Maintaining the efficiency of your agricultural machinery is crucial for optimal performance. Every piece plays a vital role in ensuring smooth operation and longevity. By exploring the intricate details of these elements, you can enhance your overall understanding and care for your tools.

In this section, we will delve into the various elements that make up your machinery. A comprehensive grasp of their functions and interconnections will ultimately lead to more informed decisions during maintenance and repairs. Recognizing how each component contributes to the whole is essential for achieving the best results in your fieldwork.

Whether you’re a seasoned professional or a newcomer, familiarizing yourself with the structure of these devices can significantly improve your operational efficiency. Equipped with this knowledge, you’ll be better prepared to troubleshoot issues and perform necessary upkeep, ensuring your equipment remains in top condition.

Understanding Lesco Sprayers

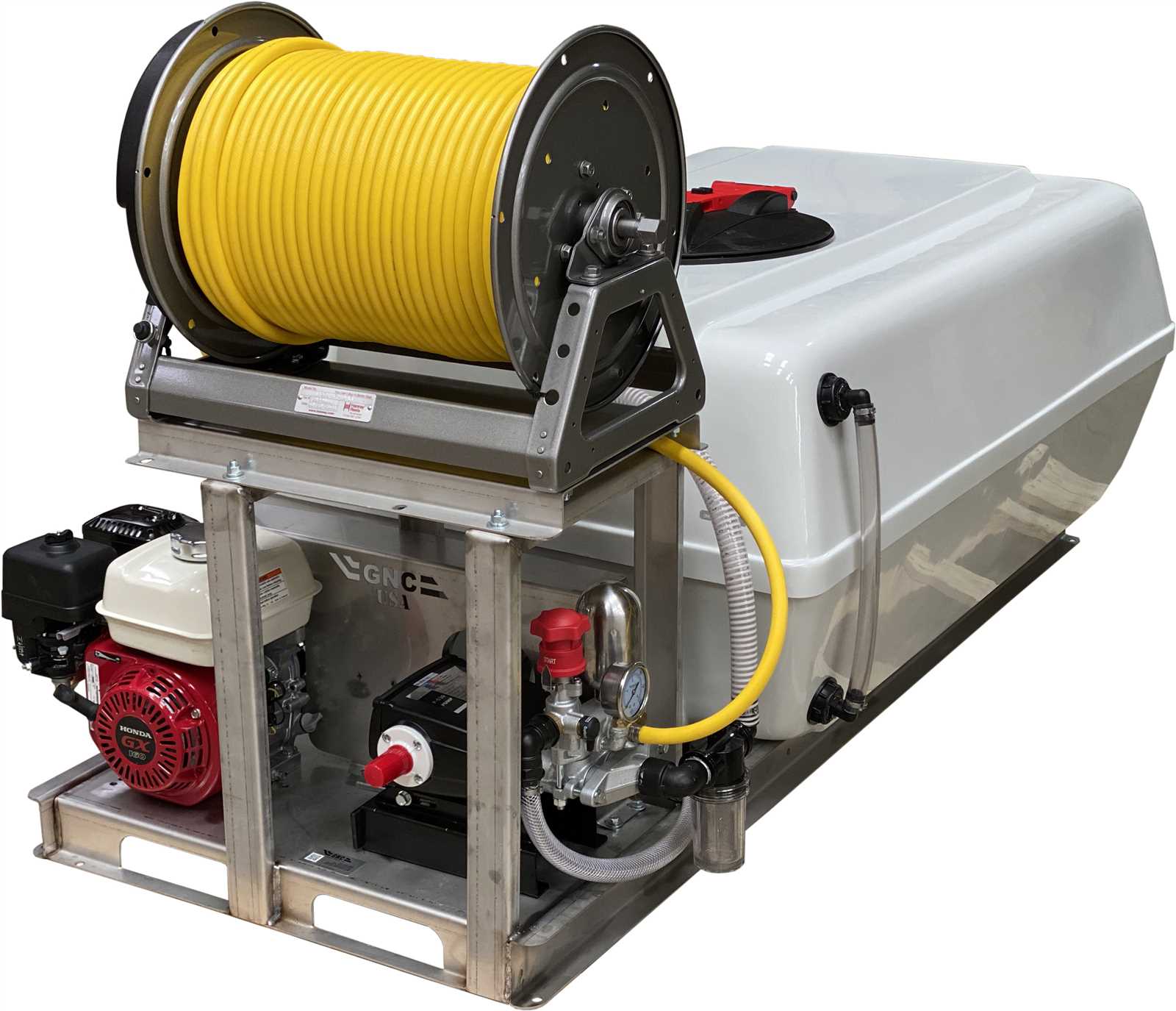

In the realm of landscape maintenance, efficient equipment plays a crucial role in achieving optimal results. Devices designed for the application of liquids are essential for ensuring healthy vegetation and effective pest control. Understanding the components and functionalities of these machines can enhance performance and longevity.

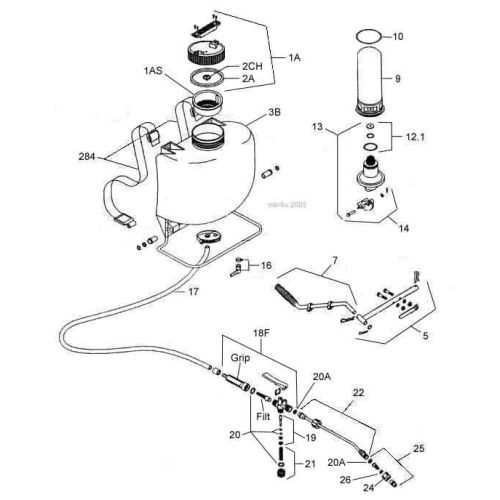

Typically, such equipment features a reservoir for holding solutions, a pump for distributing the liquid, and a variety of nozzles for precise application. Each element is engineered to work harmoniously, allowing users to tackle diverse tasks, from fertilizing gardens to managing weeds.

Maintenance is vital for operational efficiency. Regular checks on seals, filters, and hoses help prevent leaks and ensure a consistent flow. Familiarity with the inner workings and routine upkeep can significantly extend the lifespan of these essential tools.

Moreover, mastering the various settings and adjustments enables operators to customize application rates and coverage, leading to improved outcomes and reduced waste. This knowledge empowers users to make informed decisions, ensuring their efforts yield the best possible results.

Key Components of Lesco Sprayers

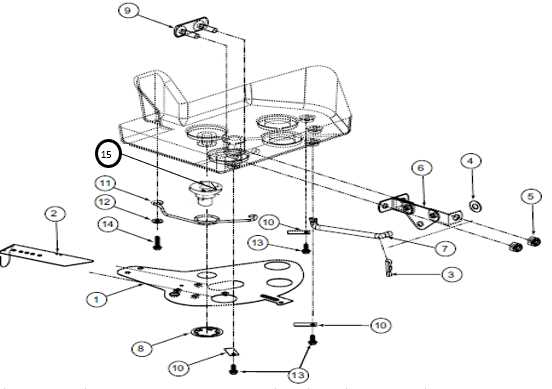

Understanding the essential elements of these application devices is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring efficient distribution of liquids, whether for agricultural use or landscaping. Familiarity with these key parts can enhance operational efficiency and prolong the life of the equipment.

Core Elements

At the heart of the mechanism is the pump, responsible for generating the necessary pressure to deliver the solution. This component is vital for achieving an even application across the targeted area. Coupled with the pump is the tank, which stores the liquid mixture. Proper maintenance of the tank is essential to avoid contamination and ensure longevity.

Distribution Mechanism

The nozzle system is another critical aspect, determining the pattern and size of the spray. Various nozzle types can be selected based on the application requirements, affecting coverage and efficiency. Additionally, hoses and valves facilitate the movement of the solution, contributing to the overall functionality of the apparatus. Understanding these components allows users to troubleshoot issues and perform effective maintenance.

Benefits of Using Lesco Equipment

Investing in high-quality tools for lawn care and landscaping can significantly enhance efficiency and effectiveness. These specialized devices are designed to deliver optimal performance, ensuring that tasks are completed with precision. By choosing reliable equipment, users can expect improved results and greater satisfaction in their outdoor maintenance endeavors.

Enhanced Efficiency

One of the key advantages of utilizing top-tier tools is the boost in productivity. Advanced technology and ergonomic designs allow for quicker and more accurate application of treatments, saving both time and effort. This efficiency not only accelerates project completion but also minimizes labor costs in the long run.

Consistent Performance

Another benefit lies in the dependable operation of these instruments. They are engineered to withstand rigorous use while maintaining consistent output. This reliability ensures that users can tackle various tasks confidently, knowing that they will achieve uniform results every time. With a focus on durability, these tools can be trusted to perform well season after season.

Common Issues with Sprayer Parts

When using equipment for liquid application, various challenges can arise that affect performance and efficiency. Understanding these common complications can help in diagnosing problems and maintaining optimal functionality.

Leaks and Drips

One of the most frequent issues encountered is the presence of leaks. These can occur due to worn seals, loose connections, or cracks in the tank. Leaks not only waste valuable resources but can also lead to uneven application, causing detrimental effects on the intended surfaces. Regular inspection of all connections and components is essential to mitigate this problem.

Clogging and Blockages

Another prevalent concern is clogging, which can occur in nozzles and hoses. Debris or residues from previous applications can obstruct the flow of liquids, resulting in inconsistent spraying patterns. To prevent this, it’s crucial to clean all components thoroughly after each use and to use filters when necessary. Regular maintenance can greatly enhance performance and longevity.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent upkeep and attention. By following a few essential practices, you can significantly extend the lifespan of your machinery while maintaining optimal performance. Regular maintenance not only prevents unexpected breakdowns but also enhances overall functionality, making your investment more reliable over time.

Regular Cleaning and Inspection

Routine cleaning is vital to remove debris and residues that can cause wear and tear. After each use, inspect components for any signs of damage or corrosion. Pay close attention to seals and joints, as these areas are often prone to wear. A thorough examination allows you to identify potential issues early and address them before they escalate.

Lubrication and Replacement

Proper lubrication of moving parts is crucial for smooth operation. Use the recommended lubricants to reduce friction and prevent overheating. Additionally, replace any worn-out components promptly to maintain efficiency. Keeping a schedule for these tasks will help ensure that everything functions smoothly and reduces the risk of costly repairs.

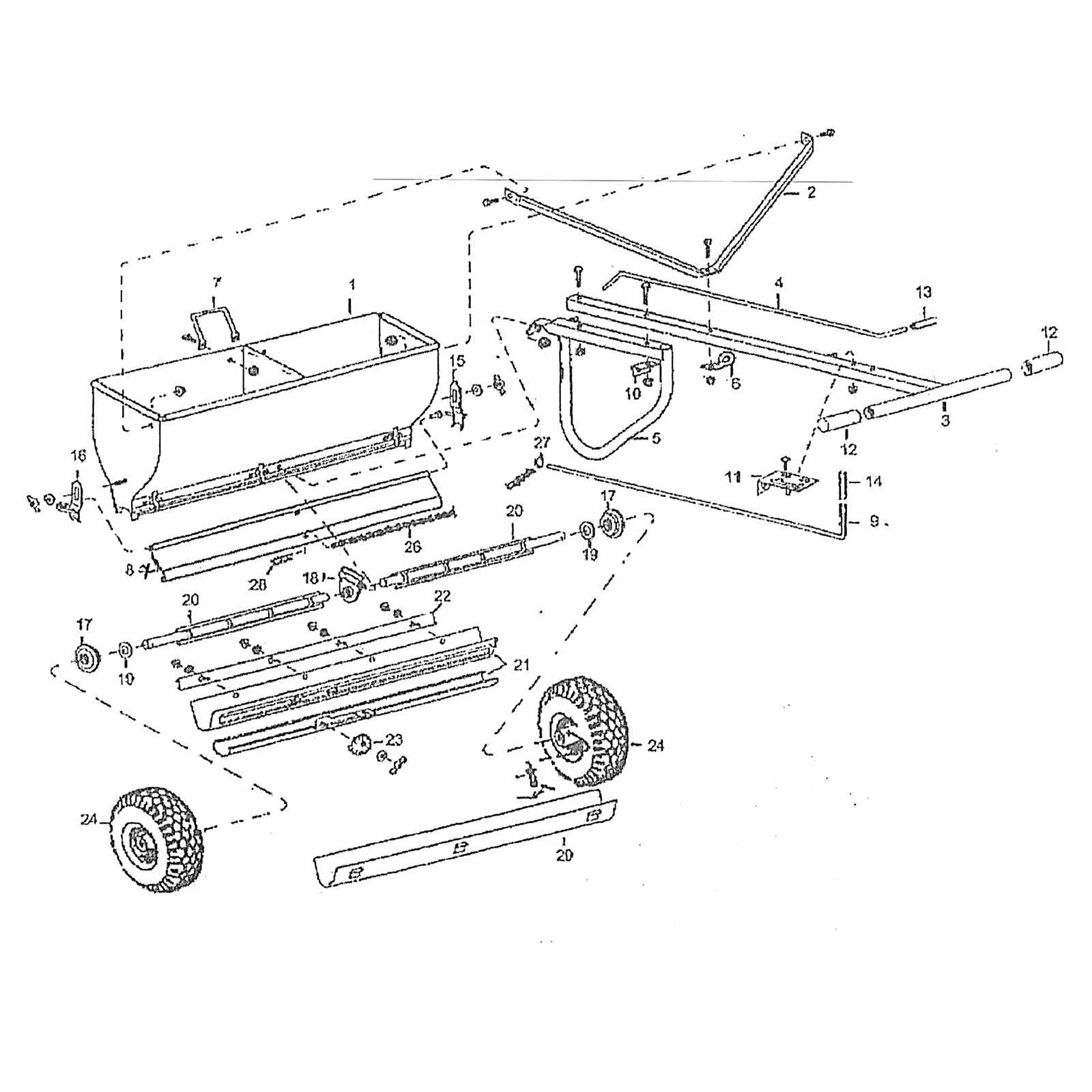

Identifying Replacement Parts Easily

Understanding the components of your equipment is essential for efficient maintenance and repair. By recognizing the different elements and their functions, you can streamline the process of finding suitable substitutes when needed. This knowledge not only saves time but also ensures that your machinery operates smoothly and effectively.

To assist you in identifying the necessary components, here is a structured table highlighting key features and their corresponding replacements:

| Feature | Description | Common Alternatives |

|---|---|---|

| Nozzle | Directs the flow of liquid, allowing for precise application. | Adjustable tips, fixed-angle nozzles |

| Pump | Moves liquid from the tank through the system. | Diaphragm pumps, centrifugal pumps |

| Tank | Holds the liquid until it is dispensed. | Polyethylene tanks, stainless steel reservoirs |

| Hoses | Transports liquid between components. | Reinforced rubber hoses, flexible PVC tubing |

| Filter | Removes impurities from the liquid before application. | Mesh filters, cartridge filters |

By familiarizing yourself with these elements and potential alternatives, you can quickly determine what you need for repairs or upgrades. This proactive approach enhances the longevity and functionality of your equipment.

Comparing Lesco Models on the Market

When exploring various models available for purchase, it’s essential to evaluate their unique features and specifications. Each version caters to different needs, making the choice pivotal for users aiming for efficiency and effectiveness. This section provides an overview of popular options, highlighting their strengths and potential drawbacks.

One of the most notable models stands out for its advanced functionality and user-friendly design. Ideal for both professionals and enthusiasts, it boasts high precision and durability, ensuring reliable performance over time. Conversely, another variant prioritizes compactness and ease of transport, making it suitable for smaller projects or tight spaces.

Additionally, a third option offers enhanced capacity and versatility, appealing to users requiring larger coverage areas. However, this model may come with a steeper learning curve, which could be a consideration for less experienced individuals. Each choice on the market reflects a balance of efficiency, convenience, and adaptability, allowing potential buyers to find the best match for their specific tasks.

DIY Repairs for Sprayer Efficiency

Ensuring optimal performance of your application device is essential for maintaining productivity and effectiveness in your tasks. A few simple repairs and maintenance tips can greatly enhance functionality, reduce downtime, and extend the lifespan of your equipment. By taking a proactive approach, you can keep your gear in top condition without the need for professional assistance.

Common Issues and Solutions

Here are some frequent problems encountered and their corresponding DIY solutions:

| Issue | Solution |

|---|---|

| Clogs in the nozzle | Use a fine wire or brush to clear any obstructions. |

| Leaking seals | Replace worn gaskets or O-rings with new ones. |

| Unresponsive motor | Check electrical connections and replace faulty wires. |

Regular Maintenance Tips

Implementing routine checks can prevent major issues. Regularly inspect and clean all components, ensure proper fluid levels, and store equipment in a dry place to avoid corrosion. Following these practices will help maintain ultimate efficiency.

Where to Find Lesco Diagrams Online

Accessing detailed schematics can significantly enhance maintenance and repair tasks for equipment. Numerous resources are available online that cater to those seeking visual aids and technical information. Utilizing these platforms can streamline the process of identifying components and understanding their functions.

Official Manufacturer Websites

Many manufacturers offer downloadable resources directly from their official sites. These typically include comprehensive manuals and clear illustrations.

Online Forums and Communities

Participating in dedicated forums can provide valuable insights and shared resources. Enthusiasts often upload diagrams and discuss troubleshooting methods.

| Resource Type | Website Example |

|---|---|

| Official Manuals | www.examplemanufacturer.com/manuals |

| Online Forums | www.equipmentforums.com |

| DIY Repair Sites | www.diyrepairs.com |