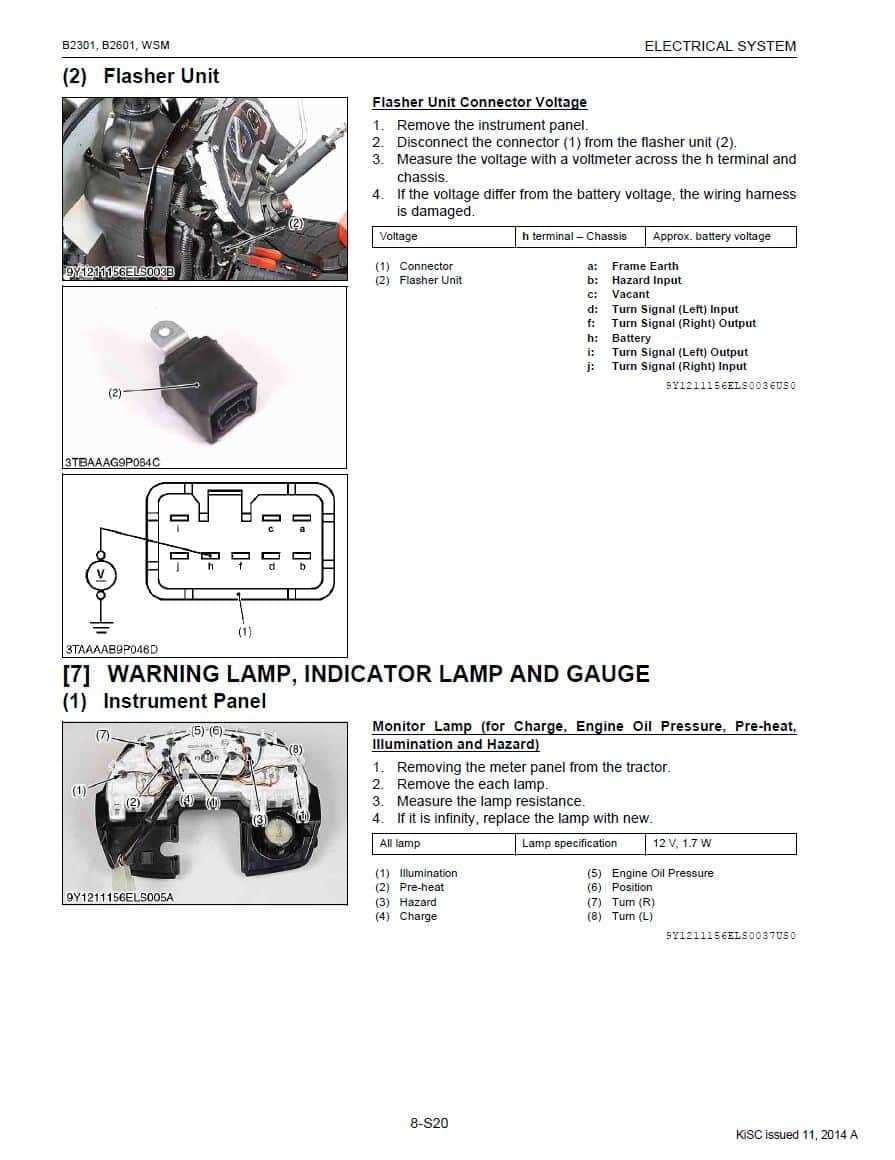

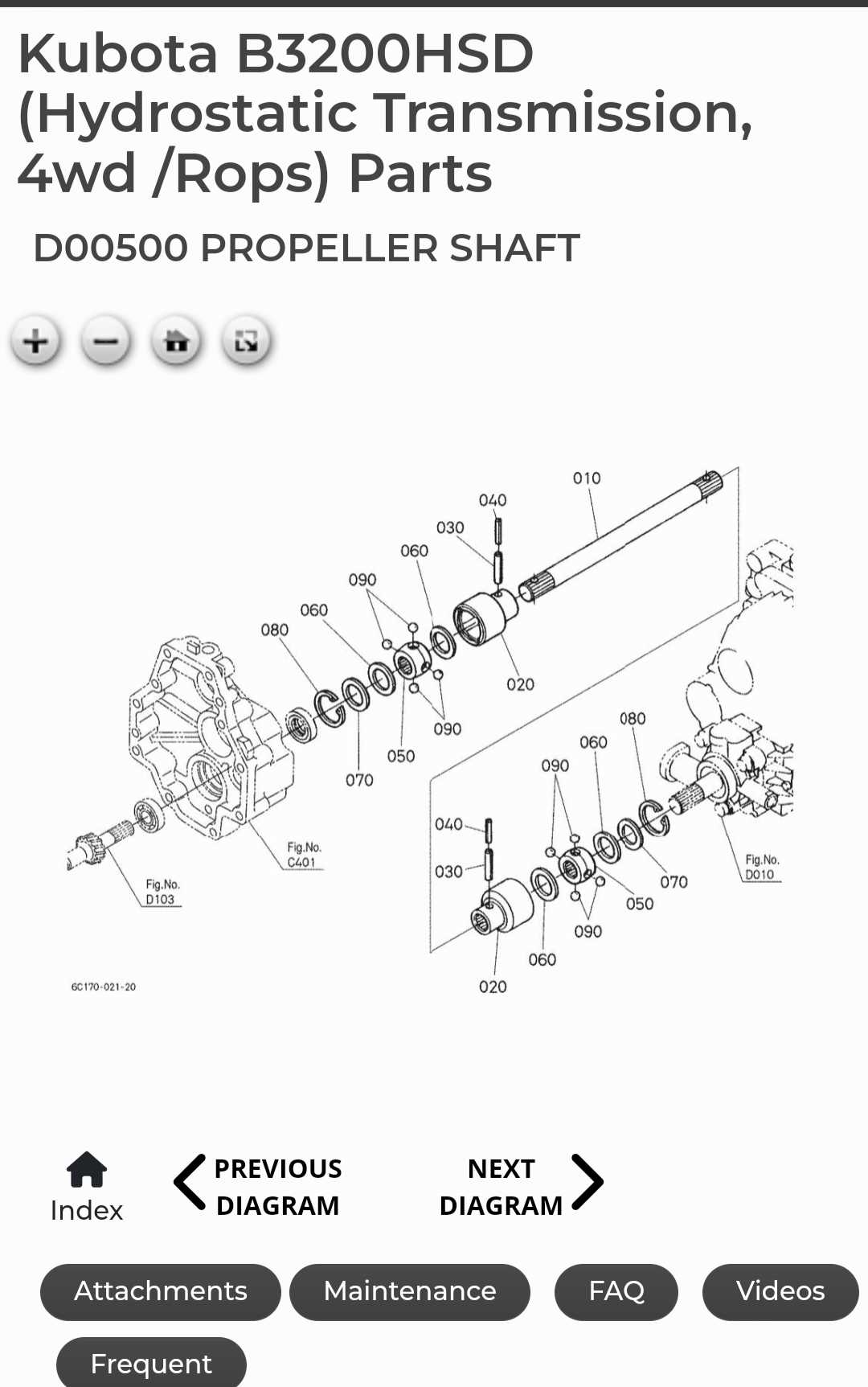

The clarity provided by visual representations of machinery components is invaluable for maintenance and repair tasks. These illustrations serve as a guide, ensuring that users can identify individual elements and their interconnections effectively. By having access to detailed schematics, operators can quickly assess the status of various pieces, making informed decisions about repairs and replacements.

Efficiency is one of the key benefits of these visual aids. When attempting to fix or maintain equipment, understanding the layout of each section streamlines the process, minimizing downtime. Technicians can quickly locate necessary items, reducing the time spent searching for specific components.

Furthermore, accurate identification of parts prevents errors during assembly or disassembly. Misunderstandings can lead to improper fittings or installations, resulting in costly mistakes. Visual guides help eliminate ambiguity, fostering a more systematic approach to repairs.

In addition, these resources can enhance learning and training for new technicians. Familiarity with the layout of machinery components can significantly improve their confidence and competence, ensuring they are well-equipped to handle challenges in the field.

Ultimately, the role of these illustrations extends beyond mere reference; they are essential tools that contribute to the overall effectiveness of maintenance and repair operations. With the right visuals, operators can maintain their equipment in optimal condition, ensuring longevity and reliability.

Common Issues with Z122R

When operating a specific model of mower, users may encounter several recurring problems that can affect performance and efficiency. Understanding these issues can help in maintaining the equipment and ensuring a smooth mowing experience.

Engine Performance

One of the most common concerns relates to engine performance. Users often report symptoms such as stalling or difficulty starting. These issues may stem from fuel-related problems, such as clogged filters or improper fuel mixtures. Regular maintenance, including checking the fuel system and replacing filters, can mitigate these problems.

Cutting Deck Challenges

The cutting deck is another area that may present difficulties. Users might experience uneven cutting or poor discharge of grass clippings. This can be attributed to dull blades or buildup of debris beneath the deck. Ensuring that blades are sharpened and the underside of the deck is cleaned regularly can improve cutting performance.

In summary, being aware of these frequent issues and addressing them promptly can greatly enhance the reliability and effectiveness of the mower.

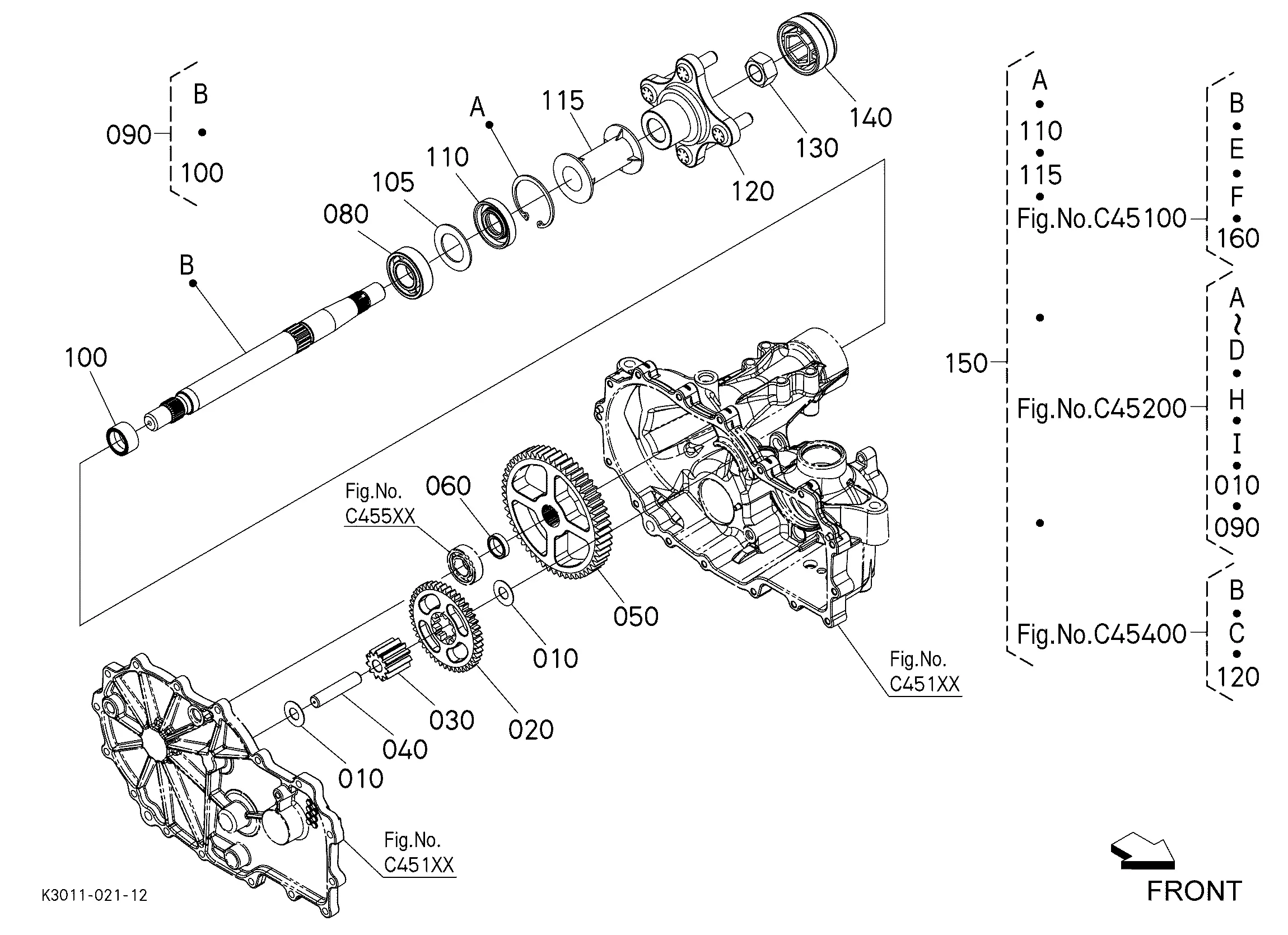

Understanding Component Functionality

In any complex machinery, recognizing how each element contributes to overall performance is essential. This understanding not only aids in maintenance but also enhances operational efficiency.

Each part plays a unique role, and together they ensure seamless functionality. Here are key components and their purposes:

- Engine: The heart of the machine, providing the necessary power.

- Transmission: Facilitates the transfer of power to the wheels, enabling movement.

- Hydraulic System: Powers various attachments and enhances maneuverability.

- Control Panel: Allows the operator to manage functions effectively.

Understanding these functionalities helps in troubleshooting and optimizing performance, ultimately leading to improved longevity and productivity.

Where to Find Replacement Parts

Finding suitable components for your machinery can be crucial for maintaining its efficiency and longevity. Various sources offer a range of options to ensure you can quickly restore your equipment to optimal working condition.

Here are some reliable places to explore:

- Authorized Dealers: These outlets provide genuine components and often have knowledgeable staff to assist with your needs.

- Online Retailers: Websites specializing in equipment supplies often have extensive inventories, making it easy to find what you need.

- Local Repair Shops: Many workshops not only perform repairs but also sell replacement items, which can be convenient.

- Salvage Yards: For those looking for budget-friendly options, salvage yards can be a goldmine for used parts.

- Manufacturer’s Website: Checking the official website can provide direct access to their catalog of available components.

Each of these sources offers unique advantages, so consider your specific requirements and budget when making your selection.

DIY Maintenance Tips for Z122R

Proper upkeep of your outdoor machinery is essential for optimal performance and longevity. Engaging in regular maintenance tasks can prevent costly repairs and ensure that your equipment runs smoothly throughout the seasons. Here are some valuable tips to help you maintain your device effectively.

1. Regular Cleaning: After each use, make it a habit to clean the exterior thoroughly. Remove dirt, grass clippings, and debris that can accumulate and affect performance. A clean machine not only looks better but also operates more efficiently.

2. Check Fluids: Monitor engine oil, fuel, and coolant levels regularly. Ensure that fluids are at the appropriate levels and change them according to the manufacturer’s recommendations. Clean or replace filters as needed to maintain optimal flow and efficiency.

3. Inspect Belts and Cables: Examine all belts and cables for signs of wear, fraying, or damage. Tighten any loose components and replace worn parts promptly to avoid operational issues.

4. Sharpen Blades: Dull blades can lead to uneven cuts and increased strain on the engine. Regularly sharpen or replace blades to maintain cutting efficiency and promote healthy growth in your lawn.

5. Battery Maintenance: Check battery connections and terminals for corrosion. Keep the battery charged and ensure it is securely mounted to prevent movement during operation.

6. Seasonal Storage: Before storing your equipment for an extended period, follow proper winterization procedures. This includes draining fuel, cleaning components, and covering the machine to protect it from the elements.

By following these straightforward maintenance tips, you can extend the life of your machinery and enhance its performance. Regular attention to these details will yield significant benefits in the long run.

Benefits of Using Genuine Parts

Opting for authentic components in machinery maintenance offers numerous advantages that enhance performance and longevity. These high-quality replacements are designed to fit perfectly and function seamlessly with the original equipment, ensuring optimal efficiency and reducing the risk of malfunctions. Using original items can significantly contribute to the overall reliability of your machinery, leading to a smoother operation.

Quality Assurance

Genuine components undergo rigorous testing and quality control processes, which guarantees their durability and performance. Unlike generic alternatives, these items are crafted to meet strict standards, ensuring that they can withstand the demands of everyday use. This quality assurance not only protects your investment but also minimizes the likelihood of unexpected repairs and downtime.

Enhanced Performance

When using authentic replacements, you can expect enhanced performance from your equipment. These parts are specifically engineered to work in harmony with your machinery, optimizing its capabilities. As a result, you’ll experience improved efficiency, better fuel consumption, and a longer lifespan for your equipment. This synergy ultimately translates to lower operating costs and increased productivity.

Upgrading vs. Replacing Components

When it comes to maintaining machinery, the decision between enhancing existing elements and substituting them entirely can significantly impact performance and longevity. Each approach has its merits and potential drawbacks, requiring careful consideration based on specific needs and conditions.

Upgrading components often involves improving their functionality or efficiency without the need for complete replacement. This can lead to enhanced performance, better fuel efficiency, and increased reliability. For example, adding modern technology to an existing system might yield substantial benefits while minimizing downtime and costs associated with complete overhauls.

On the other hand, replacing components can sometimes be the most effective solution, particularly when dealing with outdated or severely worn parts. This approach guarantees that all new parts will work seamlessly together, reducing the risk of future complications. However, it typically entails higher initial costs and may require more time for installation and adjustment.

Ultimately, the choice between upgrading and replacing hinges on various factors, including budget constraints, the age of the machinery, and long-term operational goals. Careful assessment of both options can lead to a more strategic decision that maximizes efficiency and minimizes disruption.