When maintaining or repairing equipment, it is crucial to have a clear understanding of how different elements are organized. This knowledge not only helps in identifying the individual pieces but also ensures efficient assembly and functionality. Whether it’s routine maintenance or addressing a more specific issue, recognizing how each element fits into the bigger picture is essential.

Proper identification of various components allows users to perform more accurate diagnostics and efficient repairs. Knowing where each piece belongs and how it interacts with others ensures smooth operations and minimizes downtime.

By having a visual layout of all key elements, individuals are empowered to tackle both minor adjustments and more complex mechanical work. This approach simplifies the process, making it easier to identify and replace necessary items as needed.

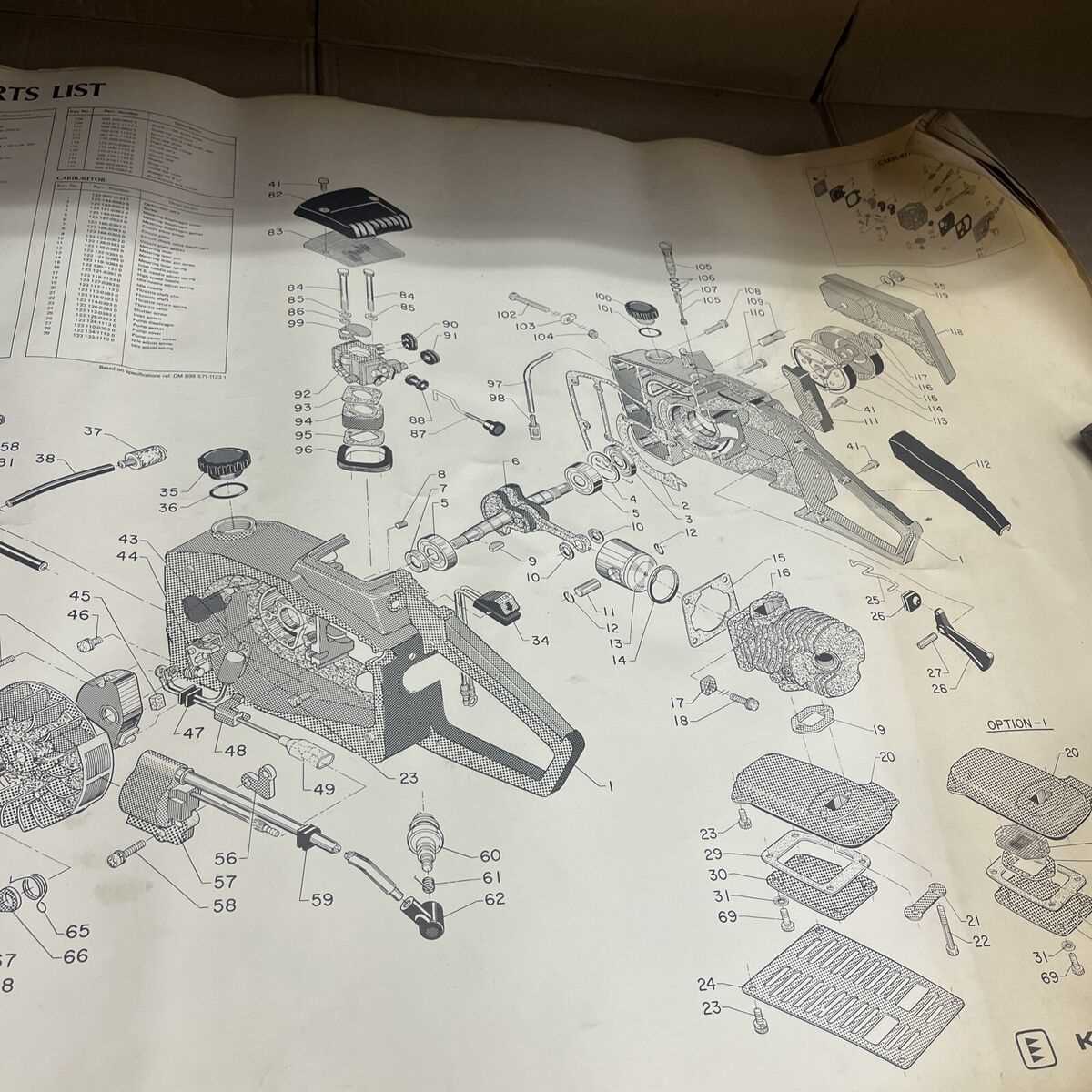

Echo CS 400 Parts Overview

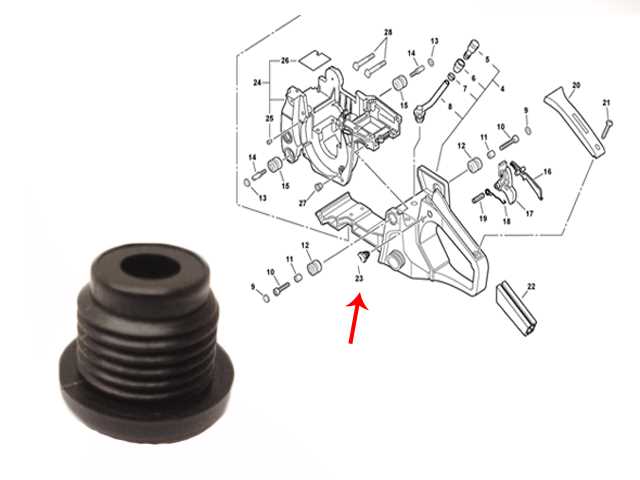

This section provides a detailed breakdown of the essential components that make up the structure and functionality of the model. These elements are crucial for both maintenance and optimal performance. Understanding the various segments and their roles will help in identifying any issues and ensuring smooth operation over time.

Main Assembly Components

The primary construction includes several key segments, each designed to contribute to the overall balance and efficiency of the machine. Below is a list of the core elements involved in the main build:

| Component | Function | |||||||

|---|---|---|---|---|---|---|---|---|

| Engine Unit | Provides power and drives the cutting mechanism. | |||||||

| Chain Bar | Supports and guides the cutting chain. | |||||||

Ignition

Chainsaw Engine Components ExplainedThe internal mechanics of a chainsaw are complex but crucial for its reliable operation. Understanding the key components that make the engine function efficiently can help in maintaining and repairing the machine. These essential elements work together to power the cutting process, ensuring the tool performs at its best under various conditions. Piston and CylinderThe piston and cylinder form the heart of the engine. The piston moves up and down within the cylinder, creating the necessary compression and power for the chainsaw to operate. This movement is essential for generating the force needed to drive the chain. Carburetor and Ignition SystemThe carburetor is responsible for mixing fuel and air in precise proportions, while the ignition system ensures the spark needed to ignite this mixture. Both component Guide Bar and Chain DetailsThe guide bar and chain are essential components of any cutting tool, designed to work together for efficient operation. Understanding their characteristics and proper maintenance is crucial for optimal performance and longevity. This section will explore the key features, types, and care tips for these parts, ensuring smooth and safe use during any cutting task. Guide Bar Types and FeaturesGuide bars come in various lengths and designs, each suited for specific tasks. Shorter bars are ideal for precision work, while longer ones are better for cutting larger materials. Durability and reduced wear are important factors when selecting the right bar, as they affect overall efficiency and safety. Chain Maintenance and SafetyRegular inspection and sharpening of the chain are essential for maintaining cutting efficiency. A well-maintained chain reduces kickback risks and prolongs the life of the tool. Proper lubrication also prevents overheatin Fuel System Structure and Key PartsThe fuel system is a crucial component designed to deliver fuel efficiently to the engine, ensuring proper combustion and performance. It consists of interconnected elements that work together to regulate the fuel flow and maintain the necessary balance for smooth operation. Understanding the structure and main components of this system can help in maintaining and troubleshooting engine issues.

Each of these components plays Ignition System and Spark Plug RoleThe ignition system is a crucial component in ensuring that an engine operates efficiently and reliably. By delivering the necessary spark at the right moment, this system ignites the fuel-air mixture, allowing the engine to function smoothly. A key element in this process is the spark plug, which plays a vital role in converting electrical energy into a spark that starts combustion. Main Functions of the Ignition System

The primary purpose of the ignition system is to create and deliver a controlled spark at the precise time, which is crucial for efficient engine performance. It coordinates with other engine components to ensure that combustion occurs in a timely manner, maximizing power and fuel efficiency. The system includes various elements, such as coils and wires, that work in tandem to provide a consistent electrical charge. The Importance of a Properly Functioning Spark PlugThe spark plug acts as the bridge between the ignition system and the combustion chamber. It receives high voltage from the ignition coil and generates the spark that Air Filter Maintenance and ReplacementProper upkeep of the air filtration system is crucial for the optimal performance and longevity of outdoor power equipment. This component prevents dirt and debris from entering the engine, ensuring it operates smoothly. Regular inspection and timely replacement of the filter can enhance efficiency and reduce potential damage caused by contaminants. Signs of a Clogged FilterIdentifying when the air filter requires attention is essential. Some common indicators include:

Replacement ProcedureTo ensure the equipment operates efficiently, follow these steps for replacing the air filter:

Handle Assembly and Vibration ControlThe handle assembly plays a crucial role in ensuring optimal performance and comfort during operation. It is designed to provide stability and ease of use, allowing the operator to maintain control while minimizing fatigue. The integration of effective vibration control mechanisms is essential for enhancing user experience and prolonging the lifespan of the equipment. Components of the Handle AssemblyThe handle assembly consists of various components that work together to provide a secure grip and facilitate smooth operation. Key elements include the main handle, grips, and mounting brackets. Each part is engineered to withstand stress and provide ergonomic support, ensuring that users can operate the device with confidence. Vibration Dampening TechniquesTo mitigate vibrations that can cause discomfort and affect performance, advanced dampening techniques are incorporated into the design. These may include the use of specialized materials and isolation mounts that absorb shock. By effectively controlling vibrations, the assembly enhances user comfort and reduces the risk of injury during extended use. Safety Features and Protective PartsEnsuring user safety during operation is paramount when working with outdoor equipment. Various features and components are designed to mitigate risks and enhance protection for the operator.

Incorporating these safety elements not only protects the operator but also promotes efficient use of the equipment, ultimately leading to better performance and longevity. Understanding the Oil Pump and LubricationThe oil pump plays a crucial role in ensuring the smooth operation of an engine by maintaining proper lubrication throughout its components. This vital mechanism circulates oil, reducing friction and wear, which ultimately prolongs the life of the machinery. Understanding how this system functions can greatly enhance maintenance practices and improve overall performance. At its core, the oil pump draws oil from the reservoir and delivers it under pressure to various parts of the engine. This continuous flow ensures that critical components, such as bearings and gears, are adequately lubricated, preventing overheating and mechanical failure. Proper lubrication not only enhances efficiency but also minimizes the risk of damage during operation. Regular inspection of the oil pump and lubrication system is essential. Identifying any signs of wear or malfunction early can prevent costly repairs and downtime. Ensuring that the oil is at the correct level and maintaining a clean filter can further enhance the effectiveness of the lubrication process. Ultimately, understanding this system is key to achieving optimal engine performance. |