In the realm of industrial machinery, having a comprehensive understanding of various components is essential for optimal performance and maintenance. This knowledge allows technicians and operators to troubleshoot issues effectively, ensuring that operations run smoothly and efficiently. The intricate relationships between different elements play a critical role in the overall functionality of equipment.

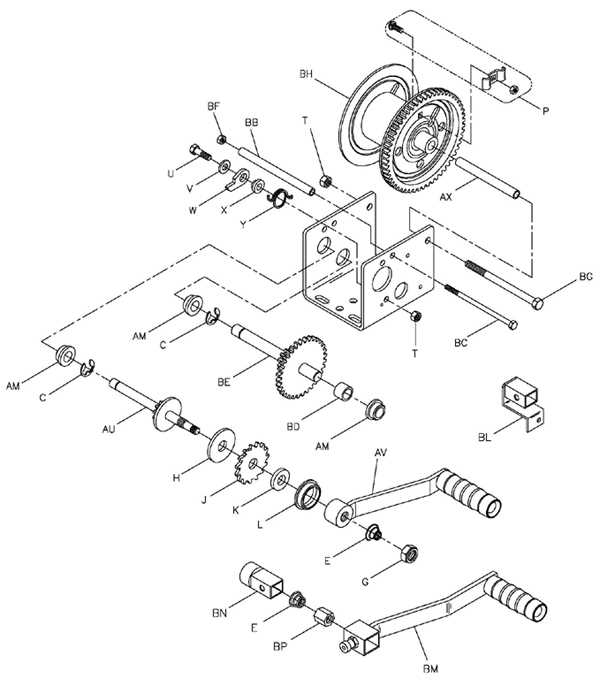

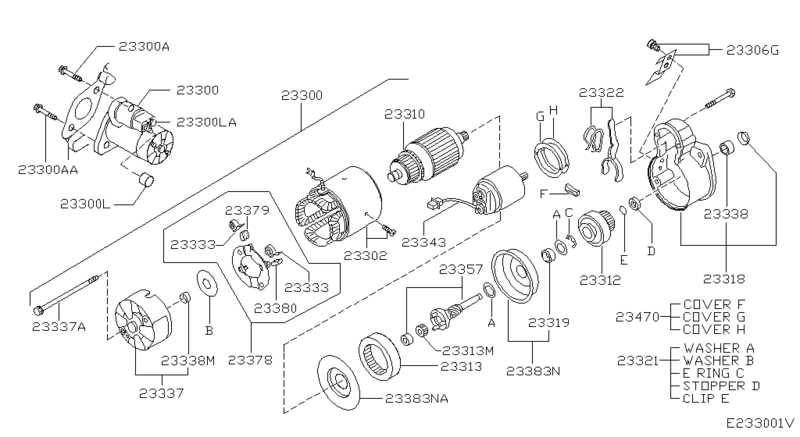

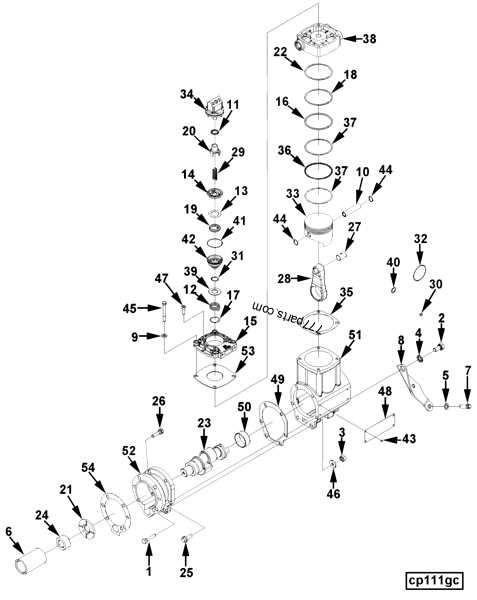

When dealing with complex systems, visual aids become invaluable. They provide clarity and help in identifying each element’s role within the larger mechanism. By examining these representations, one can gain insights into the assembly and disassembly processes, as well as the necessary maintenance protocols. This understanding can significantly reduce downtime and improve productivity.

For those involved in the upkeep of heavy machinery, familiarizing oneself with the layout and connections of these components is a vital step. It not only aids in repairs but also enhances one’s ability to foresee potential problems before they escalate. By focusing on the specifics of each part and its interaction with others, professionals can develop a more effective approach to equipment management.

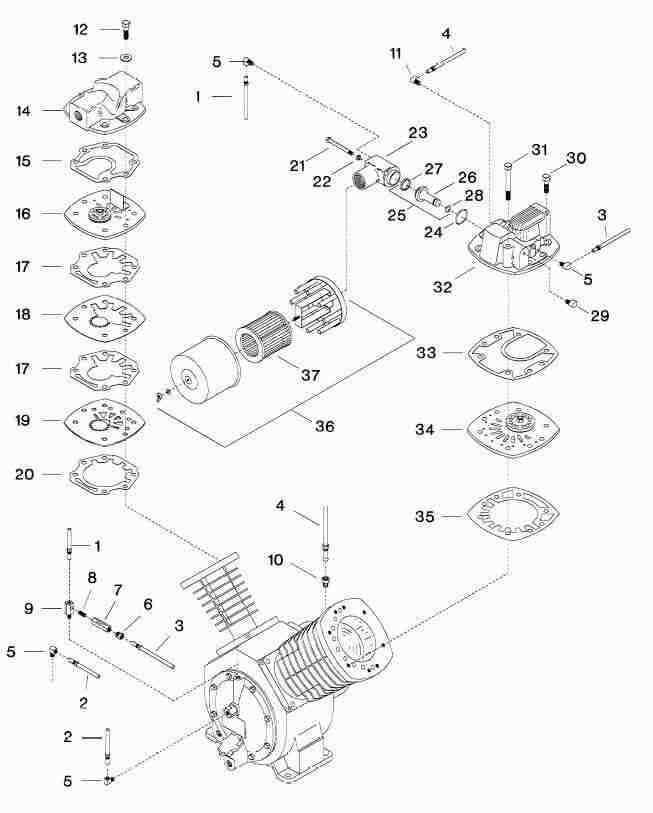

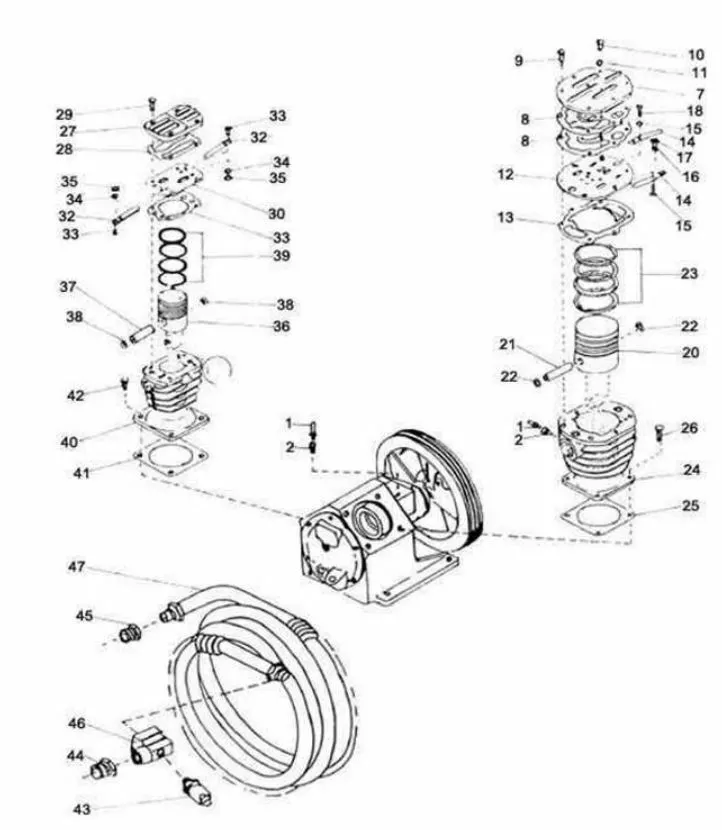

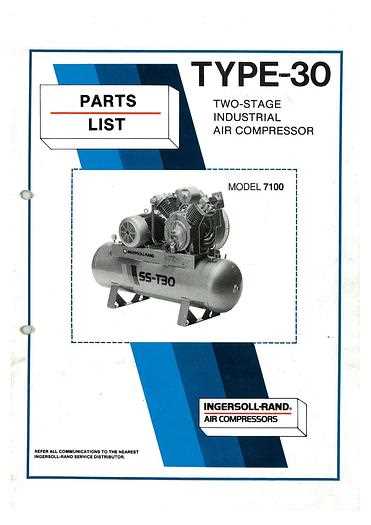

Understanding Ingersoll Rand T30 Components

Comprehending the intricacies of mechanical systems is crucial for effective maintenance and operation. Each element plays a vital role in ensuring optimal performance and longevity. This section delves into the various components, elucidating their functions and interrelations within the machinery.

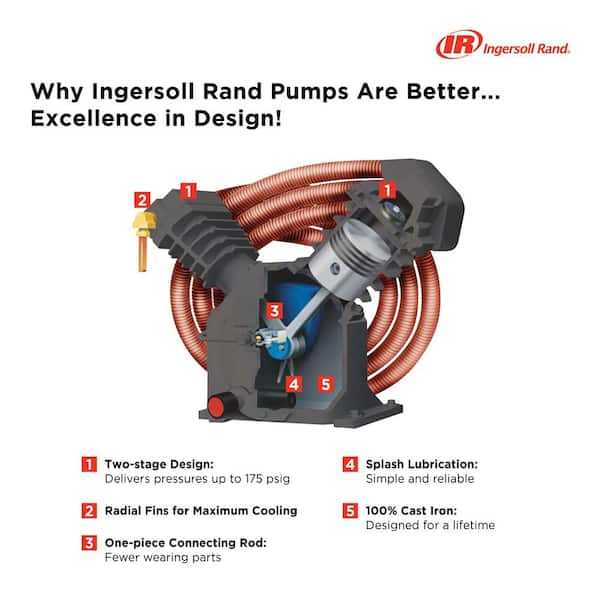

Air Compressor Mechanism consists of several key units that work in harmony. The cylinders are responsible for compressing air, while the pistons convert mechanical energy into compressed air. Additionally, the crankshaft serves as a pivotal component, facilitating the motion of the pistons through rotational energy.

Lubrication System is essential for reducing friction and heat generation. This system ensures that all moving parts receive adequate oil, enhancing their durability and performance. Understanding how this system operates is crucial for maintaining the overall efficiency of the equipment.

Cooling Mechanism prevents overheating, which could lead to component failure. By dissipating heat effectively, this system prolongs the lifespan of critical parts and maintains optimal operating temperatures.

Lastly, control systems regulate the operation of the entire assembly, allowing for adjustments in pressure and flow. Familiarity with these components enhances troubleshooting capabilities and supports proactive maintenance strategies.

Importance of Parts Diagrams

Understanding the layout of components within machinery is crucial for effective maintenance and repair. Clear illustrations serve as essential tools that help technicians identify individual elements and their functions, leading to more efficient troubleshooting and assembly processes.

Benefits of Visual Aids

- Facilitates quick identification of components.

- Enhances the accuracy of repairs.

- Reduces the likelihood of errors during reassembly.

- Streamlines the ordering process for replacements.

Efficiency in Maintenance

- Improved understanding of mechanical systems.

- Decreased downtime due to faster repairs.

- Increased confidence for technicians tackling complex issues.

Key Features of T30 Compressors

When it comes to efficient and reliable air compression, certain models stand out due to their exceptional design and functionality. These machines are engineered to deliver consistent performance while maintaining durability and ease of use. Their innovative features contribute to a wide range of applications, making them a preferred choice for many industries.

Robust Construction: One of the most notable characteristics of these compressors is their sturdy build. Crafted from high-quality materials, they are designed to withstand rigorous operating conditions, ensuring a long service life.

Enhanced Efficiency: These units incorporate advanced engineering principles that optimize energy consumption. This leads to lower operating costs and a smaller environmental footprint, making them an eco-friendly option for businesses.

Low Noise Levels: Noise reduction is a significant advantage. The design includes features that minimize operational sound, providing a quieter working environment without sacrificing performance.

Versatile Applications: Ideal for a variety of tasks, these compressors are suitable for both light and heavy-duty jobs. Their adaptability makes them a valuable asset in workshops, manufacturing plants, and service stations.

Easy Maintenance: Simplified maintenance procedures are integral to the design. Users can easily access key components, reducing downtime and ensuring the equipment remains in optimal working condition.

Powerful Performance: Equipped with a reliable motor and efficient pump, these compressors deliver robust power output. This capability ensures that they meet the demands of even the most challenging tasks.

Common Maintenance Practices

Effective upkeep is essential for ensuring optimal performance and longevity of industrial machinery. Implementing regular maintenance routines helps to identify potential issues before they escalate, thus reducing downtime and enhancing productivity. Adopting a structured approach to maintenance can significantly improve the reliability and efficiency of equipment.

Routine Inspections

Conducting frequent evaluations is crucial for detecting wear and tear. Inspections should focus on key components, including filters, belts, and seals. Look for signs of leakage, corrosion, or unusual noises, as these can indicate underlying problems. Keeping a detailed log of findings can aid in tracking performance trends over time.

Lubrication and Cleaning

Regular lubrication is vital for minimizing friction and preventing component damage. Use appropriate lubricants specified by the manufacturer to ensure compatibility. Additionally, keeping the machinery clean from dust and debris can prevent overheating and ensure efficient operation. Scheduled cleaning sessions can enhance both safety and performance, contributing to a more effective work environment.

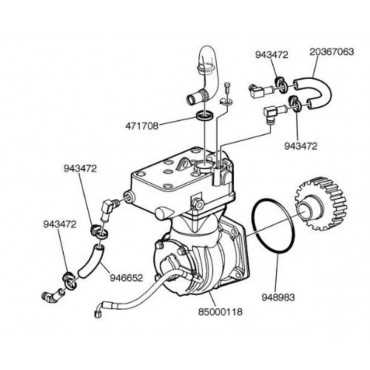

Identifying T30 Spare Parts

Understanding the components of your machinery is essential for maintaining optimal performance and ensuring longevity. Recognizing each individual element within the system allows for informed decisions when it comes to repairs and replacements. This section focuses on key identifiers to help you locate and select the necessary replacements effectively.

Common Components Overview

Familiarity with the main elements is crucial. Typically, these include items such as pistons, valves, and gaskets, each playing a vital role in the overall functionality. A thorough examination of these components can assist in diagnosing issues and pinpointing which specific elements require attention.

Utilizing Reference Guides

Reference materials, such as catalogs or manuals, provide invaluable assistance in identifying the correct elements. These documents often contain detailed illustrations and specifications that simplify the selection process. Always cross-check your findings with these resources to ensure accuracy and compatibility with your machinery.

By mastering the identification of these crucial components, you can enhance your operational efficiency and prolong the lifespan of your equipment.

Repair vs. Replacement Decisions

Making the choice between repairing an existing piece of equipment or replacing it with a new model is a common dilemma faced by many operators. This decision can significantly impact operational efficiency, costs, and overall performance. It is essential to weigh the pros and cons carefully, considering factors such as long-term reliability, financial implications, and the specific needs of your operations.

Factors to Consider

When deciding whether to repair or replace, several key aspects should be taken into account:

| Factor | Repair | Replacement |

|---|---|---|

| Cost | Generally lower initial expense | Higher upfront investment |

| Downtime | Potentially less if parts are readily available | May require longer installation time |

| Performance | May not restore original efficiency | Often includes the latest technology |

| Longevity | Shorter lifespan if components are worn | New equipment typically offers longer service life |

Making the Right Choice

Ultimately, the decision should align with your operational goals and budgetary constraints. Conducting a thorough analysis of the condition of the equipment, projected repair costs, and potential downtime will aid in making an informed choice. In many cases, investing in new technology may provide better value in the long run, while timely repairs can extend the life of essential machinery without immediate financial strain.

Where to Find Parts Diagrams

Locating comprehensive visual references for machinery components is essential for efficient maintenance and repair. These resources can simplify the identification of individual elements and their arrangement, ensuring that any replacements or repairs are executed correctly.

Online Resources

- Manufacturer Websites: Many companies provide detailed illustrations directly on their official sites, allowing easy access to the latest information.

- Specialized Forums: Engaging with online communities can lead to valuable shared resources and insights from experienced users.

- Technical Support Pages: These often include downloadable manuals and visual guides to assist with specific models.

Print Resources

- Service Manuals: Printed guides can be a reliable source of information and often contain extensive visual breakdowns.

- Catalogs: Various suppliers offer printed catalogs featuring diagrams that can aid in identifying necessary components.

- Industry Publications: Journals and magazines sometimes include detailed articles and illustrations related to equipment maintenance.

Benefits of OEM vs. Aftermarket Parts

When it comes to maintaining and repairing machinery, the choice between original manufacturer components and alternative options can significantly impact performance and longevity. Understanding the advantages of each type can help users make informed decisions tailored to their specific needs.

Quality and Reliability

Original components are typically designed with precise specifications, ensuring compatibility and reliability. These items often undergo rigorous testing and quality assurance processes, which can lead to improved performance and reduced risk of failure. Conversely, alternative options may vary in quality, with some manufacturers prioritizing cost over performance.

Cost Considerations

While original components may come at a higher initial price, they often prove to be more cost-effective in the long run due to their durability and lower failure rates. Alternative options can appear more economical upfront but may require more frequent replacements, potentially leading to increased overall costs.

| Criteria | OEM Components | Aftermarket Options |

|---|---|---|

| Quality | High, tested for performance | Variable, depends on manufacturer |

| Cost | Higher upfront | Lower initial price |

| Longevity | Long-lasting | Shorter lifespan |

| Compatibility | Designed for specific models | May not fit perfectly |

Ultimately, the decision should be based on the specific requirements of the machinery and the user’s budget considerations. Balancing quality and cost can lead to the best outcomes for maintenance and repair efforts.