When it comes to maintaining and optimizing agricultural equipment, having a clear visual representation of its components is essential. Such illustrations serve as a roadmap for technicians and enthusiasts alike, guiding them through the intricate web of machinery. By examining these layouts, one can quickly identify each element and understand how they interact within the larger system.

Accurate schematics not only aid in troubleshooting and repairs but also enhance the overall efficiency of the equipment. Knowing the arrangement of each section allows users to perform maintenance tasks more effectively, ensuring that their machinery operates at peak performance. Whether it’s for routine checks or major overhauls, these visuals are invaluable resources.

Additionally, comprehending the organization of parts contributes to better planning and decision-making in agricultural practices. From understanding wear patterns to anticipating future needs, a well-illustrated overview empowers operators to make informed choices. This clarity ultimately leads to more productive outcomes and longevity of the equipment.

Understanding Farm Pro 2425 Parts

Grasping the intricacies of machinery components is crucial for effective maintenance and operation. This knowledge empowers users to troubleshoot issues, ensure longevity, and optimize performance. A comprehensive understanding of the various elements allows for seamless repairs and enhancements, ultimately leading to greater efficiency.

Key Components Overview

Each element plays a vital role in the functionality of the machine. From the engine assembly to hydraulic systems, recognizing how these parts interact can significantly impact overall operation. Familiarity with these components helps users make informed decisions about repairs and upgrades.

Maintenance and Troubleshooting

Regular upkeep and prompt attention to potential issues are essential for maintaining optimal performance. Users should be aware of common problems associated with specific components and how to address them effectively. This proactive approach ensures a smooth operation and extends the lifespan of the equipment.

Importance of Parts Diagrams

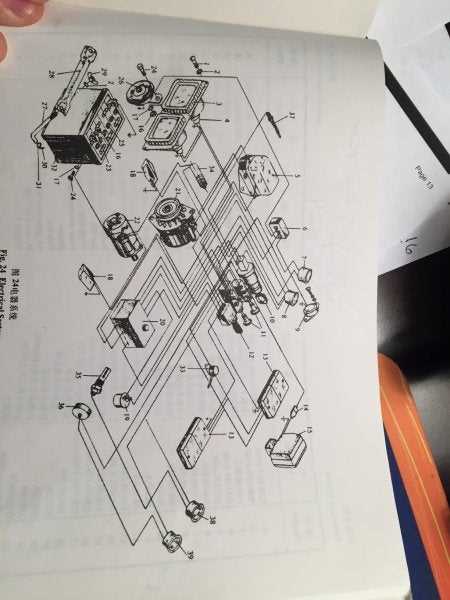

Visual representations of components play a crucial role in understanding complex machinery. They provide users with a clear overview of the various elements that make up a system, facilitating better comprehension of how each part interacts and functions together.

These illustrations serve as essential tools for maintenance and repair tasks, allowing technicians to quickly identify and locate specific elements. This efficiency not only saves time but also reduces the likelihood of errors during servicing, ultimately leading to improved operational reliability.

Moreover, such visual guides enhance communication among team members, enabling clearer discussions regarding troubleshooting and modifications. They foster a shared understanding of the equipment, ensuring that everyone involved is on the same page.

In addition, these resources support educational efforts by providing learners with an accessible way to study and grasp mechanical concepts. As a result, users can develop their skills and knowledge, contributing to a more competent workforce in the industry.

Key Components of the Tractor

Understanding the essential elements of agricultural machinery is crucial for effective maintenance and operation. Each part plays a significant role in enhancing performance and ensuring reliability, contributing to the overall efficiency of farming tasks. A comprehensive grasp of these components can aid operators in identifying issues and optimizing their equipment’s functionality.

Engine and Power Transmission

The engine serves as the heart of the machinery, providing the necessary power to perform various functions. Coupled with the transmission system, it enables the machine to transfer energy efficiently to the wheels, allowing for effective movement and operation in diverse terrains.

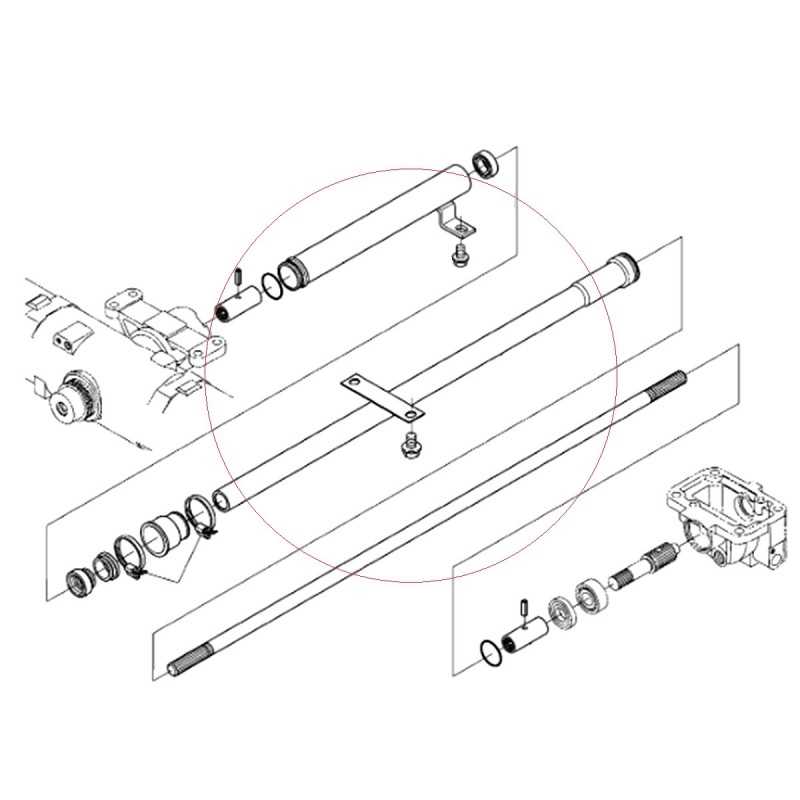

Hydraulic System

The hydraulic system is vital for powering attachments and implements. It utilizes fluid pressure to facilitate the movement of various components, ensuring that tasks such as lifting, steering, and plowing are executed smoothly. Understanding its operation can significantly enhance the versatility and effectiveness of the equipment.

Common Issues and Solutions

When working with machinery, various challenges can arise that may affect performance and efficiency. Identifying these issues early is crucial for maintaining optimal operation. This section outlines some frequent problems encountered and their corresponding remedies to ensure smooth functionality.

Overheating

One of the most prevalent issues is overheating. This can result from insufficient cooling or blocked airflow. To address this, ensure that all cooling systems are functioning properly. Regularly clean any filters and check coolant levels. If the problem persists, inspect the fan and radiator for any obstructions.

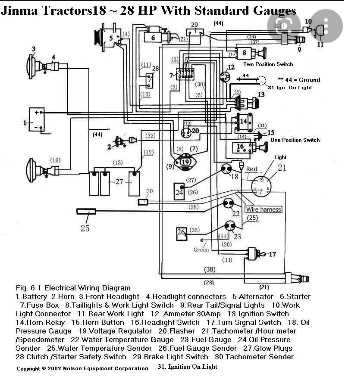

Electrical Failures

Another common complication involves electrical malfunctions. Symptoms can include inconsistent operation or complete shutdowns. To troubleshoot, first check all connections and wiring for signs of wear or damage. It’s also advisable to inspect the battery and fuses. Replacing faulty components often resolves these issues, restoring normal function.

Where to Find Replacement Parts

Finding suitable components for machinery can be a challenging task, but knowing where to look can simplify the process significantly. Whether you need original equipment or quality alternatives, various resources are available to assist you in sourcing what you need.

Online Retailers

- Websites dedicated to machinery supplies often offer a wide range of options.

- Marketplaces such as Amazon and eBay can have competitive prices and user reviews.

- Specialized online stores provide detailed descriptions and compatibility information.

Local Suppliers and Dealers

- Check with local dealerships for original parts and accessories.

- Independent repair shops may stock or order specific components.

- Networking with other operators can lead to recommendations for trustworthy suppliers.

Utilizing these avenues will help ensure you find the necessary items for your equipment efficiently.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. Regular maintenance not only extends the lifespan of equipment but also enhances performance and safety. Implementing a few straightforward practices can lead to significant benefits over time.

- Regular Inspections: Schedule routine checks to identify wear and tear. Look for signs of damage or deterioration in key components.

- Cleanliness: Keep the machinery clean from debris and dust. Regular cleaning prevents buildup that can lead to malfunctions.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent overheating. Refer to the manufacturer’s guidelines for recommended products.

- Fluid Checks: Regularly inspect and replace fluids, such as oil and coolant, to maintain optimal functioning.

- Replace Worn Parts: Address any worn components promptly. Delaying replacements can lead to more extensive damage.

Incorporating these practices into your routine will foster a more reliable operation and ultimately save time and resources in the long run.

Aftermarket vs. Original Parts

The choice between alternative and manufacturer-specific components often presents a significant decision for equipment owners. Each option comes with its own set of advantages and challenges that can impact performance, longevity, and overall satisfaction.

Advantages of Original Components

- Quality Assurance: Manufacturer-specific parts are designed to meet exact specifications, ensuring compatibility and reliability.

- Warranty Protection: Using original components often helps maintain warranty coverage, providing peace of mind for the user.

- Resale Value: Equipment maintained with genuine parts may retain a higher resale value, appealing to future buyers.

Benefits of Alternative Components

- Cost-Effectiveness: Alternative options are frequently more affordable, making them appealing for budget-conscious users.

- Availability: Aftermarket components are often easier to find, especially for older models or less common machines.

- Variety: The market for alternative options may provide a broader range of features or enhancements not available in original parts.

Assembly Instructions and Guidelines

Proper assembly of machinery components is crucial for ensuring optimal performance and longevity. Following detailed instructions not only enhances efficiency but also minimizes the risk of errors during the process. This section provides a structured approach to assembling the various elements involved, emphasizing clarity and precision.

Preparation Steps

Before starting the assembly, gather all necessary tools and components. Ensure that your workspace is clean and organized. Carefully review the assembly manual to familiarize yourself with each part’s function and the order of assembly. Double-check that you have all the required items, as missing components can lead to complications.

Assembly Process

Begin by assembling the base components first, ensuring they are securely attached. Gradually work your way up, connecting additional parts in the prescribed sequence. Use appropriate fastening techniques to avoid loosening over time. Regularly inspect connections for stability and alignment, adjusting as necessary to maintain structural integrity.

Customer Experiences and Reviews

This section explores the feedback and insights shared by users who have interacted with our equipment. Understanding their perspectives allows potential buyers to make informed decisions and enhances the overall user experience.

Positive Feedback

Many customers have praised the reliability and efficiency of the machinery. Users frequently mention how the tools perform exceptionally well under various conditions, contributing to improved productivity and satisfaction.

Areas for Improvement

Some reviewers have noted specific challenges, such as the need for better customer support and clearer assembly instructions. Addressing these concerns could further enhance user satisfaction and loyalty.

| Feedback Type | Customer Comments |

|---|---|

| Positive | Reliable performance and ease of use. |

| Negative | Need for improved customer service. |

| Neutral | Good quality but complicated setup. |