Efficient crop planting requires precision and reliability, which are achieved through the careful design and engineering of essential agricultural equipment. This machinery is composed of several interconnected elements, each playing a vital role in ensuring optimal performance during the planting process. Familiarity with these components is crucial for operators to maintain, troubleshoot, and maximize the output of their farming equipment.

Identifying the various sections of the machine helps to better understand how each part contributes to the overall functionality. Properly configured and well-maintained, these elements work in harmony to facilitate the smooth distribution of seeds across the field, ensuring even growth and minimal waste. Understanding their layout and function provides insights into the mechanics of planting systems.

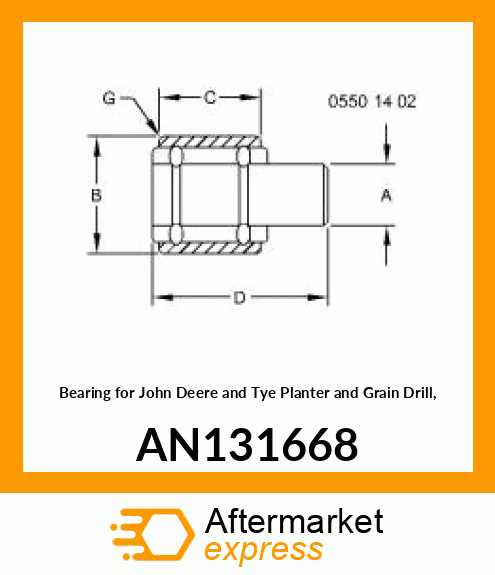

Detailed technical diagrams offer a visual representation of these components, allowing operators to identify specific areas of interest or concern. Such diagrams serve as invaluable tools for anyone seeking to optimize their use of the machinery, ensuring that each part operates as intended for maximum efficiency in the field.

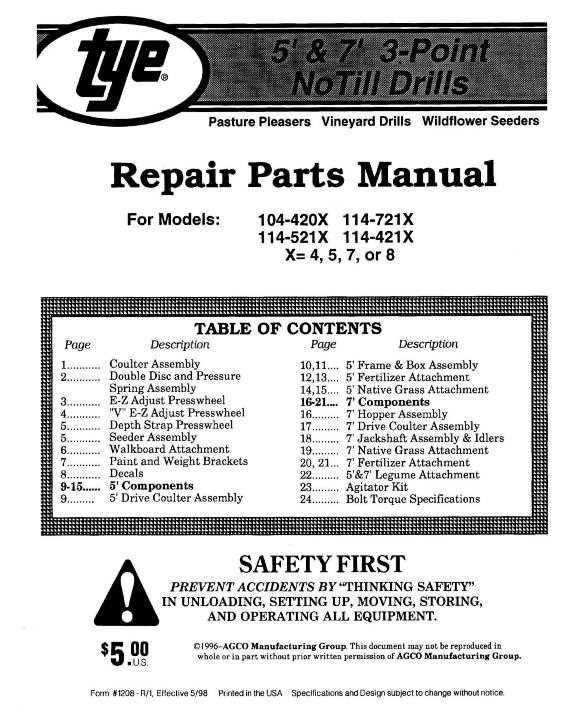

Tye Grain Drill Overview

This section provides a comprehensive insight into a specific agricultural implement designed for efficient sowing. With a focus on precision and functionality, this tool plays a crucial role in enhancing crop establishment. It combines advanced engineering with user-friendly features, making it an essential asset for modern farming practices.

Key Features

Designed for versatility, this implement offers adjustable settings to accommodate various seed types and soil conditions. Its robust construction ensures durability, while innovative mechanisms facilitate even distribution and depth control. Additionally, ease of operation and maintenance contributes to its popularity among farmers seeking efficiency and reliability in their agricultural tasks.

Applications in Agriculture

Utilized across diverse farming scenarios, this implement supports a wide range of crops, from cereals to legumes. Its design enables effective sowing in both small and large-scale operations, promoting optimal growth conditions. By ensuring precise seed placement, it significantly impacts yield potential and resource management, underscoring its importance in contemporary agriculture.

Essential Components of a Grain Drill

Understanding the fundamental elements of a seeding apparatus is crucial for effective planting. Each component plays a specific role in ensuring optimal performance and successful crop establishment.

Key Features

Several vital features contribute to the efficiency of the equipment. They include mechanisms for precise seed placement, depth adjustment, and soil engagement, all of which enhance the overall planting process.

Technical Specifications

| Component | Function |

|---|---|

| Seed Box | Holds and distributes seeds uniformly. |

| Openers | Creates furrows in the soil for seed placement. |

| Press Wheels | Firmly covers seeds and aids in soil contact. |

| Frame | Provides structural integrity and support. |

| Adjustable Depth Control | Ensures seeds are planted at the optimal depth. |

Understanding the Seed Metering System

The seed metering system plays a crucial role in the precision planting process, ensuring that seeds are distributed uniformly across the field. This mechanism is designed to control the flow of seeds, optimizing the planting efficiency and promoting healthy crop development.

Components of the Metering System

- Seed hopper: Stores the seeds prior to planting.

- Metering plate: Regulates the amount of seed dispensed.

- Drive mechanism: Powers the metering process, often linked to the main equipment.

- Delivery system: Transports seeds from the metering unit to the soil.

How It Functions

- The seed hopper fills with seeds, ready for distribution.

- As the equipment moves, the drive mechanism activates the metering plate.

- Seeds are metered out in a controlled manner, ensuring accurate spacing.

- The delivery system places the seeds in the soil at the correct depth.

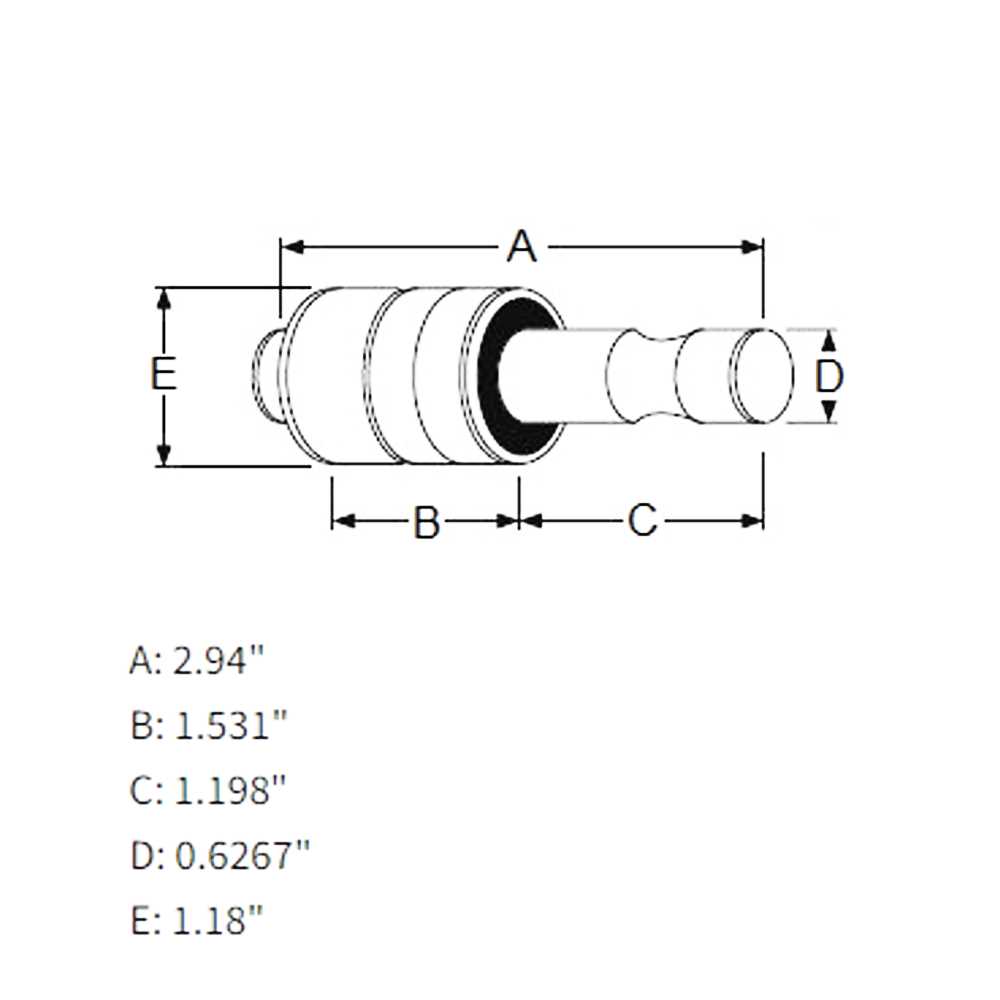

How the Seed Tube Mechanism Works

The seed tube mechanism is a crucial component in modern planting equipment, facilitating the precise delivery of seeds into the soil. This system is designed to ensure that each seed is placed at the correct depth and spacing, optimizing growth conditions and enhancing crop yields. Understanding its operation reveals the intricacies involved in the planting process and highlights the engineering that contributes to agricultural efficiency.

Mechanics of Seed Delivery

At the heart of this system is a series of tubes that guide seeds from the hopper to the soil. As the machinery moves forward, gravity assists in the downward flow of seeds through the tubes. Each seed encounters a controlled release mechanism that regulates the number of seeds dispensed. This precision is vital, as it minimizes waste and maximizes the chances of successful germination.

Importance of Proper Alignment

Proper alignment of the seed tubes with the planting surface is essential for achieving uniform planting depth. Many advanced models incorporate adjustable components that allow for easy modifications based on soil conditions. This adaptability ensures that seeds are placed in optimal conditions, promoting healthy plant development and overall productivity.

Maintenance Tips for Drill Parts

Regular upkeep of agricultural equipment is essential for ensuring optimal performance and longevity. By following a few straightforward guidelines, operators can enhance the functionality of their machinery and minimize the risk of breakdowns.

1. Clean After Use: It is crucial to remove any debris or residue after each session. Accumulated dirt can cause wear and affect precision. Utilize a brush or compressed air for thorough cleaning.

2. Lubricate Moving Components: Keeping mechanical elements well-lubricated reduces friction and wear. Use appropriate lubricants as specified in the manufacturer’s guidelines, and apply them regularly to maintain smooth operation.

3. Inspect for Wear: Periodically check all components for signs of wear and tear. Look for cracks, bends, or unusual wear patterns. Early detection can prevent costly repairs and ensure safe operation.

4. Replace Damaged Parts: If any component shows significant damage, replace it immediately. Continuing to use worn or broken pieces can lead to further issues and decreased efficiency.

5. Store Properly: When not in use, store equipment in a dry, protected area. Covering machinery helps prevent rust and deterioration from environmental factors.

6. Follow Manufacturer’s Guidelines: Always refer to the manufacturer’s maintenance schedule and recommendations. Adhering to these guidelines ensures that the equipment operates as intended and retains its value over time.

Implementing these maintenance strategies will not only extend the life of your machinery but also enhance its performance, providing reliable service season after season.

Common Issues with Grain Drill Parts

Understanding the typical challenges associated with seeding equipment is crucial for maintaining optimal performance. Various components can encounter problems that affect functionality and efficiency, leading to delays in planting and potential crop yield losses.

Wear and Tear: Over time, components can degrade due to constant use and exposure to harsh conditions. This wear can lead to misalignment and ineffective operation, resulting in uneven seed distribution.

Clogging: Debris accumulation in the delivery mechanisms is a frequent issue. When residue builds up, it can obstruct the flow of seeds, causing inconsistent planting and requiring frequent maintenance.

Calibration Problems: Accurate settings are essential for proper seed placement. If the equipment is not calibrated correctly, it may result in either over-seeding or under-seeding, which can adversely affect crop growth.

Hydraulic Failures: Many modern systems rely on hydraulics for operation. Issues such as leaks or pressure drops can hinder the effectiveness of the equipment, requiring prompt repairs to restore functionality.

Component Compatibility: Using parts that are not designed for specific models can lead to significant operational issues. Ensuring compatibility is key to maintaining performance and avoiding breakdowns.

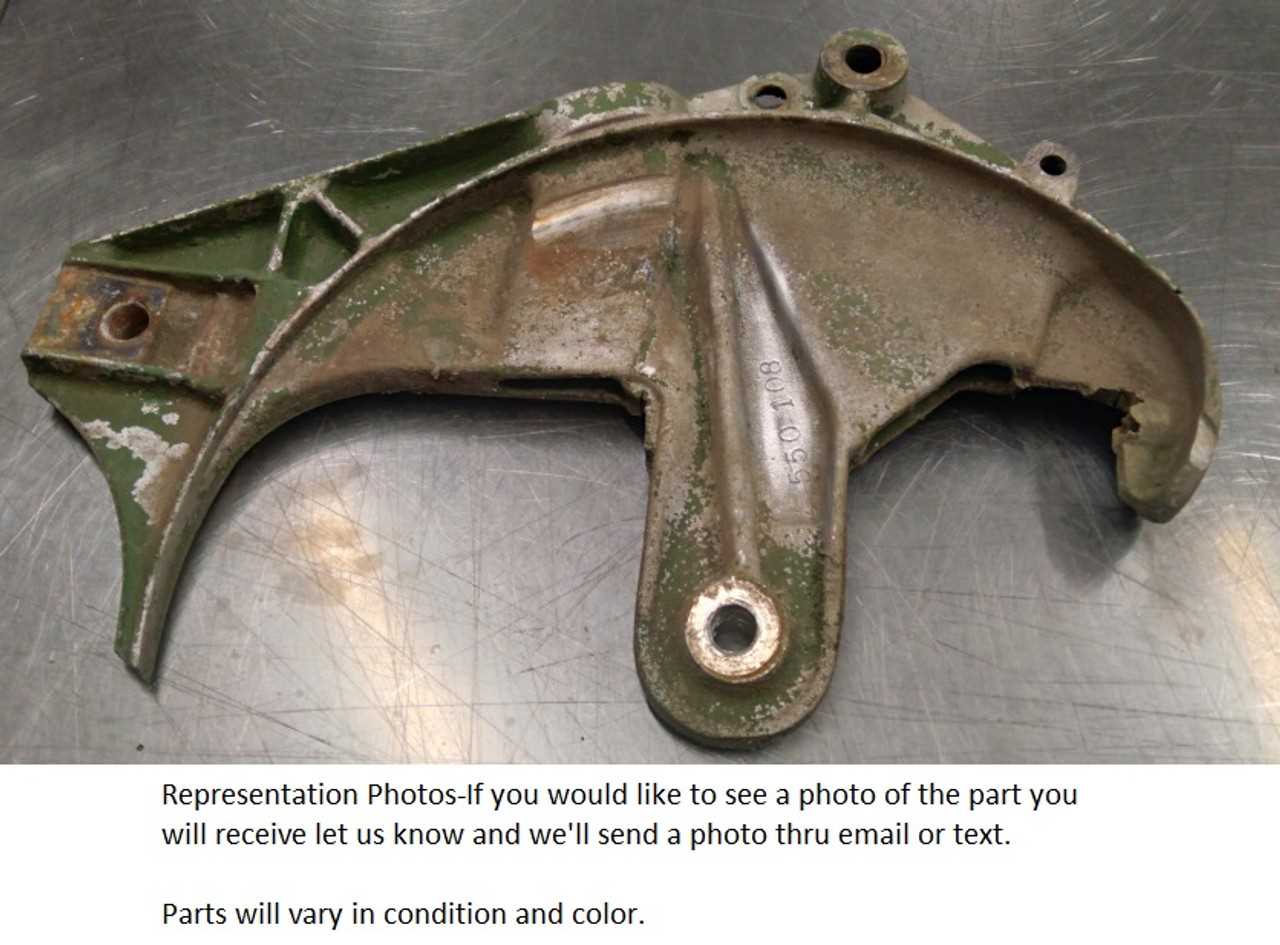

Replacing Worn-Out Tye Drill Parts

Maintaining agricultural equipment in optimal condition is crucial for efficiency and productivity. Over time, certain components can become worn and may need to be replaced to ensure smooth operation. Identifying these components and understanding how to effectively replace them can save time and money while enhancing performance.

Identifying Worn Components

Recognizing signs of wear is the first step in the replacement process. Common indicators include:

- Visible damage or cracks

- Increased friction or noise during operation

- Inconsistent performance or uneven results

- Frequent breakdowns or malfunctions

Replacement Process

Once worn components are identified, follow these steps for a successful replacement:

- Gather necessary tools and replacement items.

- Disconnect the equipment from power sources for safety.

- Carefully remove the damaged component following the manufacturer’s instructions.

- Install the new component, ensuring proper alignment and secure fastening.

- Reconnect power and perform a test run to verify functionality.

Regular inspections and timely replacements not only prolong the life of your machinery but also ensure optimal agricultural practices.

Adjusting Seed Depth and Row Spacing

Proper calibration of planting depth and spacing is crucial for optimal crop development. Achieving the right settings ensures that seeds receive adequate moisture, nutrients, and sunlight, ultimately enhancing growth and yield. This section outlines essential factors and adjustments to consider for effective planting.

When modifying the depth at which seeds are placed in the soil, several aspects come into play. Soil type, moisture levels, and the specific crop requirements are vital for determining the ideal depth. Adjustments should be made carefully to avoid issues such as poor germination or overcrowding.

Row spacing also plays a significant role in crop health. Sufficient space between rows allows for better air circulation and access to sunlight, which are both essential for growth. Additionally, the right spacing can minimize competition among plants for resources.

| Factor | Recommended Adjustment |

|---|---|

| Soil Type | 1-2 inches for sandy soils, 2-3 inches for clay |

| Moisture Level | Adjust deeper in dry conditions |

| Crop Type | Varies; consult specific guidelines |

| Row Width | 12-36 inches depending on crop |

By regularly monitoring and adjusting these parameters, growers can significantly improve planting success and enhance overall crop performance.

Improving Efficiency with Grain Drill Upgrades

Enhancing operational effectiveness in agricultural equipment can significantly impact productivity and resource management. By implementing specific enhancements, farmers can optimize their machines for better performance, reducing time and input costs while increasing yield potential.

Key Areas for Enhancement

- Precision Technology: Incorporating advanced technology such as GPS and variable rate application can ensure accurate placement of seeds, resulting in optimal growth conditions.

- Upgraded Components: Replacing outdated elements with high-quality alternatives can improve durability and functionality, reducing downtime and maintenance costs.

- Enhanced Soil Penetration: Modifying the implements to improve soil interaction can enhance seed-to-soil contact, crucial for germination and growth.

Benefits of Upgrading

- Increased Yield: Enhanced technology and components lead to better seed placement and soil interaction.

- Cost Efficiency: Reducing input waste and improving operational speed lowers overall expenses.

- Sustainability: Optimized equipment reduces environmental impact by minimizing resource usage.