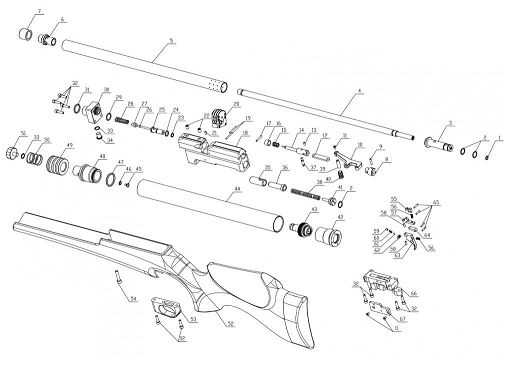

Exploring the intricacies of a firearm reveals a fascinating interplay of mechanics and design. Each element plays a crucial role in ensuring functionality and safety, contributing to the overall performance of the weapon. Grasping the relationship between these individual elements provides insight into the engineering marvels that have shaped modern weaponry.

The layout of the various sections showcases the ingenuity involved in their arrangement. From the trigger mechanism to the barrel assembly, every segment is meticulously crafted to meet specific operational standards. Understanding these components not only enhances one’s appreciation of the tool but also aids in proper maintenance and usage.

Moreover, familiarizing oneself with the structure can significantly improve proficiency. By recognizing how each piece interacts within the system, users can better anticipate the behavior of the firearm during operation. This knowledge ultimately fosters a safer and more effective experience, whether for sport, training, or defense.

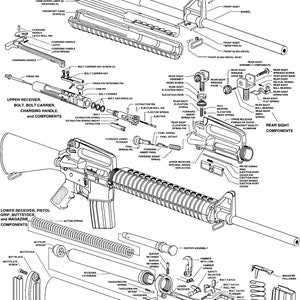

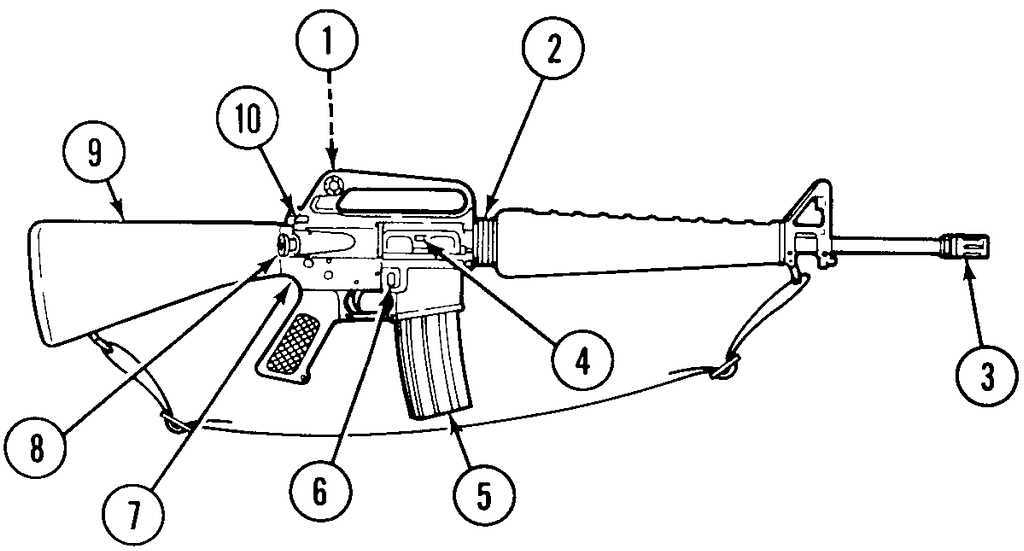

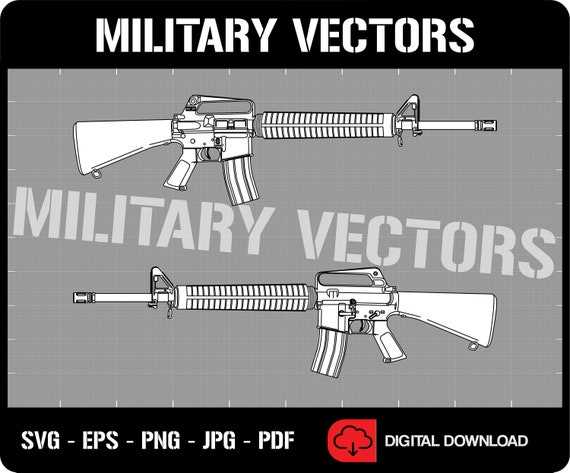

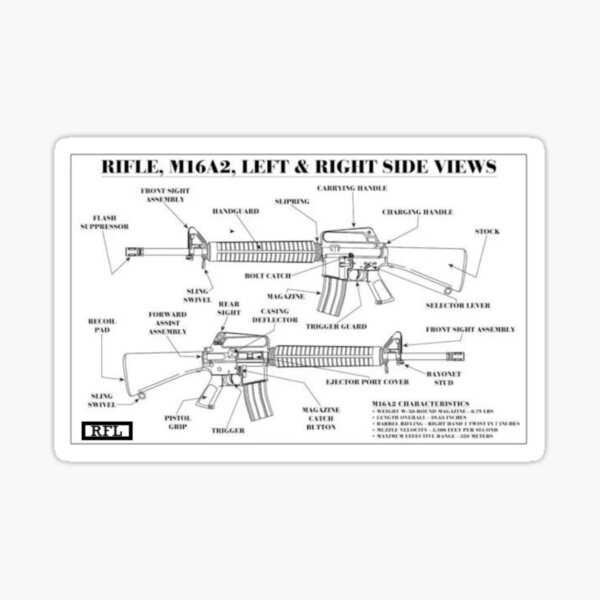

Understanding the M16 Diagram

This section delves into the intricate structure of a widely recognized firearm, providing insights into its essential components and their functions. A comprehensive understanding of these elements is crucial for both enthusiasts and users, as it enhances knowledge about the operation and maintenance of this weapon system.

Key Components and Their Functions

The assembly of this firearm includes several vital elements, each serving a specific role in its overall functionality. The core mechanism relies on an array of interconnected units that work harmoniously to ensure reliable performance. Familiarity with these components allows users to troubleshoot issues effectively and optimize the weapon’s capabilities.

Importance of Knowledge

Acquiring knowledge about the assembly not only boosts operational efficiency but also fosters a sense of responsibility among users. Understanding how each unit interacts contributes to a safer experience and enhances the appreciation for engineering precision. Moreover, it enables users to make informed decisions regarding upgrades and modifications.

Key Components of the M16 Rifle

This section delves into the essential elements that constitute a renowned firearm. Understanding these crucial components is fundamental for appreciating the functionality and effectiveness of this weapon. Each segment plays a vital role in ensuring reliability, accuracy, and ease of use, making the firearm a preferred choice among various users.

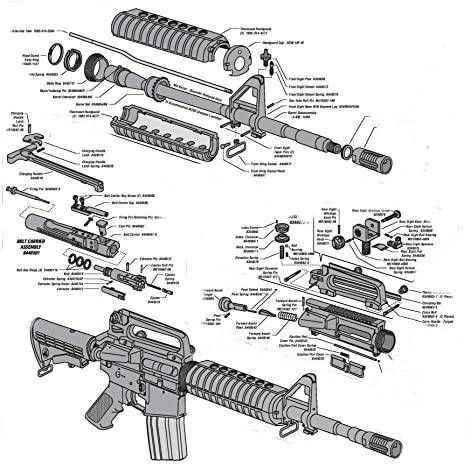

Upper Receiver

The upper receiver is a pivotal section that houses several critical mechanisms. It includes the barrel, bolt carrier group, and gas system, all of which collaborate to facilitate the firing process. This assembly is designed for seamless operation and precision, significantly impacting the overall performance of the weapon.

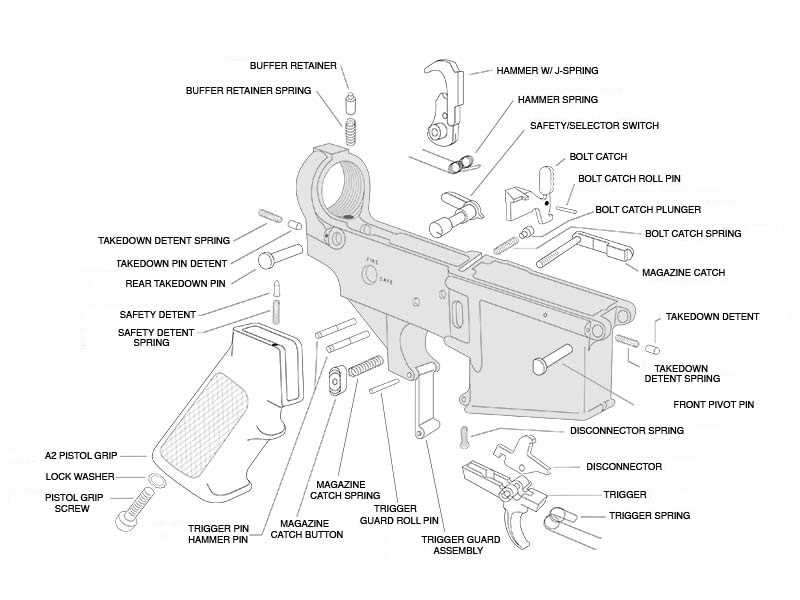

Lower Receiver

The lower receiver serves as the foundation of the firearm, containing the trigger assembly and magazine well. It is integral to the weapon’s control and handling, allowing the shooter to engage effectively. This section’s design ensures that the user can operate the firearm with confidence and ease, contributing to its popularity in various applications.

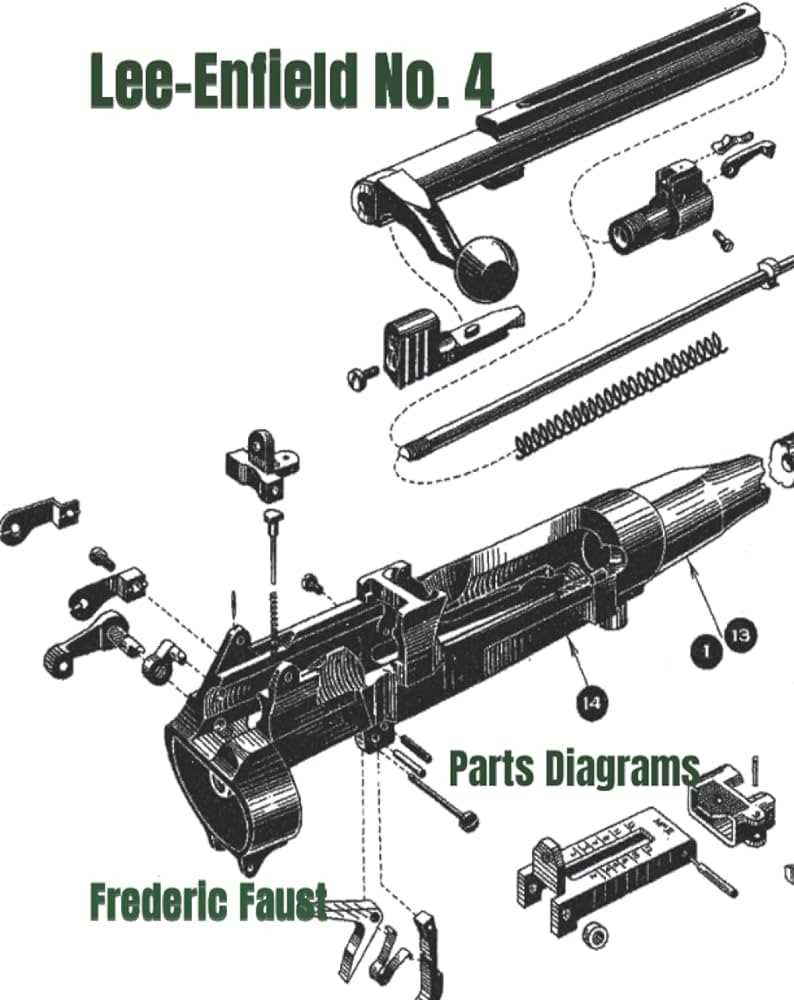

Functionality of Each Part

Understanding the roles of various components in a firearm is essential for comprehending its overall operation. Each element plays a critical function that contributes to the weapon’s effectiveness, reliability, and user experience. A thorough exploration of these components reveals the intricate design and engineering that allow for precision and efficiency in performance.

| Component | Function |

|---|---|

| Receiver | Serves as the core structure that houses and connects various elements, allowing for seamless interaction during operation. |

| Barrel | Directs the projectile’s path and provides stability, significantly influencing accuracy and range. |

| Bolt Carrier Group | Facilitates the loading, firing, and ejection of cartridges, ensuring smooth cycling of the action. |

| Trigger Mechanism | Acts as the interface between the user and the firearm, allowing for controlled discharge through careful manipulation. |

| Stock | Provides stability and support for the shooter, aiding in aiming and recoil management during firing. |

| Sight System | Enhances targeting accuracy by allowing the shooter to align the weapon with the intended point of impact. |

Assembly and Disassembly Guide

This section provides a comprehensive overview of the processes involved in the assembly and disassembly of a specific firearm. Understanding these procedures is essential for proper maintenance, ensuring optimal functionality, and enhancing overall performance. This guide aims to equip users with the necessary knowledge and techniques for safely and effectively handling the components of their weapon.

Disassembly Steps:

Begin by ensuring the weapon is unloaded and pointed in a safe direction. Remove the magazine and visually inspect the chamber. Next, follow the sequence of steps to detach the various components, such as the upper and lower receivers, bolt carrier group, and other integral elements. Each piece should be handled with care, avoiding any undue force that could lead to damage.

Assembly Steps:

To reassemble, start with the lower receiver and attach the necessary components in the correct order. Ensure all parts are properly aligned and secured, paying close attention to any pins or screws that may require tightening. After reassembling, conduct a thorough inspection to confirm that everything is functioning as intended before performing a test operation.

Note: Regular maintenance and familiarization with these procedures are crucial for any firearm owner. Proper care will extend the lifespan of the weapon and enhance its reliability.

Maintenance Tips for M16 Parts

Proper upkeep of your firearm’s components is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances reliability but also helps prevent malfunctions during use. This section provides essential guidelines to keep your weapon in excellent condition.

Regular Cleaning

Routine cleaning is vital for the longevity of your equipment. After each use, disassemble the mechanism and clean each element thoroughly. Use a suitable solvent to remove carbon buildup and debris, ensuring that all surfaces are free of residue. Pay special attention to the gas system and firing mechanism, as these areas are prone to buildup that can affect functionality.

Lubrication and Inspection

Appropriate lubrication minimizes friction and wear on moving elements. Use high-quality oils or greases designed for firearms to maintain smooth operation. Additionally, conduct regular inspections to identify any signs of wear or damage. Replace any worn-out components promptly to avoid potential failures in critical situations.

Common Issues and Solutions

In any mechanical system, a variety of challenges may arise, impacting performance and reliability. Identifying these issues is crucial for maintaining efficiency and ensuring the longevity of the equipment. This section addresses prevalent concerns encountered by users, along with practical solutions to mitigate these problems.

Issue 1: Misalignment can lead to improper functioning, resulting in decreased accuracy and increased wear. Solution: Regularly inspect and adjust components to ensure they are correctly aligned, using appropriate tools to facilitate precise adjustments.

Issue 2: Jamming is a common problem that can occur due to debris or malfunctioning mechanisms. Solution: Perform routine cleaning and maintenance to remove any obstructions, and consider replacing worn parts that may contribute to this issue.

Issue 3: Reduced Efficiency can stem from a variety of factors, including lack of lubrication or component degradation. Solution: Establish a consistent maintenance schedule that includes lubrication and inspections to detect and address wear before it escalates into significant issues.

Issue 4: Inconsistent Performance may be caused by varying external conditions or internal inconsistencies. Solution: Monitor environmental factors and implement adjustments as needed to ensure optimal performance under different conditions.

By proactively addressing these common challenges, users can enhance the functionality and reliability of their equipment, ensuring it operates at peak performance for years to come.

Comparison with Other Rifles

When examining different models of firearms, it’s essential to understand their unique characteristics and how they stand in relation to each other. This analysis highlights the distinctions and similarities in design, functionality, and performance, providing a clearer picture of what each weapon offers to its users.

One notable feature that sets this firearm apart is its gas-operated system, which enhances reliability and reduces recoil compared to traditional bolt-action designs. In contrast, other popular automatic weapons may prioritize different mechanisms, such as direct impingement, leading to variations in handling and maintenance. These differences can significantly affect the shooter’s experience and effectiveness in various scenarios.

Additionally, the versatility of attachments and modifications available for this firearm often exceeds those offered by its competitors. While some models may limit customization options, this particular design supports a wide range of accessories, allowing users to tailor their weapon to specific needs and preferences. This adaptability is crucial for modern tactical applications.

Finally, the choice of caliber plays a pivotal role in the overall performance and suitability for various missions. While some firearms excel in long-range accuracy, others focus on rapid fire and maneuverability. Understanding these differences can help potential users make informed decisions based on their intended use and operational environment.

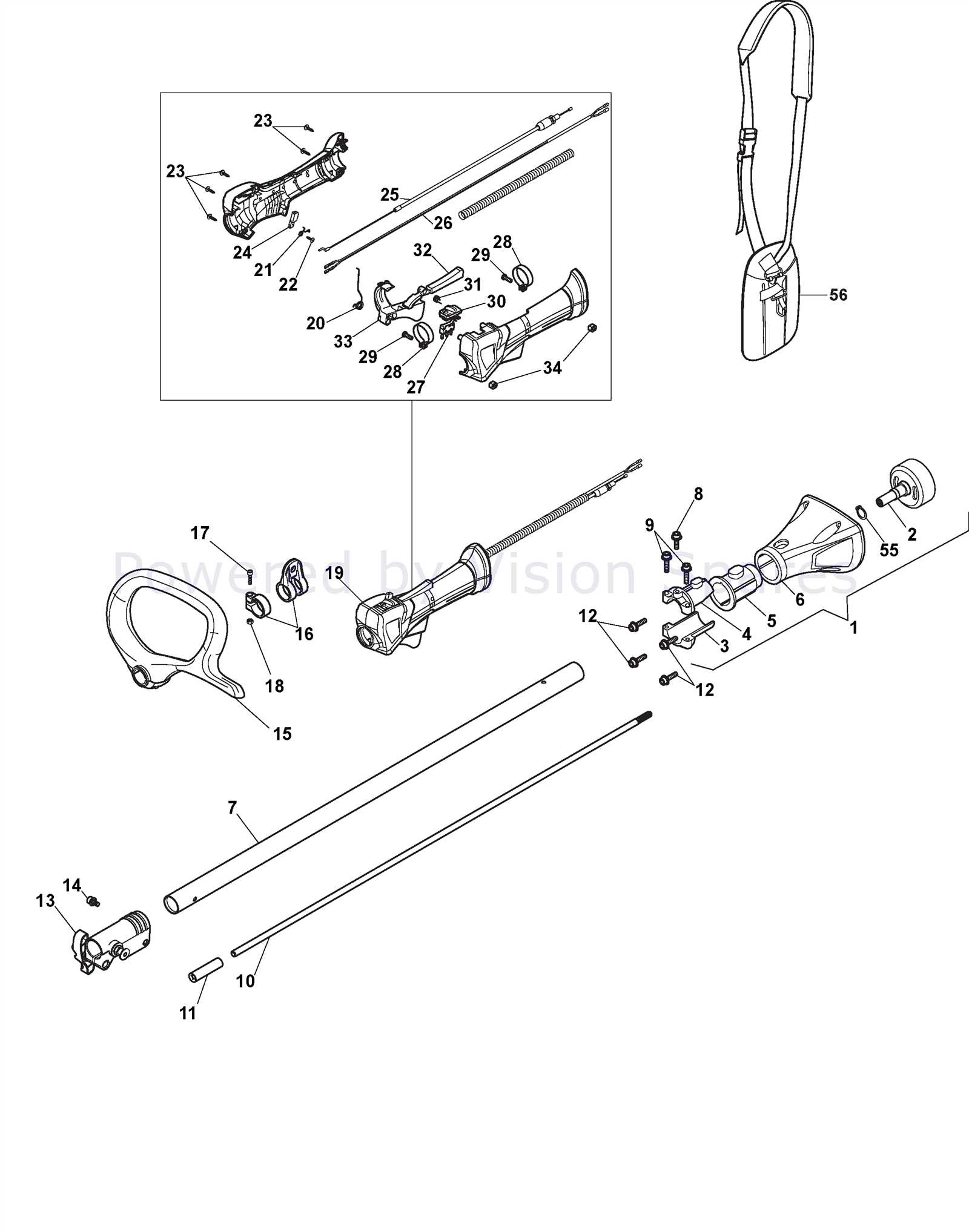

Upgrades and Customization Options

Enhancing a firearm’s functionality and aesthetics is a pursuit enjoyed by many enthusiasts. Whether for improved performance in the field or for personal expression, customization opens up a realm of possibilities. Various modifications can enhance accuracy, reliability, and overall user experience, allowing for a personalized touch that reflects the owner’s preferences.

There are numerous ways to tailor a weapon to fit specific needs:

- Optics: Upgrading sights or adding scopes can greatly improve aiming precision and target acquisition.

- Barrels: Different barrel lengths and types can affect accuracy and velocity, making it crucial to choose the right option based on intended use.

- Triggers: Installing aftermarket triggers can enhance responsiveness and reduce pull weight, leading to better control.

Furthermore, external modifications can also be considered:

- Grips: Ergonomic grips can improve handling and comfort, allowing for better control during use.

- Stocks: Adjustable stocks offer versatility in length and fit, accommodating various shooting positions and preferences.

- Rail Systems: Adding rails provides options for mounting accessories such as lights, lasers, or vertical grips, enhancing overall functionality.

When undertaking modifications, it’s essential to ensure that any upgrades comply with local regulations and maintain the firearm’s safety and reliability. Thoughtful enhancements can transform a standard model into a unique and highly functional tool tailored to the owner’s desires.

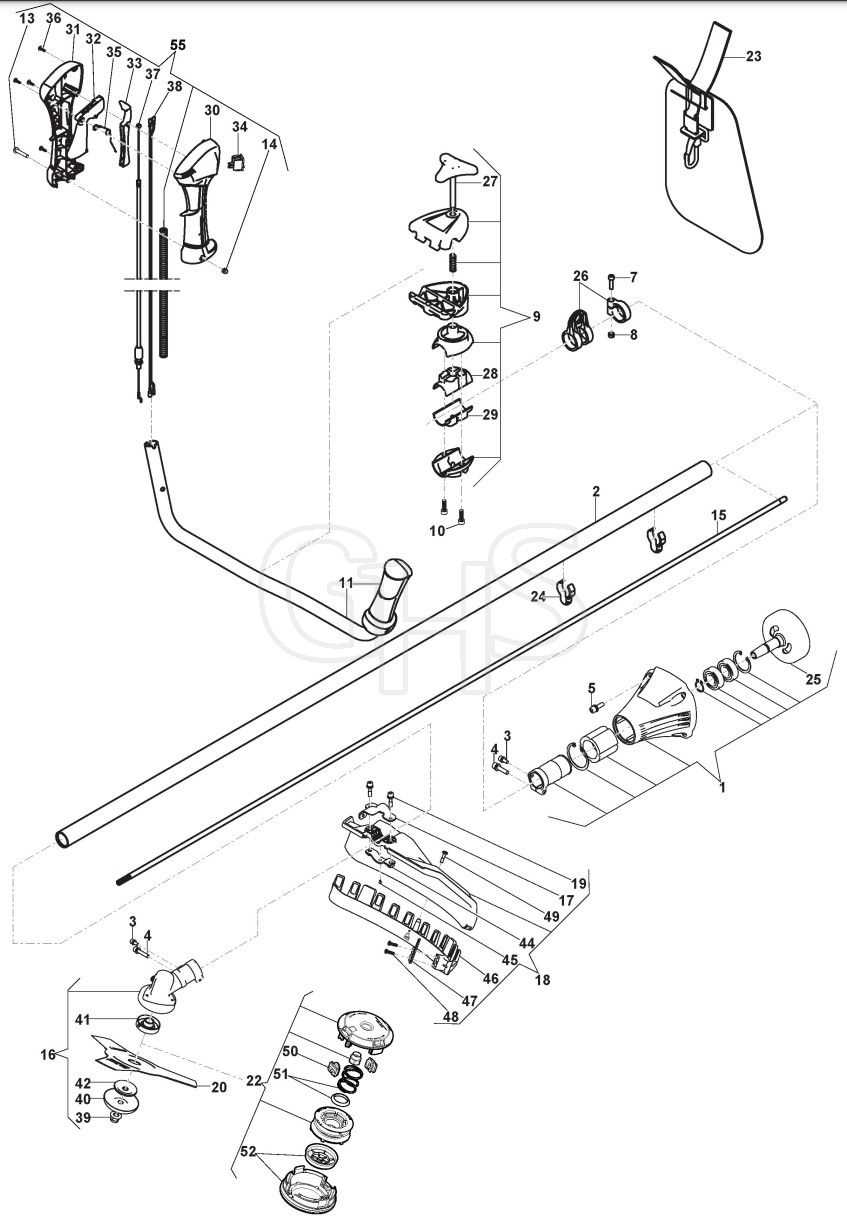

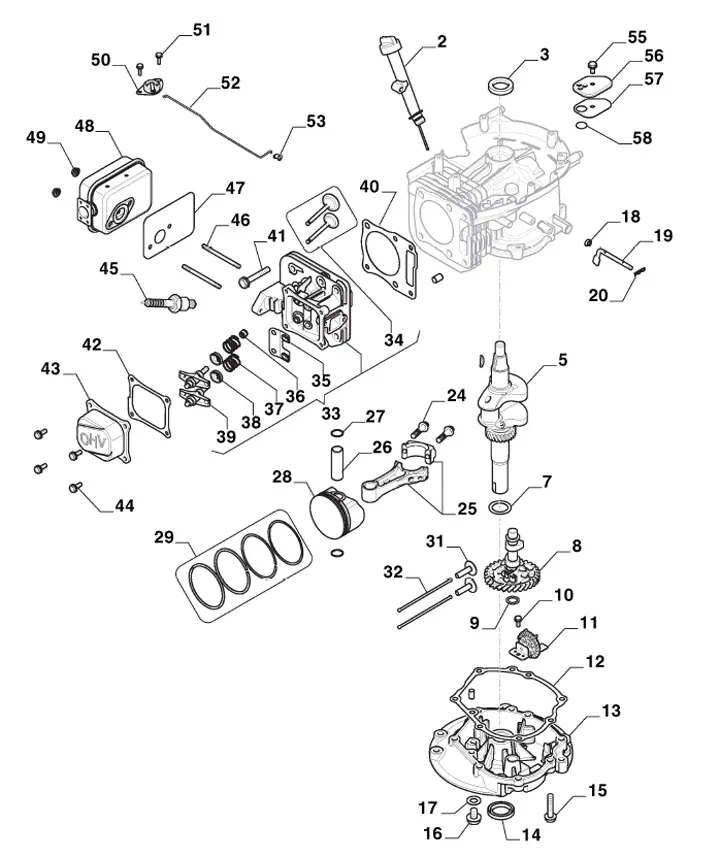

Importance of Quality Components

Ensuring the reliability and effectiveness of any mechanism relies heavily on the integrity of its individual elements. High-quality materials and precise manufacturing processes contribute significantly to the overall performance and longevity of the system. When each component meets rigorous standards, it enhances the functionality and durability of the entire assembly.

Durability is a key factor when considering the significance of superior elements. Components made from robust materials are less prone to wear and tear, which ultimately translates to a longer lifespan for the entire mechanism. Additionally, when these elements are engineered with precision, they fit together seamlessly, reducing the likelihood of malfunctions.

Moreover, the performance of a mechanism can be greatly affected by the quality of its constituents. Components designed to high specifications can improve efficiency, ensuring that the system operates at its optimum level. This not only enhances user satisfaction but also minimizes maintenance costs over time.

In summary, the selection of high-quality elements is crucial for achieving a reliable, efficient, and long-lasting mechanism. By investing in top-tier materials and craftsmanship, one can ensure that the overall system performs effectively and withstands the test of time.