Maintaining a well-functioning lawn machine requires a clear comprehension of its components and their interrelations. This knowledge is crucial for efficient operation and longevity of your equipment. An organized representation of these elements can greatly enhance your troubleshooting and repair efforts.

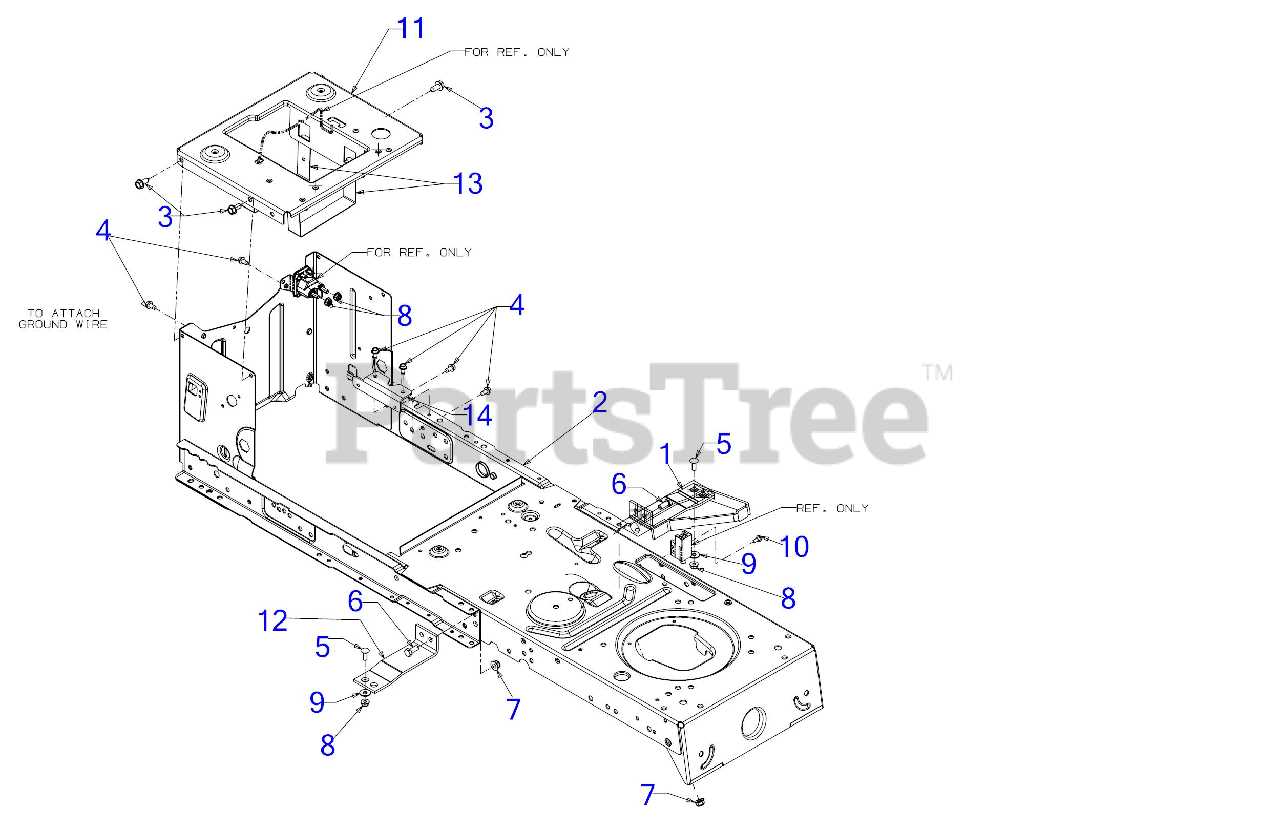

In this section, we will explore a detailed visual reference that breaks down the essential parts of a specific model. Such a resource is invaluable for both seasoned users and newcomers, enabling them to identify and manage the various elements with confidence.

As you navigate through this visual guide, you’ll uncover the intricacies of each segment, leading to a more profound understanding of how to optimize your machine’s performance. Whether you are seeking to repair or upgrade, this resource serves as your ultimate companion in achieving a well-maintained tool.

Understanding Huskee LT4200 Parts

Maintaining a mower requires a solid grasp of its components to ensure efficient operation and longevity. Each element plays a crucial role in the overall performance, from the engine to the cutting deck. Familiarity with these mechanisms allows users to diagnose issues quickly and facilitate repairs or replacements when necessary.

Key Components Overview

Critical elements include the power system, which propels the machine, and the cutting apparatus, responsible for achieving a clean finish. Additionally, the chassis and wheels contribute significantly to maneuverability, affecting how the mower navigates various terrains. Understanding how these parts interact can lead to better maintenance practices and improved functionality.

Maintenance Tips

Regular inspections of each component can prevent larger problems down the line. Checking the oil levels, air filters, and blade sharpness are simple yet effective ways to keep the mower in peak condition. Proper cleaning and storage after use also play vital roles in extending the lifespan of the machine.

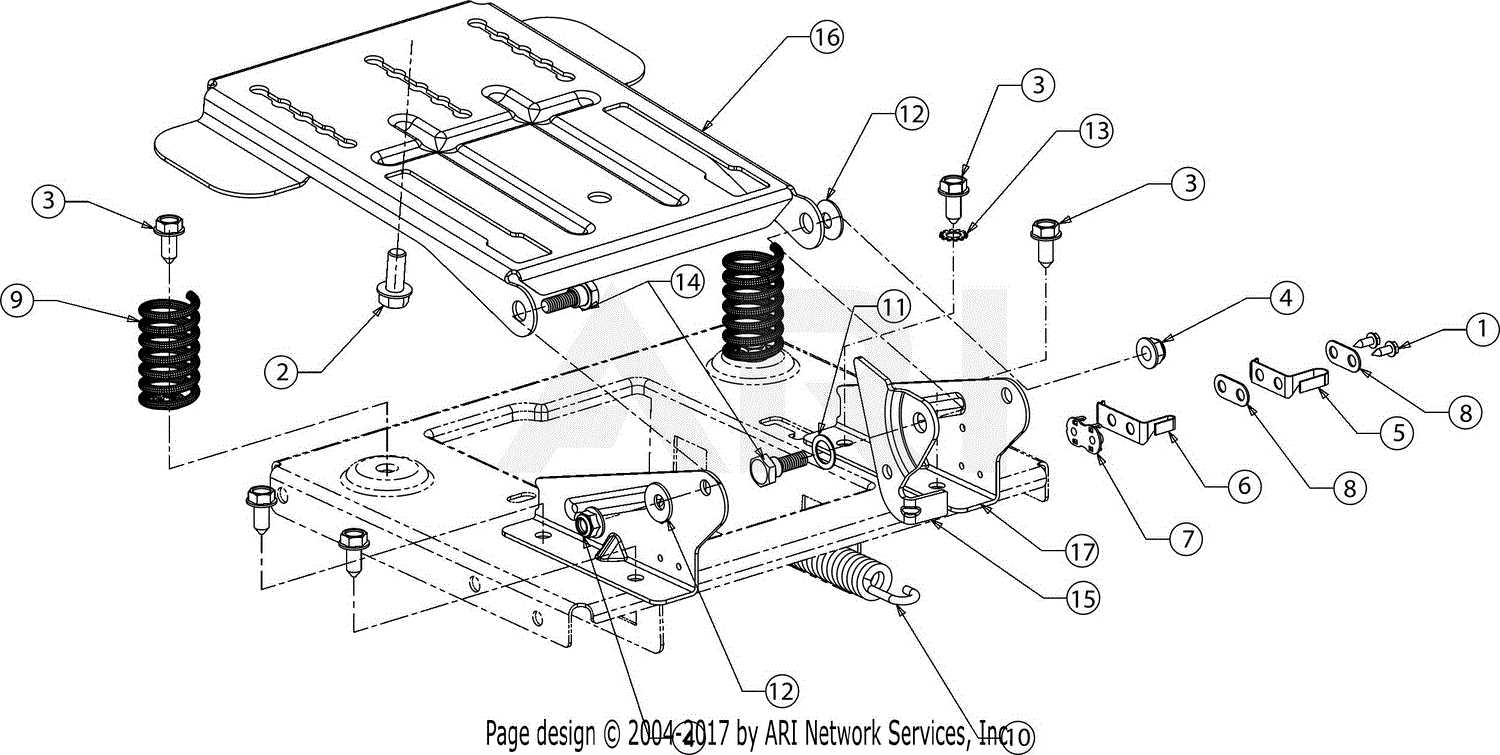

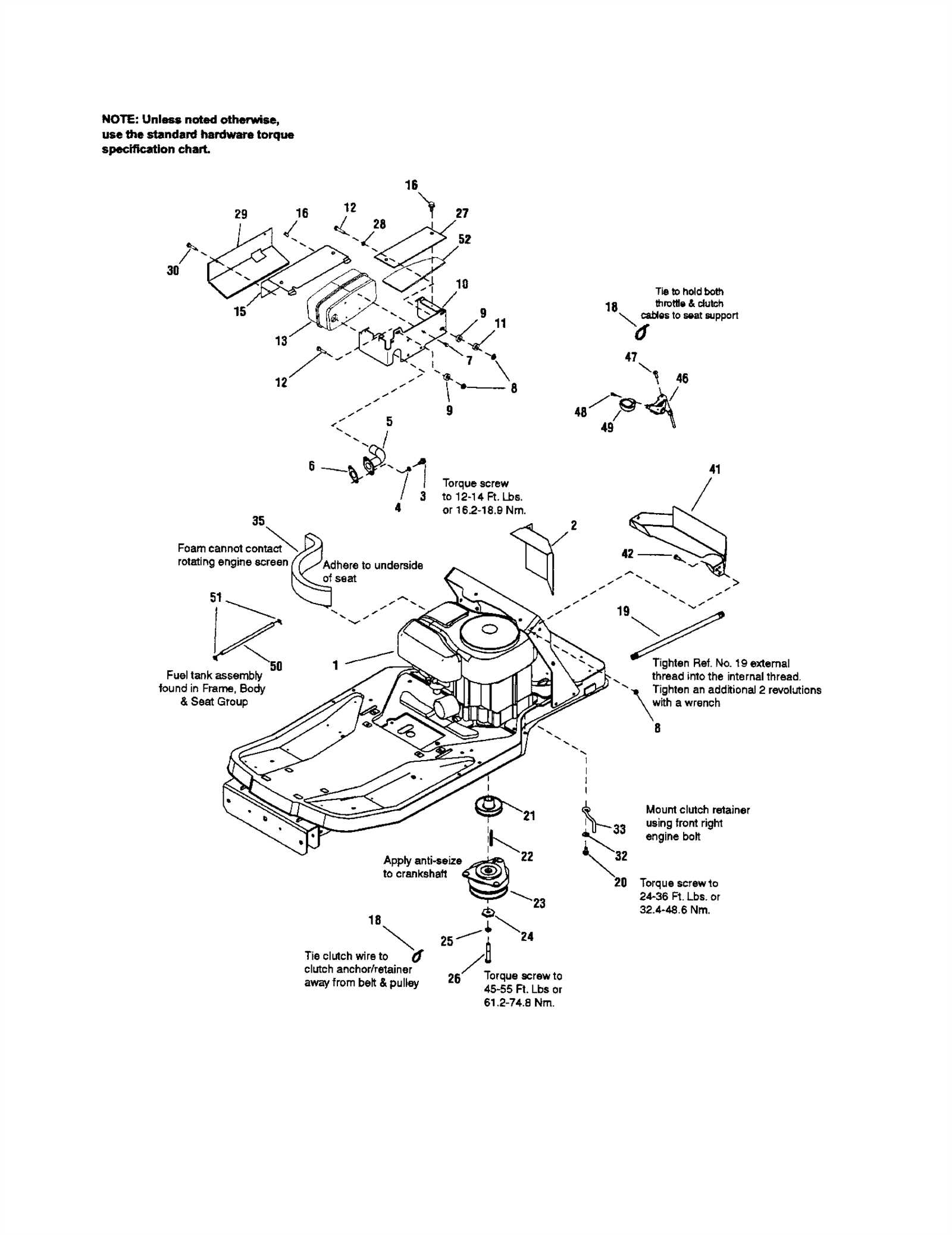

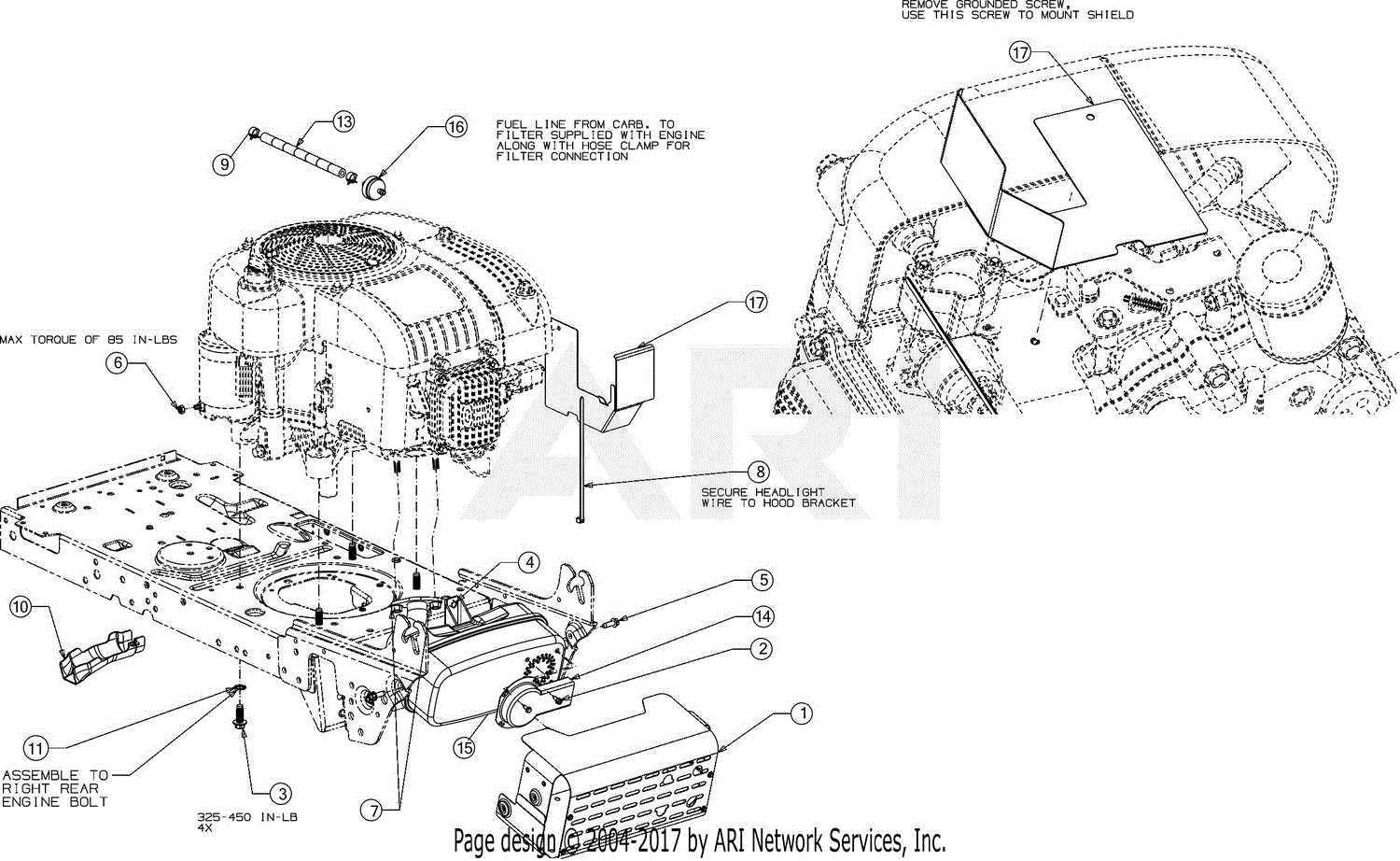

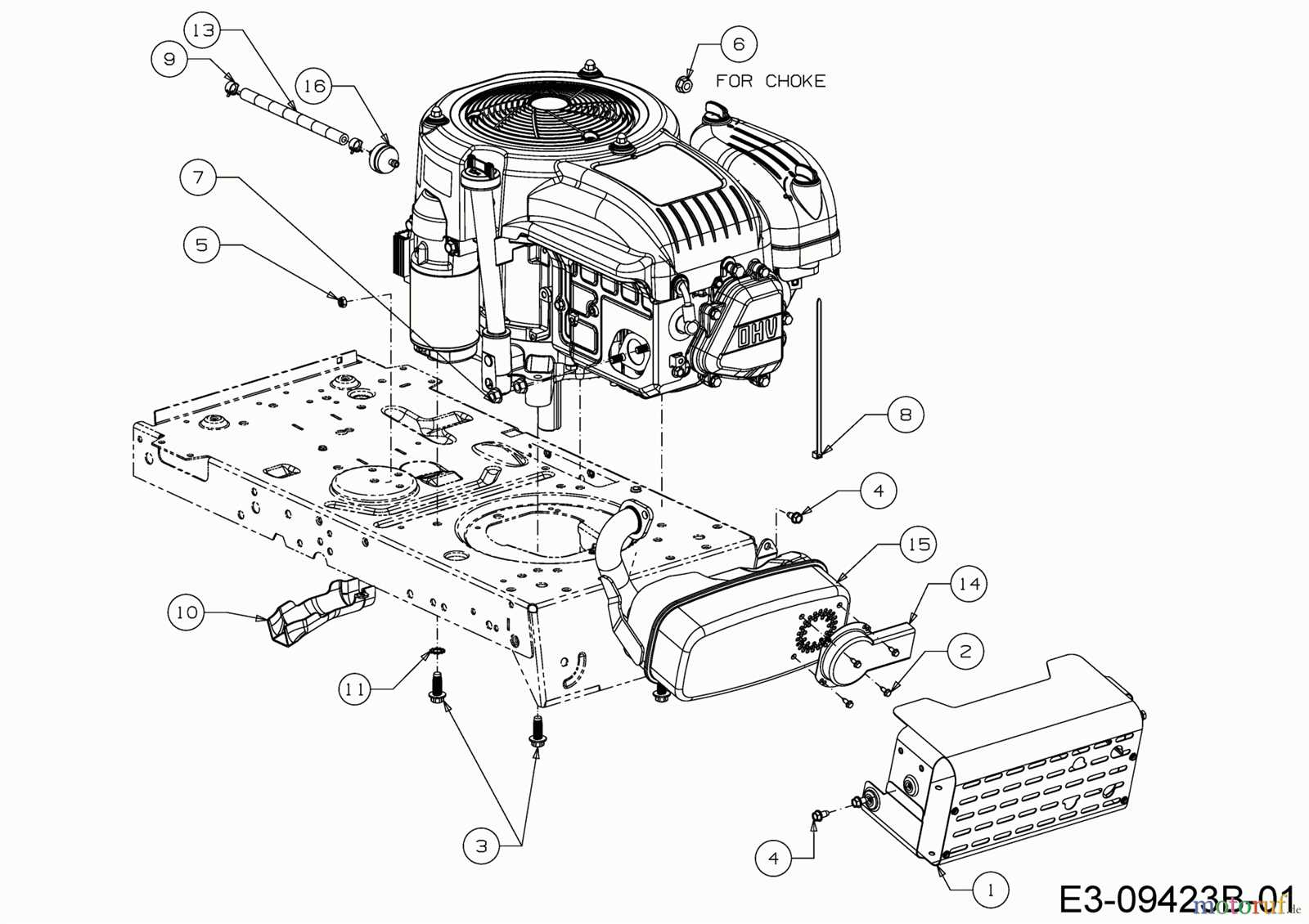

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. They serve as a guide for maintenance and repair, enabling users to identify specific elements and their relationships within the system. This clarity ensures that technicians can efficiently troubleshoot issues and perform necessary replacements.

Enhanced Understanding

Detailed illustrations allow for a deeper comprehension of the overall structure. Users can easily recognize how each piece fits into the larger picture, fostering better maintenance practices.

Efficiency in Repairs

Access to these visual guides streamlines the repair process, reducing downtime and enhancing productivity. Technicians can quickly pinpoint problems and find the correct replacements without unnecessary delays.

| Benefit | Description |

|---|---|

| Clarity | Improves understanding of component relationships. |

| Time-saving | Accelerates the identification of necessary parts. |

| Accuracy | Reduces the chances of errors during repairs. |

Common Issues with LT4200 Models

Owners of this particular line of garden machinery often encounter several recurring challenges that can affect performance and longevity. Understanding these common problems can help users take preventive measures and ensure smoother operation.

One frequent issue is engine starting difficulties, which can arise from various factors such as a drained battery, fuel supply problems, or faulty ignition systems. Regular maintenance, including checking the battery and ensuring proper fuel levels, can mitigate these concerns.

Another prevalent challenge involves the cutting deck, where users may experience uneven cuts or clumping of grass. This can result from dull blades, improper deck height, or clogged discharge paths. Routine blade sharpening and cleaning can significantly improve cutting efficiency.

Additionally, transmission troubles may surface, leading to sluggish movement or inability to change speeds. These issues often stem from low fluid levels or worn-out components. Keeping an eye on fluid levels and conducting timely inspections can prevent more severe transmission problems down the line.

Lastly, overheating is a common concern, typically due to debris accumulation around the engine or insufficient cooling. Regular cleaning and checks on air intake paths can help maintain optimal operating temperatures and prevent breakdowns.

How to Locate Replacement Parts

Finding the right components for your equipment is essential for maintaining its performance and longevity. This process can seem daunting, but with the right approach, you can efficiently identify the necessary items for repairs or upgrades.

Identify Your Model

Before you begin your search, ensure you have the correct model information. This includes:

- Model number

- Serial number

- Year of manufacture

Having this information readily available will help you narrow down your options and find suitable replacements.

Where to Search

There are several reliable sources to explore when looking for components:

- Manufacturer’s Website: Visit the official website of the equipment’s maker. They often provide a dedicated section for replacements.

- Authorized Dealers: Reach out to certified dealers who specialize in your equipment type. They usually have access to genuine parts.

- Online Marketplaces: Utilize platforms that cater to aftermarket components. Ensure to check reviews and ratings for reliability.

- Local Repair Shops: Consider consulting local service providers who might have access to the required items or can assist you in finding them.

By following these steps, you can effectively locate the necessary components to keep your machinery running smoothly.

Step-by-Step Repair Process

Repairing machinery can seem daunting, but by following a structured approach, the task becomes manageable. Understanding each component’s role and how to efficiently address issues will streamline the process. This guide outlines the necessary steps to ensure a successful repair, enabling you to restore functionality with confidence.

Preparation and Assessment

Begin by gathering the tools and materials you will need for the task. Assess the equipment thoroughly to identify the specific areas requiring attention. This step is crucial, as it allows you to create a clear action plan. Take note of any visible wear or damage and consult the manufacturer’s guidelines for reference on common issues and solutions.

Execution of Repairs

Once you have prepared and assessed the situation, proceed with the repairs. Start by disassembling the relevant parts carefully, ensuring that you document each step for reassembly. Replace or repair any damaged components as identified during the assessment. After making the necessary adjustments, reassemble the unit methodically, double-checking each connection for security. Finally, test the equipment to verify that it operates correctly before returning it to service.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of any machinery. Regular attention not only enhances efficiency but also minimizes the risk of unexpected breakdowns. By following a few key practices, users can extend the lifespan of their equipment significantly.

Regular Inspections

Conduct routine checks to identify any wear and tear before it becomes a major issue. Look for loose components, leaks, or unusual noises that may indicate a need for adjustments or replacements. Keeping a maintenance log can also help track the condition over time.

Cleanliness and Lubrication

Maintaining cleanliness is vital for optimal functionality. Remove debris and dirt regularly, particularly from moving parts. Additionally, ensure that all necessary components are adequately lubricated to reduce friction and prevent premature wear, enhancing overall performance.

Choosing Quality Aftermarket Parts

When it comes to maintaining equipment, opting for high-quality alternatives can make a significant difference. These components can enhance performance, extend lifespan, and ensure reliability. However, not all replacements are created equal. Understanding how to identify superior options is crucial for effective upkeep.

Here are some key factors to consider when selecting replacements:

- Brand Reputation: Research manufacturers with a proven track record for producing reliable items. Customer reviews and industry feedback can provide valuable insights.

- Material Quality: Examine the materials used in construction. Durable substances often indicate longevity and resilience under stress.

- Compatibility: Ensure that the alternative fits seamlessly with your existing machinery. Mismatched items can lead to inefficiency or damage.

- Warranty: A robust warranty can be a sign of confidence from the manufacturer. It also offers peace of mind in case of defects.

By focusing on these elements, you can make informed decisions that will enhance the functionality of your equipment while ensuring you get the best value for your investment.

Resources for Troubleshooting Problems

When encountering issues with outdoor equipment, having reliable resources at hand can make all the difference. This section provides various tools and materials that can aid in diagnosing and resolving common malfunctions. Access to the right information not only saves time but can also prevent unnecessary repairs.

Online Manuals and Guides

- User manuals specific to your model

- Manufacturer websites for downloadable resources

- Video tutorials on troubleshooting common issues

Community Support and Forums

- Online forums where users share experiences and solutions

- Social media groups dedicated to outdoor equipment maintenance

- Local workshops or clubs where enthusiasts gather to exchange tips

Utilizing these resources can enhance your understanding and capability in addressing issues efficiently, ensuring your equipment remains in optimal working condition.

FAQs About Huskee LT4200 Parts

This section addresses common inquiries related to components for a specific lawn maintenance machine. Understanding these elements is essential for proper upkeep and efficient operation. Below are some frequently asked questions that provide clarity on various aspects of these essential items.

What are the most common issues with machine components?

Many users encounter problems such as wear and tear on belts and blades, which can affect performance. Regular inspection and timely replacements can mitigate these issues.

How can I identify the right component for my machine?

It’s important to refer to the user manual for specifications or consult with a professional. This ensures that you obtain the correct replacement that fits your model’s requirements.

Are aftermarket components reliable?

While aftermarket options can be cost-effective, their quality may vary. It’s advisable to research and read reviews to ensure you select a reputable brand that meets safety and performance standards.

What maintenance tips can prolong the life of these components?

Regular cleaning, proper storage, and timely replacements of worn parts are crucial. Additionally, following the manufacturer’s maintenance schedule can significantly enhance durability.

Where can I find replacement items?

Replacement items can be sourced from authorized dealers, local hardware stores, or online marketplaces. Ensure that the source is reliable to avoid compatibility issues.