The efficiency and functionality of your frozen beverage appliance rely on its various components working seamlessly together. To ensure optimal performance, it’s essential to familiarize yourself with the internal mechanisms that contribute to its operation. This knowledge empowers you to troubleshoot issues and maintain your unit effectively.

In this guide, we will explore the essential elements that form the backbone of your unit. By understanding how each component interacts with others, you can enhance the longevity and efficiency of your appliance. This exploration will also provide insights into potential upgrades or replacements when necessary.

Whether you’re a seasoned user or new to the world of frozen beverage machines, grasping the layout and function of these key elements will elevate your experience. Engaging with this information will not only streamline maintenance tasks but also deepen your appreciation for the technology behind your favorite refreshing creations.

Understanding Ge Opal Ice Maker Functionality

This section explores the essential operations of a well-known appliance designed for producing frozen water in a convenient manner. Understanding how this device works can enhance its efficiency and extend its lifespan, ensuring optimal performance for various needs.

Core Components

The primary elements of this appliance include a refrigeration unit, water reservoir, and control system. Each component plays a vital role in ensuring that the device operates smoothly, contributing to the ultimate goal of providing consistently frozen shapes.

Operational Mechanism

Initially, water fills the reservoir, where it is chilled through a cooling process. Once the optimal temperature is reached, the liquid transforms into solid form. This entire cycle is carefully managed by the internal controls, allowing users to enjoy refreshing cubes without hassle.

Essential Components of Ice Makers

The functionality of a freezing appliance relies on several crucial elements that work together seamlessly to produce frozen cubes. Understanding these key components enhances appreciation for the appliance’s efficiency and performance.

Refrigeration System: This core unit is responsible for lowering temperatures, enabling the formation of solidified water. It typically includes a compressor, condenser, and evaporator, each playing a vital role in the refrigeration cycle.

Water Supply: A consistent and clean source of liquid is essential for operation. This may involve a direct line connection or a reservoir that fills automatically, ensuring the appliance has adequate resources to function.

Control Mechanism: This system governs the entire process, regulating temperature and timing to optimize production. It can range from simple mechanical timers to sophisticated electronic sensors that monitor conditions in real time.

Heating Element: To facilitate the release of solidified cubes, a heating element may be employed. This component warms the surface slightly, easing the transition from frozen to free state.

Storage Bin: This is where the final product accumulates, allowing easy access and ensuring that the frozen goods remain at a safe temperature until needed.

Each of these elements plays an integral role, and a comprehensive understanding of their functions can lead to improved maintenance and longevity of the appliance.

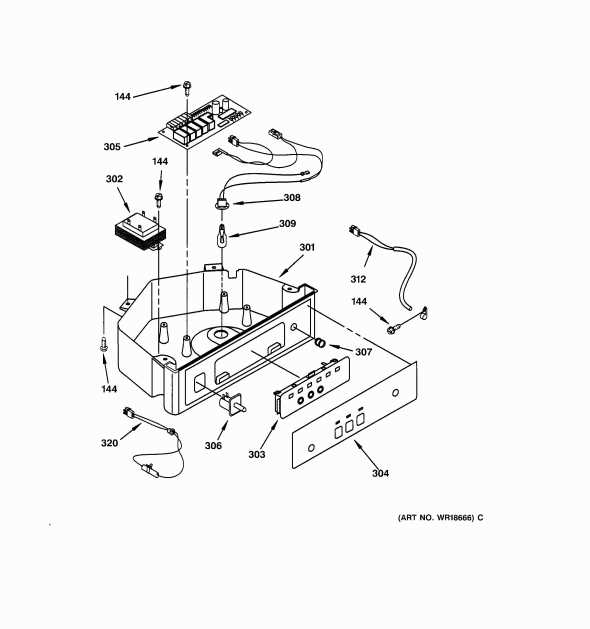

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, guiding users through the intricate details of assembly and function. By familiarizing oneself with the structure and labeling within these visuals, anyone can enhance their ability to identify and address issues.

Interpreting Symbols and Labels

Every illustration contains unique symbols and annotations that denote various elements. Familiarity with these markings is crucial. Often, each component is accompanied by a label that provides essential information, such as part numbers and descriptions. Paying close attention to these details can save time and prevent confusion when sourcing replacements.

Understanding Relationships Between Components

Visual guides also highlight the relationships and connections among different parts. Recognizing how each piece interacts with others is vital for a comprehensive understanding. Look for lines or arrows that indicate assembly order or flow of function; this insight can greatly assist in troubleshooting and reassembly.

Common Issues with Ice Makers

Many individuals encounter various challenges when it comes to producing frozen cubes for beverages. Understanding these frequent problems can help users troubleshoot and maintain their appliances effectively.

Frequent Challenges

- Insufficient production: When the appliance fails to generate a satisfactory quantity of frozen cubes, it may indicate underlying issues.

- Unusual noises: Odd sounds during operation can suggest mechanical faults or misalignment within the unit.

- Water leakage: Accumulation of moisture around the appliance may result from faulty seals or blockages.

- Temperature fluctuations: Inconsistent coldness can affect the quality and formation of cubes.

Potential Causes

- Clogged filters: Dirty or blocked filters can hinder water flow and affect freezing efficiency.

- Electrical issues: Power supply disruptions or faulty wiring may lead to performance problems.

- Incorrect settings: Improper adjustments can significantly impact the functioning of the unit.

- Wear and tear: Over time, components may degrade, leading to operational failures.

Identifying Replacement Parts Easily

Finding the correct components for your appliance can often feel overwhelming. However, understanding how to navigate through the options and identify what you need can simplify the process significantly. This section will guide you through effective strategies to locate and recognize the necessary elements without unnecessary frustration.

Key Strategies for Identification

- Familiarize yourself with the appliance’s model number.

- Utilize manufacturer resources, such as manuals or online databases.

- Join user forums or groups to share insights and experiences.

Visual Aids and Resources

Utilizing visual tools can greatly enhance your ability to pinpoint the right components:

- Reference schematics provided by manufacturers.

- Watch tutorial videos that demonstrate assembly and disassembly.

- Consult online retailers that offer detailed images and descriptions.

By implementing these strategies, you can streamline the identification process, ensuring you acquire the right elements for your needs efficiently.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your appliance requires consistent care and attention. By adopting a few simple practices, you can extend its lifespan significantly and maintain optimal performance.

Regular cleaning is essential. Accumulated debris can lead to decreased efficiency and potential malfunctions. Make it a habit to wipe down surfaces and remove any buildup to keep the unit operating smoothly.

Monitoring water quality is crucial as well. Impurities can affect functionality, so using filtered water may help in preserving the internal components. Additionally, changing the water source periodically can prevent mineral deposits.

Check for any signs of wear and tear on moving elements. Addressing minor issues promptly can prevent them from developing into major problems. Regular inspections can save time and money in the long run.

Finally, ensure proper placement of the device. Keeping it in a well-ventilated area, away from direct sunlight or heat sources, can significantly impact its efficiency and overall longevity. By following these straightforward guidelines, you can enjoy your appliance for years to come.

Upgrading Your Ice Maker Model

Enhancing your appliance can lead to improved performance and efficiency, providing a more satisfying experience in your kitchen. As technology advances, newer models often come equipped with features that make them more reliable and user-friendly. Whether you’re seeking increased production capacity, energy efficiency, or additional functionalities, considering an upgrade can significantly benefit your daily routine.

Before making a decision, it’s essential to assess your current needs and usage patterns. Understanding how often you require frozen creations can help you choose a model that aligns perfectly with your lifestyle. Additionally, exploring different brands and their unique offerings can uncover innovative solutions that were previously unavailable.

When transitioning to a new unit, consider compatibility with existing setups. Ensure that the installation process is straightforward and that any necessary adjustments are manageable. With the right choice, you can enjoy the advantages of a more advanced unit while minimizing any disruption to your culinary activities.

Ultimately, upgrading your appliance not only enhances functionality but also adds a touch of modernity to your kitchen. Investing in a higher-quality model can lead to long-term satisfaction and convenience, making it a worthwhile consideration for any home cook or entertainer.

Where to Buy Quality Parts

Finding high-quality components for your appliance can significantly enhance its performance and longevity. With numerous options available, it’s essential to know where to source reliable replacements that ensure your unit operates smoothly.

Here are some recommended places to consider:

- Authorized Retailers: These vendors often provide genuine components, ensuring compatibility and reliability.

- Online Marketplaces: Websites like Amazon and eBay offer a wide variety of options, often with user reviews to help guide your decision.

- Specialty Stores: Local shops focusing on home appliances may carry specific components tailored for various models.

- Manufacturer’s Website: Direct purchases from the official website can guarantee authenticity and often provide customer support.

When selecting a source, consider factors such as warranty, customer service, and shipping options to ensure a hassle-free experience.

By taking the time to choose the right suppliers, you can maintain the efficiency and reliability of your equipment.