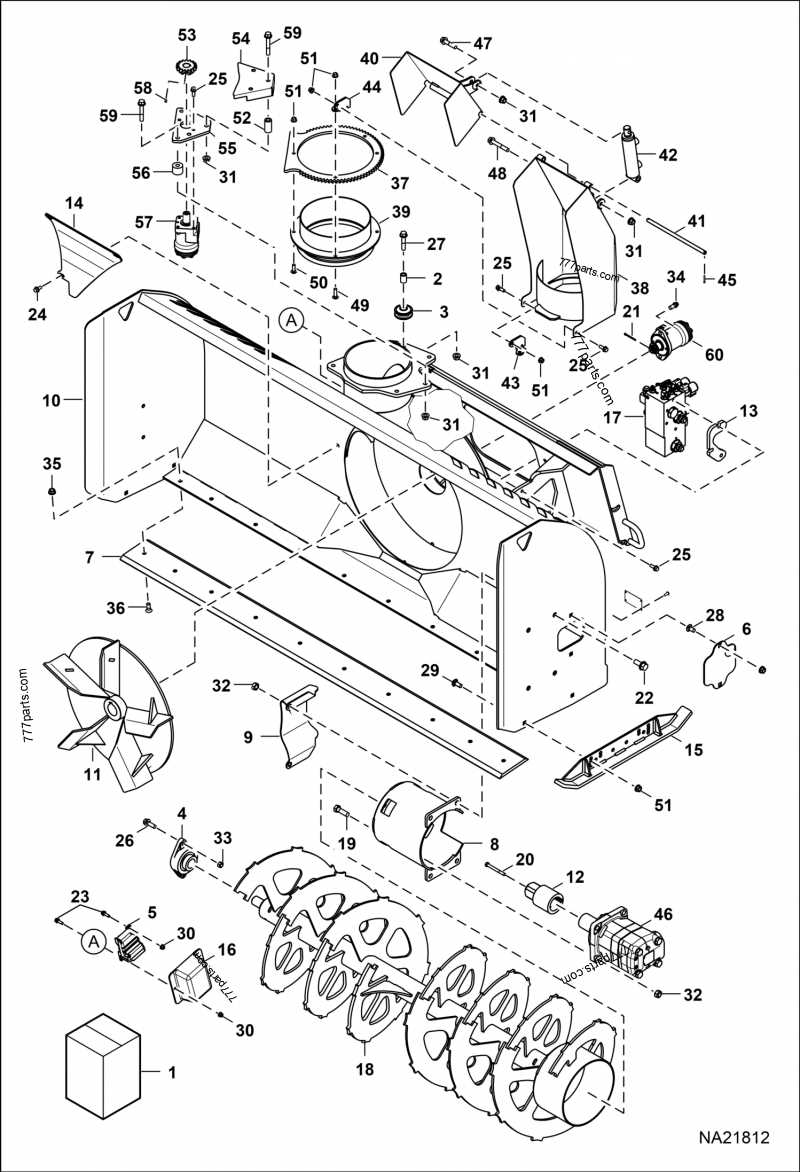

When delving into the intricate world of machinery, a comprehensive understanding of its assembly is crucial. Each element plays a vital role in ensuring seamless operation, and recognizing how they interconnect can significantly enhance maintenance and repair efforts. A detailed visual representation of these components serves as an invaluable resource for both enthusiasts and professionals alike.

Exploring the intricacies of mechanical systems unveils the relationship between various parts, highlighting their functions and interactions. Such insights not only aid in troubleshooting but also facilitate the optimization of performance. A well-structured visual reference allows users to identify components quickly, leading to more efficient servicing.

Moreover, grasping the layout of essential elements empowers individuals to make informed decisions regarding replacements and upgrades. Understanding how each piece fits into the larger assembly is a step towards mastering the art of maintenance. Whether you’re a seasoned technician or a curious learner, familiarizing yourself with these layouts can significantly enhance your technical prowess.

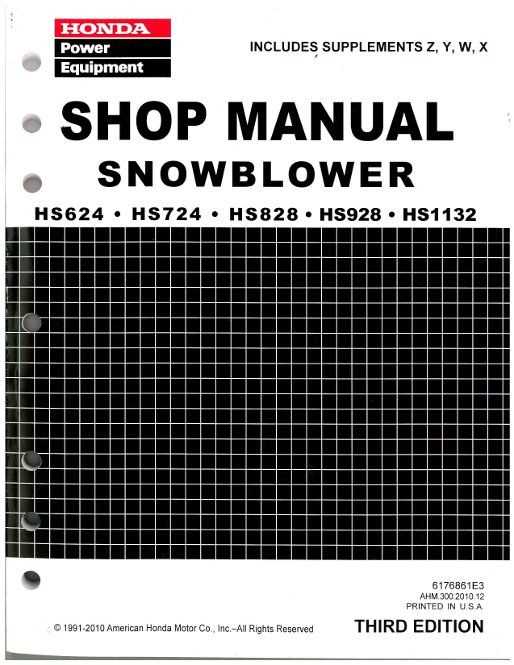

Understanding Honda HS828 Components

Gaining insight into the various elements of a snow-clearing machine is essential for optimal performance and maintenance. Each component plays a vital role in ensuring the equipment functions smoothly, especially during harsh winter conditions.

- Engine: The powerhouse that drives the entire system, providing the necessary energy for operation.

- Auger: Responsible for breaking up and gathering snow, facilitating efficient removal.

- Impeller: Assists in throwing the snow away from the cleared area, enhancing overall efficacy.

- Chassis: The frame that houses all components, ensuring stability and durability.

Understanding these elements enables users to troubleshoot issues effectively and maintain their machinery in peak condition.

Importance of Parts Diagrams

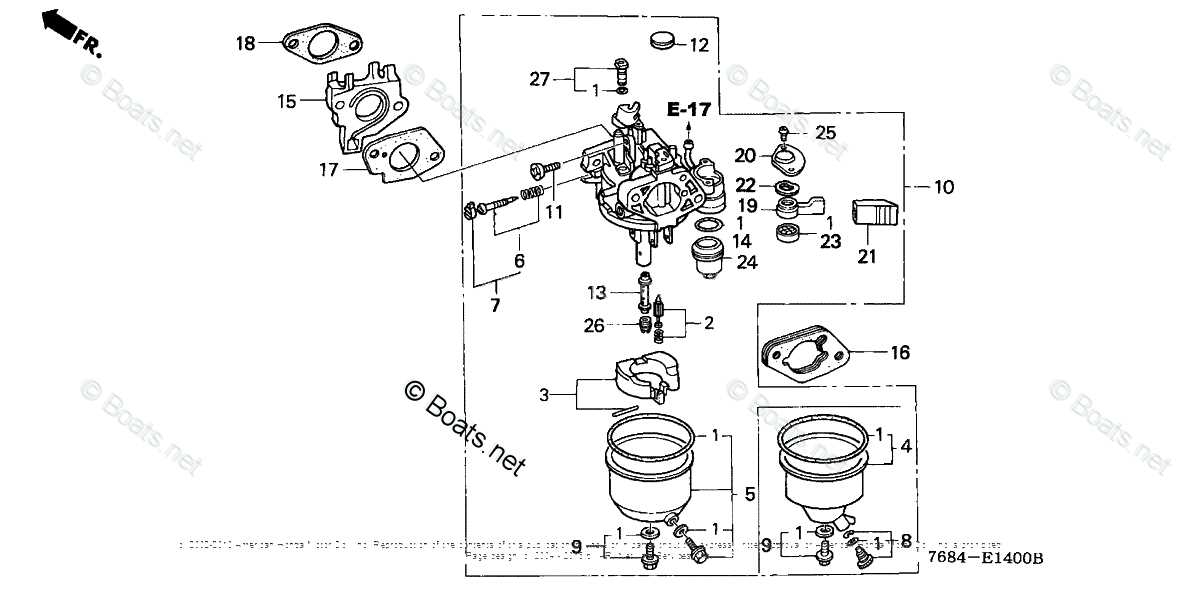

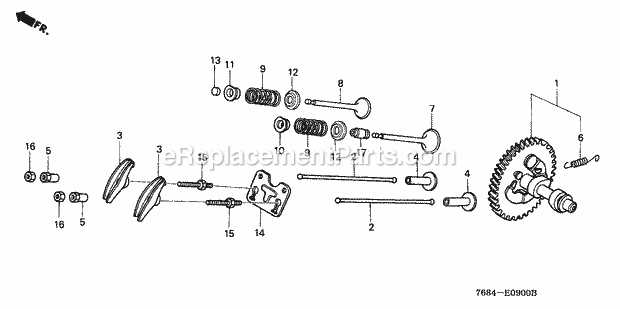

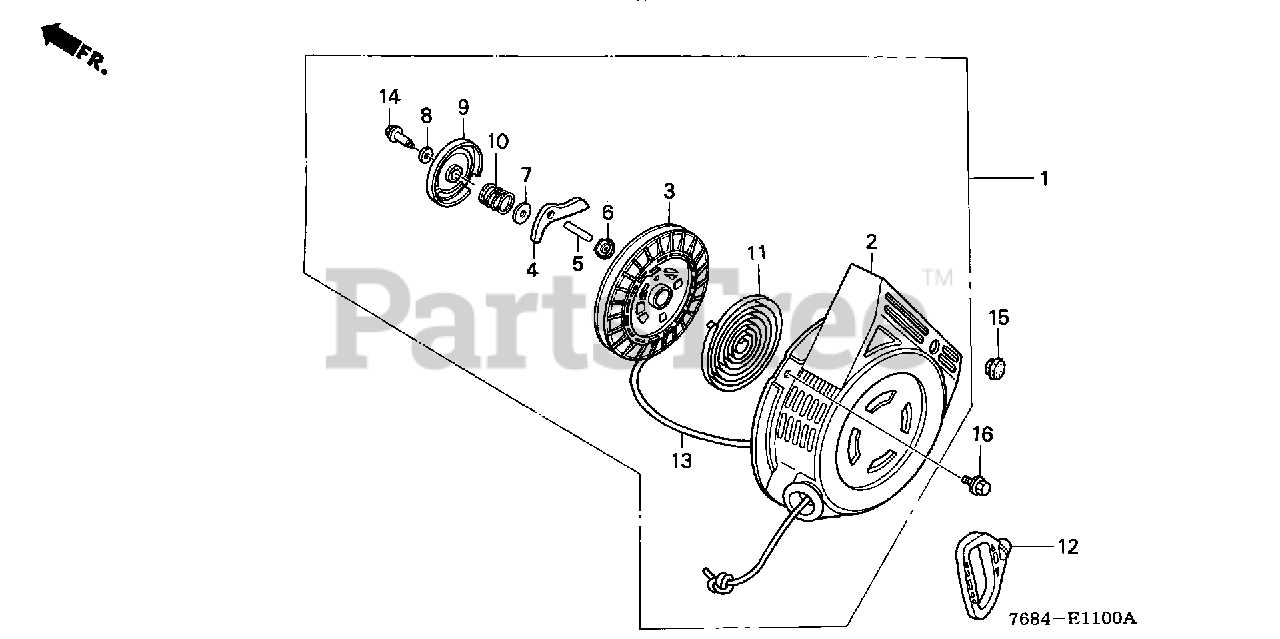

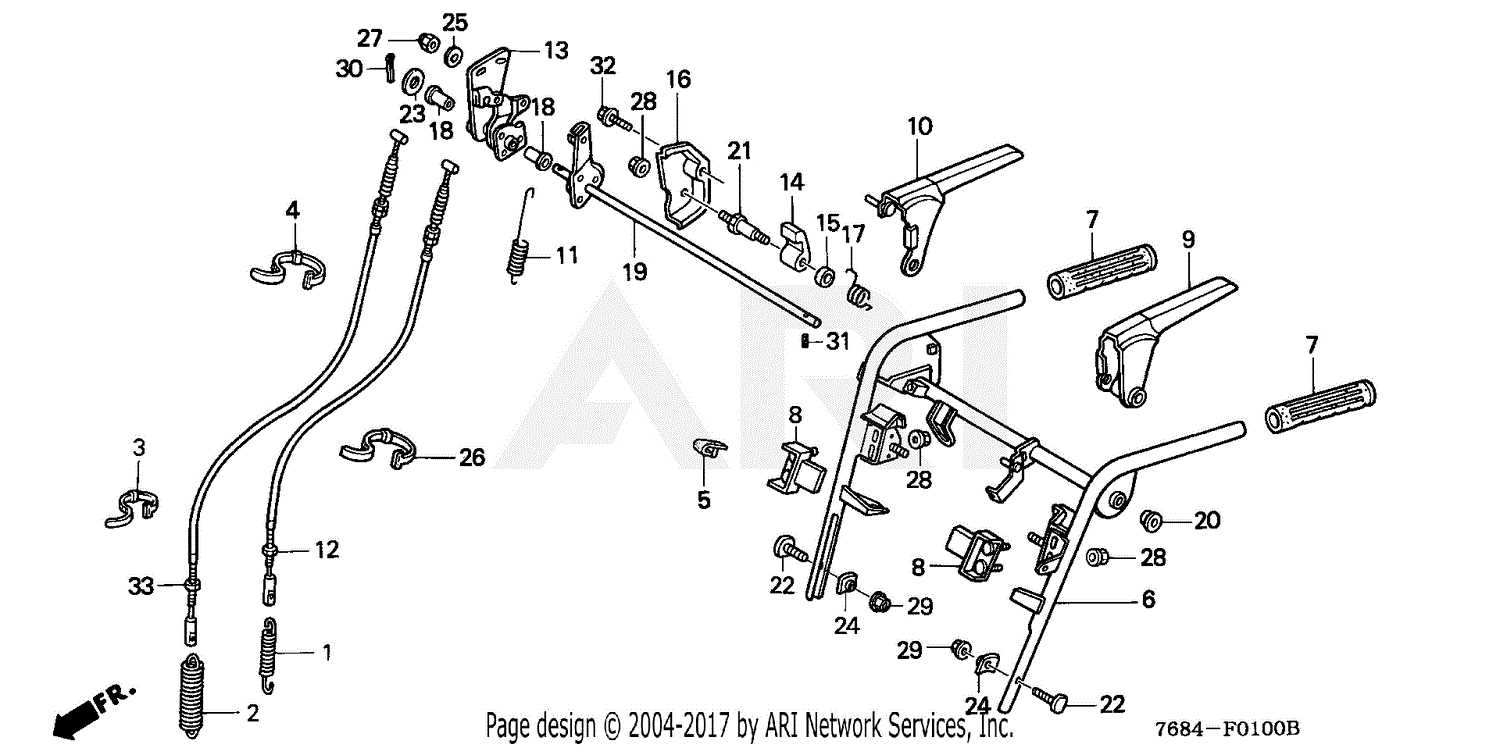

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide clarity, helping users identify individual elements and their respective functions within a system. This understanding is essential for effective troubleshooting and assembly.

Enhanced Understanding

Utilizing visual guides can significantly improve comprehension of complex assemblies. Here are some key benefits:

- Clear identification of each component.

- Facilitates easier communication among technicians.

- Reduces errors during repairs and replacements.

Efficiency in Maintenance

When working on equipment, visual aids contribute to faster diagnostics and repairs:

- Streamlines the process of locating faulty parts.

- Helps in planning maintenance schedules effectively.

- Supports proper reassembly of components after servicing.

Common Issues with HS828 Parts

In any machine, certain components may experience frequent problems that can affect overall performance. Understanding these common difficulties can help users maintain optimal functionality and longevity. It’s essential to recognize these issues early to prevent further damage and ensure smooth operation.

Wear and Tear: Over time, various elements can degrade due to regular usage. This deterioration often leads to decreased efficiency and can require timely replacements to keep the equipment running effectively.

Misalignment: Components can shift from their original positions, leading to operational inefficiencies. Regular checks and adjustments can mitigate this risk, ensuring everything remains in proper alignment.

Blockages: Accumulation of debris or contaminants can impede functionality. Regular cleaning and maintenance are crucial to prevent obstructions that could hinder performance.

Fluid Leaks: Many systems rely on fluids for optimal operation. Leaks can arise due to worn seals or connectors, which need prompt attention to avoid further complications.

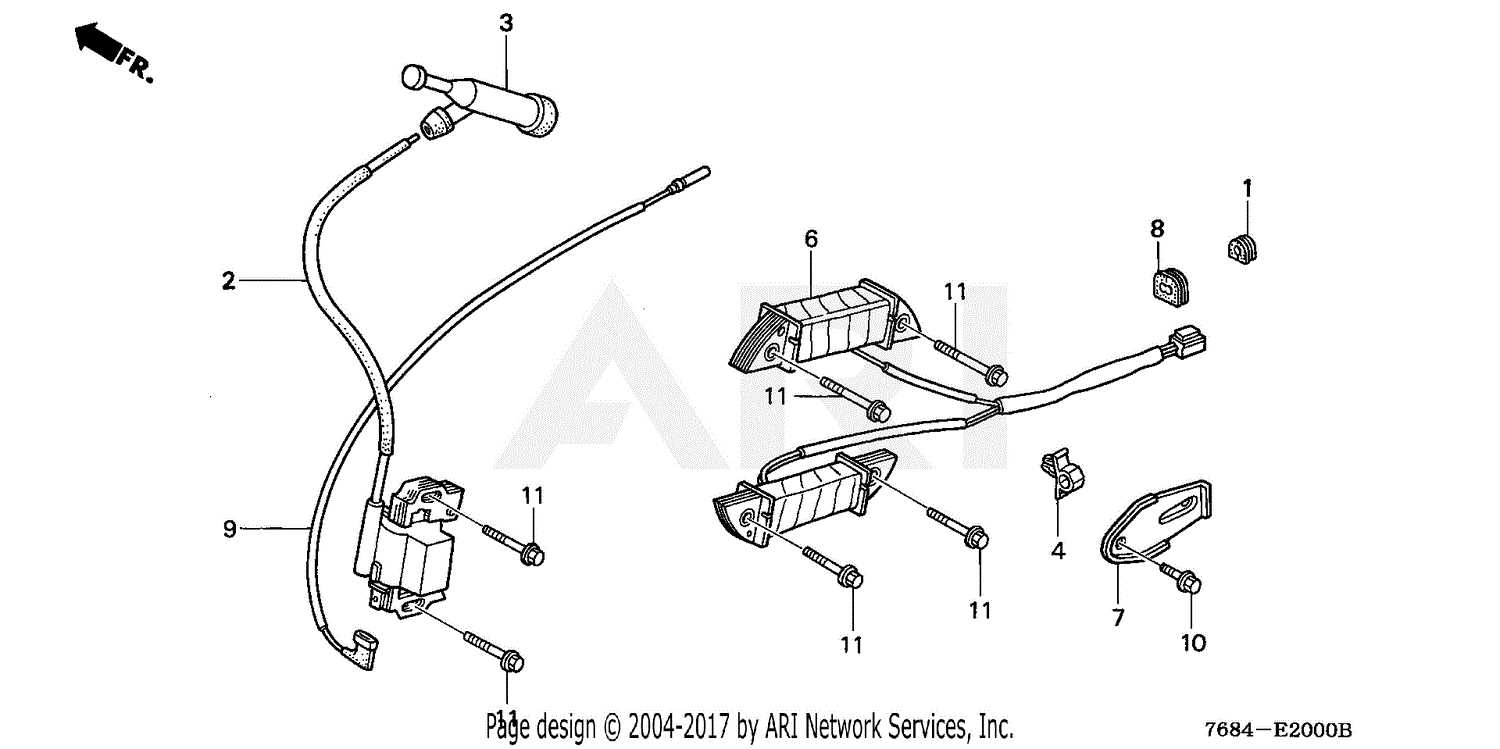

Electrical Failures: Issues with wiring or connectors can lead to malfunctions. Regular inspections can help identify and rectify these problems before they escalate.

Addressing these common challenges is key to maintaining efficiency and prolonging the life of your equipment. Regular maintenance and prompt repairs are the ultimate strategies for ensuring reliable performance.

Where to Find Replacement Parts

When maintaining outdoor machinery, sourcing quality components is essential for optimal performance and longevity. Identifying reliable sources can help ensure that the equipment operates smoothly and efficiently. Here are several effective avenues to explore when seeking replacements.

Online Retailers

- Specialty Websites: Many retailers specialize in outdoor equipment, offering a wide range of components tailored to various models.

- Marketplaces: Platforms such as eBay and Amazon often feature both new and used items, providing multiple options at different price points.

- Manufacturer’s Website: The official site may have a dedicated section for ordering specific items directly from the source.

Local Stores and Service Centers

- Authorized Dealers: Check with local dealers who are licensed to sell and service specific brands, ensuring access to genuine components.

- Hardware Stores: Some general hardware stores carry a selection of replacement items for popular outdoor equipment.

- Repair Shops: Local repair centers may have spare parts available or can assist in ordering the correct replacements.

Exploring these options can lead to the successful acquisition of needed components, enhancing the functionality and durability of your equipment.

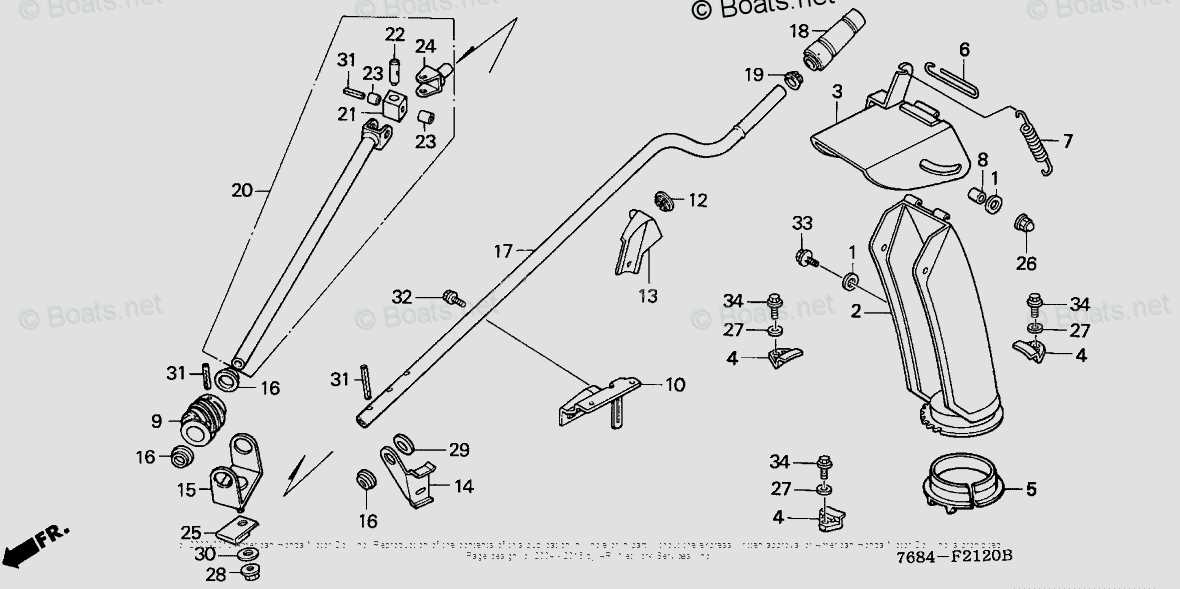

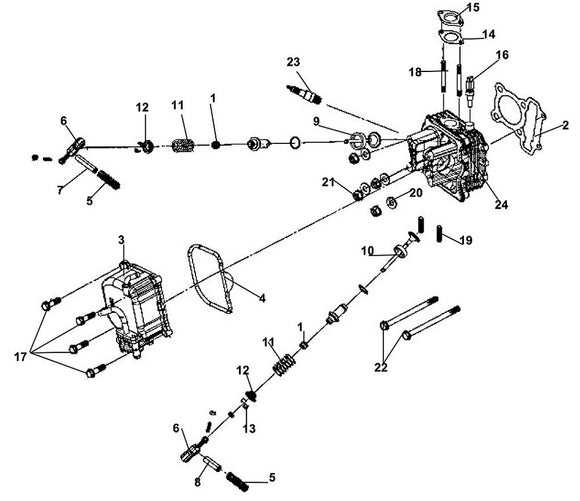

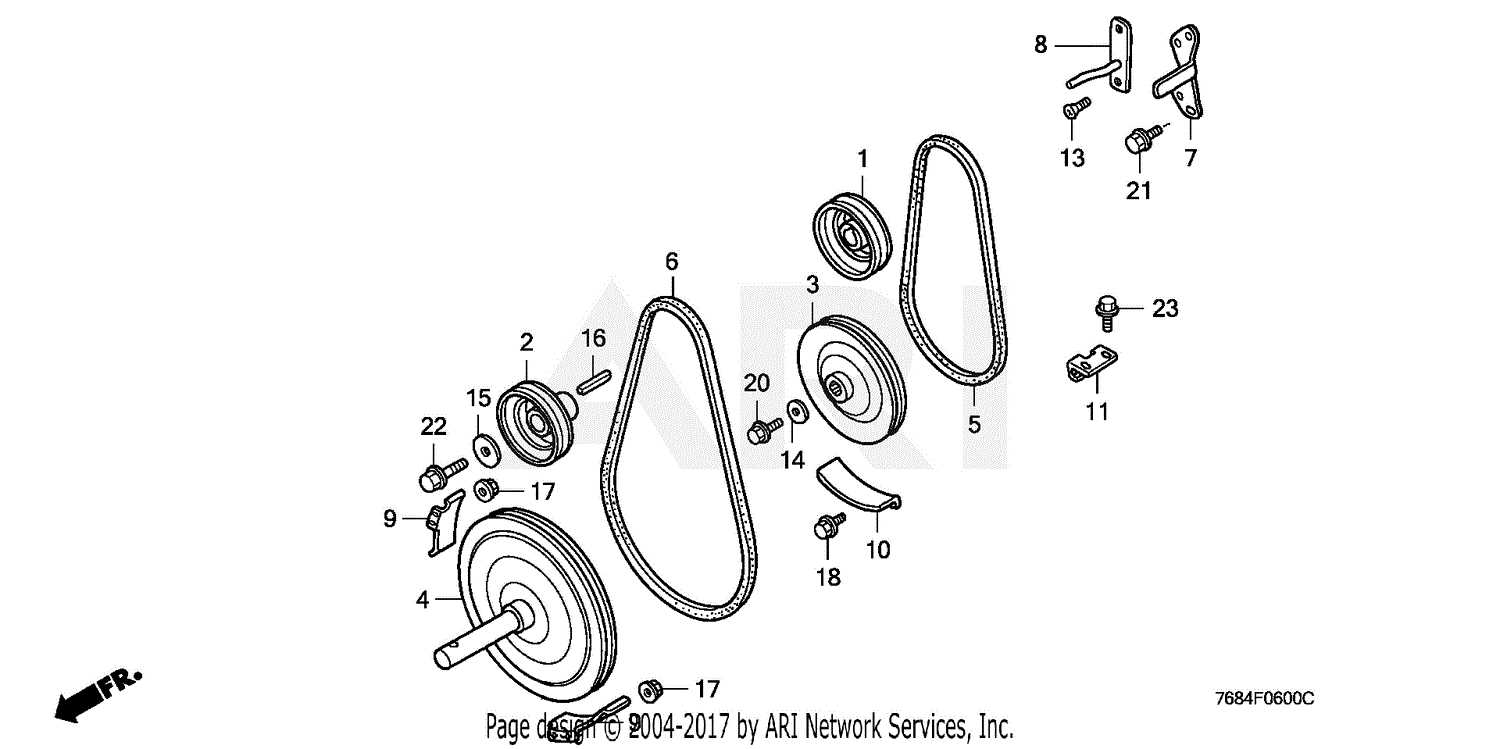

How to Read Parts Diagrams

Understanding the visual representations of components can greatly enhance your ability to identify and source necessary items for maintenance or repairs. These illustrations provide a detailed overview, allowing users to see how various elements interact and are arranged within a system. By familiarizing yourself with the symbols and notations used, you can streamline the process of locating specific parts and comprehending their functions.

Start by examining the layout of the illustration. Typically, components are organized in a way that mirrors their physical arrangement in the machinery. This spatial organization helps to visualize how each piece fits into the larger assembly. Pay attention to any labels or numbers accompanying the visuals, as these often correspond to lists or catalogs that provide additional information on specifications and availability.

Next, focus on the various symbols that represent different types of items. Each symbol often has a specific meaning–some indicate fasteners, while others may represent larger components. Familiarizing yourself with these symbols will save you time and reduce confusion when navigating the materials needed for your project.

Finally, cross-reference the illustration with accompanying documentation. Often, detailed explanations or parts lists accompany these visuals, providing crucial insights into compatibility and alternatives. By combining your understanding of the visual layout with the descriptive text, you will enhance your overall comprehension and efficiency in sourcing the right elements for your needs.

Maintenance Tips for Honda HS828

Regular upkeep is essential for ensuring the longevity and efficiency of your snow-clearing machine. Adhering to a systematic maintenance routine can help prevent breakdowns and enhance performance, making winter tasks more manageable.

Routine Inspections

Perform periodic checks on key components to identify wear and tear early. Inspect the blades for sharpness, examine belts for signs of fraying, and ensure all fasteners are secure. Addressing minor issues promptly can prevent major repairs down the line.

Fluid Management

Maintain optimal performance by regularly changing the engine oil and replacing the fuel filter as recommended. Using high-quality fluids tailored for your equipment can significantly improve efficiency and reduce the risk of mechanical failures.

Upgrading HS828 Components Effectively

Enhancing the efficiency of your equipment can lead to significant improvements in performance and longevity. By focusing on key elements, you can ensure that your machine operates at its ultimate potential. This section will explore effective strategies for upgrading various components.

First and foremost, identifying which parts require enhancement is crucial. Evaluate the current state of each component and prioritize upgrades based on wear, functionality, and overall impact on performance. Regular maintenance can also highlight areas that might need attention.

Next, consider high-quality replacements. Opting for superior materials or advanced designs can significantly elevate performance. Research compatible upgrades that offer improved efficiency and durability, ensuring they meet specific requirements.

Lastly, installation should be approached with care. Follow guidelines meticulously, and if needed, consult with professionals. A well-executed upgrade can transform your equipment into a more reliable and powerful asset.

Identifying Original vs. Aftermarket Parts

When it comes to equipment maintenance, distinguishing between authentic components and those from third-party manufacturers is crucial. Understanding the differences can ensure optimal performance and longevity, reducing the risk of potential issues down the line.

Key Differences

Original components are typically produced by the original manufacturer and are designed to meet specific standards. In contrast, aftermarket options may vary widely in quality and compatibility. Here are some characteristics to help differentiate between the two:

| Feature | Original | Aftermarket |

|---|---|---|

| Quality | Consistent, meets OEM standards | Varies, not always tested to the same standards |

| Warranty | Often comes with a warranty | May or may not have a warranty |

| Cost | Generally higher price | Usually more affordable |

| Availability | Readily available through authorized dealers | Available through various retailers |

Making an Informed Choice

To ensure the best decision, it’s essential to consider factors such as intended use, budget, and reliability. Investing in authentic components can lead to better performance and peace of mind, while third-party alternatives may provide cost-effective solutions for less demanding applications.

Resources for HS828 Enthusiasts

For those passionate about their beloved machine, accessing quality information and resources is essential for maintenance, upgrades, and community engagement. This section highlights valuable tools and platforms that can enhance the ownership experience and foster connections among enthusiasts.

Online Communities

- Dedicated forums for discussions and advice

- Social media groups for sharing experiences and photos

- Local clubs for meetups and events

Educational Resources

- How-to guides for repairs and modifications

- Video tutorials for visual learners

- Books and manuals focusing on maintenance techniques