When working with heavy machinery, it’s essential to know how each element functions to ensure smooth operations and safety. The equipment used for lifting and transporting loads in warehouses or construction sites consists of numerous key mechanisms that work together. Recognizing these various elements can help with maintenance, troubleshooting, and overall machine performance.

In this section, we will explore the essential components that enable the machine to carry out its primary tasks efficiently. By understanding how these systems interact, operators can maintain equipment more effectively and address potential issues before they escalate. Knowing the layout and structure of this machinery can also provide insight into proper care and upgrades.

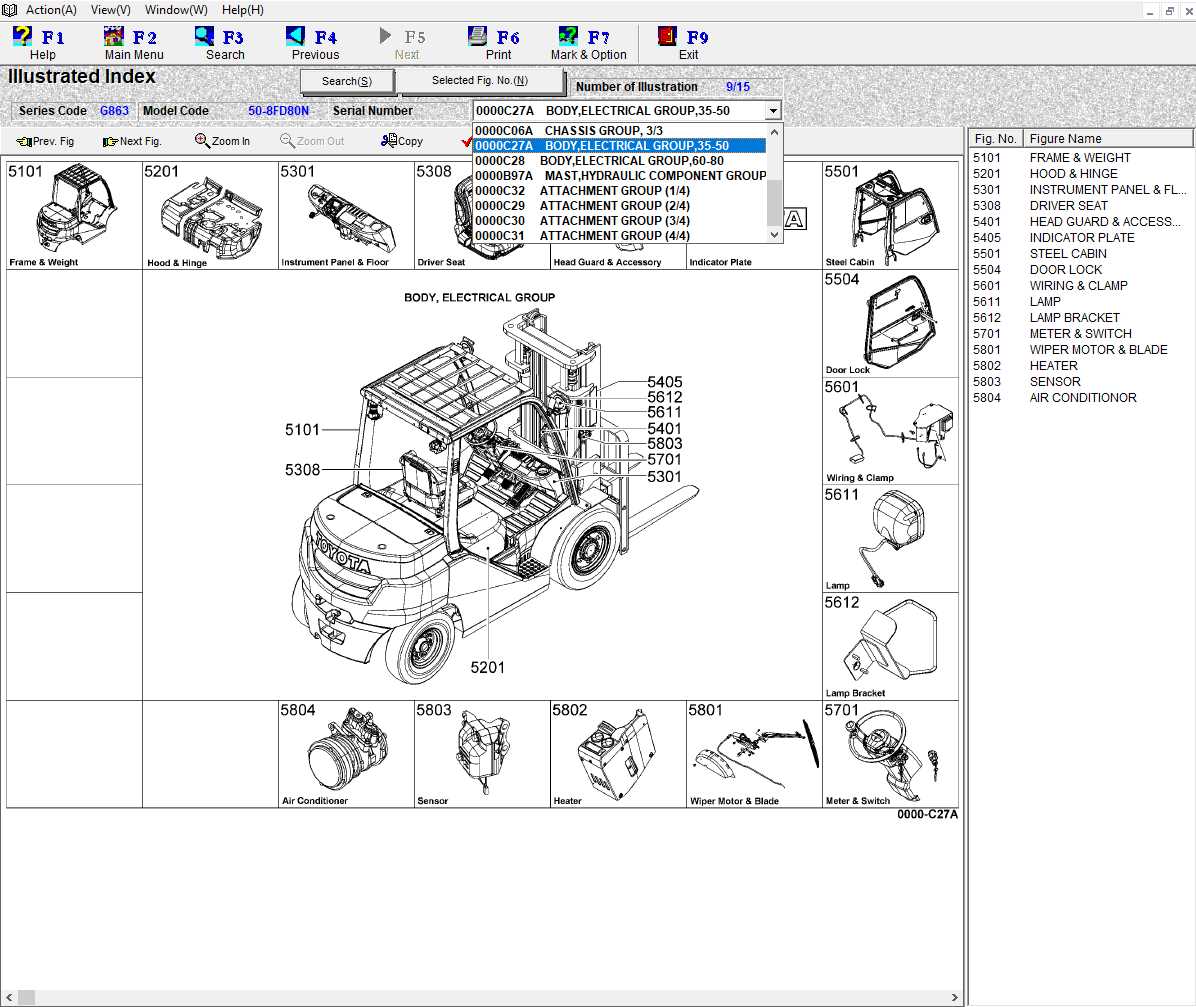

Forklift Component Overview

The machinery used for heavy lifting consists of several key elements that work together to ensure proper functionality. Each component plays a vital role in maintaining balance, power, and control, allowing the equipment to perform tasks efficiently in various industrial environments. Understanding these essential elements helps operators ensure safe and smooth operations.

Key Structural Elements

The main structure includes the frame, which provides the foundation, and the mast, responsible for the vertical movement of loads. The operator compartment offers controls, while the counterweight balances the system during operations. All of these elements are essential for stability and precision.

Power and Motion Systems

Energy for movement is supplied through the engine or electric motor, depending on the model. A hydraulic system handles lifting, while the wheels, supported by the steering mechanism, enable smooth mobility. These systems ensure both power and maneuverability for handling loads in various settings.

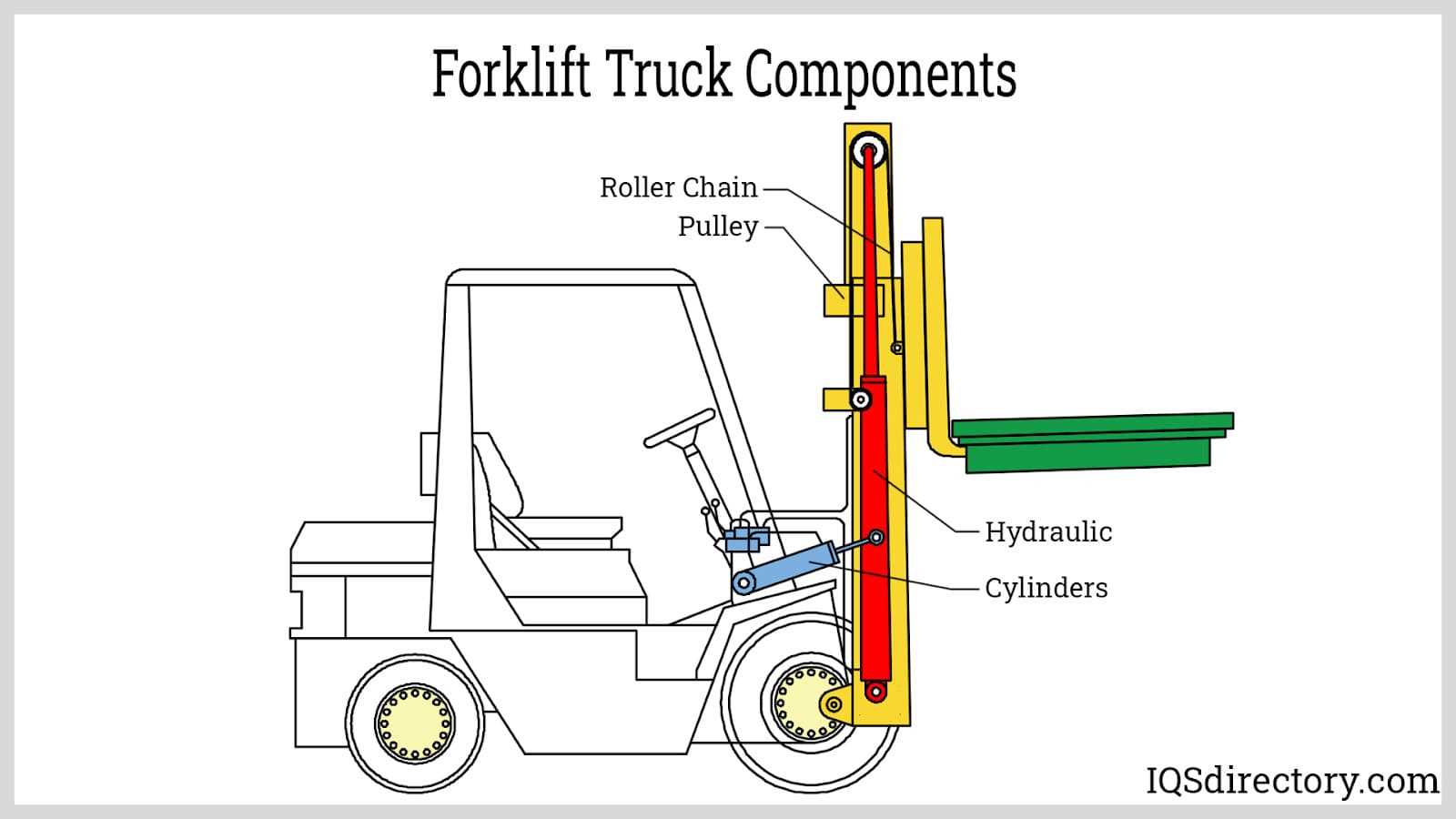

Understanding the Hydraulic System

The hydraulic system is a key component that enables controlled movement and force application. It works by using fluid pressure to generate motion and lift heavy loads, ensuring smooth and efficient operation. This section will explore the primary elements that make up this system and their functions.

Main Components

The system consists of several important elements, including the pump, valves, and cylinders. The pump creates pressure by moving the fluid, while the valves regulate its flow. The cylinders then convert this pressure into mechanical energy, enabling motion. Each part plays a crucial role in maintaining the balance and functionality of the system.

Pressure Control and Safety

Pressure control is critical to prevent damage and ensure safe operations. Valves are designed to relieve excess pressure, protecting the system from overloading. Regular maintenance and checks are essential to keep everything running smoothly and avoid costly repairs.

Key Features of the Steering Mechanism

The steering mechanism is an essential component that enables controlled movement and maneuverability in heavy-duty vehicles. Understanding the primary characteristics of this system is crucial for ensuring optimal performance and safety.

Steering System Components

Each element of the steering system works together to provide smooth and accurate control. These components ensure that the vehicle responds efficiently to directional input, enhancing both precision and safety during operation.

| Component | Function |

|---|---|

| Steering Wheel | Initiates the directional input |

| Hydraulic Cylinder | Assists in power steering to reduce effort |

| Control Linkages | Transmits motion from the wheel to the vehicle’s axle |

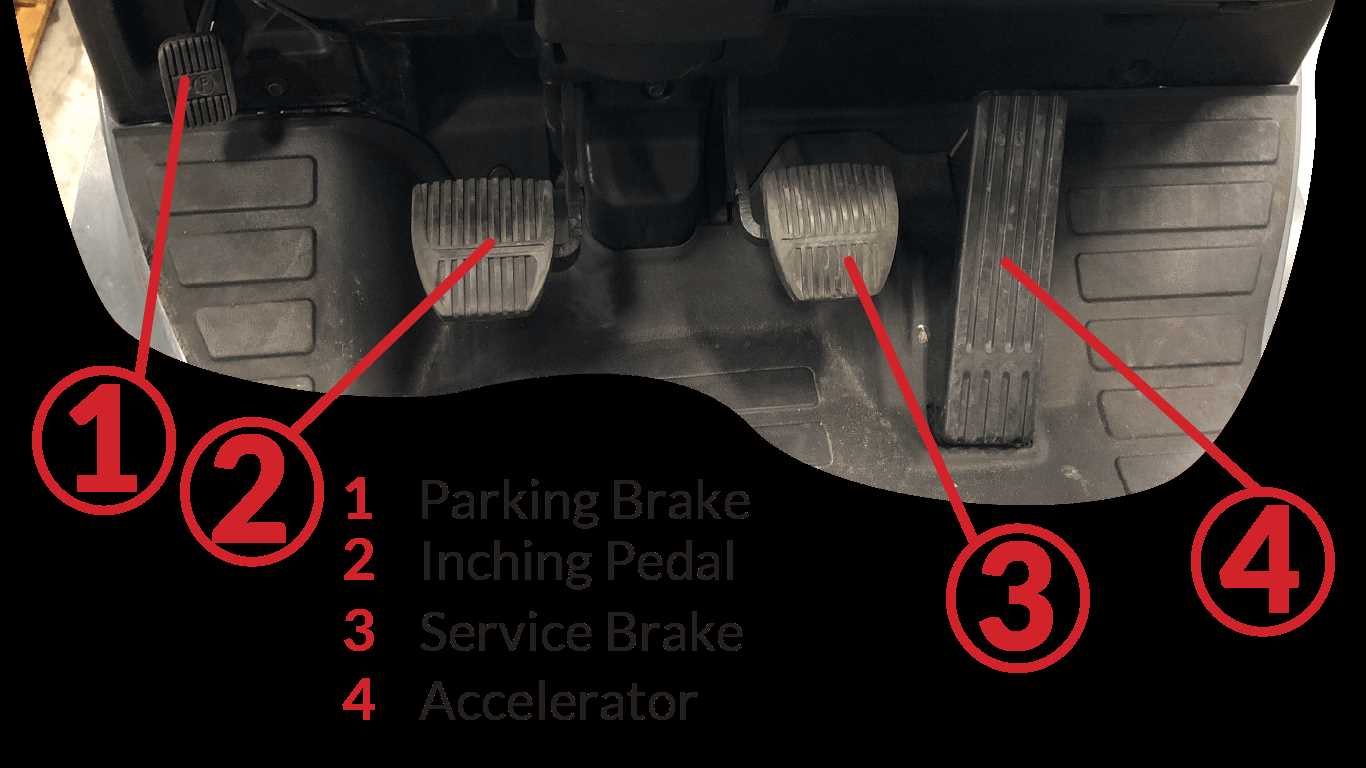

Brake Assembly and Functionality

The brake system plays a crucial role in ensuring safe and efficient operation by controlling the vehicle’s speed and bringing it to a complete stop when needed. It consists of various interconnected components that work together to apply friction and slow down movement. The system is designed to be both reliable and responsive, offering the operator full control over deceleration in different situations.

The primary elements of the braking mechanism include pads, discs, and hydraulic lines, each of which has a specific function in applying pressure and distributing force. When the operator presses the control, the system transfers force through the hydraulic fluid, causing the pads to squeeze against the rotating discs. This process generates friction, which effectively slows down or stops the movement.

Proper maintenance of these components is essential to ensure consistent performance and to prevent potential failures. Regular inspections help identify wear or damage to the pads and discs, which are the most vulnerable to friction and heat. Replacing worn-out parts promptly and maintaining optimal fluid levels in the system contribute to long-term reliability and safety.

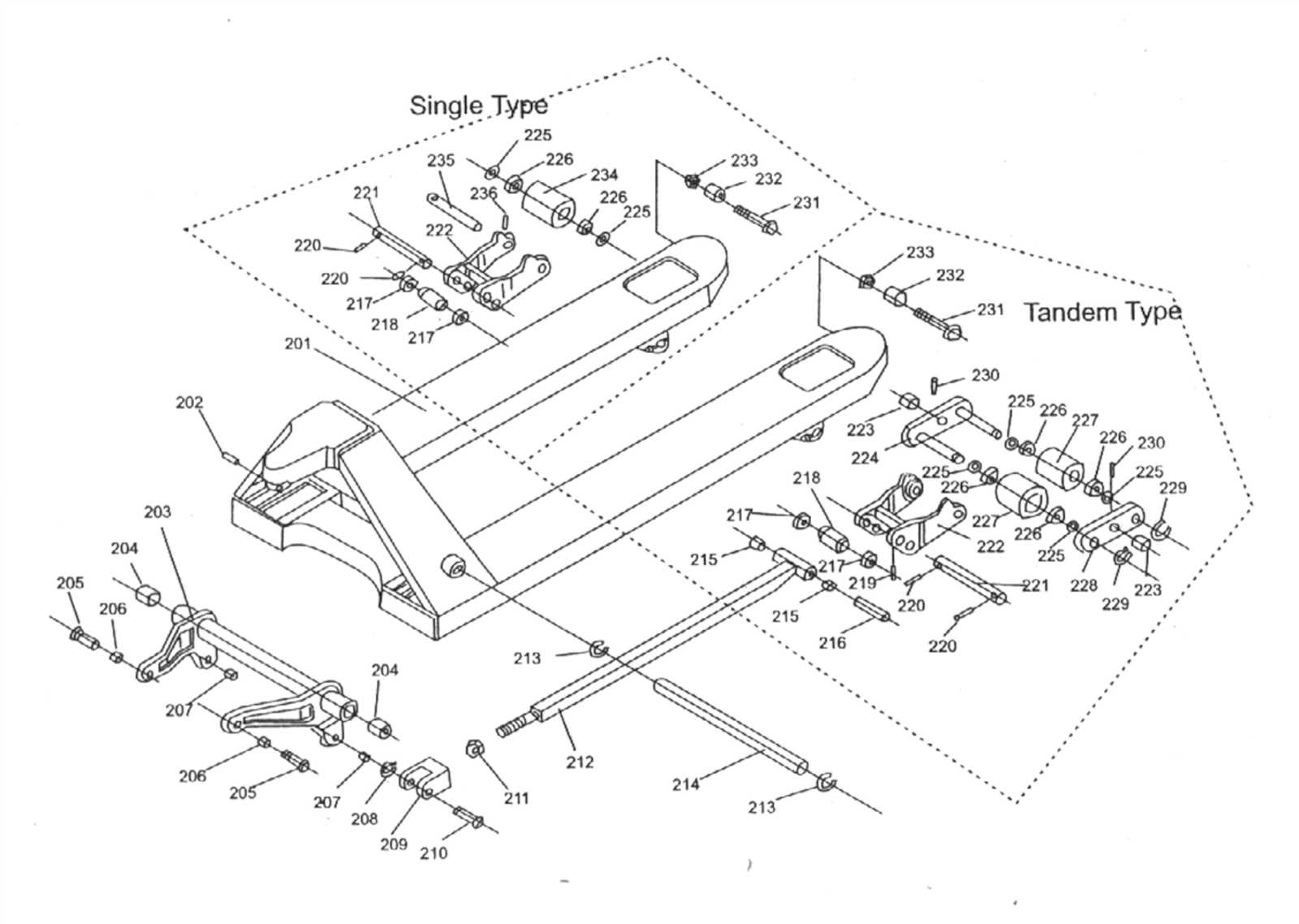

Lift Chain and Mast Configuration

The lift chain and mast system plays a critical role in the vertical movement of the load, ensuring smooth and reliable lifting and lowering. The system’s efficiency depends on the interaction between the lifting mechanisms and the structural support of the mast, allowing the load to move securely and accurately.

Lift Chain Functionality

The lift chain is designed to bear the weight of the load while distributing the force evenly across the mast. It works in sync with hydraulic systems to provide controlled vertical movement, ensuring that the load can be raised or lowered with precision. The chain’s strength and durability are vital for maintaining safety and functionality.

Mast Structure and Design

The mast consists of several interlocking sections that extend and retract to provide height and stability during lifting. It supports the load by guiding its vertical movement, ensuring balance and preventing tipping. The mast’s design is optimized to handle different load sizes, making it an essential component of the lifting system.

Battery and Power Supply Parts

The energy source and distribution system in industrial vehicles play a crucial role in their performance and efficiency. Understanding the components involved in providing and managing power is essential for effective maintenance and operation.

The primary components that contribute to the energy system include the storage unit, charging mechanisms, and electrical connections. Each of these elements works in harmony to ensure that the vehicle operates smoothly and reliably.

| Component | Description | Function |

|---|---|---|

| Storage Unit | A device that holds electrical energy for later use. | Provides power to the vehicle’s systems during operation. |

| Charging System | Equipment that replenishes the storage unit’s energy. | Ensures the vehicle is ready for use by maintaining energy levels. |

| Electrical Connections | Cables and connectors that link various components. | Facilitates the flow of electricity between the storage unit and the vehicle’s systems. |

Types of Fork Attachments

Various accessories are essential for enhancing the functionality and versatility of lifting equipment. These attachments allow operators to handle different types of loads more efficiently, catering to diverse operational needs across various industries.

Common Attachments

- Standard Pallet Shifter: Ideal for moving pallets with ease.

- Side Shifter: Enables lateral movement of the load for precise positioning.

- Fork Extensions: Increases the reach of the lifting device for larger loads.

- Rotating Attachment: Allows for 360-degree rotation of the load.

Specialized Attachments

- Clamps: Useful for securely holding specific items like pipes or sheets.

- Multi-Pallet Handler: Designed to lift multiple pallets simultaneously.

- Container Handler: Optimized for lifting and stacking shipping containers.

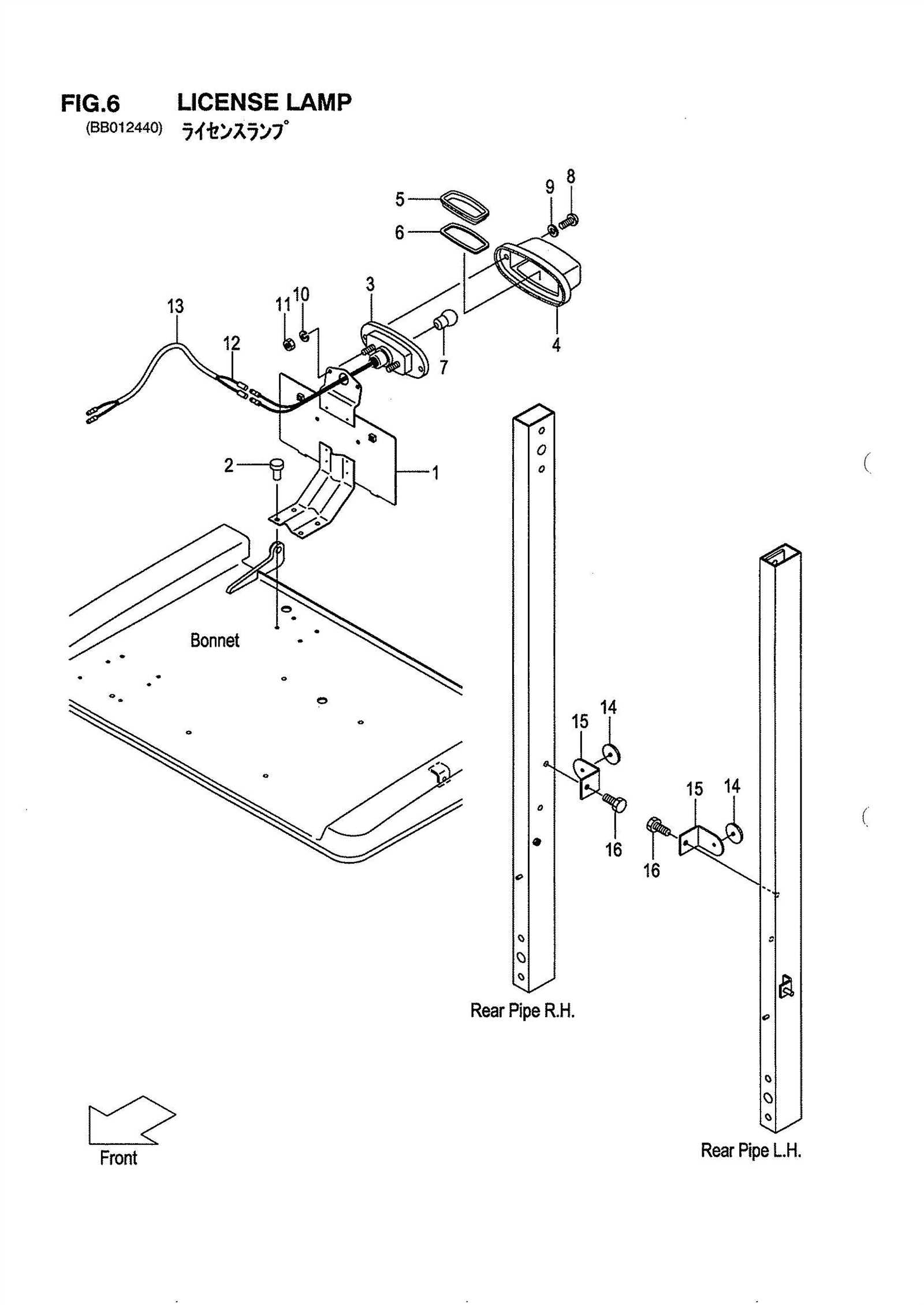

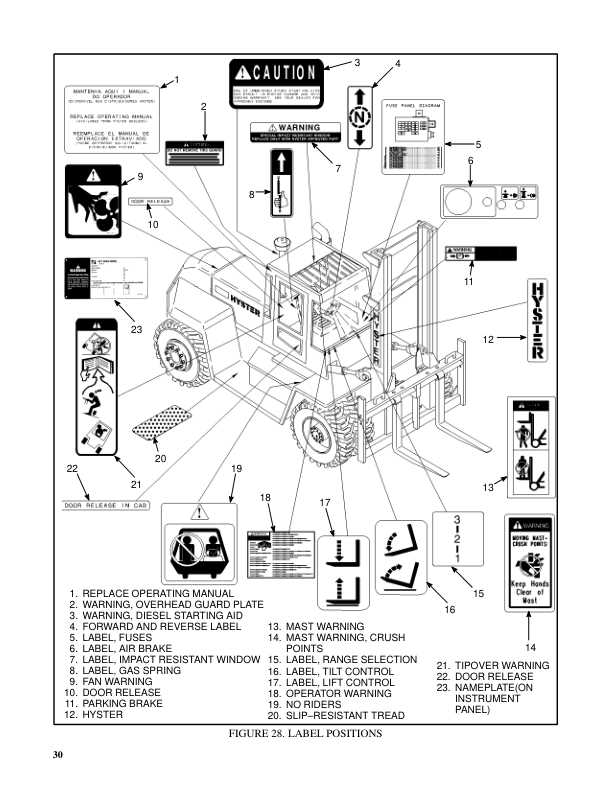

Control Panel and Dashboard Layout

The layout of the control interface is crucial for effective operation and management. It serves as the command center, allowing the operator to monitor and manipulate various functionalities efficiently. Understanding the arrangement of controls and indicators can enhance productivity and safety.

Main Components

- Control Switches: These are used to operate different functions, such as lifting and lowering mechanisms.

- Indicators: Visual signals that provide real-time information regarding the status of the machine, including battery level and load weight.

- Emergency Stop: A critical feature designed for quick deactivation of the system in case of an emergency.

Dashboard Features

- Speedometer: Displays the current operating speed, ensuring that the operator maintains safe handling speeds.

- Control Levers: Essential for precise manipulation of various actions, allowing for smooth operation.

- Warning Lights: These alert the operator to any issues that may require immediate attention, promoting safety.

Transmission and Drive System Components

The transmission and drive system play a crucial role in the operation of industrial vehicles, ensuring the efficient transfer of power from the engine to the wheels. Understanding the various elements within this system is essential for optimal performance and maintenance. This section delves into the key components that contribute to the overall functionality of these systems.

Key Elements of the Transmission System

The transmission system consists of several vital components that work together to facilitate smooth movement. These include gears, shafts, and hydraulic systems. Each part has a specific function that contributes to the overall efficiency of power delivery.

Drive System Overview

The drive system encompasses components responsible for transferring the power generated by the engine to the vehicle’s wheels. This includes differentials, axles, and drive belts. Proper understanding and maintenance of these elements are essential for ensuring the reliability of the vehicle.

| Component | Function |

|---|---|

| Transmission Gears | Adjusts torque and speed ratios. |

| Hydraulic Pump | Facilitates fluid movement for gear operation. |

| Differential | Allows for wheel speed variation during turns. |

| Drive Belts | Transfers power from the engine to the wheels. |