The intricate machinery behind powerful outdoor equipment relies on a variety of essential components working in harmony. This section delves into the specific elements that contribute to the performance and efficiency of a 23 horsepower system, illustrating how each piece plays a vital role in overall functionality.

By examining the layout of these crucial elements, users can gain valuable insights into maintenance, troubleshooting, and optimization. This knowledge not only enhances operational effectiveness but also extends the lifespan of the equipment, ensuring reliable performance over time.

For anyone looking to understand the inner workings of their high-performance machinery, familiarizing oneself with the arrangement and function of these vital components is an indispensable step. Whether for DIY repairs or routine upkeep, this guide aims to equip you with the necessary information to tackle any challenge that may arise.

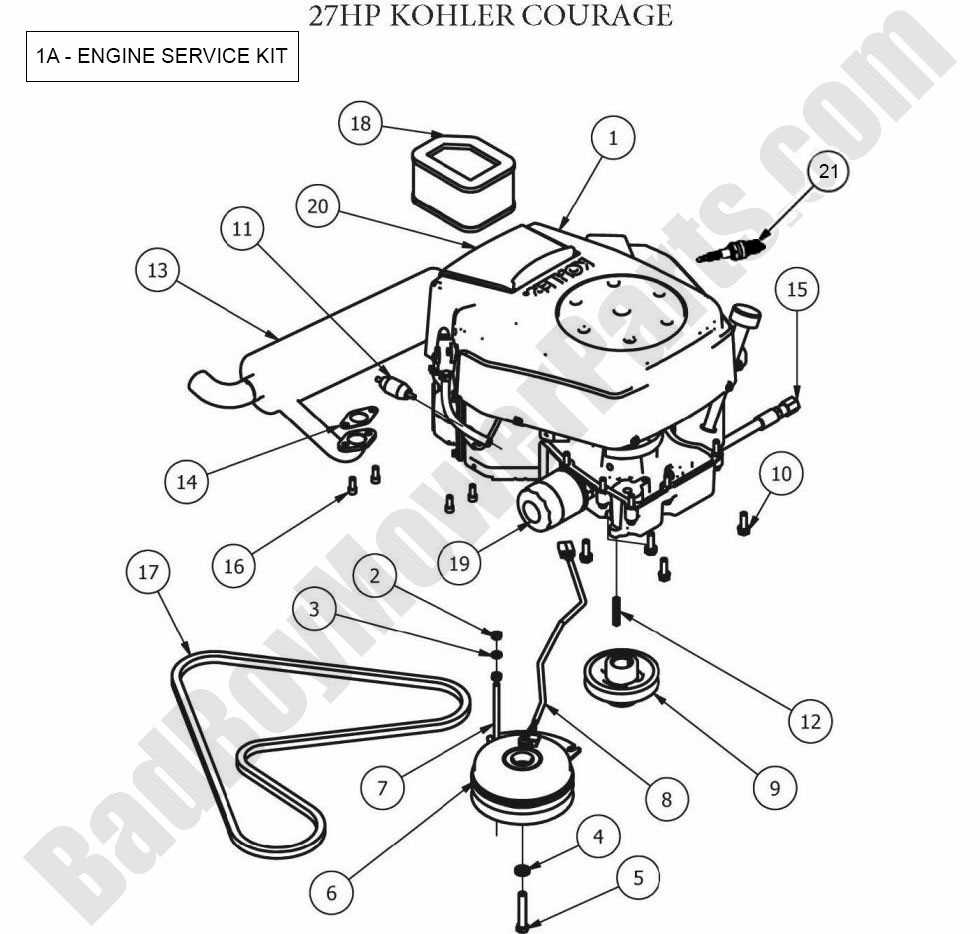

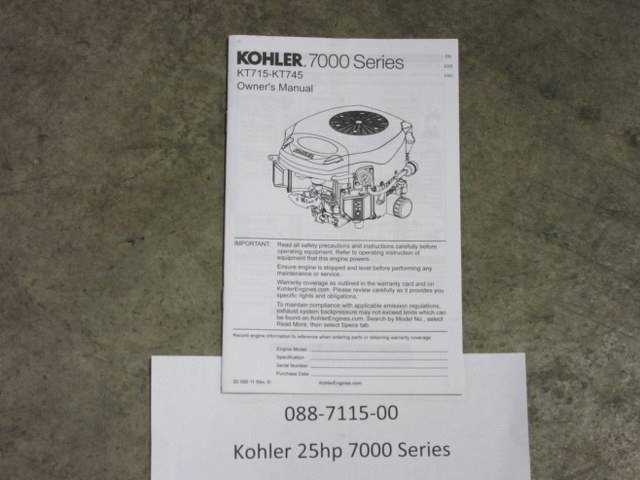

Kohler 23 HP Engine Overview

This section provides a comprehensive insight into a robust power unit renowned for its reliability and performance. Designed for various applications, this model excels in delivering consistent power and efficiency, making it a preferred choice for many users.

Key Features

- High torque output for demanding tasks

- Compact design suitable for tight spaces

- Durable construction for long-lasting use

- Low maintenance requirements

Applications

- Lawn and garden equipment

- Commercial mowers

- Generators

- Other outdoor machinery

With its advanced technology and user-friendly features, this power unit is ideal for both residential and professional environments, ensuring optimal performance across various applications.

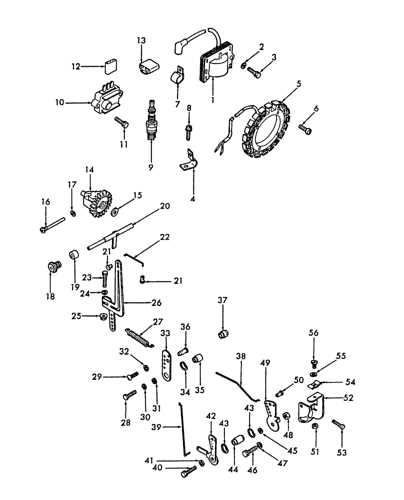

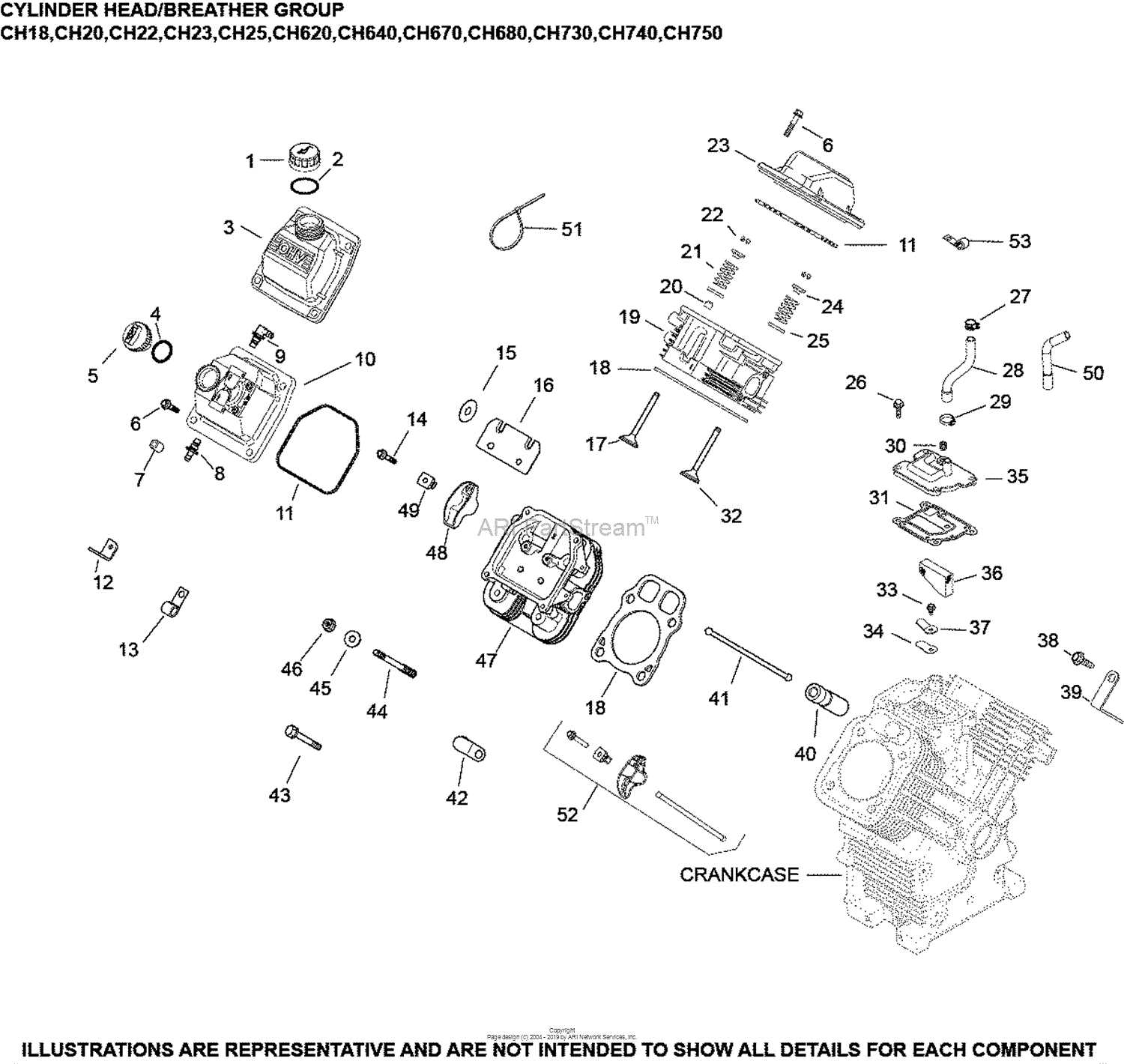

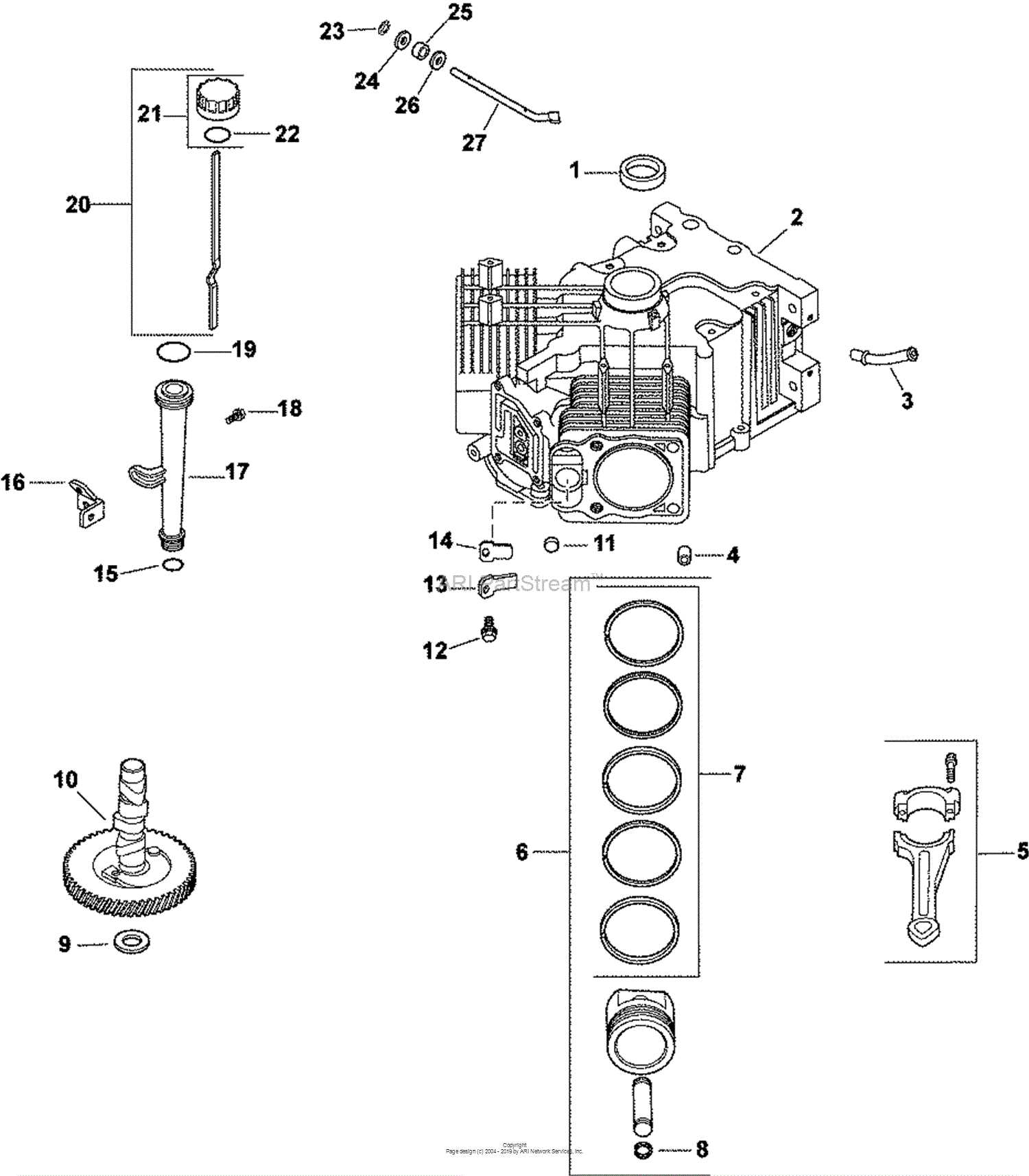

Understanding Engine Parts and Functions

Grasping the intricacies of a power unit is essential for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance and longevity. By familiarizing oneself with these elements, one can troubleshoot issues more efficiently and enhance overall functionality.

The main components can be categorized into several groups, each serving a distinct purpose:

- Fuel System: Responsible for delivering the necessary fuel to the combustion chamber. Key elements include the fuel tank, pump, and carburetor.

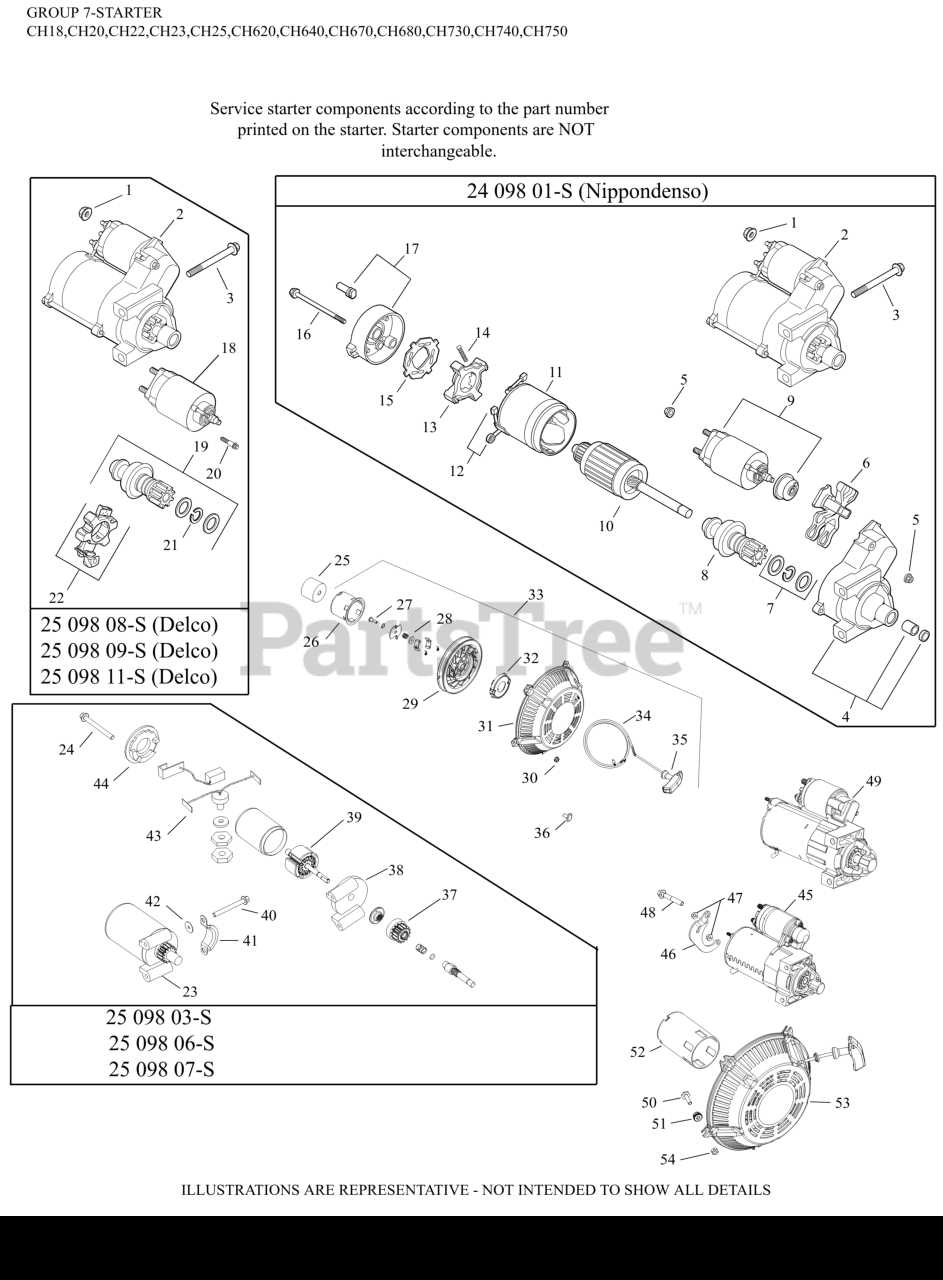

- Ignition System: Initiates combustion within the chamber. This includes spark plugs, ignition coils, and timing mechanisms.

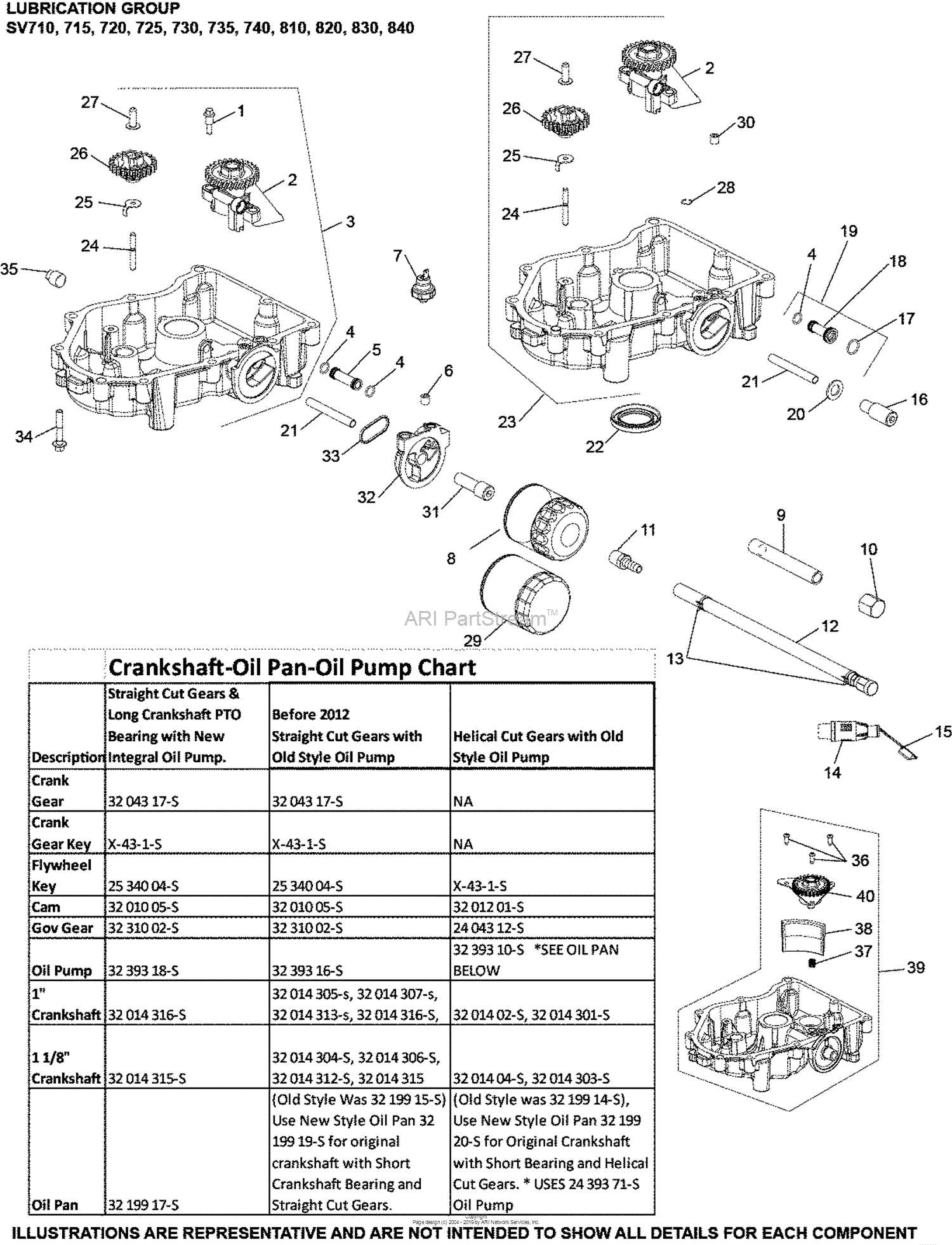

- Lubrication System: Ensures all moving parts are adequately lubricated to minimize friction and wear. This comprises the oil pump, filters, and reservoirs.

- Cooling System: Regulates temperature to prevent overheating. It includes radiators, coolant, and thermostats.

- Exhaust System: Channels exhaust gases away from the power unit. Components include mufflers, pipes, and catalytic converters.

Understanding how these groups interact is crucial. For instance, the fuel system must work in tandem with the ignition system to achieve efficient combustion. Similarly, the cooling system plays a vital role in maintaining the integrity of all components under high operational stresses.

Regular inspection and maintenance of these components are necessary to ensure reliability and performance. Knowledge of each element’s function aids in diagnosing problems and implementing timely repairs.

Common Issues with Kohler Engines

Various challenges can arise with small power units, affecting their performance and reliability. Understanding these common problems can help users maintain their equipment effectively and ensure optimal functioning over time.

Fuel Delivery Problems: One frequent issue involves the supply of fuel. Clogs in the lines or a malfunctioning carburetor can lead to insufficient fuel reaching the combustion chamber, resulting in poor performance or failure to start.

Electrical Failures: Electrical components, such as spark plugs and ignition coils, are susceptible to wear and tear. A faulty spark plug can hinder the ignition process, causing misfires and reducing efficiency.

Overheating: Excessive heat build-up often stems from insufficient lubrication or coolant issues. Regular checks on oil levels and coolant systems can prevent severe damage and prolong the lifespan of the unit.

Wear and Tear: Continuous operation can lead to deterioration of internal components. Regular maintenance, including timely oil changes and inspections, is crucial to mitigate this risk and ensure longevity.

Starting Difficulties: Problems with starting can arise from several factors, including battery issues or fuel starvation. Diagnosing the root cause early on can save time and costly repairs.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your machinery requires consistent care and attention. Implementing a routine maintenance schedule can significantly extend the lifespan of your equipment, preventing costly repairs and downtime. By focusing on essential upkeep tasks, you can enhance performance and reliability.

Regular Inspections

Frequent checks are crucial for identifying potential issues before they escalate. Look for signs of wear, leaks, or unusual noises that may indicate underlying problems. Regularly inspecting components helps in maintaining optimal functioning and catching discrepancies early.

Fluid Changes and Cleanliness

Maintaining clean fluids is vital for the smooth operation of any machinery. Regularly replace oils, coolants, and other fluids as per the manufacturer’s guidelines. Keeping the area around the equipment clean helps prevent dirt and debris from causing damage, ensuring efficient performance over time.

Replacement Parts Availability and Options

Access to high-quality components is essential for maintaining optimal performance and longevity of machinery. A wide array of options is available to ensure that users can find the right replacements for their needs.

When considering replacement options, various factors come into play:

- Compatibility: Ensure that the replacements match the specific model requirements.

- Quality: Look for components that meet or exceed original specifications to guarantee reliability.

- Cost: Evaluate different suppliers to find competitive pricing without compromising quality.

- Warranty: Opt for products that come with a warranty to protect against defects and failures.

Sources for acquiring these components include:

- Authorized dealers: Often provide genuine replacements with assurance of quality.

- Online retailers: Offer convenience and a wide selection, making it easy to compare options.

- Local hardware stores: May carry commonly needed items, perfect for quick repairs.

- Aftermarket suppliers: Provide alternative options that can be more cost-effective.

In conclusion, understanding the various avenues for obtaining high-quality replacements can significantly enhance the efficiency and durability of equipment. Making informed choices based on quality, compatibility, and availability will lead to better performance outcomes.

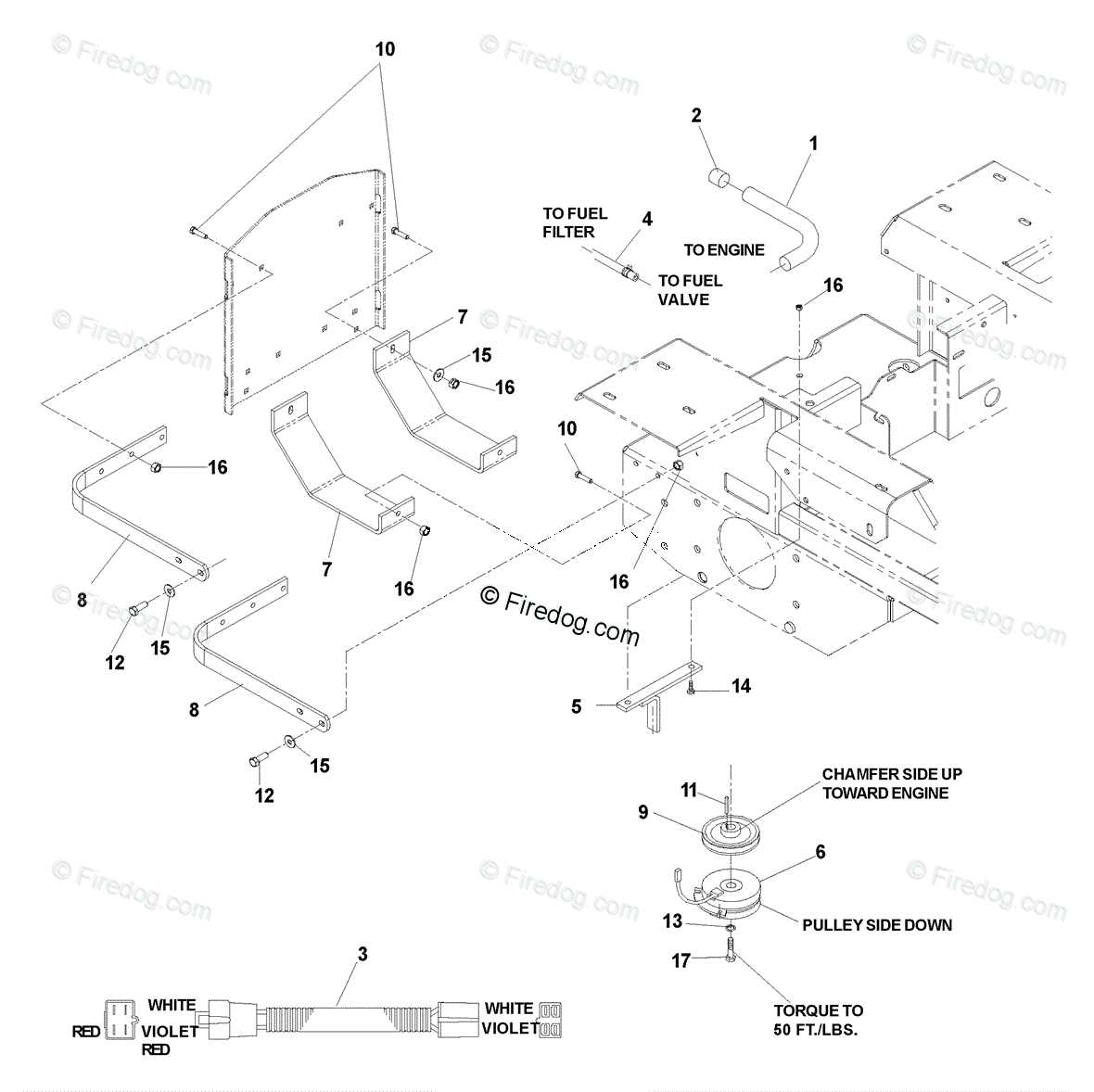

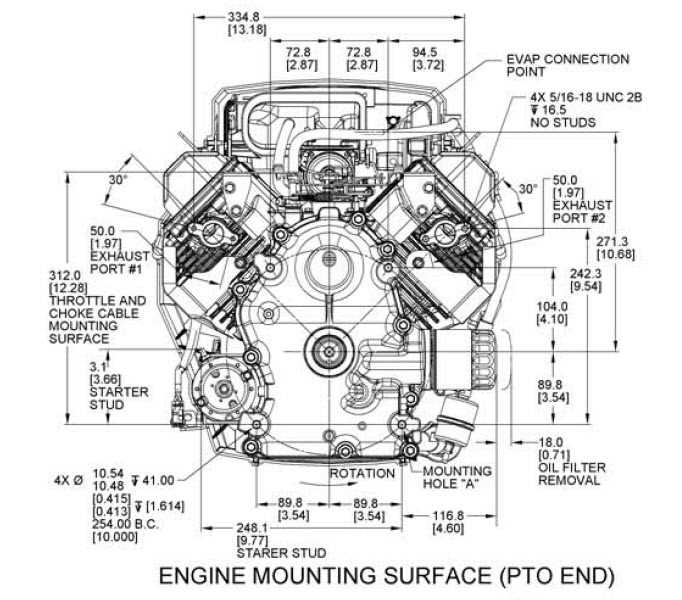

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a clear overview of various elements and their relationships, allowing users to identify what is needed for assembly or troubleshooting.

To effectively interpret these visuals, consider the following steps:

- Familiarize Yourself with Symbols: Many illustrations use specific icons to denote various parts. Learn these symbols to quickly identify components.

- Study the Legend: Most visuals come with a legend or key that explains the symbols and numbers. Refer to this for clarity on each item represented.

- Follow the Flow: Components are often arranged in a logical sequence. Trace the layout to understand how parts interact with one another.

- Identify Connections: Look for lines or arrows that indicate how elements connect or fit together. This can help you visualize assembly.

By applying these strategies, you’ll enhance your ability to analyze and utilize these representations, making your maintenance tasks more efficient and effective.

Choosing the Right Tools for Repairs

Selecting the appropriate instruments for maintenance tasks is crucial for achieving optimal results and ensuring safety. The right tools not only streamline the repair process but also enhance precision, allowing for effective troubleshooting and solutions.

When embarking on any repair project, consider the following factors to guide your tool selection:

- Type of Repair: Identify the specific task at hand to determine which instruments are necessary.

- Quality and Durability: Invest in high-quality tools that withstand regular use and provide reliable performance.

- Comfort and Ergonomics: Choose tools that are comfortable to handle to reduce fatigue during extended use.

- Safety Features: Ensure that your tools are equipped with safety mechanisms to prevent accidents.

Here are some essential categories of tools you might consider:

- Hand Tools: Wrenches, screwdrivers, and pliers are fundamental for many repair tasks.

- Power Tools: Drills and saws can significantly speed up your work but require careful handling.

- Diagnostic Tools: Multimeters and gauges are invaluable for identifying issues accurately.

- Specialty Tools: Depending on the complexity of the task, you may need specific instruments tailored for particular functions.

By carefully considering your needs and the nature of the repair, you can assemble a toolkit that enhances efficiency and effectiveness, ensuring a successful maintenance experience.

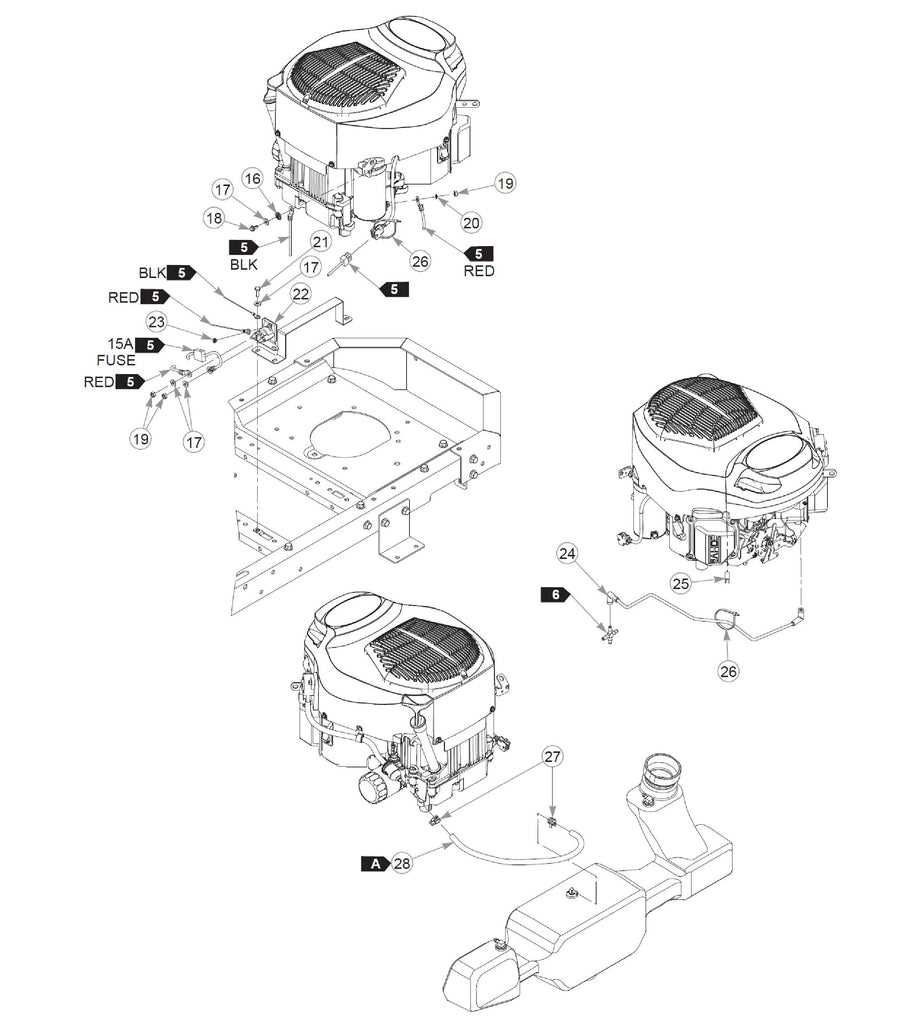

Installation Process for Key Components

Proper assembly of essential elements is crucial for optimal performance and longevity. Each step must be executed with precision to ensure that everything functions harmoniously. Below is a guide to facilitate the installation of critical components.

Preparation Steps

- Gather all necessary tools and materials.

- Ensure that the work area is clean and organized.

- Review the manufacturer’s guidelines for specific instructions.

Installation Steps

- Begin by securing the main unit in a stable position.

- Align the primary component carefully, ensuring all mounting holes are accessible.

- Insert bolts and fasteners, tightening them gradually to avoid misalignment.

- Connect any necessary wiring or hoses, making sure to follow the correct routing.

- Double-check all connections and fastenings before proceeding.

Following these steps will help achieve a successful assembly, allowing the system to operate efficiently and reliably.