The complexity of agricultural machinery necessitates a comprehensive understanding of its various elements. Each component plays a crucial role in ensuring the effective operation and longevity of the equipment. Familiarity with these parts can aid in maintenance, troubleshooting, and ultimately enhance productivity in the field.

By examining the arrangement and function of each section, operators can gain insights into how these mechanisms interact. A well-organized visual representation can serve as an invaluable tool, providing clarity and guidance during repairs or upgrades. Understanding these intricate relationships can significantly improve the efficiency of machinery handling.

Investing time in learning about individual elements empowers users to make informed decisions regarding repairs and replacements. This knowledge not only facilitates smoother operations but also contributes to the overall performance of agricultural activities. Mastering the layout and functionality of these components lays the foundation for effective equipment management.

This section delves into the essential aspects of a specific agricultural vehicle, emphasizing its significance and functional features. Understanding its components and systems is vital for optimal performance and maintenance. This guide outlines key areas of focus to ensure a comprehensive overview.

- Introduction to the Vehicle

Overview of the machine’s purpose and primary applications in farming and land management.

- Key Specifications

A detailed look at the technical specifications that define its capabilities.

- Common Components

Identification of the main elements that make up the machinery, including engines and transmission systems.

- Maintenance Essentials

Guidelines for routine upkeep to ensure longevity and efficiency.

- Repair Considerations

Critical factors to evaluate when addressing malfunctioning parts or systems.

- Replacement Options

Insights on sourcing alternative parts or components for upgrades or repairs.

- Performance Optimization

Strategies for enhancing the machine’s functionality and operational efficiency.

- Conclusion

A summary of the vehicle’s importance and a recap of best practices for maintenance and repair.

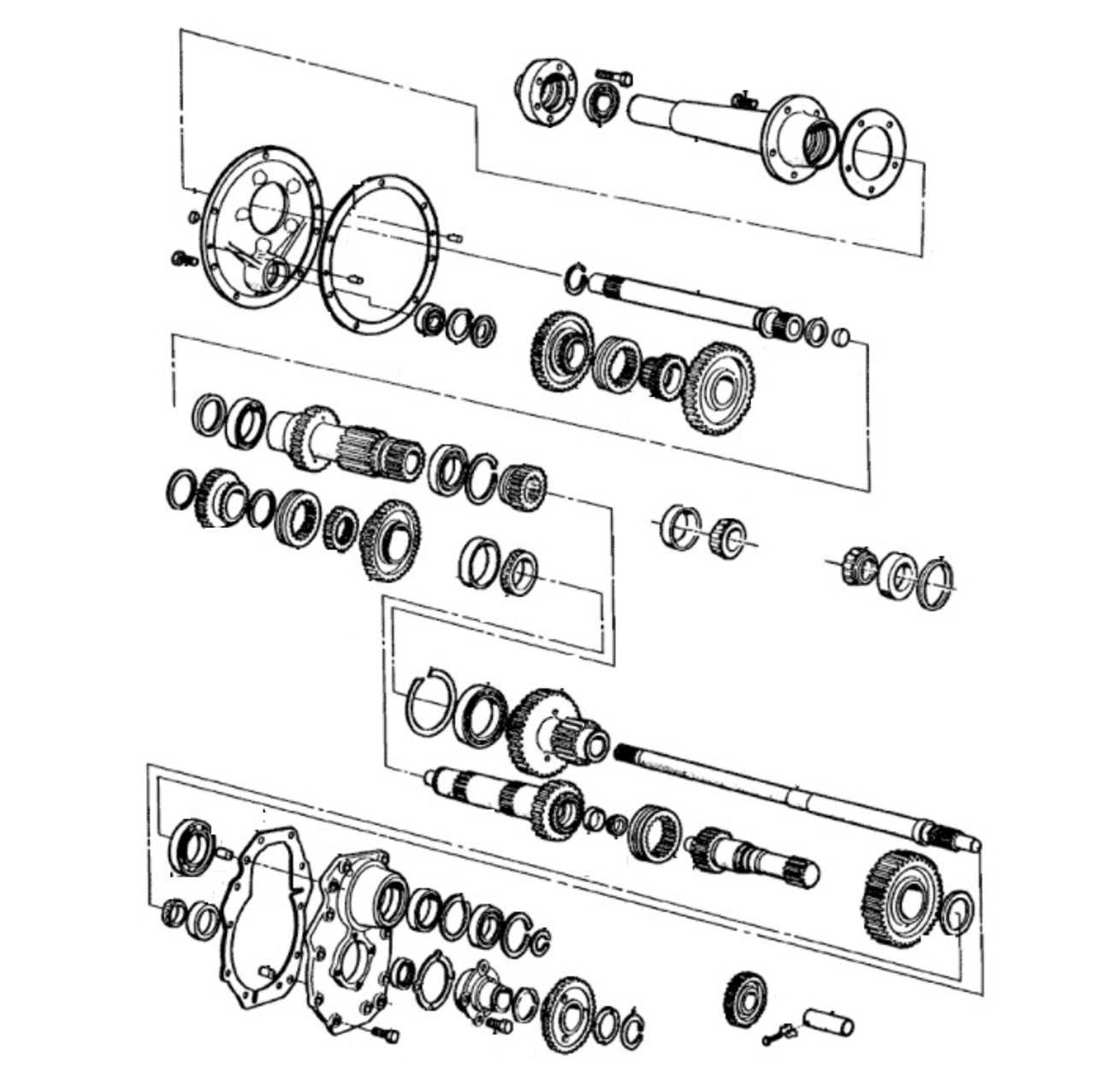

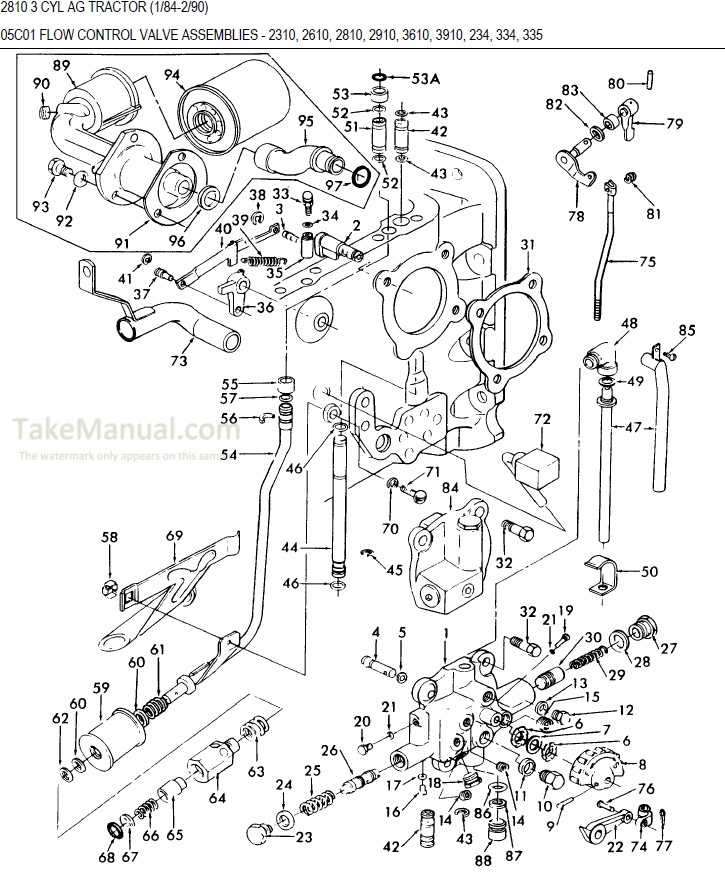

Overview of Essential Components

This section provides a comprehensive look at the fundamental elements that comprise a robust agricultural vehicle. Understanding these crucial components is vital for ensuring optimal performance and longevity.

The essential components can be categorized into several key areas:

- Engine System: This includes the power unit, which is responsible for generating the energy necessary for operation.

- Transmission: A critical mechanism that facilitates the transfer of power from the engine to the wheels, allowing for varied speed and torque.

- Hydraulic System: This system enables various functions, such as lifting and lowering attachments, enhancing the vehicle’s versatility.

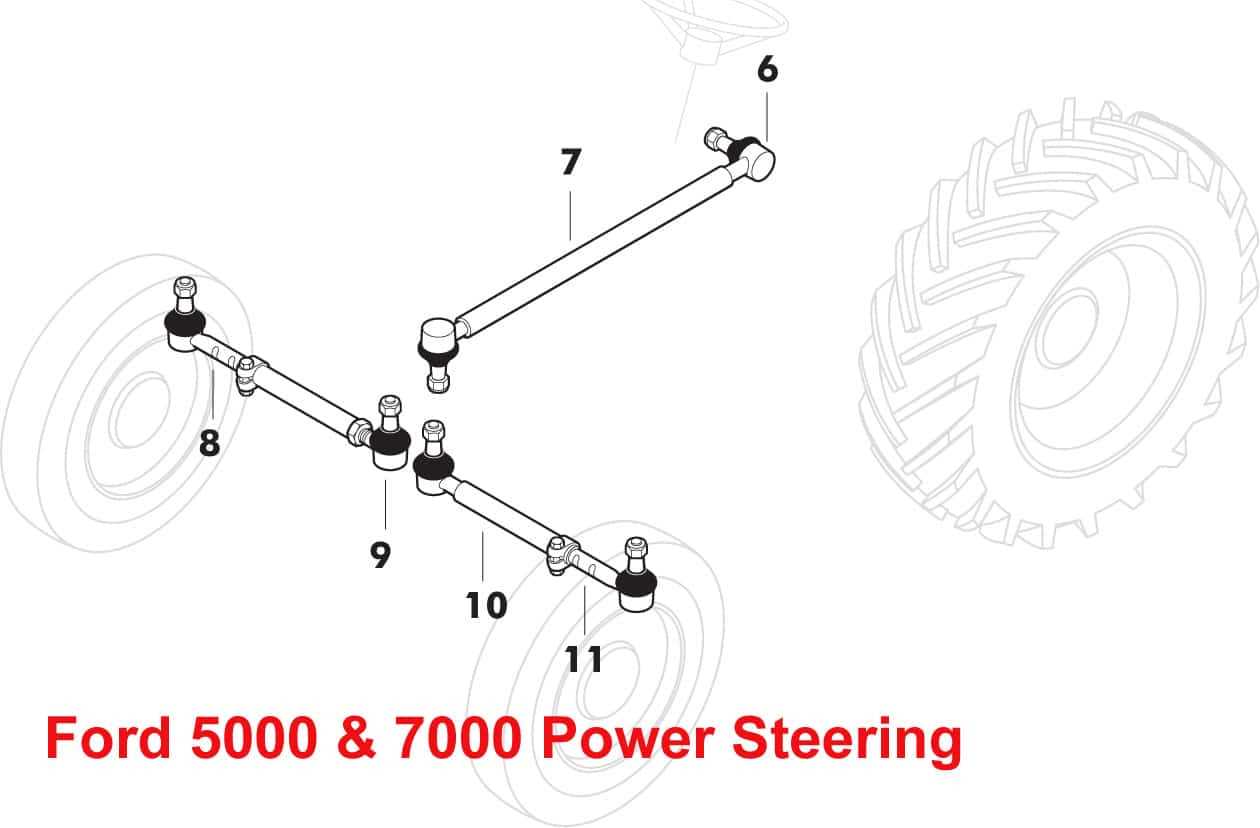

- Steering Assembly: Responsible for directing the vehicle, ensuring maneuverability and control during operation.

- Brake System: Essential for safety, this component allows for the effective slowing and stopping of the vehicle when necessary.

Each of these components plays a vital role in the overall functionality and efficiency of the vehicle, contributing to its performance in diverse agricultural tasks.

Common Replacement Parts

Maintaining machinery often necessitates the replacement of specific components to ensure optimal performance and longevity. Understanding which elements are prone to wear and tear can significantly enhance the efficiency of your equipment.

Among the frequently replaced components are filters, which play a crucial role in keeping systems clean and operational. Regularly changing oil and air filters can prevent damage to the engine and improve fuel efficiency. Additionally, batteries are vital for reliable starting and operation; their lifespan can be extended through proper maintenance and timely replacement.

Another essential category includes belts and hoses. These components are critical for various functions, such as power transmission and fluid movement. Ensuring their integrity through regular inspections can help avoid unexpected failures. Lastly, brake parts are paramount for safety; timely replacement of worn-out brake shoes or pads is essential to maintain effective stopping power.

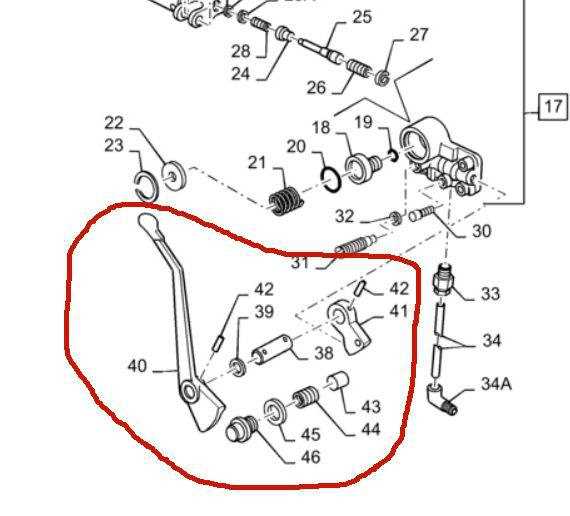

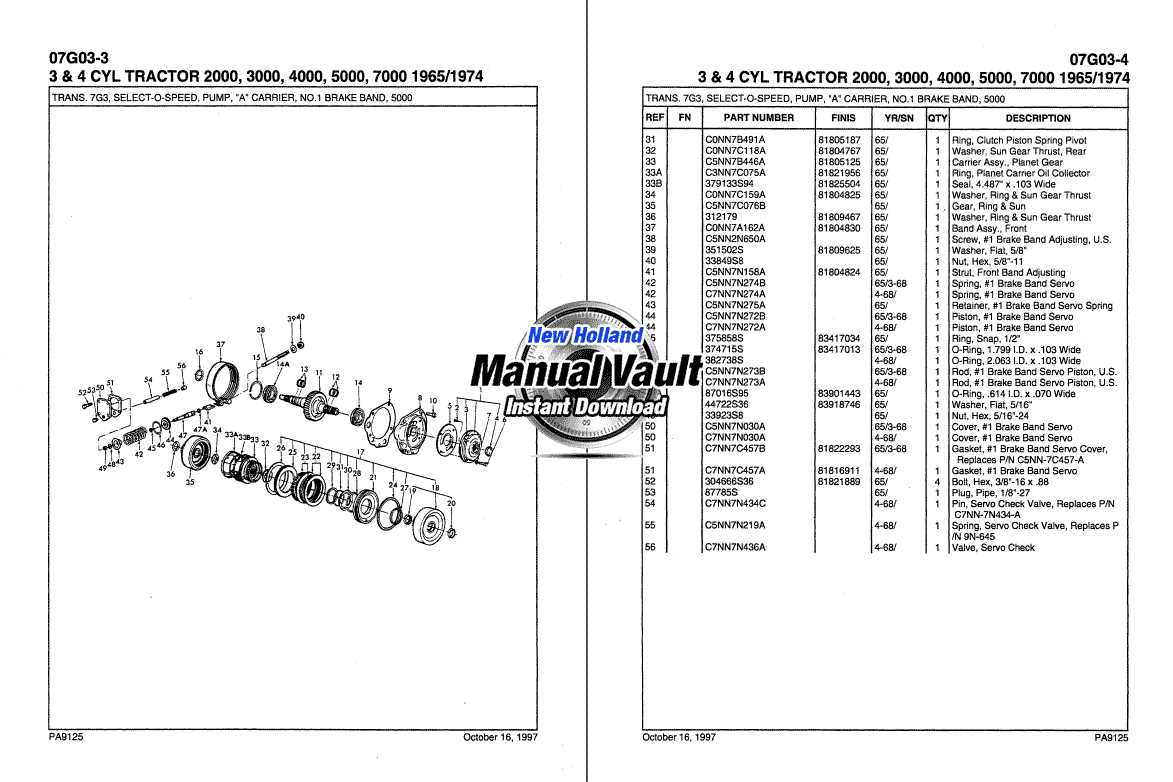

Visual Guide to Component Locations

This section aims to provide a comprehensive overview of various elements within the machinery, focusing on their specific placements and functions. Understanding the layout of these components is essential for effective maintenance and repair, ensuring that each part operates seamlessly within the system.

The following table illustrates the locations and descriptions of key elements, helping users familiarize themselves with the equipment:

| Component | Location | Description |

|---|---|---|

| Engine Block | Front Center | The main component where combustion occurs, providing power to the entire system. |

| Transmission Assembly | Rear Center | Responsible for transmitting power from the engine to the wheels. |

| Fuel Tank | Rear Left | Stores fuel, ensuring a continuous supply for combustion. |

| Cooling System | Front Right | Maintains optimal temperature during operation to prevent overheating. |

| Steering Mechanism | Front Center | Allows for directional control, ensuring maneuverability of the unit. |

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your agricultural machinery requires a proactive approach to upkeep. Regular maintenance not only enhances performance but also extends the lifespan of equipment, preventing costly repairs and downtime.

Regular Inspection

Conducting frequent evaluations of essential components is crucial. This includes:

- Checking fluid levels and quality

- Inspecting belts and hoses for wear

- Examining the battery for corrosion and charge

Cleaning and Lubrication

Keeping machinery clean and well-lubricated significantly impacts functionality:

- Remove debris and dirt from the exterior

- Apply appropriate lubricants to moving parts

- Ensure ventilation systems are clear to prevent overheating

By following these essential maintenance practices, you can help your equipment operate smoothly and efficiently for years to come.

Identifying Parts by Serial Number

Understanding how to accurately identify components is crucial for effective maintenance and repair. Serial numbers serve as unique identifiers, allowing individuals to trace the history and specifications of various elements. This process ensures that the right replacements are sourced, thereby enhancing the functionality and longevity of the equipment.

When attempting to locate specific components using their serial numbers, consider the following steps:

- Locate the Serial Number: Familiarize yourself with where serial numbers are typically found on machinery or equipment.

- Consult Manufacturer Resources: Utilize official manuals or online databases that provide information related to serial numbers.

- Cross-reference with Catalogs: Match the serial number against component catalogs to find the appropriate items.

- Contact Technical Support: If needed, reach out to customer service or technical support for assistance in identifying specific elements.

By following these guidelines, individuals can effectively determine the required components for repairs, ensuring optimal performance of their machinery.

Aftermarket vs. OEM Options

When it comes to sourcing components for your vehicle, the choice between aftermarket and original equipment manufacturer (OEM) alternatives can significantly impact performance and reliability. Understanding the distinctions between these two categories is essential for making informed decisions about replacements and upgrades.

Aftermarket components are produced by third-party manufacturers and can offer a wide range of options, often at a lower cost. These alternatives may come with unique features or enhancements not found in OEM products. However, their quality can vary significantly depending on the manufacturer.

On the other hand, OEM components are created by the original manufacturer of the vehicle. They are designed to meet specific standards and specifications, ensuring compatibility and performance. While they typically come at a higher price, their reliability is often favored by those seeking to maintain the original integrity of the vehicle.

- Cost: Aftermarket options are generally more affordable.

- Quality: OEM parts offer guaranteed quality and compatibility.

- Variety: Aftermarket components may provide a broader selection.

- Warranty: OEM products usually come with a warranty.

Ultimately, the choice between aftermarket and OEM components depends on individual needs, budget considerations, and the desired level of quality. Careful evaluation of both options can lead to a more satisfactory outcome in vehicle maintenance.

Repair Techniques for Common Issues

Addressing frequent malfunctions in agricultural machinery requires a systematic approach and a solid understanding of underlying mechanisms. By employing effective repair strategies, operators can restore functionality and prolong the lifespan of their equipment. This section will explore several techniques that can be applied to rectify typical challenges encountered in these machines.

One essential method involves performing regular inspections to identify wear and tear before they escalate into more significant problems. By checking components such as belts, hoses, and seals for signs of deterioration, proactive measures can be taken to replace or repair affected parts.

Another effective technique is the use of diagnostic tools to troubleshoot issues accurately. Equipment equipped with electronic monitoring systems can provide valuable insights into operational anomalies, allowing for targeted interventions rather than guesswork. Ensuring proper calibration of these systems is crucial for accurate readings.

Additionally, familiarizing oneself with the maintenance schedules outlined in the user manual can help ensure that routine tasks, such as oil changes and filter replacements, are completed timely. Adhering to these schedules not only enhances performance but also minimizes the risk of unexpected breakdowns.

Finally, developing a comprehensive toolkit with essential tools and replacement components enables swift responses to minor issues, reducing downtime. By implementing these repair techniques, operators can maintain their machinery in optimal condition, enhancing productivity and efficiency in their agricultural operations.

Resources for Parts and Diagrams

Accessing reliable sources for components and illustrations is essential for maintaining and repairing machinery. A variety of resources are available that provide valuable information, including detailed schematics, manuals, and community forums dedicated to equipment enthusiasts. These platforms can guide users through troubleshooting, repairs, and upgrades, ensuring efficient and effective handling of equipment issues.

Here are some recommended resources:

| Resource Type | Description | Website |

|---|---|---|

| Online Forums | Communities where users share advice and solutions. | www.exampleforum.com |

| Parts Retailers | Websites offering a wide range of components for purchase. | www.exampleparts.com |

| Technical Manuals | Downloadable guides that provide in-depth information. | www.examplemanuals.com |

| Video Tutorials | Visual guides demonstrating repair and maintenance processes. | www.examplevideos.com |