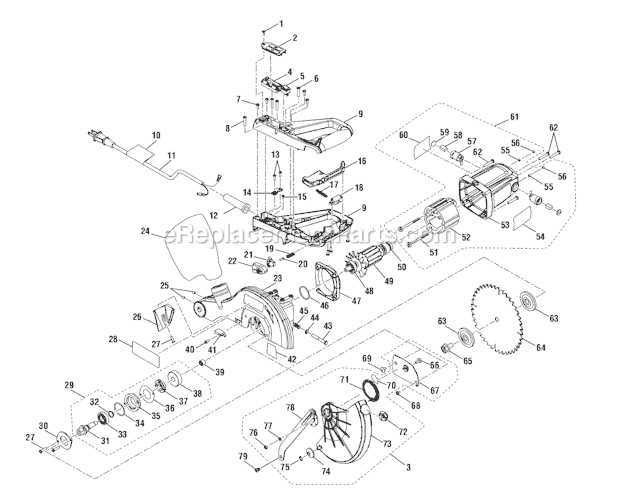

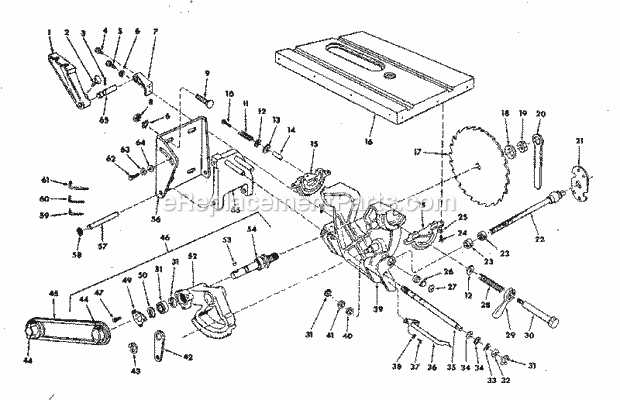

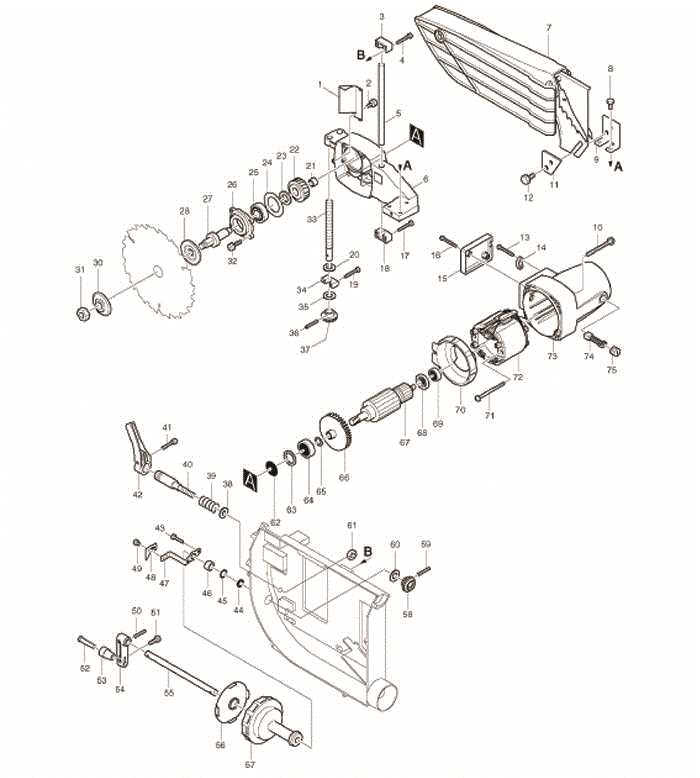

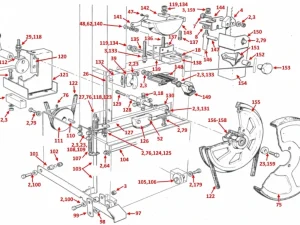

Exploring the intricacies of a cutting apparatus unveils the essential elements that contribute to its functionality and efficiency. Each segment plays a crucial role, ensuring precision and safety during operation. Gaining insight into these components can enhance your maintenance skills and optimize performance.

Identifying each part allows users to grasp how they interact, creating a cohesive mechanism. From the motor to the blade assembly, comprehending the relationships between these elements is vital for effective troubleshooting and repair.

Furthermore, detailed illustrations serve as invaluable resources, offering clarity on assembly and disassembly procedures. With the right knowledge, you can confidently tackle any issues that arise, ensuring your equipment remains in top condition.

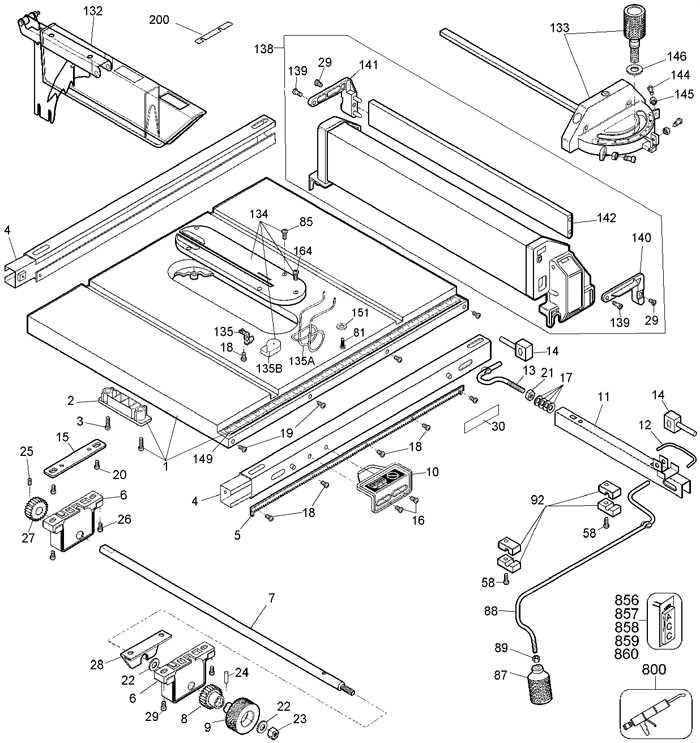

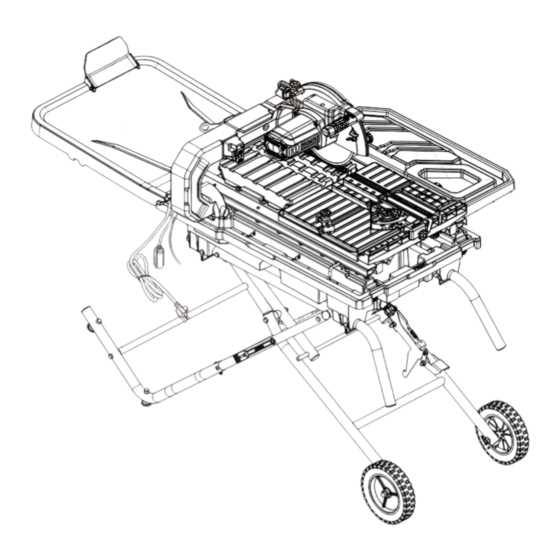

Kobalt Table Saw Overview

This section provides a comprehensive insight into a popular power tool that excels in precision and efficiency. Designed for both hobbyists and professionals, it combines robust features with user-friendly operations, making it an essential addition to any workshop.

Key Features

The tool is equipped with various attributes that enhance its functionality. It boasts an adjustable blade height, ensuring accuracy in cutting different materials. Additionally, its sturdy construction offers stability, allowing users to tackle extensive projects with confidence.

Specifications

| Feature | Details |

|---|---|

| Motor Power | 15 Amps |

| Blade Diameter | 10 inches |

| Cutting Depth | 3.5 inches at 90 degrees |

| Weight | 80 lbs |

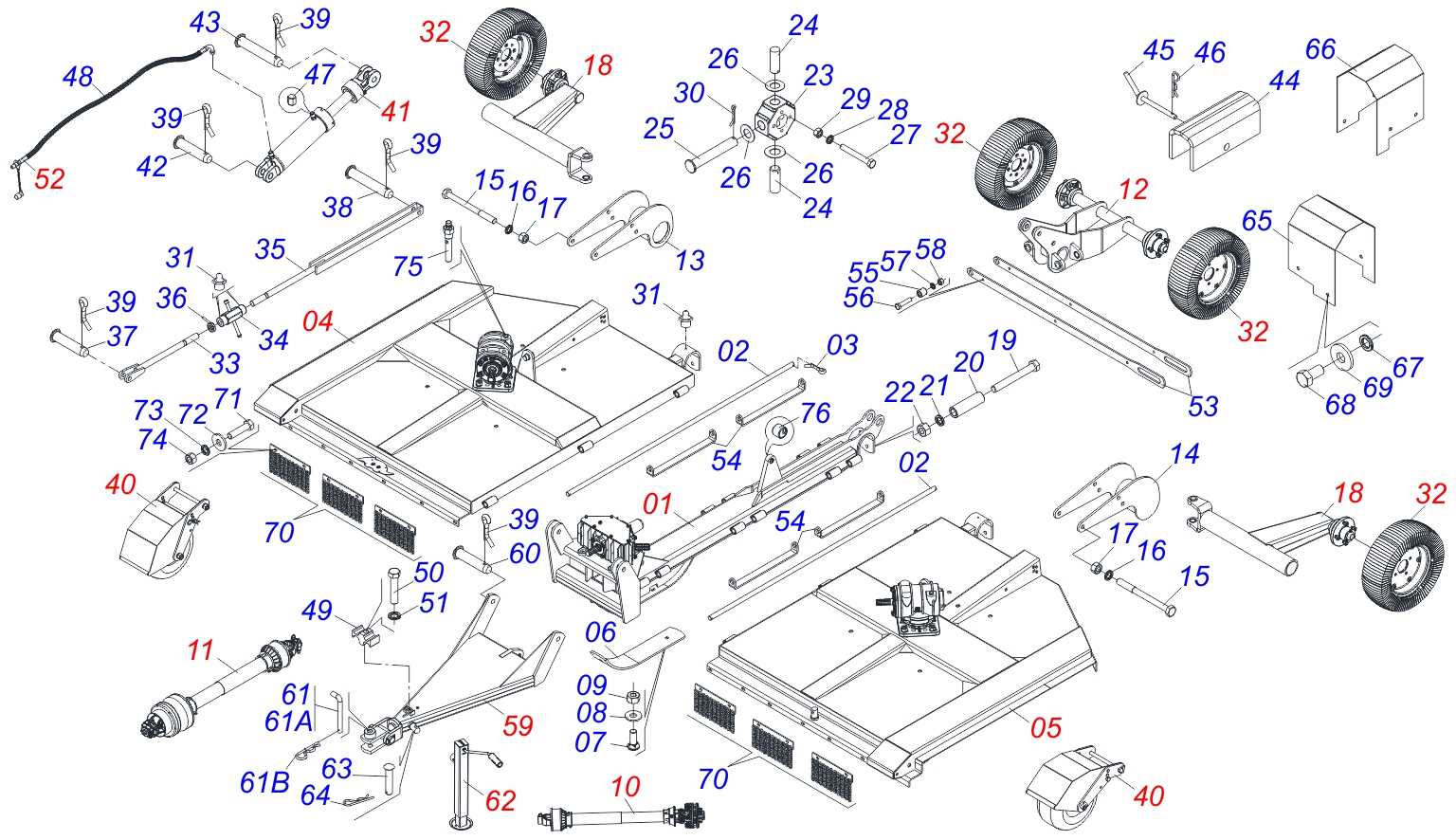

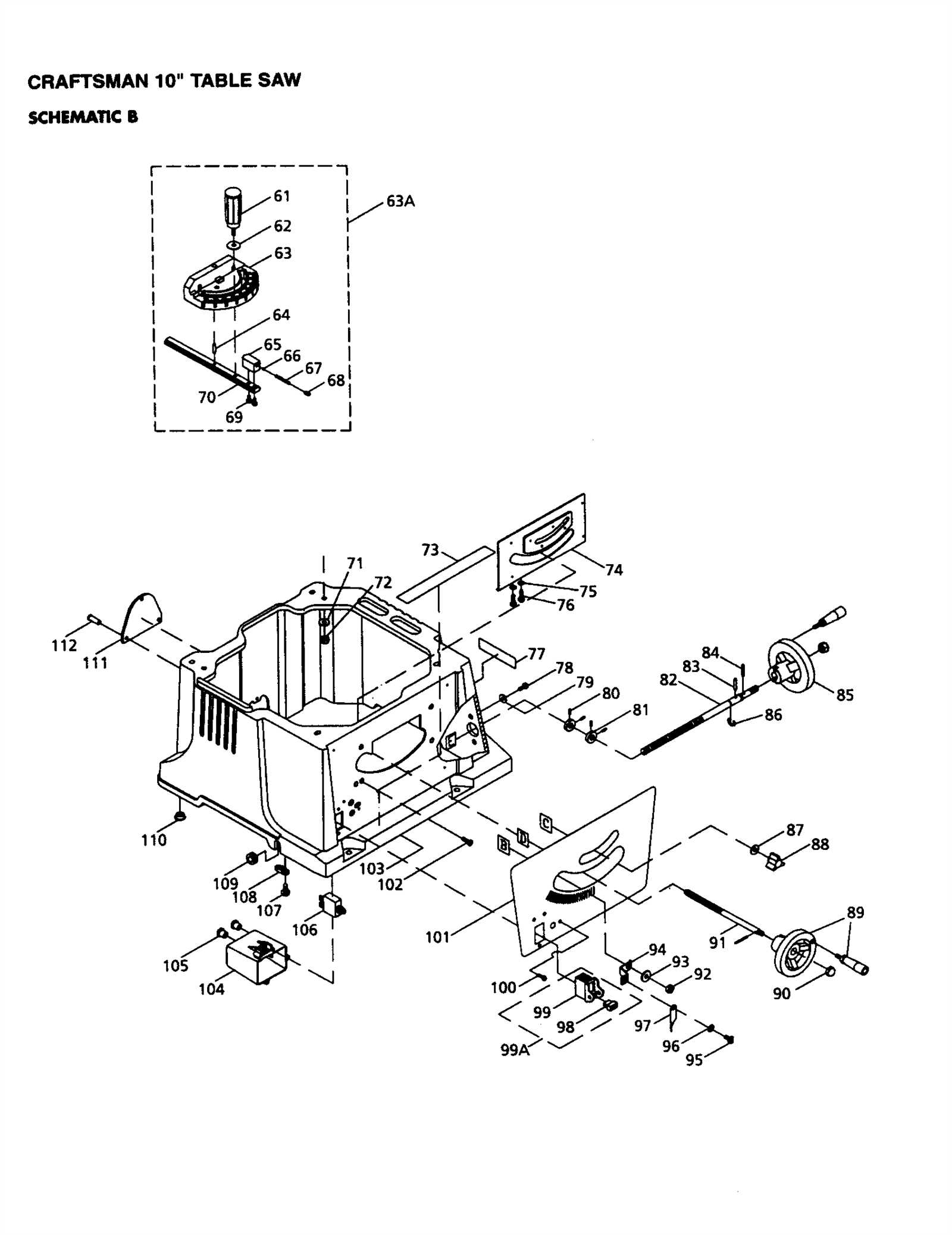

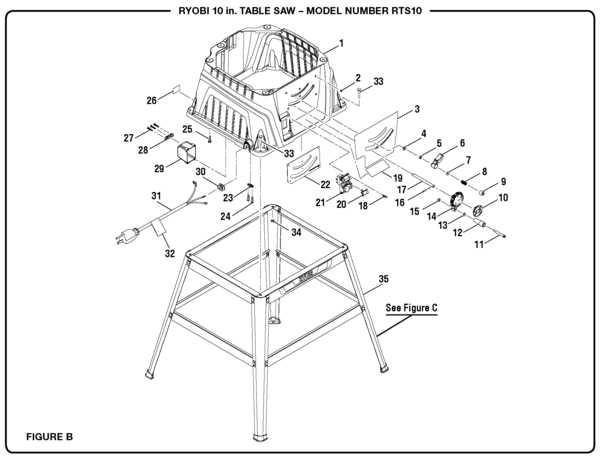

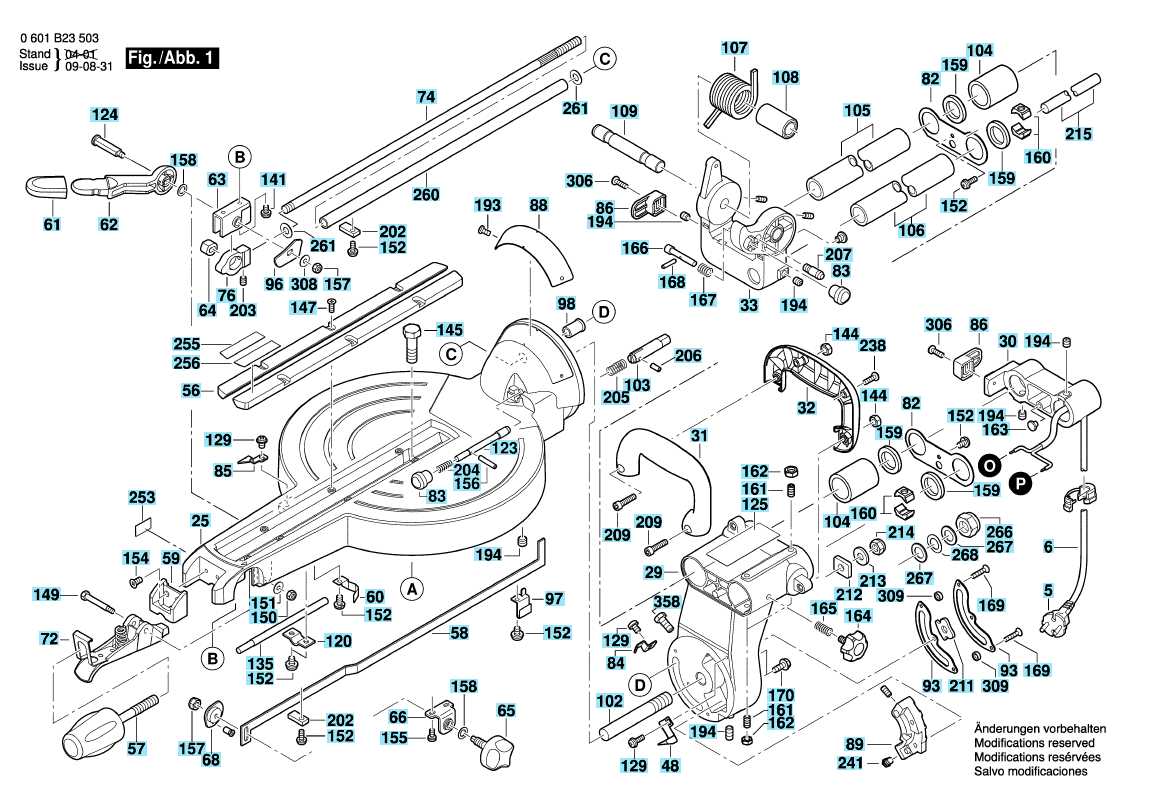

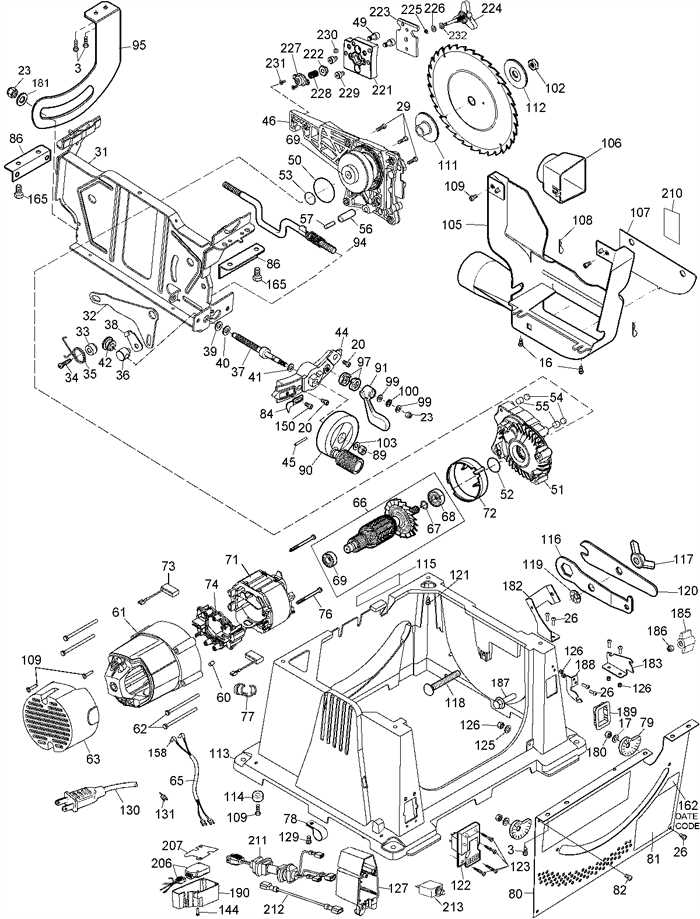

Importance of Parts Diagrams

Understanding the components of a machine is crucial for effective maintenance and repair. Visual representations play a vital role in identifying each element and their interconnections.

- Facilitates quick recognition of components

- Aids in troubleshooting issues efficiently

- Enhances the learning process for new users

- Streamlines the assembly and disassembly process

By utilizing these visuals, users can delve deeper into the functionality of their equipment, ultimately improving performance and longevity.

Key Components of Kobalt Saws

Understanding the essential elements of these tools is crucial for optimal performance and safety. Each component plays a vital role in ensuring precision and efficiency during operation.

- Blade: The cutting edge that determines the quality of the cut.

- Motor: Powers the mechanism, influencing speed and torque.

- Fence: Provides a guide for straight cuts and enhances accuracy.

- Table: The surface where materials are placed for cutting.

- Safety Guard: Protects the user from accidental contact with the blade.

Each of these components can significantly impact the overall functionality and user experience. Regular maintenance and understanding their roles can lead to better results.

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a structured overview of individual elements, their arrangement, and their interconnections. By familiarizing yourself with the layout and symbols used, you can enhance your ability to identify parts and comprehend assembly processes.

Identifying Key Features

Most illustrations include specific markers that highlight various components. Look for labels, numbers, or color codes that correspond to a parts list. This information is often invaluable when ordering replacements or discussing issues with a technician.

Utilizing Reference Tables

| Symbol | Description |

|---|---|

| ⬤ | Component |

| ➔ | Connection |

| ⚙️ | Mechanism |

By paying attention to these symbols, you can more easily navigate the layout and gain a clearer understanding of how everything fits together.

Common Issues with Table Saws

Understanding frequent challenges encountered during woodworking can enhance both safety and efficiency. Many individuals, whether beginners or seasoned professionals, experience various obstacles while working with these tools. Recognizing these common problems allows users to address them proactively, ensuring a smoother experience.

- Misalignment: Components may become misaligned over time, affecting the precision of cuts.

- Dull Blades: Blades that have lost their sharpness can lead to poor performance and safety risks.

- Inconsistent Power Supply: Fluctuations in power can cause irregular operation, impacting the quality of work.

- Dust Accumulation: Excessive dust buildup can hinder performance and pose health risks.

- Motor Issues: Problems with the motor can lead to inefficiencies and possible failure.

By addressing these issues, users can maintain optimal functionality and prolong the lifespan of their equipment. Regular maintenance and careful monitoring are key to avoiding complications.

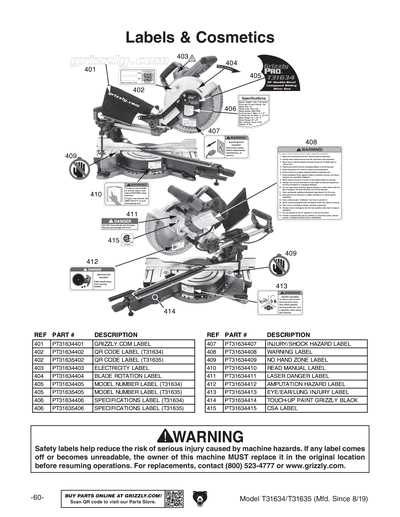

Finding Replacement Parts Easily

Locating the necessary components for your equipment can be a straightforward process when you know where to look. Understanding the various sources and methods available will enhance your experience and ensure your tools remain in optimal condition.

Online Retailers: Numerous websites specialize in offering a vast array of components. A simple search using the model number or a description can yield many options. Always verify the seller’s credibility to ensure quality.

Manufacturer’s Website: Visiting the official site of the manufacturer can provide direct access to a catalog of available items. This method often guarantees that you receive genuine components, minimizing compatibility issues.

Local Hardware Stores: Physical stores can be invaluable for urgent needs. Many retailers stock essential components or can order them for you. Engaging with knowledgeable staff can also lead to helpful recommendations.

Community Forums and Groups: Engaging with online communities dedicated to similar equipment can offer insights and recommendations for where to find the right components. Members often share their experiences and sources, which can be beneficial.

By leveraging these resources, you can simplify the search for necessary components, ensuring that your tools remain functional and efficient.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential to ensure its durability and optimal performance over time. By adhering to a consistent maintenance routine, you can prevent unnecessary wear and extend the lifespan of your machinery.

Here are some essential practices to follow:

- Regular Cleaning: Keep the surface free from dust and debris to prevent damage and enhance functionality.

- Lubrication: Apply appropriate lubricants to moving components to reduce friction and wear.

- Inspect Components: Frequently check parts for signs of wear, cracks, or damage. Replace any defective components promptly.

- Proper Storage: Store the equipment in a dry, protected area to avoid exposure to moisture and environmental factors that can cause deterioration.

- Follow Manufacturer Guidelines: Adhere to the recommended maintenance schedule provided by the manufacturer for best results.

By implementing these maintenance strategies, you will not only enhance the efficiency of your machinery but also prolong its operational life, ensuring you get the most value from your investment.

Upgrading Your Table Saw Features

Enhancing the functionality of your woodworking equipment can significantly improve your overall efficiency and precision. By incorporating advanced elements and tools, you can elevate your craftsmanship and make tasks easier. Various upgrades can enhance performance, safety, and user experience, allowing for a more versatile work environment.

Key Upgrades to Consider

- Rip Fence Improvement: Upgrading to a high-quality, adjustable rip fence can ensure more accurate cuts and easier setup.

- Blade Replacement: Opting for a premium blade tailored to your specific projects can result in cleaner cuts and longer tool life.

- Dust Collection System: Implementing an efficient dust collection setup minimizes cleanup and promotes a healthier workspace.

- Table Extension: Adding a table extension provides additional support for larger materials, enhancing stability during cutting.

Benefits of Upgrades

- Improved accuracy and precision in cutting tasks.

- Enhanced safety features that reduce the risk of accidents.

- Increased efficiency, allowing for quicker project completion.

- Greater versatility to accommodate a wider range of materials.

By thoughtfully selecting and implementing these enhancements, you can transform your setup into a more powerful and efficient workstation, ultimately elevating your woodworking projects to new heights.